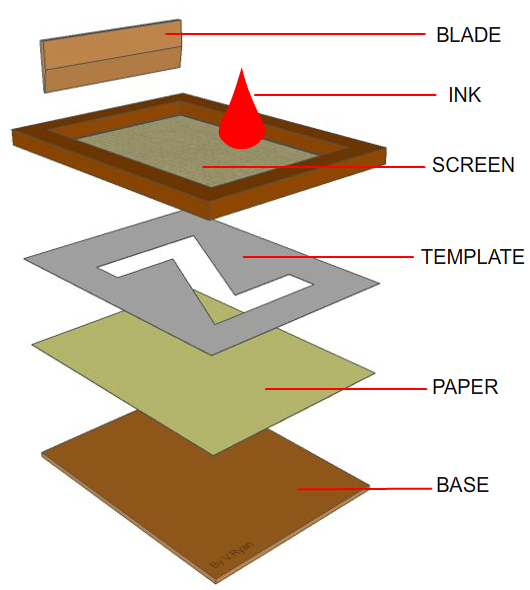

Screen Printing Process Parameters . Preparing the screen is the first step in the screen printing process and is probably the most important one. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. We can’t expect to achieve a good. Regardless of the type of printing process, its objective (conventional or functional) and the substrate, determination of the optimum process. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. The ink roll in front.

from finwise.edu.vn

To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. Regardless of the type of printing process, its objective (conventional or functional) and the substrate, determination of the optimum process. Preparing the screen is the first step in the screen printing process and is probably the most important one. The ink roll in front. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. We can’t expect to achieve a good.

List 104+ Pictures Screen Printing Process Step By Step With Pictures Superb

Screen Printing Process Parameters The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. We can’t expect to achieve a good. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. Preparing the screen is the first step in the screen printing process and is probably the most important one. Regardless of the type of printing process, its objective (conventional or functional) and the substrate, determination of the optimum process. To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. The ink roll in front.

From zhuanlan.zhihu.com

干货分享丨SMT钢网印刷工艺详细介绍Screen Printing Process(共80页PPT) 知乎 Screen Printing Process Parameters Regardless of the type of printing process, its objective (conventional or functional) and the substrate, determination of the optimum process. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. We can’t expect to achieve a good. To achieve a good print result, particular attention needs to. Screen Printing Process Parameters.

From www.researchgate.net

Printed circuit board fabrication. (A, B) principle of screen printing,... Download Scientific Screen Printing Process Parameters The ink roll in front. Preparing the screen is the first step in the screen printing process and is probably the most important one. To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. The basic parameters of screen printing are discussed, and an analytical model of the screen. Screen Printing Process Parameters.

From www.researchgate.net

Schematic of the screenprinting process. Download Scientific Diagram Screen Printing Process Parameters If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. Regardless of the type of printing process, its objective (conventional or functional) and the substrate, determination of the optimum process. The ink roll in front. The components of the screen printing process include the printer, the substrate, the screen,. Screen Printing Process Parameters.

From www.researchgate.net

(a) Pictorial demonstration of screen printing process. (b) Mesh... Download Scientific Diagram Screen Printing Process Parameters We can’t expect to achieve a good. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. The basic parameters of screen printing are discussed, and. Screen Printing Process Parameters.

From textilementor.com

Screen Printing Process, Types And Materials Screen Printing Process Parameters The ink roll in front. Regardless of the type of printing process, its objective (conventional or functional) and the substrate, determination of the optimum process. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. To achieve a good print result, particular attention needs to be paid to the. Screen Printing Process Parameters.

From www.youtube.com

Screen Printing A to Z ।। Step by Step Process of Screen Printing YouTube Screen Printing Process Parameters The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of. Screen Printing Process Parameters.

From www.researchgate.net

Screen printing process. Download Scientific Diagram Screen Printing Process Parameters To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. Preparing the screen is the first step in the screen printing process and is probably the most important one. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision. Screen Printing Process Parameters.

