Pin And Hole Fits . Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. Select class xx based on required functional fit to access page. The first provides the charts for the fundamental. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. The minimum recommended hole is the drill size and.

from www.gdandtbasics.com

Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. Select class xx based on required functional fit to access page. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. The first provides the charts for the fundamental. The minimum recommended hole is the drill size and. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator.

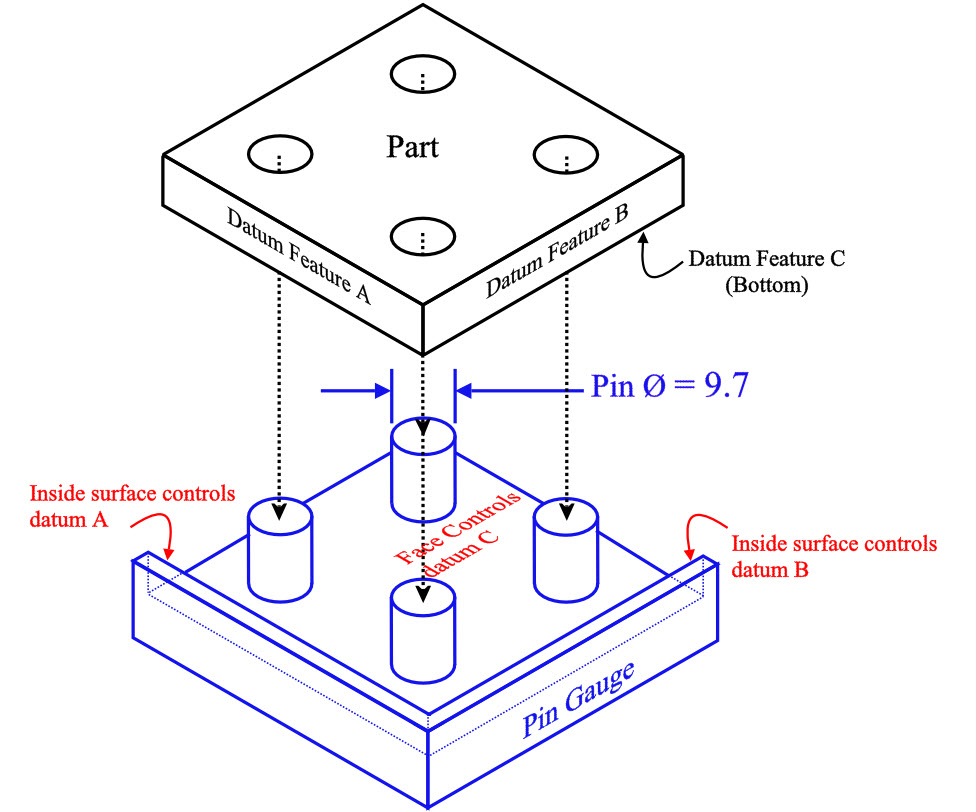

True Position GD&T Basics

Pin And Hole Fits Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. The minimum recommended hole is the drill size and. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. The first provides the charts for the fundamental. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. Select class xx based on required functional fit to access page. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator.

From ar.inspiredpencil.com

Dowel Pin Hole Tolerance Chart Pin And Hole Fits Dowel pins should be installed into press fit holes after finishing processes and not removed there after. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. Fixed fastener calculations will show minimal interference between. Pin And Hole Fits.

From www.youtube.com

Fits Hole Basis System and Shaft Basis System YouTube Pin And Hole Fits Dowel pins should be installed into press fit holes after finishing processes and not removed there after. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. Select class xx based on required functional fit to access page. The first provides. Pin And Hole Fits.

From engineering.stackexchange.com

mechanical engineering Tolerances in a pinhole assembly Engineering Stack Exchange Pin And Hole Fits According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. Select class xx based on required functional fit to access page. The first provides the charts for the fundamental. Dowel pins should be installed into press. Pin And Hole Fits.

From www.rechargecolorado.org

Metric Dowel Pin Slip Fit Hole Size Chart Best Picture Of Chart Pin And Hole Fits Dowel pins should be installed into press fit holes after finishing processes and not removed there after. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. Select class xx based on required functional fit to access page. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. The minimum recommended. Pin And Hole Fits.

