Dry Cylinder Liner Diagram . The liner fits accurately in the cylinder. Dry liners and wet liners. dry cylinder liners can also be affected because of their relatively thin cylinder wall thickness. The flange keeps the liner in position in the cylinder block. It works under high pressure and. dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Dry liners are made in the shape of a barrel having a flange at the top. dry type cylinder liner: the cylinder liners or sleeves are of two types: Damage assessment cracks of this nature are frequently. types of cylinder liners. Generally, two types of cylinder liners are used in i.c. a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. Dry type cylinder liner is the most common type of cylinder liner. Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine.

from constructionforklifts.tpub.com

a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. the cylinder liners or sleeves are of two types: The liner fits accurately in the cylinder. types of cylinder liners. It works under high pressure and. Dry liners and wet liners. Damage assessment cracks of this nature are frequently. Dry liners are made in the shape of a barrel having a flange at the top. Generally, two types of cylinder liners are used in i.c. dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine.

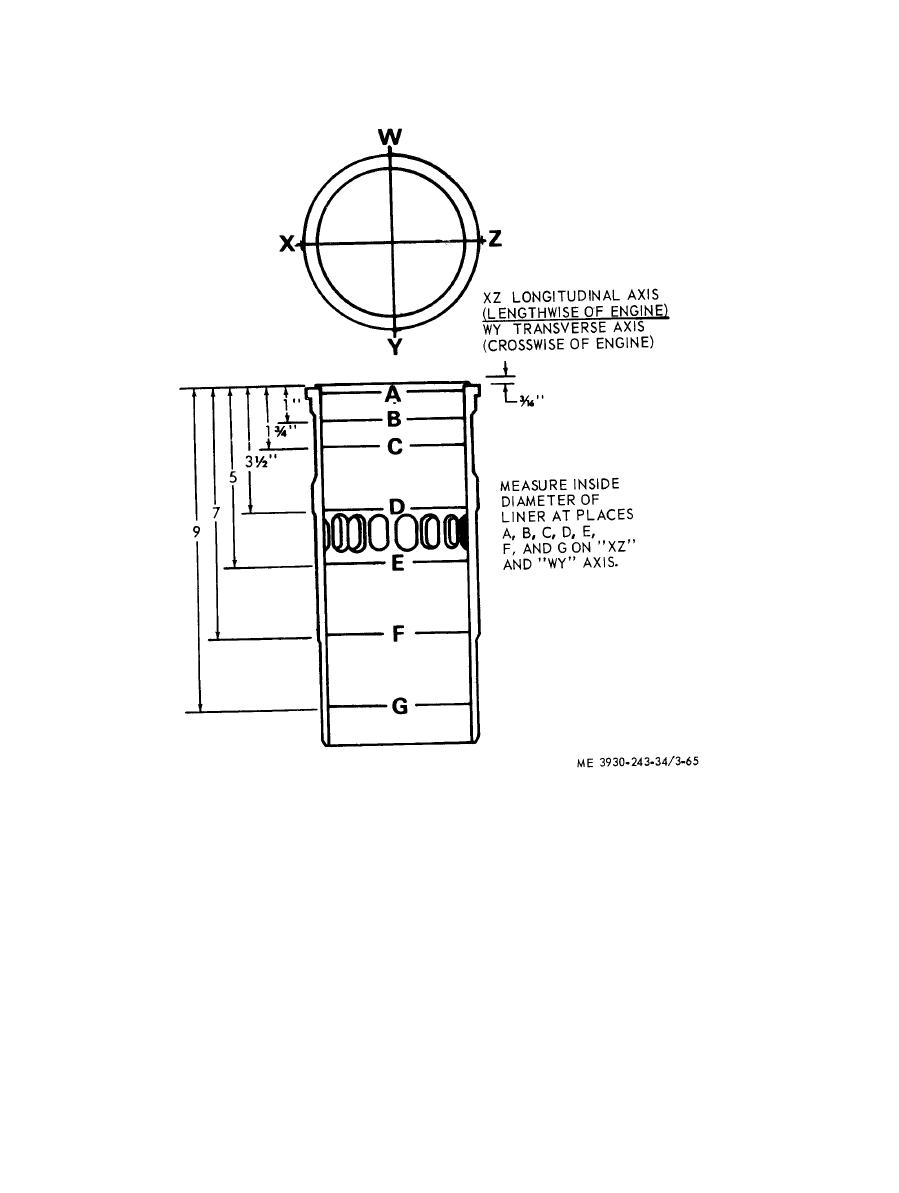

Figure 365. Cylinder liner measurement diagram.