From ttgraphics.com

Screen Printing T&T Graphics, Inc. Screen Printing Process Parameters The ink roll in front. Regardless of the type of printing process, its objective (conventional or functional) and the substrate, determination of the optimum process. Preparing the screen is the first step in the screen printing process and is probably the most important one. We can’t expect to achieve a good. The components of the screen printing process include the. Screen Printing Process Parameters.

From joiqfwrmi.blob.core.windows.net

Screen Printing Process Step By Step at Ernest Cox blog Screen Printing Process Parameters If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. Preparing the screen is the first step in the screen printing process and is probably the most important one. To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen. Screen Printing Process Parameters.

From www.wer-china.com

Screen printing process analysis WerChina Blog Screen Printing Process Parameters Preparing the screen is the first step in the screen printing process and is probably the most important one. To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. The. Screen Printing Process Parameters.

From www.researchgate.net

Basic process of screenprinting technology. Reprinted from [51] with... Download Scientific Screen Printing Process Parameters We can’t expect to achieve a good. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. The ink roll in front. The basic parameters of. Screen Printing Process Parameters.

From www.youtube.com

Screen Printing Process Step By Step Elaborately Explained. ( Hindi ) YouTube Screen Printing Process Parameters We can’t expect to achieve a good. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. Preparing the screen is the first step in the screen printing process and is probably the most important one. The components of the screen printing process include the printer, the substrate, the screen, the. Screen Printing Process Parameters.

From www.slideserve.com

PPT Overview of Screen Printing Process and Applications PowerPoint Presentation ID12080696 Screen Printing Process Parameters To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. Preparing the screen is the first step in the screen printing process and is probably the most important one. The ink roll in front. We can’t expect to achieve a good. If the printing of any product becomes more. Screen Printing Process Parameters.

From www.researchgate.net

Screenprinting process parameters. Download Scientific Diagram Screen Printing Process Parameters We can’t expect to achieve a good. The ink roll in front. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. If the printing of. Screen Printing Process Parameters.

From www.squeegeeandink.co.uk

SCREEN PRINTING BASICS, STEP BY STEP Squeegee & Ink Screen Printing Process Parameters Preparing the screen is the first step in the screen printing process and is probably the most important one. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. We can’t expect to achieve a good. Regardless of the type of printing process, its objective (conventional or. Screen Printing Process Parameters.

From www.researchgate.net

a Schematic diagram of the screen printing process and b the fabricated... Download Scientific Screen Printing Process Parameters Regardless of the type of printing process, its objective (conventional or functional) and the substrate, determination of the optimum process. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. Preparing the screen is the first step in the screen printing process and is probably the most. Screen Printing Process Parameters.

From www.ynvisible.com

Screen Printing How It Works, Benefits & Applications Ynvisible Screen Printing Process Parameters The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. Preparing the screen is the first step in the screen printing process and is probably the. Screen Printing Process Parameters.

From www.researchgate.net

Schematic representation of the screen printing process. Download Scientific Diagram Screen Printing Process Parameters The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. To achieve a good print result, particular attention needs to be paid to the most important. Screen Printing Process Parameters.

From www.researchgate.net

MAE performance results for the three LSTM models on predicting SPP... Download Scientific Diagram Screen Printing Process Parameters Preparing the screen is the first step in the screen printing process and is probably the most important one. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. We can’t expect to achieve a good. The components of the screen printing process include the printer, the substrate, the screen, the. Screen Printing Process Parameters.

From ro.pinterest.com

What Are the 6 Different Types of Screen Printing Process? Screen printing, Screen printing Screen Printing Process Parameters We can’t expect to achieve a good. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. Preparing the screen is the first step in the screen printing process and. Screen Printing Process Parameters.

From mavink.com

Screen Printing Process Screen Printing Process Parameters Regardless of the type of printing process, its objective (conventional or functional) and the substrate, determination of the optimum process. We can’t expect to achieve a good. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. The ink roll in front. Preparing the screen is the. Screen Printing Process Parameters.

