Setting Control Limits . the control limits of your control chart represent your process variation and help indicate when your process is out of. Use the standard control limit formula and the. We use two statistics, the overall average and the average range,. control limits are one key to process improvement actions. In other words, the distance between upper specified. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where a process. Determine the appropriate time period for collecting and plotting data. Standard deviation of qc sample results. the control limits can be set: Choose the appropriate control chart for your data. 1) based on method performance characteristics i.e. the control limits may be set at a level such that the c pk is higher than a required value. ever wonder where the control limit equations come from?

from www.semanticscholar.org

the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where a process. In other words, the distance between upper specified. Standard deviation of qc sample results. control limits are one key to process improvement actions. 1) based on method performance characteristics i.e. the control limits can be set: We use two statistics, the overall average and the average range,. the control limits of your control chart represent your process variation and help indicate when your process is out of. Determine the appropriate time period for collecting and plotting data. ever wonder where the control limit equations come from?

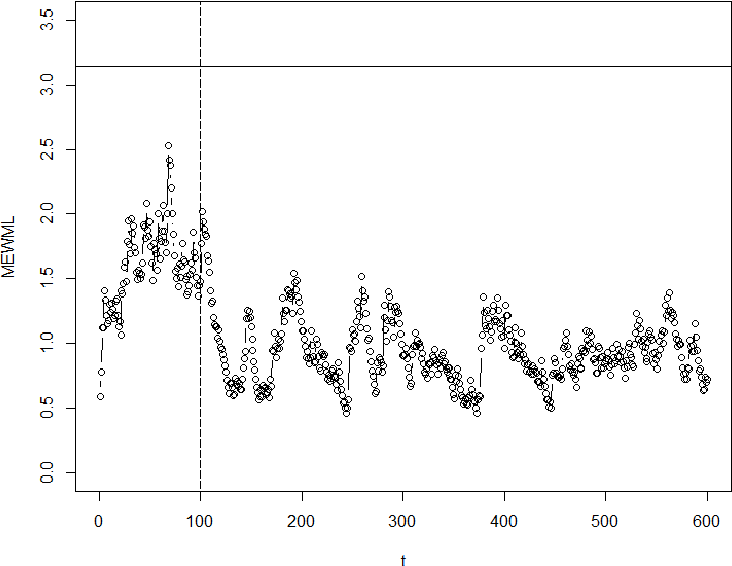

Setting Control Limits in a Multivariate Exponentially Weighted Moving

Setting Control Limits Standard deviation of qc sample results. the control limits of your control chart represent your process variation and help indicate when your process is out of. Use the standard control limit formula and the. Choose the appropriate control chart for your data. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where a process. Determine the appropriate time period for collecting and plotting data. We use two statistics, the overall average and the average range,. Standard deviation of qc sample results. ever wonder where the control limit equations come from? In other words, the distance between upper specified. control limits are one key to process improvement actions. the control limits may be set at a level such that the c pk is higher than a required value. 1) based on method performance characteristics i.e. the control limits can be set:

From www.chegg.com

Solved Set control limits for this process for the Rchart. Setting Control Limits Choose the appropriate control chart for your data. ever wonder where the control limit equations come from? the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where a process. Standard deviation of qc sample results. the control limits of your control chart represent. Setting Control Limits.

From www.slideserve.com

PPT Quality Control PowerPoint Presentation, free download ID1545400 Setting Control Limits the control limits can be set: In other words, the distance between upper specified. Use the standard control limit formula and the. the control limits may be set at a level such that the c pk is higher than a required value. the control limits of your control chart represent your process variation and help indicate when. Setting Control Limits.

From www.slideserve.com

PPT Chartrunner Tutorial PowerPoint Presentation, free download ID Setting Control Limits Determine the appropriate time period for collecting and plotting data. the control limits of your control chart represent your process variation and help indicate when your process is out of. Use the standard control limit formula and the. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits. Setting Control Limits.

From www.pinterest.com

Control Limit Vs Specification Limit Difference between Control Setting Control Limits In other words, the distance between upper specified. We use two statistics, the overall average and the average range,. the control limits may be set at a level such that the c pk is higher than a required value. Standard deviation of qc sample results. the main features of a control chart include the data points, a centerline. Setting Control Limits.

From slideplayer.com

Statistical Process Control (SPC) ppt download Setting Control Limits Determine the appropriate time period for collecting and plotting data. ever wonder where the control limit equations come from? 1) based on method performance characteristics i.e. the control limits can be set: Choose the appropriate control chart for your data. the main features of a control chart include the data points, a centerline (mean value), and upper. Setting Control Limits.

From www.slideserve.com

PPT Control Charts PowerPoint Presentation, free download ID996623 Setting Control Limits Choose the appropriate control chart for your data. We use two statistics, the overall average and the average range,. ever wonder where the control limit equations come from? the control limits of your control chart represent your process variation and help indicate when your process is out of. Standard deviation of qc sample results. 1) based on method. Setting Control Limits.

