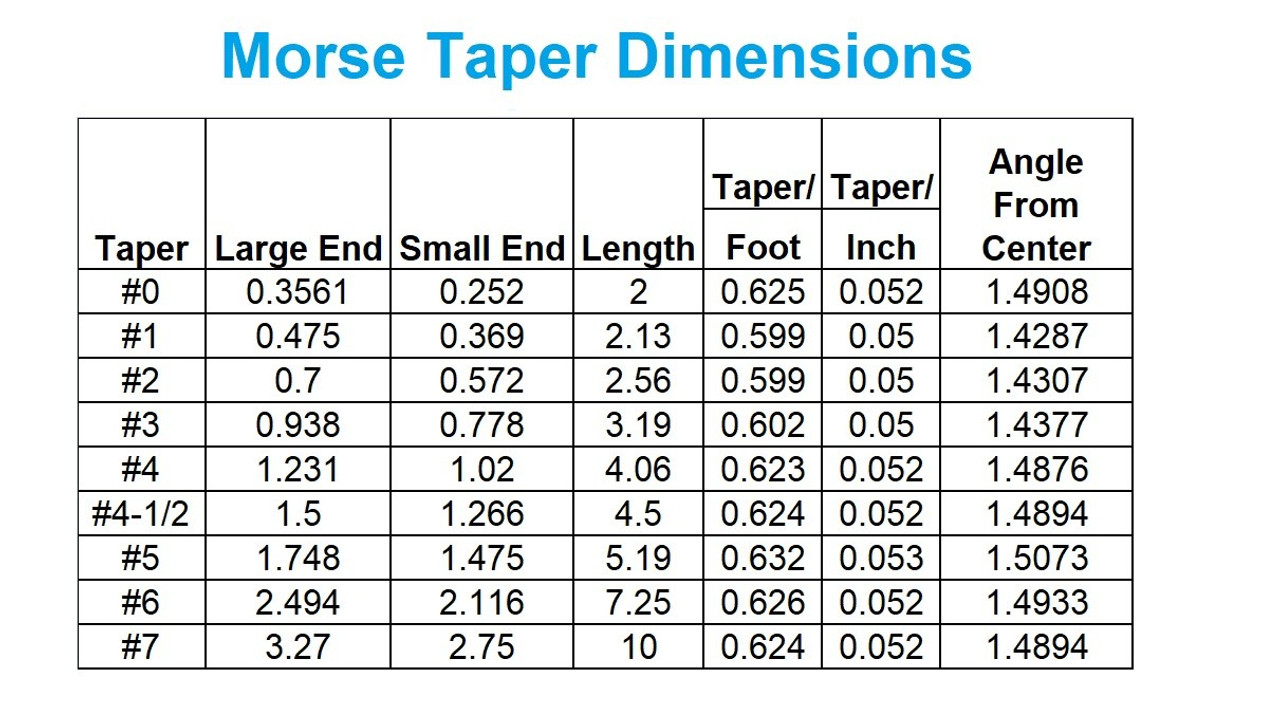

What Degree Is A Morse Taper . The taper angle of the morse taper varies somewhat with size but is typically 1.49°. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! Watch this video and learn how. What is a morse taper on a drill press and how does it work? How to measure a morse taper. Jacobs tapers are used almost exclusively for drill chuck mounting. A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill. They come in eight sizes identified by whole. A machine taper secures tool holders or cutting tools in the spindle. To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse taper #2 has a taper angle of 2.861. Dimensions of morse tapers, jacobs tapers, and brown + sharpe tapers.

from www.penntoolco.com

Watch this video and learn how. What is a morse taper on a drill press and how does it work? For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse taper #2 has a taper angle of 2.861. Dimensions of morse tapers, jacobs tapers, and brown + sharpe tapers. How to measure a morse taper. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! The taper angle of the morse taper varies somewhat with size but is typically 1.49°. They come in eight sizes identified by whole. A machine taper secures tool holders or cutting tools in the spindle. A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill.

