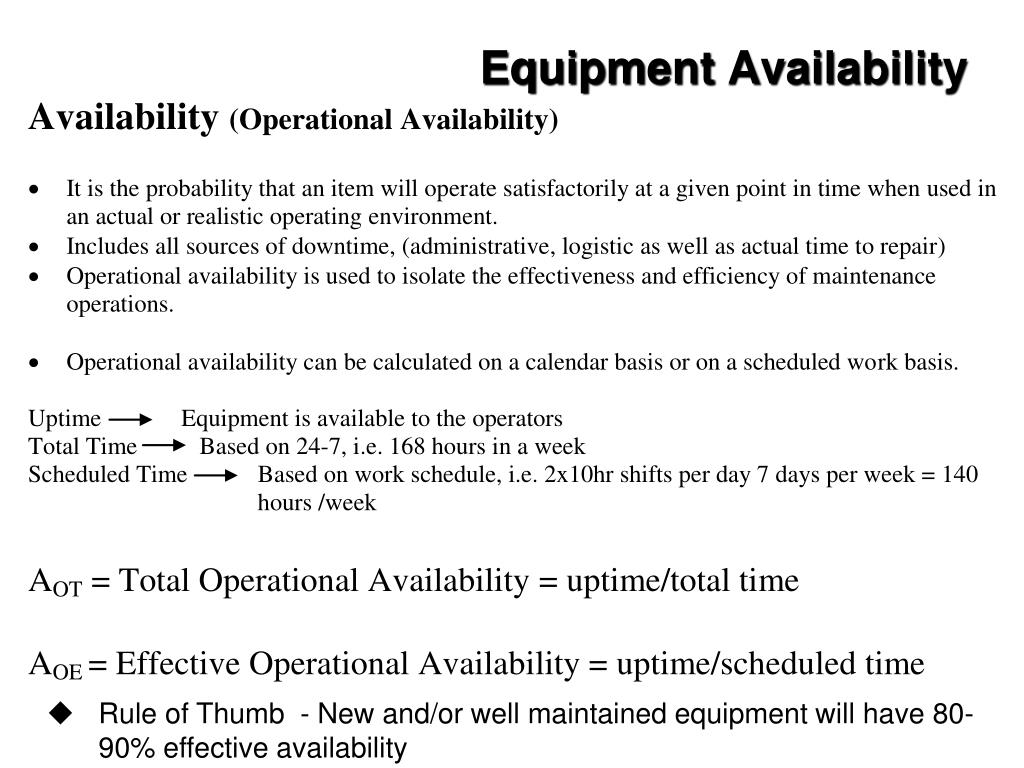

Equipment Availability Definition . Machine availability, in the context of the manufacturing industry, is one of three major factors in. As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. High machine availability means that a. Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run.

from www.slideserve.com

Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. Machine availability, in the context of the manufacturing industry, is one of three major factors in. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. High machine availability means that a. Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run.

PPT University of Saskatchewan Geological Engineering GEOE 498.3 Introduction to Mineral

Equipment Availability Definition Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. Machine availability, in the context of the manufacturing industry, is one of three major factors in. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. High machine availability means that a. Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run.

From www.slideserve.com

PPT RELIABILITY, MAINTAINABILITY & AVAILABILITY INTRODUCTION PowerPoint Presentation ID3360761 Equipment Availability Definition Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. As. Equipment Availability Definition.

From www.elearningfactory.com

What is Overall Equipment Effectiveness? OEE1 or OEE2? Equipment Availability Definition Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. High. Equipment Availability Definition.

From www.slideserve.com

PPT Systems Availability Concepts & Metrics PowerPoint Presentation ID3104793 Equipment Availability Definition Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time. Equipment Availability Definition.

From www.advancedmobilityservices.nl

Equipment available maintained and certified Equipment Availability Definition High machine availability means that a. Machine availability, in the context of the manufacturing industry, is one of three major factors in. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability, also referred to as uptime, is the total amount of time a machine actually. Equipment Availability Definition.

From www.slideserve.com

PPT Systems Availability Concepts & Metrics PowerPoint Presentation ID3104793 Equipment Availability Definition As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. High machine availability means that a. Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability, or uptime, is the total amount. Equipment Availability Definition.

From www.slideshare.net

Availability “System reliability refers to Equipment Availability Definition Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Availability is a performance criterion for repairable systems that accounts for both the. Equipment Availability Definition.

From instrumentationtools.com

Difference between Availability, Reliability & SIL Instrumentation Tools Equipment Availability Definition Machine availability, in the context of the manufacturing industry, is one of three major factors in. Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. High machine availability means that a. Machine availability, also referred to as uptime, is the total amount of time a machine actually. Equipment Availability Definition.

From cqeacademy.com

Overall Equipment Effectiveness (OEE) CQE Academy Equipment Availability Definition Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the. Equipment Availability Definition.

From www.slideserve.com

PPT Systems Availability Concepts & Metrics PowerPoint Presentation ID3104793 Equipment Availability Definition As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability, also referred to as uptime, is the total amount. Equipment Availability Definition.

From www.machinemetrics.com

How to Calculate and Improve Machine Availability Equipment Availability Definition Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability, in the context of the manufacturing industry, is one of three major factors in. High machine availability means that a. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. As. Equipment Availability Definition.

From limblecmms.com

What Is Asset Availability And How Do You Calculate It? Equipment Availability Definition Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. As such, availability is a function of how often the system fails (a. Equipment Availability Definition.

From www.clearmark.uk

Calculating Overall Effective Equipment (OEE) Clearmark Equipment Availability Definition As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. High machine availability means that a. Machine availability, in the context of the manufacturing industry,. Equipment Availability Definition.

