Tool Design Simple Definition . Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Reduce overall cost to manufacture a product. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. It refers to the plans and components used to build a product or part, from start to finish. Reduce cost of tooling (cost effective) design safe and. What are the fundamentals of tooling design? This type of design covers everything from. A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity. It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their.

from learnmechanical.com

Reduce overall cost to manufacture a product. What are the fundamentals of tooling design? It refers to the plans and components used to build a product or part, from start to finish. Reduce cost of tooling (cost effective) design safe and. This type of design covers everything from. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity. It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the.

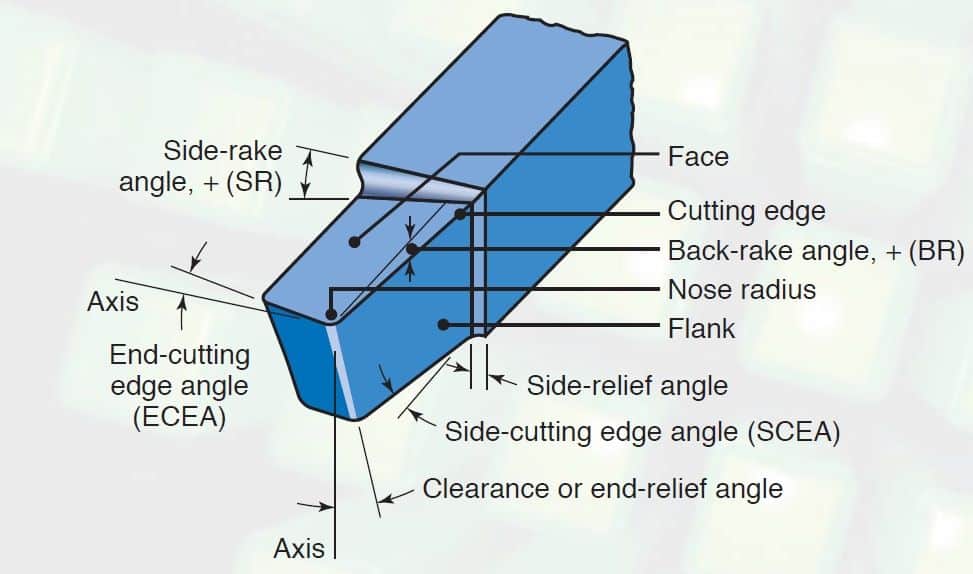

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature

Tool Design Simple Definition Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. What are the fundamentals of tooling design? Reduce cost of tooling (cost effective) design safe and. It refers to the plans and components used to build a product or part, from start to finish. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Reduce overall cost to manufacture a product. This type of design covers everything from. A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity.

From www.alamy.com

Isolated pencil tool design Stock Vector Image & Art Alamy Tool Design Simple Definition Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Reduce overall cost to manufacture a product. A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced.. Tool Design Simple Definition.

From www.sphinxworldbiz.com

Different Types of Tool and Die Design Tool Design Simple Definition Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. It refers to the plans and components. Tool Design Simple Definition.

From ceyqqjxr.blob.core.windows.net

Hand Tools Beginner Guide at Bradley Saunders blog Tool Design Simple Definition Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Reduce overall cost to manufacture a product. This type of design covers everything from. It refers to the plans and components used to build a product or part, from start to finish. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Reduce. Tool Design Simple Definition.

From design.udlvirtual.edu.pe

Design Thinking Define Stage Tools Design Talk Tool Design Simple Definition It refers to the plans and components used to build a product or part, from start to finish. This type of design covers everything from. It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Tool. Tool Design Simple Definition.

From www.hays-nyc.com

5 Simple Tips to Do Woodwork like a Pro Tool Design Simple Definition Reduce overall cost to manufacture a product. Reduce cost of tooling (cost effective) design safe and. What are the fundamentals of tooling design? It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Explore manufacturing tool. Tool Design Simple Definition.

From www.ple.com.au

EXDEMO Fractal Design Define 7 TG Dark Tint Mid Tower Case Black Tool Design Simple Definition What are the fundamentals of tooling design? Reduce overall cost to manufacture a product. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. It. Tool Design Simple Definition.

