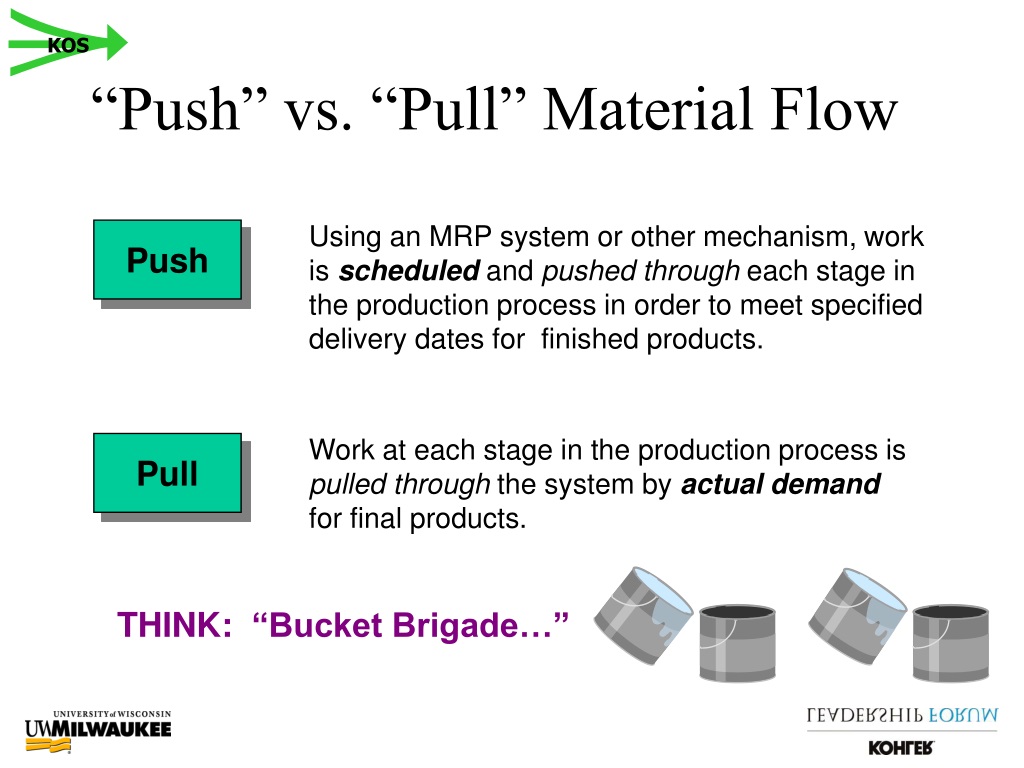

Push Vs Pull Flow . By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. This article will explore the fundamental differences between a push vs. The concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers.

from www.slideserve.com

Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. This article will explore the fundamental differences between a push vs. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. The concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together.

PPT Lean Manufacturing PowerPoint Presentation, free download ID9570099

Push Vs Pull Flow This article will explore the fundamental differences between a push vs. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. The concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. This article will explore the fundamental differences between a push vs. Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling.

From ar.inspiredpencil.com

Pull Vs Push System Push Vs Pull Flow In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. The concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. Lean. Push Vs Pull Flow.

From 101blockchains.com

Push and Pull Strategy in Supply Chain Management A Comprehensive Guide Push Vs Pull Flow In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling. This article will explore the fundamental differences between a push vs. By understanding and appropriately applying. Push Vs Pull Flow.

From www.slideserve.com

PPT The Lean Enterprise PowerPoint Presentation, free download ID325080 Push Vs Pull Flow In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling. Explaining the difference. Push Vs Pull Flow.

From dev.powerslides.com

Push vs Pull Strategy 7,000+ Templates PowerSlides™ Push Vs Pull Flow We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. Explaining the difference between push and pull in lean six sigma, and why the goal in. Push Vs Pull Flow.

From gomingo.io

Push vs. Pull System Mingo Manufacturing Productivity Push Vs Pull Flow In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. This article will explore the fundamental differences between a push vs. Lean manufacturing. Push Vs Pull Flow.

From www.deskera.com

Push System vs. Pull System in Manufacturing Management Push Vs Pull Flow By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. This article will explore the fundamental differences between a push vs. Explaining the difference between push. Push Vs Pull Flow.

From businessmap.io

What Is a Pull System? A Practical Guide to Increasing Process Efficiency Push Vs Pull Flow Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling. In lean manufacturing, push system vs pull system represent the contrasting philosophies that. Push Vs Pull Flow.

From www.slideserve.com

PPT Lean Manufacturing PowerPoint Presentation, free download ID9570099 Push Vs Pull Flow We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. Lean manufacturing is primarily a “pull system”, but it’s important to understand the. Push Vs Pull Flow.

From www.youtube.com

Push, Pull and Flow in the Lean Manufacturing Material Flow YouTube Push Vs Pull Flow Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly. Push Vs Pull Flow.

From www.novelvista.com

Strategic Dynamics Exploring Push vs. Pull Systems in Operations Push Vs Pull Flow In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. In the pull flow, each person at his or her workstation agrees with the person who will follow “we. Push Vs Pull Flow.

From slidemodel.com

Manufacturing Pull vs Push PowerPoint Template SlideModel Push Vs Pull Flow In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. This article will explore the fundamental differences between a push vs. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. We will weigh the pros. Push Vs Pull Flow.

