Fluidized Bed Quenching . fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. Designers and operators should carefully. the quenching power of fluidized beds is flexible and very effective.

from www.mdpi.com

the quenching power of fluidized beds is flexible and very effective. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. Designers and operators should carefully. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for.

ChemEngineering Free FullText Experimental Investigation and

Fluidized Bed Quenching fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. the quenching power of fluidized beds is flexible and very effective. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. Designers and operators should carefully. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low.

From www.researchgate.net

Fluidized bed apparatus a photograph, b schematic Download Fluidized Bed Quenching Designers and operators should carefully. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. the quenching power of fluidized beds is flexible and. Fluidized Bed Quenching.

From www.evt.tf.fau.eu

100 kW fluidized bed furnace Chair of Energy Process Engineering Fluidized Bed Quenching the quenching power of fluidized beds is flexible and very effective. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. Designers and operators should carefully. the lower heat transfer rate. Fluidized Bed Quenching.

From foodfeedfinechemicals.glatt.com

Fluid Bed Technology for Food, Feed & Fine Chemicals Fluidized Bed Quenching Designers and operators should carefully. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. the quenching power of fluidized beds is flexible and very effective. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. as quenching media, fluidized beds at ambient temperature exhibit cooling rates. Fluidized Bed Quenching.

From www.researchgate.net

(PDF) QUENCHING IN FLUIDISED BEDS. Fluidized Bed Quenching the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. the quenching power of fluidized beds is flexible and very effective. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. Designers and operators should carefully. fluidized bed drying. Fluidized Bed Quenching.

From temaprocess.com

Tema Fluidized Bed Reactor Tema Process Fluidized Bed Quenching the quenching power of fluidized beds is flexible and very effective. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. fluidized bed drying (fbd) is. Fluidized Bed Quenching.

From www.youtube.com

Fluidized bed CFD simulation YouTube Fluidized Bed Quenching as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy.. Fluidized Bed Quenching.

From www.researchgate.net

Cooling curves for fluidizedbed quenching of a 430 kg (946 lb) H13 Fluidized Bed Quenching Designers and operators should carefully. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. the quenching power of fluidized beds is flexible and very effective. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. fluidized bed quenching is an attractive alternative. Fluidized Bed Quenching.

From www.firstnano.com

Fluidized Bed CVD (FBCVD) FirstNano® Fluidized Bed Quenching the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. the quenching power of fluidized beds is flexible and very effective. fluidized bed drying (fbd) is considered one of the most appealing technologies. Fluidized Bed Quenching.