From joisyjank.blob.core.windows.net

Dowel Pin Hole Size Chart Inches at Linda Whittington blog Pin And Hole Fits The minimum recommended hole is the drill size and. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes.. Pin And Hole Fits.

From www.gdandtbasics.com

True Position GD&T Basics Pin And Hole Fits Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. Select class xx based on required functional. Pin And Hole Fits.

From exozflqcl.blob.core.windows.net

Dowel Pin Hole Size Chart at Dorothy Frost blog Pin And Hole Fits Select class xx based on required functional fit to access page. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. Fixed fastener calculations will show minimal interference between dowel pins and slip. Pin And Hole Fits.

From ar.inspiredpencil.com

Dowel Pin Hole Tolerance Chart Pin And Hole Fits Dowel pins should be installed into press fit holes after finishing processes and not removed there after. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. The minimum recommended hole is the drill size and. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational.. Pin And Hole Fits.

From www.pcb-hero.com

What is a PressFit Hole PCB ? PCB HERO Pin And Hole Fits The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. Select class xx based on required functional fit to access page. The minimum recommended. Pin And Hole Fits.

From engineering.stackexchange.com

mechanical engineering Tolerances in a pinhole assembly Engineering Stack Exchange Pin And Hole Fits Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. The first provides the charts for the fundamental. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. Fixed fastener calculations will show minimal interference between dowel pins and slip fit. Pin And Hole Fits.

From www.youtube.com

Interference fit types of fits interference fit Explained Mechanical Measurement Pin And Hole Fits The minimum recommended hole is the drill size and. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. The first provides the charts for the fundamental. Select class xx based on required functional fit to access page. Dowel pins should be installed into press fit holes after finishing processes. Pin And Hole Fits.

From www.villageinframe.com

Metric Dowel Pin Hole Tolerance Chart A Pictures Of Hole 2018 Pin And Hole Fits Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. Fixed fastener calculations will show minimal interference between dowel pins and. Pin And Hole Fits.

From www.researchgate.net

Assembly procedure for two segments. (a) Reaming the pin holes; (b)... Download Scientific Diagram Pin And Hole Fits Dowel pins should be installed into press fit holes after finishing processes and not removed there after. The first provides the charts for the fundamental. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. The minimum recommended hole is the drill size and. According to nominal size and fit type selection among running and sliding. Pin And Hole Fits.

From joijunain.blob.core.windows.net

Din 7 Dowel Pin Hole Size at Miriam Hiller blog Pin And Hole Fits Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. Select class xx based on required functional fit to access page. The first provides the charts for the fundamental. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. According to nominal size and. Pin And Hole Fits.

From www.eenewseurope.com

Pressfit PCB pins for platedthrough holes Pin And Hole Fits Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. The minimum recommended hole is the drill size and. The first. Pin And Hole Fits.

From mavink.com

Metric Dowel Pin Press Fit Tolerances Pin And Hole Fits The first provides the charts for the fundamental. The minimum recommended hole is the drill size and. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. Fixed fastener calculations will show minimal interference between dowel pins and slip. Pin And Hole Fits.

From joisyjank.blob.core.windows.net

Dowel Pin Hole Size Chart Inches at Linda Whittington blog Pin And Hole Fits Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. Select class xx based on required functional fit to access page. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. The minimum recommended hole is the drill size and. The first provides the. Pin And Hole Fits.

From joijunain.blob.core.windows.net

Din 7 Dowel Pin Hole Size at Miriam Hiller blog Pin And Hole Fits According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. The minimum recommended hole is the drill size. Pin And Hole Fits.

From www.fictiv.com

Slip Fit Tolerances and Geometry Fictiv Pin And Hole Fits Select class xx based on required functional fit to access page. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. The minimum recommended hole is the drill. Pin And Hole Fits.

From ar.inspiredpencil.com

Dowel Pin Hole Tolerance Chart Pin And Hole Fits The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. The first provides the charts for the fundamental. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. According. Pin And Hole Fits.

From fastenerandfixing.com

How to properly pin a shaft and hub assembly Fastener + Fixing Magazine Pin And Hole Fits According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. The first provides the charts for the fundamental. The. Pin And Hole Fits.