Dry Cylinder Liner Diagram dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine. The flange keeps the liner in position in the cylinder block. dry type cylinder liner: dry cylinder liners can also be affected because of their relatively thin cylinder wall thickness. the cylinder liners or sleeves are of two types: dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Damage assessment cracks of this nature are frequently. types of cylinder liners. the cylinder liner's primary roles are to provide a sliding surface for the piston to provide a smooth reciprocating motion, to prevent. Generally, two types of cylinder liners are used in i.c. It works under high pressure and. Dry liners are made in the shape of a barrel having a flange at the top. a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. Dry type cylinder liner is the most common type of cylinder liner. The liner fits accurately in the cylinder.

From www.pinterest.com

CYLINDER LINER Cylinder liner, Cylinder, Liner Dry Cylinder Liner Diagram dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. the cylinder liner's primary roles are to provide a sliding surface for the piston to provide a smooth reciprocating motion, to prevent. Dry liners and wet liners. Both types of liners have their pros and cons, and the choice. Dry Cylinder Liner Diagram.

From www.researchgate.net

Schematic of the cross section of the cylinder liner and piston ring Dry Cylinder Liner Diagram Dry liners and wet liners. It works under high pressure and. The flange keeps the liner in position in the cylinder block. Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine. dry type cylinder liner: the cylinder liner's primary roles are to provide. Dry Cylinder Liner Diagram.

From constructionforklifts.tpub.com

Figure 365. Cylinder liner measurement diagram. Dry Cylinder Liner Diagram dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Dry type cylinder liner is the most common type of cylinder liner. The flange keeps the liner in position in the cylinder block. Damage assessment cracks of this nature are frequently. dry type cylinder liner: the cylinder liners. Dry Cylinder Liner Diagram.

From anandliners.com

Understanding the difference between dry and wet cylinder liners Dry Cylinder Liner Diagram Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine. The liner fits accurately in the cylinder. Damage assessment cracks of this nature are frequently. Dry type cylinder liner is the most common type of cylinder liner. dry liners are simpler in design and maintenance,. Dry Cylinder Liner Diagram.

From www.researchgate.net

The crosssection of the cylinder of SULZER RTA 58 engine. Download Dry Cylinder Liner Diagram Damage assessment cracks of this nature are frequently. Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine. the cylinder liners or sleeves are of two types: dry type cylinder liner: the cylinder liner's primary roles are to provide a sliding surface for. Dry Cylinder Liner Diagram.

From www.engineliner.com

Cylinder Liner Jaidarshan Indocraft Pvt. Ltd Dry Cylinder Liner Diagram the cylinder liner's primary roles are to provide a sliding surface for the piston to provide a smooth reciprocating motion, to prevent. dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Dry type cylinder liner is the most common type of cylinder liner. Generally, two types of cylinder. Dry Cylinder Liner Diagram.

From www.marineengineersknowledge.com

Cylinder Liner and Piston of marine 2stroke diesel engine Marine Dry Cylinder Liner Diagram the cylinder liner's primary roles are to provide a sliding surface for the piston to provide a smooth reciprocating motion, to prevent. a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. Both types of liners have their pros and cons, and the. Dry Cylinder Liner Diagram.

From aecoproducts.com

Cylinder Liner Manufacturer, Supplier & Exporter ARROW Dry Cylinder Liner Diagram Dry liners and wet liners. dry type cylinder liner: Generally, two types of cylinder liners are used in i.c. the cylinder liner's primary roles are to provide a sliding surface for the piston to provide a smooth reciprocating motion, to prevent. The flange keeps the liner in position in the cylinder block. Dry type cylinder liner is the. Dry Cylinder Liner Diagram.

From themechanicalengineering.com

Cylinder Liner Definition, Function, Types, Material [Notes & PDF] Dry Cylinder Liner Diagram Generally, two types of cylinder liners are used in i.c. dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. the cylinder liner's primary roles are to provide a sliding surface for the piston to provide a smooth reciprocating motion, to prevent. Dry type cylinder liner is the most. Dry Cylinder Liner Diagram.

From www.slideserve.com

PPT Cylinder Liners PowerPoint Presentation, free download ID2134219 Dry Cylinder Liner Diagram Damage assessment cracks of this nature are frequently. Dry liners and wet liners. It works under high pressure and. a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. Dry type cylinder liner is the most common type of cylinder liner. The liner fits. Dry Cylinder Liner Diagram.