From eftect.pics

What exactly is design thinking? [Updated Guide for 2023] (2023) Tool Design Simple Definition Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. What are the fundamentals of tooling design? Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. A tool design is a process of designing. Tool Design Simple Definition.

From www.scribd.com

Cutting Tool Design PDF Machining Wear Tool Design Simple Definition Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Reduce cost of tooling (cost effective) design safe and. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency. Tool Design Simple Definition.

From www.ple.com.au

EXDEMO Fractal Design Define 7 TG Dark Tint Mid Tower Case Black Tool Design Simple Definition Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. This type of design covers everything from. A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity. Tool design in machine tooling is the art and science of crafting the perfect instrument for the. Tool Design Simple Definition.

From www.youtube.com

Best Design Systems Examples and Tools Design Tool Tuesday, Ep21 Tool Design Simple Definition A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity. Reduce cost of tooling (cost effective) design safe and. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. It’s not. Tool Design Simple Definition.

From analyseameter.com

Press Tool Design Basics Sheet Metal Stamping process Analyse A Meter Tool Design Simple Definition Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Explore manufacturing tool design with us, covering essentials. Tool Design Simple Definition.

From www.slideserve.com

PPT Cutting Tool Design Tool Materials, Tool Geometry PowerPoint Tool Design Simple Definition Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity. It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their.. Tool Design Simple Definition.

From www.decipherzone.com

Software Design Process and Tools Tool Design Simple Definition It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Reduce cost of tooling (cost effective) design safe. Tool Design Simple Definition.

From www.pinterest.co.uk

Hand Tools Antique woodworking tools, Used woodworking tools Tool Design Simple Definition What are the fundamentals of tooling design? It refers to the plans and components used to build a product or part, from start to finish. This type of design covers everything from. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Reduce. Tool Design Simple Definition.

From www.shiksha.com

What is Design Tools? Know Design Tools Skills, Career Path Tool Design Simple Definition A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Reduce overall cost to manufacture a product. Reduce cost of tooling (cost effective) design safe and. Tool design in machine tooling is the art. Tool Design Simple Definition.

From usabilityhub.com

What is user experience (UX) design? UsabilityHub Tool Design Simple Definition This type of design covers everything from. It refers to the plans and components used to build a product or part, from start to finish. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Reduce cost of tooling (cost effective) design safe. Tool Design Simple Definition.

From www.pinterest.com

Design Parameters in press tools design Tool design, Design Tool Design Simple Definition Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. It refers to the plans and components used to build a product or part, from start to finish. This type of design covers everything from. What are the fundamentals of tooling design? Whether it’s a lathe, milling machine, or a cnc (computer. Tool Design Simple Definition.

From de.linkedin.com

A key to good UX Design Emotions Tool Design Simple Definition Reduce overall cost to manufacture a product. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. What are the fundamentals of tooling design? Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. It’s. Tool Design Simple Definition.

From www.toools.design

Best AI Tools for Designers & Marketing Toools.design Tool Design Simple Definition What are the fundamentals of tooling design? It refers to the plans and components used to build a product or part, from start to finish. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. It’s not possible to cover every tooling design decision that a product developer needs to make in. Tool Design Simple Definition.

From dreamstime.com

Architectural Design & Tools Stock Images Image 1285324 Tool Design Simple Definition It refers to the plans and components used to build a product or part, from start to finish. Reduce overall cost to manufacture a product. Reduce cost of tooling (cost effective) design safe and. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Tool design in machine tooling is the art and science of crafting. Tool Design Simple Definition.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature Tool Design Simple Definition Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. What are the fundamentals of tooling design? This type of design covers everything from. It refers to the plans and components used to build a product or part, from start to finish. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Tool. Tool Design Simple Definition.

From www.oodlesstudio.com

A Comprehensive List Of Designing Tools You Must Use Tool Design Simple Definition What are the fundamentals of tooling design? It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Reduce cost of tooling (cost effective) design safe and. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. It refers to the plans and components used to build. Tool Design Simple Definition.