From www.researchgate.net

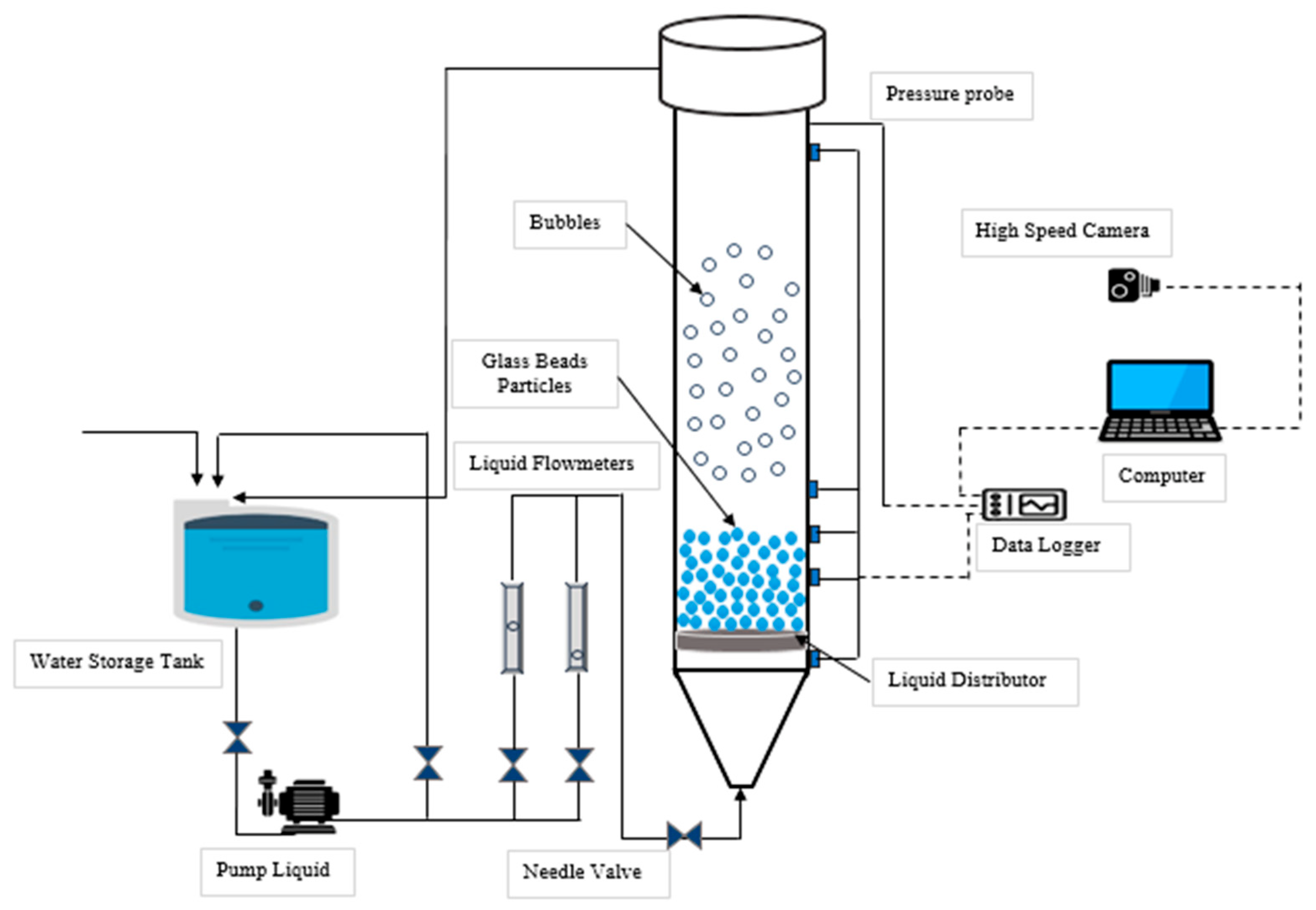

A simplified schematic representation of the fluidized bed setup Fluidized Bed Quenching Designers and operators should carefully. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. in the heat. Fluidized Bed Quenching.

From www.mdpi.com

ChemEngineering Free FullText Experimental Investigation and Fluidized Bed Quenching fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. the quenching power of fluidized beds is flexible and very effective. the lower heat transfer rate. Fluidized Bed Quenching.

From www.google.com

Patent US20130209638 Fluidized bed coffee roaster having dualstage Fluidized Bed Quenching in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one. Fluidized Bed Quenching.

From electricalworkbook.com

What is Fluidized Bed Dryer? Working Principle, Construction, Diagram Fluidized Bed Quenching the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. Designers and operators should carefully.. Fluidized Bed Quenching.

From www.researchgate.net

1 Schematic representation of the different regimes of fluidized bed Fluidized Bed Quenching fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. Designers and operators should carefully. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. the article discusses the advantages, disadvantages, various applications and processes, including conventional. Fluidized Bed Quenching.

From www.researchgate.net

Guide to the range of heattransfer coefficients for various quench Fluidized Bed Quenching the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. the quenching power of fluidized beds is flexible and very effective. the lower heat transfer rate may rule out fluidized bed quenching for some. Fluidized Bed Quenching.

From powderprocess.net

Fluidized beds overview Fundamentals of fluidized beds design Fluidized Bed Quenching fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. as quenching media, fluidized. Fluidized Bed Quenching.

From www.aboutboilers.com

What are the types of Fluidized Bed Combustion Fluidized Bed Quenching Designers and operators should carefully. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where. Fluidized Bed Quenching.

From www.researchgate.net

Internally circulating fluidised bed reactor ICFBR [22,99,107 Fluidized Bed Quenching the quenching power of fluidized beds is flexible and very effective. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. Designers and operators should carefully. the article discusses the advantages,. Fluidized Bed Quenching.