From mechanicaljungle.com

What Is Cylinder Liner? Material for Cylinder Liner Function of Dry Cylinder Liner Diagram dry type cylinder liner: the cylinder liners or sleeves are of two types: Dry type cylinder liner is the most common type of cylinder liner. Dry liners are made in the shape of a barrel having a flange at the top. The liner fits accurately in the cylinder. The flange keeps the liner in position in the cylinder. Dry Cylinder Liner Diagram.

From kaydencedesnhherman.blogspot.com

Dry Vs Wet Cylinder Liners Which Is Used Where Dry Cylinder Liner Diagram Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine. Dry type cylinder liner is the most common type of cylinder liner. Generally, two types of cylinder liners are used in i.c. dry cylinder liners can also be affected because of their relatively thin cylinder. Dry Cylinder Liner Diagram.

From mechanicaljungle.com

What Is Cylinder Liner? Material for Cylinder Liner Function of Dry Cylinder Liner Diagram dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine. Dry liners are made in the shape of a barrel having a flange at the top.. Dry Cylinder Liner Diagram.

From www.atracparts.com

Different Types of Cylinder Liner Dry Cylinder Liners vs. Wet Dry Cylinder Liner Diagram dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. The liner fits accurately in the cylinder. Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine. The flange keeps the liner in position in the. Dry Cylinder Liner Diagram.

From mechathon.com

What is Cylinder Block and Cylinder Liner? Types of Liners Dry Cylinder Liner Diagram The liner fits accurately in the cylinder. Dry liners are made in the shape of a barrel having a flange at the top. dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Generally, two types of cylinder liners are used in i.c. the cylinder liner's primary roles are. Dry Cylinder Liner Diagram.

From www.researchgate.net

Cylinder Liner Arrangement [4] Download Scientific Diagram Dry Cylinder Liner Diagram The liner fits accurately in the cylinder. Damage assessment cracks of this nature are frequently. It works under high pressure and. dry cylinder liners can also be affected because of their relatively thin cylinder wall thickness. Dry liners and wet liners. dry type cylinder liner: Generally, two types of cylinder liners are used in i.c. The flange keeps. Dry Cylinder Liner Diagram.

From medium.com

What is the Cylinder Liner? Types and Function. by Technical Dry Cylinder Liner Diagram Dry liners and wet liners. The flange keeps the liner in position in the cylinder block. dry type cylinder liner: types of cylinder liners. Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine. dry cylinder liners can also be affected because of. Dry Cylinder Liner Diagram.

From ghaemg.com

?What is Cylinder Liner/Material cylinder liner گروه صنعتی قائم Dry Cylinder Liner Diagram Dry type cylinder liner is the most common type of cylinder liner. Dry liners and wet liners. Damage assessment cracks of this nature are frequently. It works under high pressure and. the cylinder liner's primary roles are to provide a sliding surface for the piston to provide a smooth reciprocating motion, to prevent. Both types of liners have their. Dry Cylinder Liner Diagram.

From www.semanticscholar.org

A Wear Model for Assessing the Reliability of Cylinder Liners in Marine Dry Cylinder Liner Diagram dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Damage assessment cracks of this nature are frequently. dry cylinder liners can also be affected because of their relatively thin cylinder wall thickness. Both types of liners have their pros and cons, and the choice between the two ultimately. Dry Cylinder Liner Diagram.

From exovnfrfr.blob.core.windows.net

Dry Liners Wiltshire at Paul Brock blog Dry Cylinder Liner Diagram Generally, two types of cylinder liners are used in i.c. dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Dry type cylinder liner is the most common type of cylinder liner. a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine. Dry Cylinder Liner Diagram.

From www.engineeringchoice.com

What is Cylinder Liner? Function and Types Engineering Choice Dry Cylinder Liner Diagram Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine. dry type cylinder liner: Dry liners and wet liners. the cylinder liner's primary roles are to provide a sliding surface for the piston to provide a smooth reciprocating motion, to prevent. dry cylinder. Dry Cylinder Liner Diagram.

From engineeringlearn.com

Cylinder Liner Types and Function Engineering Learn Dry Cylinder Liner Diagram Generally, two types of cylinder liners are used in i.c. dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. the cylinder liner's primary roles are to provide a sliding surface for the piston to provide a smooth reciprocating motion, to prevent. dry cylinder liners can also be. Dry Cylinder Liner Diagram.

From www.atracparts.com

Different Types of Cylinder Liner Dry Cylinder Liners vs. Wet Dry Cylinder Liner Diagram dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. dry type cylinder liner: It works under high pressure and. Dry liners and wet liners. the cylinder liners or sleeves are of two types: types of cylinder liners. Both types of liners have their pros and cons,. Dry Cylinder Liner Diagram.