Precise 2MT Morse Taper Shank 3Jaw Self Centering Chuck 39004706

What Degree Is A Morse Taper They come in eight sizes identified by whole. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse taper #2 has a taper angle of 2.861. A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill. Jacobs tapers are used almost exclusively for drill chuck mounting. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! The taper angle of the morse taper varies somewhat with size but is typically 1.49°. A machine taper secures tool holders or cutting tools in the spindle. Watch this video and learn how. They come in eight sizes identified by whole. Dimensions of morse tapers, jacobs tapers, and brown + sharpe tapers. How to measure a morse taper. What is a morse taper on a drill press and how does it work? To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks.

From www.researchgate.net

(a) Morse taper and (b) one‐piece dental implant design and dimensions What Degree Is A Morse Taper To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. Watch this video and learn how. A machine taper secures tool holders or cutting tools in the spindle. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at. What Degree Is A Morse Taper.

From chileb.cl

New MT2 Morse Taper 60 Degree Rotary Live Center Shaft Morse Taper What Degree Is A Morse Taper To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. Jacobs tapers are used almost exclusively for drill chuck mounting. Dimensions of morse tapers, jacobs tapers, and brown + sharpe tapers. A machine taper secures tool holders or cutting tools in the spindle. They come in eight sizes. What Degree Is A Morse Taper.

From alexnld.com

MT2 Morse Taper 60 Degree Rotary Live Center Shaft Morse Taper Lathe What Degree Is A Morse Taper Jacobs tapers are used almost exclusively for drill chuck mounting. What is a morse taper on a drill press and how does it work? A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill. Watch this video and learn how. A machine taper secures tool holders or cutting. What Degree Is A Morse Taper.

From www.walmart.com

Modern MT5 Live Center 60 Degree Morse Taper Precision Lathe Medium What Degree Is A Morse Taper Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! Watch this video and learn how. What is a morse taper on a drill press and how does it work? For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of. What Degree Is A Morse Taper.

From antigua.desertcart.com

Buy MT2 Rotary Live Center Shaft, 0.01mm Accuracy MT25 Slot Heavy Duty What Degree Is A Morse Taper They come in eight sizes identified by whole. What is a morse taper on a drill press and how does it work? Watch this video and learn how. How to measure a morse taper. A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill. Jacobs tapers are used. What Degree Is A Morse Taper.

From www.mdpi.com

Healthcare Free FullText Mechanical Behavior of OnePiece and Two What Degree Is A Morse Taper What is a morse taper on a drill press and how does it work? To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. How to measure a morse taper. Watch this video and learn how. A morse taper is a commonly used tool fitting in drill presses. What Degree Is A Morse Taper.

From www.practicalmachinist.com

Name that taper What Degree Is A Morse Taper How to measure a morse taper. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse taper #2 has a taper angle of 2.861. A machine taper secures tool holders or cutting tools in the spindle. Watch this video and learn how. They come. What Degree Is A Morse Taper.

From www.shop.strojnisveraky.cz

Morse taper sleeve MT3/1 What Degree Is A Morse Taper Watch this video and learn how. A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! They come in eight sizes identified by whole. What. What Degree Is A Morse Taper.

From www.youtube.com

How To Identify & Determine The Size Of Your Morse Taper YouTube What Degree Is A Morse Taper Watch this video and learn how. To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse taper #2 has a taper angle. What Degree Is A Morse Taper.

From chileb.cl

New MT2 Morse Taper 60 Degree Rotary Live Center Shaft Morse Taper What Degree Is A Morse Taper A machine taper secures tool holders or cutting tools in the spindle. Jacobs tapers are used almost exclusively for drill chuck mounting. How to measure a morse taper. A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill. The taper angle of the morse taper varies somewhat with. What Degree Is A Morse Taper.

From www.pinterest.com

findmall MT3 Medium Duty Live Center Morse Taper 3MT Triple Bearing What Degree Is A Morse Taper Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! The taper angle of the morse taper varies somewhat with size but is typically 1.49°. A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill.. What Degree Is A Morse Taper.