From getmaeveblog.blob.core.windows.net

Symbol For Effect at Getmaeveblog Blog Tool Design Simple Definition Reduce overall cost to manufacture a product. It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. A tool design is a process of designing and developing the tools, methods, and techniques. Tool Design Simple Definition.

From en.eagle.cool

7 Free AI Design Tools to Make Creating Easier Eagle Blog Tool Design Simple Definition Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Reduce overall cost to manufacture a product. It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. It refers to the plans and components used to build a product or part, from start to finish. A. Tool Design Simple Definition.

From www.vecteezy.com

Pen tool design application software 10682366 Vector Art at Vecteezy Tool Design Simple Definition Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Reduce cost of tooling (cost effective) design safe and. It refers to the plans and components used to build a product or part, from start to finish. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. It’s not. Tool Design Simple Definition.

From windowsreport.com

8 Best Shoe Design Software For Windows 10/11 [2024 Guide] Tool Design Simple Definition What are the fundamentals of tooling design? Reduce overall cost to manufacture a product. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. This type of design covers everything from. It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Reduce cost of tooling (cost effective). Tool Design Simple Definition.

From klahvejas.blob.core.windows.net

Design Tools And Methods at Ryan Hart blog Tool Design Simple Definition What are the fundamentals of tooling design? Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Reduce overall cost to manufacture a product. A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity. It refers to the plans and components used to build a. Tool Design Simple Definition.

From sitio-gluo-2022.vercel.app

What is Design Thinking? Stages and How to Create it Tool Design Simple Definition What are the fundamentals of tooling design? Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Reduce overall cost to manufacture a product. This. Tool Design Simple Definition.

From www.system-concepts.com

Design Thinking Define System Concepts Ltd. Making places, products Tool Design Simple Definition It refers to the plans and components used to build a product or part, from start to finish. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Reduce cost of tooling (cost effective) design safe and. Reduce overall cost to manufacture a product. Whether it’s a lathe, milling machine, or a. Tool Design Simple Definition.

From www.deel.com

30+ Technical Competencies Examples to Add to Your Company's Competency Tool Design Simple Definition Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Reduce overall cost to manufacture a product. This. Tool Design Simple Definition.

From www.interaction-design.org

What is Design Thinking and Why Is It So Popular? IxDF Tool Design Simple Definition Reduce cost of tooling (cost effective) design safe and. A tool design is a process of designing and developing the tools, methods, and techniques needed to improve manufacturing efficiency and productivity. Reduce overall cost to manufacture a product. What are the fundamentals of tooling design? Tool design in machine tooling is the art and science of crafting the perfect instrument. Tool Design Simple Definition.

From design.udlvirtual.edu.pe

Design Thinking Define Stage Tools Design Talk Tool Design Simple Definition It refers to the plans and components used to build a product or part, from start to finish. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Tool design in machine tooling is the art and science of crafting the perfect instrument for the job. Explore manufacturing tool design with us, covering essentials from cutting. Tool Design Simple Definition.

From www.ple.com.au

EXDEMO Fractal Design Define 7 TG Dark Tint Mid Tower Case Black Tool Design Simple Definition It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. What are the fundamentals of tooling design? Reduce cost of tooling (cost effective) design safe and. Reduce overall cost to manufacture a product. Tool design in machine. Tool Design Simple Definition.

From www.behance.net

Tool Design (Design & Analysis of Press Tools) Behance Tool Design Simple Definition It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Whether it’s a lathe, milling machine, or a cnc (computer numerical control) system, the. Reduce cost of tooling (cost effective) design safe and. This type of design covers everything from. Explore manufacturing tool design with us, covering essentials from cutting. Tool Design Simple Definition.

From myproject.co.il

Uses of Design Thinking Tools at every stage of Design Thinking My Tool Design Simple Definition Reduce overall cost to manufacture a product. This type of design covers everything from. What are the fundamentals of tooling design? It’s not possible to cover every tooling design decision that a product developer needs to make in partnership with their. Explore manufacturing tool design with us, covering essentials from cutting tools to advanced. A tool design is a process. Tool Design Simple Definition.