From jnhtgas.en.made-in-china.com

Quench Tower for Circulating Fluidized Bed Gasifier China Quench Fluidized Bed Quenching fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. as quenching media, fluidized beds at ambient. Fluidized Bed Quenching.

From www.jstage.jst.go.jp

Directional Growth of Eutectic Composite by Fluidized Bed Quenching Fluidized Bed Quenching the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. as quenching media, fluidized beds at ambient. Fluidized Bed Quenching.

From www.acrossinternational.com.au

1Zone Vertical Split Quenching Tube Furnace w/ Fluid Bed Fluidized Bed Quenching in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part. Fluidized Bed Quenching.

From exolnlsbl.blob.core.windows.net

Fluidized Bed Types at Robert Gile blog Fluidized Bed Quenching the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. Designers and operators should carefully. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. in the heat. Fluidized Bed Quenching.

From www.semanticscholar.org

Figure 2 from Directional Growth of Eutectic Composite by Fluidized Bed Fluidized Bed Quenching fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. the. Fluidized Bed Quenching.

From www.alamy.com

Schematic diagram of a fluidizedbed combustion boiler Stock Photo Alamy Fluidized Bed Quenching the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. Designers and operators should carefully. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive. Fluidized Bed Quenching.

From www.semanticscholar.org

Directional Growth of Eutectic Composite by Fluidized Bed Quenching Fluidized Bed Quenching as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part. Fluidized Bed Quenching.

From pharmaguides.in

Fluidized Bed Reactor Working, Parts, Design, Types, Specification Fluidized Bed Quenching as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. . Fluidized Bed Quenching.

From www.mdpi.com

Processes Free FullText Review of CFDDEM Modeling of Wet Fluidized Bed Quenching Designers and operators should carefully. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. the article discusses the advantages, disadvantages, various applications and processes, including conventional. Fluidized Bed Quenching.

From www.utminc.com

Fluidized Bed Fluidized Bed Quenching fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. Designers and operators should carefully. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. in the. Fluidized Bed Quenching.

From dxosehmgv.blob.core.windows.net

Fluidised Bed Treatment at Martin Curry blog Fluidized Bed Quenching Designers and operators should carefully. the quenching power of fluidized beds is flexible and very effective. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. as. Fluidized Bed Quenching.

From www.researchgate.net

Diagram of the fluidized bed drying process Download Scientific Diagram Fluidized Bed Quenching in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. Designers and operators should carefully. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. fluidized bed. Fluidized Bed Quenching.

From mavink.com

Fluidized Bed Reactor Diagram Fluidized Bed Quenching Designers and operators should carefully. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy.. Fluidized Bed Quenching.

From www.takuma.co.jp

Circulating fluidized bed sludge incinerators|Water Treatment Plants Fluidized Bed Quenching the quenching power of fluidized beds is flexible and very effective. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. the article discusses the advantages, disadvantages,. Fluidized Bed Quenching.

From www.researchgate.net

Diagram of the combined fluidized bed [110]. Download Scientific Diagram Fluidized Bed Quenching fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. in the heat treatment of aluminum alloys, fluidized. Fluidized Bed Quenching.

From chemicalengineeringworld.com

BUBBLING FLUIDIZED BED REACTOR Chemical Engineering World Fluidized Bed Quenching as quenching media, fluidized beds at ambient temperature exhibit cooling rates between those of oil and air while heated beds offer a medium for. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive. Fluidized Bed Quenching.

From dxoyyxkot.blob.core.windows.net

Fluidised Bed Gasifier at Joyce Marrs blog Fluidized Bed Quenching fluidized bed drying (fbd) is considered one of the most appealing technologies for producing uniformly dried. the lower heat transfer rate may rule out fluidized bed quenching for some applications due to part geometry or alloy. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. Designers and operators should carefully. as quenching. Fluidized Bed Quenching.

From www.youtube.com

How It Works Circulating Fluidized Bed Boiler Process YouTube Fluidized Bed Quenching in the heat treatment of aluminum alloys, fluidized bed quenching is an attractive alternative to liquid. Designers and operators should carefully. fluidized bed quenching is an attractive alternative for parts exhibiting high surface to weight ratios where one requires low. the article discusses the advantages, disadvantages, various applications and processes, including conventional batch. fluidized bed drying. Fluidized Bed Quenching.