From www.pinterest.com

findmall MT4 Medium Duty Live Center Morse Taper 4MT Triple Bearing What Degree Is A Morse Taper Jacobs tapers are used almost exclusively for drill chuck mounting. They come in eight sizes identified by whole. To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at. What Degree Is A Morse Taper.

From www.penturners.org

Morse Taper Dimensions The International Association of Penturners What Degree Is A Morse Taper For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse taper #2 has a taper angle of 2.861. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! How to measure. What Degree Is A Morse Taper.

From www.electronicpro.co.za

MT2 Morse Taper 60 Degree Rotary Live Center Shaft Morse Taper Lathe T What Degree Is A Morse Taper They come in eight sizes identified by whole. A machine taper secures tool holders or cutting tools in the spindle. The taper angle of the morse taper varies somewhat with size but is typically 1.49°. What is a morse taper on a drill press and how does it work? Watch this video and learn how. Jacobs tapers are used almost. What Degree Is A Morse Taper.

From www.cgtk.co.uk

CGTK Morse Taper Dimensions What Degree Is A Morse Taper What is a morse taper on a drill press and how does it work? How to measure a morse taper. Jacobs tapers are used almost exclusively for drill chuck mounting. Watch this video and learn how. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while. What Degree Is A Morse Taper.

From www.ctctools.biz

MORSE TAPER 3 METRIC COLLET SET (15 PCS) F79 CTC Tools What Degree Is A Morse Taper Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! How to measure a morse taper. Watch this video and learn how. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a. What Degree Is A Morse Taper.

From www.youtube.com

How To Put a Morse Taper Drill Bit into a Standard Drill Chuck YouTube What Degree Is A Morse Taper A machine taper secures tool holders or cutting tools in the spindle. To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse. What Degree Is A Morse Taper.

From www.aliexpress.com

MT2 Live Center Morse Taper CNC Long Spindle Lathe Tool 2MT Angle 60 What Degree Is A Morse Taper Dimensions of morse tapers, jacobs tapers, and brown + sharpe tapers. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! The taper angle of the morse taper varies somewhat with size but is typically 1.49°. A machine taper secures tool holders or cutting tools in the. What Degree Is A Morse Taper.

From www.zoro.com

What are the Dimensions and Angles of Morse Tapers and Jacobs Tapers What Degree Is A Morse Taper What is a morse taper on a drill press and how does it work? To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. They come in eight sizes identified by whole. Watch this video and learn how. Dimensions of morse tapers, jacobs tapers, and brown + sharpe. What Degree Is A Morse Taper.

From www.pinterest.com

findmall MT2 Medium Duty Live Center Morse Taper 2MT Triple Bearing What Degree Is A Morse Taper They come in eight sizes identified by whole. Jacobs tapers are used almost exclusively for drill chuck mounting. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! How to measure a morse taper. A machine taper secures tool holders or cutting tools in the spindle. To. What Degree Is A Morse Taper.

From www.amazon.com

MT2 Live Center 2MT 60 Degree Morse Taper 2 Live Center 220 LB Load What Degree Is A Morse Taper The taper angle of the morse taper varies somewhat with size but is typically 1.49°. How to measure a morse taper. They come in eight sizes identified by whole. A machine taper secures tool holders or cutting tools in the spindle. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches. What Degree Is A Morse Taper.

From architecturalstudio.com

Morse Taper What Degree Is A Morse Taper Watch this video and learn how. Dimensions of morse tapers, jacobs tapers, and brown + sharpe tapers. What is a morse taper on a drill press and how does it work? Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! A machine taper secures tool holders. What Degree Is A Morse Taper.

From www.aliexpress.com

60 Degree Taper Handle Woodworking Turning Center MT2 Live Center Morse What Degree Is A Morse Taper They come in eight sizes identified by whole. A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill. What is a morse taper on a drill press and how does it work? For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter. What Degree Is A Morse Taper.