From www.slideserve.com

PPT Systems Availability Concepts & Metrics PowerPoint Presentation ID3104793 Equipment Availability Definition Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine. Equipment Availability Definition.

From learntransformation.com

What Is Overall Equipment Effectiveness (OEE) Formula? Learn Transformation Equipment Availability Definition Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. Machine availability measures the proportion of time a machine is actually in operation compared to the time. Equipment Availability Definition.

From scw.ai

OEE Calculation Optimizing Overall Equipment Efficiency Equipment Availability Definition As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. Machine availability, in the context of the manufacturing industry, is one of three major factors. Equipment Availability Definition.

From www.slideserve.com

PPT Systems Availability Modeling & Analysis PowerPoint Presentation ID2943283 Equipment Availability Definition Machine availability, in the context of the manufacturing industry, is one of three major factors in. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. High machine availability means that a. Machine availability measures the proportion of time a machine is actually in operation compared to the. Equipment Availability Definition.

From www.slideshare.net

Equipment Availability Analysis Equipment Availability Definition Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. Machine. Equipment Availability Definition.

From lifeandwork.blog

What is System Availability? Equipment Availability Definition Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. Asset availability (sometimes called equipment availability) is a metric used to understand if the. Equipment Availability Definition.

From www.bmc.com

Reliability vs Availability What’s The Difference? BMC Software Blogs Equipment Availability Definition Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. High machine availability means that a. Machine availability, in the context of the manufacturing industry, is one of three. Equipment Availability Definition.

From www.slideshare.net

Equipment Availability Analysis Equipment Availability Definition Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. High machine availability means that a. Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability, in the context of the. Equipment Availability Definition.

From www.slideserve.com

PPT Chapter 6 PowerPoint Presentation, free download ID1968650 Equipment Availability Definition As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. High machine availability means that a. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability measures the proportion. Equipment Availability Definition.

From www.slideserve.com

PPT Chapter 6 PowerPoint Presentation, free download ID1968650 Equipment Availability Definition Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability measures the proportion of time a machine is actually in operation compared to the. Equipment Availability Definition.

From www.planettogether.com

Advantages of Overall Equipment Effectiveness (OEE) Equipment Availability Definition Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be. Equipment Availability Definition.

From www.slideserve.com

PPT Systems Availability Concepts & Metrics PowerPoint Presentation ID3104793 Equipment Availability Definition Machine availability, in the context of the manufacturing industry, is one of three major factors in. Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. High machine availability means that a. Machine availability, or uptime, is the total amount of time a machine actually runs versus the. Equipment Availability Definition.

From www.smartsheet.com

Availability Management Solution Smartsheet Equipment Availability Definition Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. High machine availability means that a. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability, in the context of the manufacturing industry, is. Equipment Availability Definition.

From www.slideserve.com

PPT Systems Availability Concepts & Metrics PowerPoint Presentation ID3104793 Equipment Availability Definition Machine availability, in the context of the manufacturing industry, is one of three major factors in. Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was. Equipment Availability Definition.

From www.oee.com

What Is OEE (Overall Equipment Effectiveness)? OEE Equipment Availability Definition Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability measures the proportion of time a machine is actually in operation compared to the time it should be in operation. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or. Equipment Availability Definition.

From www.researchgate.net

(PDF) OEE Can Be Your Key Change Formula for Equipment Availability to Improve Performance Equipment Availability Definition Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Machine availability measures the proportion of time a machine is actually in operation compared to the time it should. Equipment Availability Definition.

From www.slideserve.com

PPT Systems Availability Concepts & Metrics PowerPoint Presentation ID3104793 Equipment Availability Definition Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. Machine availability, in the context of the manufacturing industry, is one of three major factors in. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. As such, availability is. Equipment Availability Definition.

From www.researchgate.net

Breakdown of SEMI E10 standard (Specification for Definition and... Download Scientific Diagram Equipment Availability Definition Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. High machine availability means that a. Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability, in the context of the manufacturing industry, is. Equipment Availability Definition.

From www.slideserve.com

PPT Systems Availability Concepts & Metrics PowerPoint Presentation ID3104793 Equipment Availability Definition Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. High machine availability means that a. Machine availability measures the proportion of time a. Equipment Availability Definition.

From www.whatissixsigma.net

What is Overall Equipment Effectiveness (OEE)? Equipment Availability Definition High machine availability means that a. Machine availability, or uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Machine availability, in the context of the manufacturing industry, is one of three. Equipment Availability Definition.

From www.scribd.com

6. Equipment Efficiency Availability Reliability Engineering Systems Theory Equipment Availability Definition Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. Asset availability (sometimes called equipment availability) is a metric used to understand if the machine or system is. High machine availability means that a. Machine availability, also referred to as uptime, is the total amount of time a machine actually runs. Equipment Availability Definition.

From www.mudamasters.com

Overall Equipment Effectiveness (OEE) MudaMasters Equipment Availability Definition Machine availability, in the context of the manufacturing industry, is one of three major factors in. As such, availability is a function of how often the system fails (a function of reliability) and how long it takes to restore the system to an. Machine availability, also referred to as uptime, is the total amount of time a machine actually runs. Equipment Availability Definition.

From www.slideserve.com

PPT University of Saskatchewan Geological Engineering GEOE 498.3 Introduction to Mineral Equipment Availability Definition Machine availability, also referred to as uptime, is the total amount of time a machine actually runs versus the time it was scheduled to run. Availability is a performance criterion for repairable systems that accounts for both the reliability and maintainability properties of a. As such, availability is a function of how often the system fails (a function of reliability). Equipment Availability Definition.