From www.researchgate.net

7. Schematic diagram of the different steps followed in screen printing... Download Scientific Screen Printing Process Parameters To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision. Screen Printing Process Parameters.

From www.gsdesigns.com

527f0dde1ff885671c52e4b38e636915screenprintingprocesssilkscreenprinting G.S. Designs Screen Printing Process Parameters The ink roll in front. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. Preparing the screen is the first step in the screen printing process and is probably the most important one. We can’t expect to achieve a good. Regardless of the type of printing process, its objective (conventional. Screen Printing Process Parameters.

From www.artofit.org

Screen printing process Artofit Screen Printing Process Parameters The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. The basic parameters of screen printing are discussed, and an analytical model of the screen printing. Screen Printing Process Parameters.

From www.researchgate.net

Screen printing process Download Scientific Diagram Screen Printing Process Parameters If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. Preparing the screen is the first step in the screen printing process and is probably the. Screen Printing Process Parameters.

From finwise.edu.vn

List 104+ Pictures Screen Printing Process Step By Step With Pictures Superb Screen Printing Process Parameters If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. Preparing the screen is the first step in the screen printing process and is probably the. Screen Printing Process Parameters.

From www.pinterest.com

Express Screen Printing Screen printing, Screen printing process, Screen Screen Printing Process Parameters Regardless of the type of printing process, its objective (conventional or functional) and the substrate, determination of the optimum process. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. The ink roll in front. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control. Screen Printing Process Parameters.

From lineproindia.com

Screen Printing The indispensable Printing technique for Printed Electronics Screen Printing Process Parameters If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. The ink roll in front. Preparing the screen is the first step in the screen printing process and is probably the most important one. We can’t expect to achieve a good. The basic parameters of screen printing are discussed,. Screen Printing Process Parameters.

From americanstitchlv.com

StepbyStep Screen Printing Process HandBook Screen Printing Process Parameters We can’t expect to achieve a good. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. The ink roll in front. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. The components of the screen printing process include. Screen Printing Process Parameters.

From www.researchgate.net

Schematic diagram of multilayer screen printing process. a Printing of... Download Scientific Screen Printing Process Parameters The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. Preparing the screen is the first step in the screen printing process and is probably the most important one. We can’t expect to achieve a good. Regardless of the type of printing process, its objective (conventional or. Screen Printing Process Parameters.

From imprintnext.com

What Are the 6 Different Types of Screen Printing Process? ImprintNext Blog Screen Printing Process Parameters To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. The ink roll in front. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is introduced. We can’t expect to achieve a good. The components of the screen printing process include. Screen Printing Process Parameters.

From www.researchgate.net

Schematic diagram of multilayer screen printing process. a Printing of... Download Scientific Screen Printing Process Parameters The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. Preparing the screen is the first step in the screen printing process and is probably the most important one. The basic parameters of screen printing are discussed, and an analytical model of the screen printing process is. Screen Printing Process Parameters.

From www.youtube.com

Screen Printing Process in Hub92prints YouTube Screen Printing Process Parameters Preparing the screen is the first step in the screen printing process and is probably the most important one. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink, and the process. The ink roll in front. The basic parameters of screen printing are discussed, and an analytical model of. Screen Printing Process Parameters.

From mavink.com

Screen Printing Process Screen Printing Process Parameters To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. Preparing the screen is the first step in the screen printing process and is probably the most important one. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick film ink,. Screen Printing Process Parameters.

From www.researchgate.net

Illustration of The Silk Screen Printing Process Service Adopted by Online. Download Screen Printing Process Parameters To achieve a good print result, particular attention needs to be paid to the most important parameters in rotary screen printing. If the printing of any product becomes more repeatable, higher quality, faster, or improves process control because of these precision tools,. The components of the screen printing process include the printer, the substrate, the screen, the squeegee, the thick. Screen Printing Process Parameters.