From jaydenpatel.z19.web.core.windows.net

Metric Dowel Pin Press Fit Tolerance Chart Pin And Hole Fits Dowel pins should be installed into press fit holes after finishing processes and not removed there after. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. The minimum recommended hole is the drill size and. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational.. Pin And Hole Fits.

From charlotteanderson.z13.web.core.windows.net

Dowel Pin Press Fit Hole Size Chart Pin And Hole Fits Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational. Pin And Hole Fits.

From www.alibaba.com

Metric Dowel Pin Press Fit Tolerances Screw In Dowel Pins Steel Dowel Rod Sizes Buy Aluminium Pin And Hole Fits Dowel pins should be installed into press fit holes after finishing processes and not removed there after. The minimum recommended hole is the drill size and. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. The recommended drill and hole sizes for metric fasteners are tabulated in this table. Pin And Hole Fits.

From mungfali.com

ISO Hole Tolerance Chart Pin And Hole Fits According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. Fixed fastener calculations will. Pin And Hole Fits.

From rubyfrench.z21.web.core.windows.net

Dowel Pin Hole Size Chart Pin And Hole Fits Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. Select class xx based on required functional fit to access page. According to nominal size and fit type selection among running and sliding [rc],. Pin And Hole Fits.

From mungfali.com

Dowel Pin Slip Fit Tolerance Chart Pin And Hole Fits Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. The first provides the charts for the fundamental. According to. Pin And Hole Fits.

From www.slideserve.com

PPT Fits and Tolerances PowerPoint Presentation, free download ID2640481 Pin And Hole Fits Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. Select class xx based on required functional fit to access page. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. The first provides. Pin And Hole Fits.

From www.researchgate.net

Pin hole loading configurations (a) uniformly distributed, (b) uniform... Download Scientific Pin And Hole Fits Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. Select class xx based on required functional fit to. Pin And Hole Fits.

From www.villageinframe.com

Dowel Pin Hole Tolerance H7 A Pictures Of Hole 2018 Pin And Hole Fits The minimum recommended hole is the drill size and. The first provides the charts for the fundamental. Find out the standardized nomenclature, tolerance ranges, and examples of clearance and interference fits. The recommended drill and hole sizes for metric fasteners are tabulated in this table calculator. According to nominal size and fit type selection among running and sliding [rc], locational. Pin And Hole Fits.

From www.automationmagazine.co.uk

Hole preparation for press fit pins Automation Magazine Pin And Hole Fits According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. The minimum recommended hole is the drill size and. Select class xx based on required functional fit to access page. The first provides the charts for the fundamental. Dowel pins should be installed into press fit holes after finishing processes. Pin And Hole Fits.

From engineeringlearn.com

3 Types of Fits Clearance Fit, Interference Fit, Transition Fit Guide] Engineering Pin And Hole Fits Dowel pins should be installed into press fit holes after finishing processes and not removed there after. The minimum recommended hole is the drill size and. Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. The first provides the charts for the fundamental. Fixed fastener calculations will. Pin And Hole Fits.

From www.villageinframe.com

Metric Dowel Pin Hole Tolerance Chart A Pictures Of Hole 2018 Pin And Hole Fits Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. Dowel pins should be installed into press fit holes after finishing processes and not removed there after. Find out the standardized nomenclature, tolerance ranges, and examples. Pin And Hole Fits.

From cexksore.blob.core.windows.net

Dowel Pin Hole Size Calculator at Sandra Palermo blog Pin And Hole Fits Learn about the different types of shaft and hole fits, how to determine and specify them, and how they affect mechanical design. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. Select class xx based. Pin And Hole Fits.

From www.reddit.com

Limit and Fits Tolerances too tight for general machining? AskEngineers Pin And Hole Fits Select class xx based on required functional fit to access page. Fixed fastener calculations will show minimal interference between dowel pins and slip fit holes. According to nominal size and fit type selection among running and sliding [rc], locational clearance [lc], locational transition [lt], locational. The first provides the charts for the fundamental. Find out the standardized nomenclature, tolerance ranges,. Pin And Hole Fits.