From mavink.com

Morse Taper Sizes What Degree Is A Morse Taper Dimensions of morse tapers, jacobs tapers, and brown + sharpe tapers. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse taper #2 has a taper angle of 2.861. Jacobs tapers are used almost exclusively for drill chuck mounting. They come in eight sizes. What Degree Is A Morse Taper.

From www.penntoolco.com

Precise 2MT Morse Taper Shank 3Jaw Self Centering Chuck 39004706 What Degree Is A Morse Taper Watch this video and learn how. The taper angle of the morse taper varies somewhat with size but is typically 1.49°. Dimensions of morse tapers, jacobs tapers, and brown + sharpe tapers. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! How to measure a morse. What Degree Is A Morse Taper.

From www.shop-apt.co.uk

BT40 Size 3 Morse Taper Adaptor 70mm Gauge Length Balance 12000 RPM G6 What Degree Is A Morse Taper A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill. How to measure a morse taper. A machine taper secures tool holders or cutting tools in the spindle. Dimensions of morse tapers, jacobs tapers, and brown + sharpe tapers. Jacobs tapers are used almost exclusively for drill chuck. What Degree Is A Morse Taper.

From mavink.com

Morse Taper Dimensions Chart What Degree Is A Morse Taper They come in eight sizes identified by whole. Dimensions of morse tapers, jacobs tapers, and brown + sharpe tapers. How to measure a morse taper. To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. A machine taper secures tool holders or cutting tools in the spindle. What. What Degree Is A Morse Taper.

From cme-tools.com

3" 90 degree indexable face mill, shell mill,APKT w. MT2 morse taper 2 What Degree Is A Morse Taper Jacobs tapers are used almost exclusively for drill chuck mounting. To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. Watch this video and learn how. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large. What Degree Is A Morse Taper.

From uwoodcraft.com

Morse Taper Dimensions What Degree Is A Morse Taper Jacobs tapers are used almost exclusively for drill chuck mounting. They come in eight sizes identified by whole. The taper angle of the morse taper varies somewhat with size but is typically 1.49°. A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill. Watch this video and learn. What Degree Is A Morse Taper.

From www.youtube.com

Making a 3 Morse Taper Center YouTube What Degree Is A Morse Taper How to measure a morse taper. What is a morse taper on a drill press and how does it work? Jacobs tapers are used almost exclusively for drill chuck mounting. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse taper #2 has a. What Degree Is A Morse Taper.

From www.youtube.com

Morse taper angle set up Copying the angle when whole dead center is What Degree Is A Morse Taper How to measure a morse taper. To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse taper #2 has a taper angle. What Degree Is A Morse Taper.

From www.walmart.com

5MT Single Point Dead Center Morse Taper MT5 Lathe 60 Degree Point What Degree Is A Morse Taper They come in eight sizes identified by whole. What is a morse taper on a drill press and how does it work? For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end, while a morse taper #2 has a taper angle of 2.861. A machine taper secures. What Degree Is A Morse Taper.

From ubicaciondepersonas.cdmx.gob.mx

Morse Taper ubicaciondepersonas.cdmx.gob.mx What Degree Is A Morse Taper How to measure a morse taper. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! A morse taper is a commonly used tool fitting in drill presses that allows for the secure attachment and removal of drill. The taper angle of the morse taper varies somewhat. What Degree Is A Morse Taper.

From chileb.cl

New MT2 Morse Taper 60 Degree Rotary Live Center Shaft Morse Taper What Degree Is A Morse Taper The taper angle of the morse taper varies somewhat with size but is typically 1.49°. To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. For example, a morse taper #1 has a taper angle of 1.4807 degrees and a diameter of 0.475 inches at the large end,. What Degree Is A Morse Taper.

From www.aliexpress.com

1pc 30mm 90 Degree Morse Taper Shank Metal Countersink Bit Charmfer What Degree Is A Morse Taper How to measure a morse taper. To identify the size of a morse taper, you can use a morse taper gauge or a set of morse taper shanks. Download and print our taper dimension pdf for a quick reference table that will help you determine your machine's taper correctly, every time! For example, a morse taper #1 has a taper. What Degree Is A Morse Taper.