From www.slideserve.com

PPT Operations Management PowerPoint Presentation, free download ID Setting Control Limits In other words, the distance between upper specified. Choose the appropriate control chart for your data. Use the standard control limit formula and the. We use two statistics, the overall average and the average range,. 1) based on method performance characteristics i.e. control limits are one key to process improvement actions. the control limits can be set: . Setting Control Limits.

From www.youtube.com

Calculating Control Limits for a c chart by hand YouTube Setting Control Limits the control limits of your control chart represent your process variation and help indicate when your process is out of. In other words, the distance between upper specified. Standard deviation of qc sample results. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where. Setting Control Limits.

From smartersolutions.com

Control Limits for p chart, traditional approach Smarter Solutions, Inc. Setting Control Limits the control limits can be set: ever wonder where the control limit equations come from? We use two statistics, the overall average and the average range,. Standard deviation of qc sample results. Use the standard control limit formula and the. Determine the appropriate time period for collecting and plotting data. the main features of a control chart. Setting Control Limits.

From www.linkedin.com

Setting and Adjusting Control Limits for SPC Charts Setting Control Limits the control limits of your control chart represent your process variation and help indicate when your process is out of. We use two statistics, the overall average and the average range,. Choose the appropriate control chart for your data. the control limits can be set: 1) based on method performance characteristics i.e. In other words, the distance between. Setting Control Limits.

From www.slideserve.com

PPT Chapter 6 Statistical Quality Control (SQC) PowerPoint Setting Control Limits Use the standard control limit formula and the. Standard deviation of qc sample results. 1) based on method performance characteristics i.e. We use two statistics, the overall average and the average range,. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where a process. In. Setting Control Limits.

From www.linkedin.com

How to Set and Adjust Control Limits for a Control Chart Setting Control Limits We use two statistics, the overall average and the average range,. Standard deviation of qc sample results. 1) based on method performance characteristics i.e. the control limits can be set: In other words, the distance between upper specified. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits. Setting Control Limits.

From www.slideserve.com

PPT Positive Discipline & Guidance PowerPoint Presentation, free Setting Control Limits the control limits may be set at a level such that the c pk is higher than a required value. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where a process. control limits are one key to process improvement actions. We use. Setting Control Limits.

From www.slideserve.com

PPT QUALITY IMPROVEMENT TOOLS AND TECHNIQUES PowerPoint Presentation Setting Control Limits Choose the appropriate control chart for your data. the control limits of your control chart represent your process variation and help indicate when your process is out of. control limits are one key to process improvement actions. 1) based on method performance characteristics i.e. In other words, the distance between upper specified. Standard deviation of qc sample results.. Setting Control Limits.

From www.semanticscholar.org

Setting Control Limits in a Multivariate Exponentially Weighted Moving Setting Control Limits control limits are one key to process improvement actions. Standard deviation of qc sample results. Determine the appropriate time period for collecting and plotting data. ever wonder where the control limit equations come from? In other words, the distance between upper specified. Use the standard control limit formula and the. the control limits can be set: . Setting Control Limits.

From www.semanticscholar.org

Setting Control Limits in a Multivariate Exponentially Weighted Moving Setting Control Limits In other words, the distance between upper specified. Use the standard control limit formula and the. 1) based on method performance characteristics i.e. the control limits of your control chart represent your process variation and help indicate when your process is out of. Choose the appropriate control chart for your data. We use two statistics, the overall average and. Setting Control Limits.

From www.learnleansigma.com

Control Limits Calculator (UCL and LCL) Learn Lean Sigma Setting Control Limits We use two statistics, the overall average and the average range,. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where a process. Determine the appropriate time period for collecting and plotting data. ever wonder where the control limit equations come from? control. Setting Control Limits.

From www.chegg.com

Set the control limits for this process for the Setting Control Limits Use the standard control limit formula and the. Standard deviation of qc sample results. the control limits of your control chart represent your process variation and help indicate when your process is out of. control limits are one key to process improvement actions. the main features of a control chart include the data points, a centerline (mean. Setting Control Limits.

From www.bluecorpsolutions.com

[solved]Set Control Limits Process X Chart Ucl Grams Round Response Setting Control Limits 1) based on method performance characteristics i.e. In other words, the distance between upper specified. control limits are one key to process improvement actions. Choose the appropriate control chart for your data. ever wonder where the control limit equations come from? the control limits of your control chart represent your process variation and help indicate when your. Setting Control Limits.

From www.linkedin.com

How to Set and Adjust Control Limits for SPC Setting Control Limits the control limits of your control chart represent your process variation and help indicate when your process is out of. the control limits can be set: control limits are one key to process improvement actions. In other words, the distance between upper specified. We use two statistics, the overall average and the average range,. Standard deviation of. Setting Control Limits.