From www.youtube.com

CYLINDER LINERCONSTRUCTIONMATERIAL(PART1) YouTube Dry Cylinder Liner Diagram The flange keeps the liner in position in the cylinder block. Dry type cylinder liner is the most common type of cylinder liner. a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. the cylinder liner's primary roles are to provide a sliding. Dry Cylinder Liner Diagram.

From marineinfobox.blogspot.com

Measuring cylinder liner wear in Marine I.C Engine Marine InfoSite Dry Cylinder Liner Diagram Dry liners and wet liners. The liner fits accurately in the cylinder. a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. dry type cylinder liner: Dry liners are made in the shape of a barrel having a flange at the top. . Dry Cylinder Liner Diagram.

From www.slideserve.com

PPT Cylinder liner PowerPoint Presentation, free download ID9196633 Dry Cylinder Liner Diagram The liner fits accurately in the cylinder. Dry type cylinder liner is the most common type of cylinder liner. It works under high pressure and. dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Dry liners and wet liners. dry cylinder liners can also be affected because of. Dry Cylinder Liner Diagram.

From boatmanuals.tpub.com

Figure 377. Cylinder liner measurement diagram. Dry Cylinder Liner Diagram Damage assessment cracks of this nature are frequently. the cylinder liner's primary roles are to provide a sliding surface for the piston to provide a smooth reciprocating motion, to prevent. types of cylinder liners. dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. Both types of liners. Dry Cylinder Liner Diagram.

From www.me-autoparts.com

Cylinder Liner For Diesel Engine Dry Cylinder Liner Diagram Both types of liners have their pros and cons, and the choice between the two ultimately depends on the specific requirements of your engine. Damage assessment cracks of this nature are frequently. The flange keeps the liner in position in the cylinder block. Dry liners and wet liners. It works under high pressure and. dry liners are simpler in. Dry Cylinder Liner Diagram.

From www.atracparts.com

Different Types of Cylinder Liner Dry Cylinder Liners vs. Wet Dry Cylinder Liner Diagram a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. Dry type cylinder liner is the most common type of cylinder liner. dry type cylinder liner: dry cylinder liners can also be affected because of their relatively thin cylinder wall thickness. Both. Dry Cylinder Liner Diagram.

From www.hc-enginepart.com

Features of dry cylinder liners Dry Cylinder Liner Diagram Damage assessment cracks of this nature are frequently. Dry liners and wet liners. The liner fits accurately in the cylinder. dry cylinder liners can also be affected because of their relatively thin cylinder wall thickness. It works under high pressure and. the cylinder liners or sleeves are of two types: Generally, two types of cylinder liners are used. Dry Cylinder Liner Diagram.

From mirmarine.net

Cylinder Liner procedures for Inspection and Calibration MirMarine Dry Cylinder Liner Diagram a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. dry type cylinder liner: Dry liners are made in the shape of a barrel having a flange at the top. dry cylinder liners can also be affected because of their relatively thin. Dry Cylinder Liner Diagram.

From www.slideserve.com

PPT Cylinder Liners PowerPoint Presentation, free download ID2134219 Dry Cylinder Liner Diagram dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. The flange keeps the liner in position in the cylinder block. Dry liners are made in the shape of a barrel having a flange at the top. Damage assessment cracks of this nature are frequently. The liner fits accurately in. Dry Cylinder Liner Diagram.

From www.hars.com.tr

What are the types of Cylinder Liner? HARS Dry Cylinder Liner Diagram types of cylinder liners. It works under high pressure and. dry liners are simpler in design and maintenance, while wet liners provide better cooling and lubrication for the engine. The liner fits accurately in the cylinder. Generally, two types of cylinder liners are used in i.c. Dry liners and wet liners. the cylinder liner's primary roles are. Dry Cylinder Liner Diagram.

From www.highpowermedia.com

Keeping the faith High Power Media Dry Cylinder Liner Diagram a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. The flange keeps the liner in position in the cylinder block. dry type cylinder liner: It works under high pressure and. types of cylinder liners. dry cylinder liners can also be. Dry Cylinder Liner Diagram.

From www.slideserve.com

PPT Types of Cylinder Liners and The Advantages PowerPoint Dry Cylinder Liner Diagram the cylinder liners or sleeves are of two types: a cylinder liner, also known as a cylinder sleeve, is a cylindrical component inserted into an engine block to provide a durable, smooth, and wear. dry cylinder liners can also be affected because of their relatively thin cylinder wall thickness. the cylinder liner's primary roles are to. Dry Cylinder Liner Diagram.