From www.researchgate.net

Example of a push versus pull strategy in channel marketing (Source... Download Scientific Push Vs Pull Flow In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. The concepts of push, pull, and flow are not just strategies. Push Vs Pull Flow.

From www.slideserve.com

PPT Push and Pull Production Systems PowerPoint Presentation ID385010 Push Vs Pull Flow In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. The concepts of push, pull, and flow are not just strategies but are. Push Vs Pull Flow.

From www.scribd.com

Push Vs Pull Part2 Slide Set 10 PDF Applied Mathematics Push Vs Pull Flow By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. This article will explore the fundamental differences between a push vs. In the pull flow, each person at his. Push Vs Pull Flow.

From www.slideserve.com

PPT Justintime PowerPoint Presentation, free download ID575116 Push Vs Pull Flow In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. This article will explore the fundamental differences between a push vs. Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling. We will weigh the pros. Push Vs Pull Flow.

From www.youtube.com

PUSH PRODUCTION PULL PRODUCTION PUSH VS PULL Lean manufacturing Leanseekho YouTube Push Vs Pull Flow Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as. Push Vs Pull Flow.

From www.sketchbubble.com

Push and Pull Strategy PowerPoint Template SketchBubble Push Vs Pull Flow The concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences. Push Vs Pull Flow.

From slidebazaar.com

Push and Pull Strategy PowerPoint Template Ppt Diagram Slidebazaar Push Vs Pull Flow In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. Explaining the difference between push and pull in lean six sigma, and why the goal in. Push Vs Pull Flow.

From powerslides.com

Push vs Pull Strategy 7,000+ Templates PowerSlides™ Push Vs Pull Flow The concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push. Push Vs Pull Flow.

From www.impactfirst.co

Pull System Definition, Its 3 Types & Differences with Push Push Vs Pull Flow We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. This article will explore the fundamental differences between a push vs. In the pull flow, each. Push Vs Pull Flow.

From slidemodel.com

Manufacturing Pull vs Push PowerPoint Template SlideModel Push Vs Pull Flow We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. In the pull flow, each person at his or her workstation agrees with the person who. Push Vs Pull Flow.

From www.inflowinventory.com

Push vs Pull System Manufacturing An InDepth Analysis Push Vs Pull Flow We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. The concepts of push, pull, and flow are not just strategies but are integral to the. Push Vs Pull Flow.

From operationsinsider.com

Push vs Pull — Operations Insider Push Vs Pull Flow The concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. We will weigh the pros and cons of each and demonstrate how organizations can make the best. Push Vs Pull Flow.

From www.retaildogma.com

Push & Pull Strategy Explained With RealLife Example Push Vs Pull Flow By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. Explaining the difference between push and pull in lean six sigma,. Push Vs Pull Flow.

From www.dozuki.com

Push vs. Pull System in Manufacturing A Complete Overview for Optimizing Production Push Vs Pull Flow Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. This article will explore the. Push Vs Pull Flow.

From elsmar.com

Push vs. Pull Push Vs Pull Flow This article will explore the fundamental differences between a push vs. The concepts of push, pull, and flow are not just strategies but are integral to the philosophy of lean manufacturing. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. Explaining the difference between push and pull in lean six sigma,. Push Vs Pull Flow.

From www.slideserve.com

PPT International Operations Management PowerPoint Presentation, free download ID5681795 Push Vs Pull Flow Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. We. Push Vs Pull Flow.

From www.leaneast.com

The Difference Between Push and Pull Lean East Push Vs Pull Flow We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. Lean manufacturing is primarily a “pull system”, but it’s important to understand the differences between traditional push signaling. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as. Push Vs Pull Flow.

From www.allaboutlean.com

The (true) Difference between Push and Pull Push Vs Pull Flow We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. Lean manufacturing is primarily a “pull system”, but it’s important to understand the. Push Vs Pull Flow.

From www.inflowinventory.com

An InDepth Look Into Push vs Pull System Manufacturing Push Vs Pull Flow By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and reduce wastage. In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. We will weigh the pros and cons of each and demonstrate. Push Vs Pull Flow.

From www.inflowinventory.com

Push vs Pull System Manufacturing An InDepth Analysis Push Vs Pull Flow In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency,. Push Vs Pull Flow.

From www.slideserve.com

PPT Operations Management JustinTime and Lean Production Systems Chapter 16 PowerPoint Push Vs Pull Flow This article will explore the fundamental differences between a push vs. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. Lean manufacturing is primarily a “pull system”, but it’s important. Push Vs Pull Flow.

From www.dozuki.com

Push vs. Pull System in Manufacturing A Complete Overview for Optimizing Production Push Vs Pull Flow In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. In lean manufacturing, push system vs pull system represent the contrasting philosophies that. Push Vs Pull Flow.

From www.youtube.com

Lean Pull System vs Push System The Only Real Difference YouTube Push Vs Pull Flow In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. We will weigh the pros and cons of each and demonstrate how organizations can make the best choice for their customers. By understanding and appropriately applying these concepts, businesses can improve their operational efficiency, adapt more quickly to changes in demand, and. Push Vs Pull Flow.

From www.smart-storage.eu

Just In Time or nowaste manufacturing SMART STORAGE SYSTEMS Push Vs Pull Flow In the pull flow, each person at his or her workstation agrees with the person who will follow “we work as a team to succeed together. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. By understanding and appropriately applying. Push Vs Pull Flow.