From www.slideserve.com

PPT Inspection “backend quality control” PowerPoint Presentation Setting Control Limits In other words, the distance between upper specified. ever wonder where the control limit equations come from? We use two statistics, the overall average and the average range,. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where a process. Choose the appropriate control. Setting Control Limits.

From www.linkedin.com

Setting and Adjusting Control Limits for SPC Charts Setting Control Limits In other words, the distance between upper specified. the control limits of your control chart represent your process variation and help indicate when your process is out of. Standard deviation of qc sample results. We use two statistics, the overall average and the average range,. the control limits can be set: Use the standard control limit formula and. Setting Control Limits.

From www.slideserve.com

PPT Chapter 6 Statistical Quality Control PowerPoint Presentation Setting Control Limits the control limits can be set: We use two statistics, the overall average and the average range,. Determine the appropriate time period for collecting and plotting data. In other words, the distance between upper specified. control limits are one key to process improvement actions. Standard deviation of qc sample results. the control limits may be set at. Setting Control Limits.

From www.slideserve.com

PPT CCP PowerPoint Presentation, free download ID3889765 Setting Control Limits the control limits can be set: the control limits of your control chart represent your process variation and help indicate when your process is out of. control limits are one key to process improvement actions. Use the standard control limit formula and the. the main features of a control chart include the data points, a centerline. Setting Control Limits.

From www.cell.com

Setting process control chart limits for roundedoff measurements Heliyon Setting Control Limits the control limits may be set at a level such that the c pk is higher than a required value. Use the standard control limit formula and the. We use two statistics, the overall average and the average range,. the control limits can be set: In other words, the distance between upper specified. 1) based on method performance. Setting Control Limits.

From www.slideserve.com

PPT Statistical Process Control PowerPoint Presentation, free Setting Control Limits Use the standard control limit formula and the. 1) based on method performance characteristics i.e. Choose the appropriate control chart for your data. We use two statistics, the overall average and the average range,. the control limits may be set at a level such that the c pk is higher than a required value. Determine the appropriate time period. Setting Control Limits.

From marketplace.trueprojectinsight.com

Setting Control Limits and Next Steps TrueProject Marketplace Setting Control Limits Determine the appropriate time period for collecting and plotting data. control limits are one key to process improvement actions. In other words, the distance between upper specified. Standard deviation of qc sample results. the control limits of your control chart represent your process variation and help indicate when your process is out of. 1) based on method performance. Setting Control Limits.

From www.slideserve.com

PPT Operations Management PowerPoint Presentation, free download ID Setting Control Limits Choose the appropriate control chart for your data. In other words, the distance between upper specified. 1) based on method performance characteristics i.e. the control limits can be set: the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where a process. the control. Setting Control Limits.

From www.slideserve.com

PPT Operations Management PowerPoint Presentation, free download ID Setting Control Limits control limits are one key to process improvement actions. the control limits of your control chart represent your process variation and help indicate when your process is out of. Standard deviation of qc sample results. Determine the appropriate time period for collecting and plotting data. the control limits can be set: We use two statistics, the overall. Setting Control Limits.

From www.researchgate.net

Critical limits, monitoring procedures, corrective actions and Setting Control Limits ever wonder where the control limit equations come from? the control limits can be set: We use two statistics, the overall average and the average range,. Choose the appropriate control chart for your data. In other words, the distance between upper specified. the control limits of your control chart represent your process variation and help indicate when. Setting Control Limits.

From vocal.media

What is the difference between Control Limits and Specification Limits Setting Control Limits the control limits can be set: Use the standard control limit formula and the. the control limits may be set at a level such that the c pk is higher than a required value. ever wonder where the control limit equations come from? Determine the appropriate time period for collecting and plotting data. Choose the appropriate control. Setting Control Limits.

From ar.inspiredpencil.com

Control Chart Table Setting Control Limits In other words, the distance between upper specified. Standard deviation of qc sample results. 1) based on method performance characteristics i.e. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to indicate where a process. We use two statistics, the overall average and the average range,. . Setting Control Limits.

From familyfire.reframemedia.com

Setting Limits How Can Boundaries Help My Family? FamilyFire Setting Control Limits We use two statistics, the overall average and the average range,. ever wonder where the control limit equations come from? the control limits may be set at a level such that the c pk is higher than a required value. Standard deviation of qc sample results. control limits are one key to process improvement actions. the. Setting Control Limits.

From community.jmp.com

Solved Setting Control limits manually for Level Jennings chart JMP Setting Control Limits control limits are one key to process improvement actions. the control limits may be set at a level such that the c pk is higher than a required value. Determine the appropriate time period for collecting and plotting data. In other words, the distance between upper specified. 1) based on method performance characteristics i.e. the control limits. Setting Control Limits.

From www.slideserve.com

PPT QUALITY IMPROVEMENT TOOLS AND TECHNIQUES PowerPoint Presentation Setting Control Limits the control limits can be set: the control limits may be set at a level such that the c pk is higher than a required value. Determine the appropriate time period for collecting and plotting data. the main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds. Setting Control Limits.