Carbon Fiber Layup . Wet layup refers to draping carbon fiber fabric over a core or mold. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. First, cut the carbon fiber into sections. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Here’s how to use this technique:

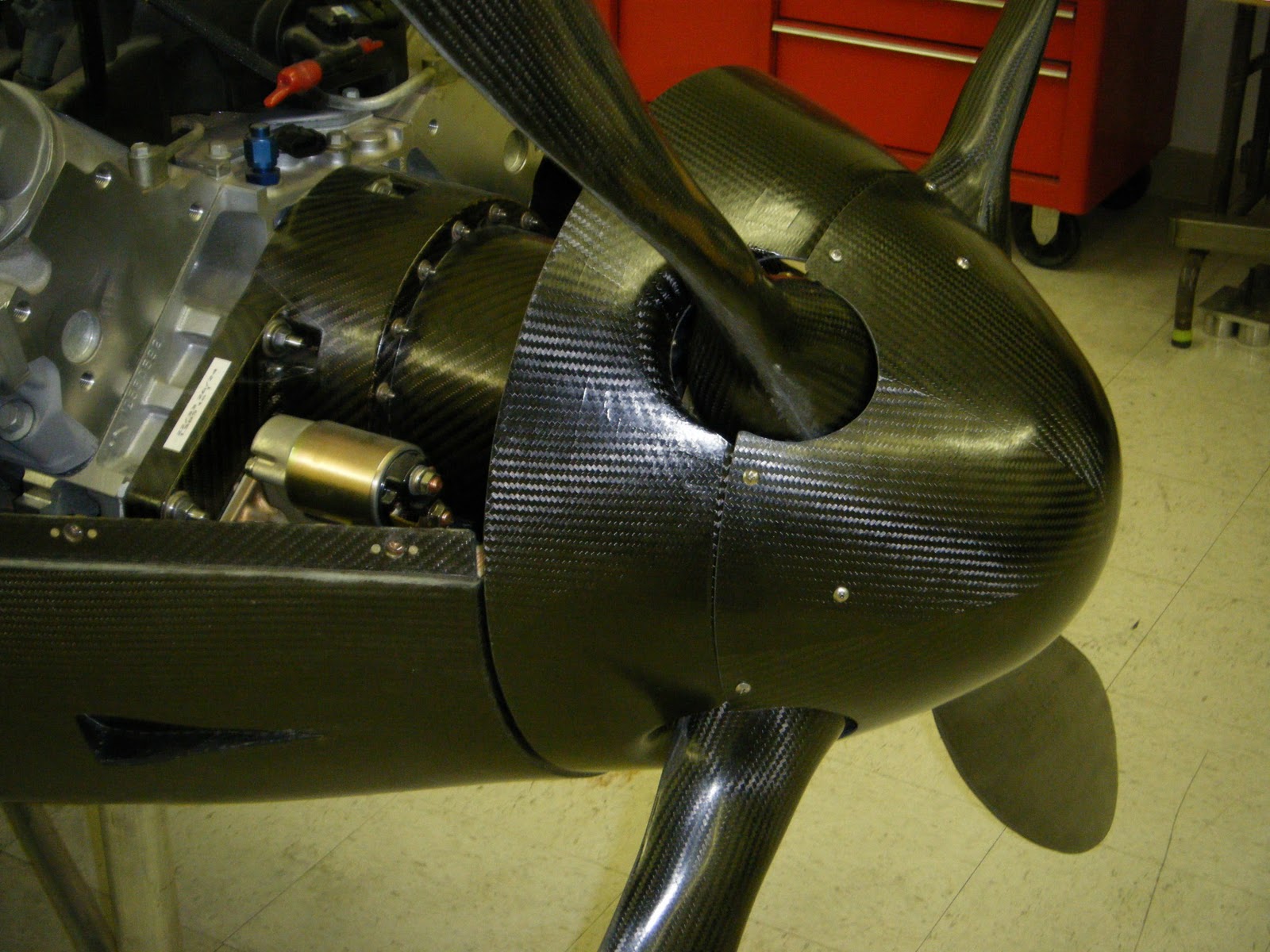

from meechcustombikes.blogspot.com

First, cut the carbon fiber into sections. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. Wet layup refers to draping carbon fiber fabric over a core or mold. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Here’s how to use this technique: A single tow can be pulled out of the fabric to cut a straight line to guide your cut. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate.

MEECH Custom Bicycles How is this for some sweet carbon fiber layup?

Carbon Fiber Layup Here’s how to use this technique: We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. First, cut the carbon fiber into sections. Here’s how to use this technique: In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Wet layup refers to draping carbon fiber fabric over a core or mold. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate.

From www.youtube.com

What NOT To Do When Working With A Wet layup Of Carbon Fiber YouTube Carbon Fiber Layup Here’s how to use this technique: Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. Wet layup refers to draping carbon fiber fabric over a core or mold. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. In this section, we. Carbon Fiber Layup.

From www.instructables.com

Easy Carbon Fiber Mold 7 Steps (with Pictures) Instructables Carbon Fiber Layup Wet layup refers to draping carbon fiber fabric over a core or mold. Here’s how to use this technique: Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. Learn how carbon. Carbon Fiber Layup.

From journals.sagepub.com

Development and validation of recycled carbon fiberbased binder tapes Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. In this section,. Carbon Fiber Layup.

From www.hotrod.com

Carbon Fiber StepbyStep How to Lay Up Carbon Fiber Hot Rod Hot Carbon Fiber Layup First, cut the carbon fiber into sections. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. A single tow can be pulled out of the fabric to cut a straight line to guide. Carbon Fiber Layup.

From www.technicaltooling.com

Technical Tooling VACUGRIP RAVIN Layup Molds Advanced Composite Carbon Fiber Layup In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Wet layup refers to draping carbon fiber fabric over a core or mold. Here’s how to use this technique: Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic. Carbon Fiber Layup.

From www.singletracks.com

How Carbon Fiber Layup Makes Bike Frames Stiff and Compliant in all the Carbon Fiber Layup First, cut the carbon fiber into sections. Wet layup refers to draping carbon fiber fabric over a core or mold. Here’s how to use this technique: We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. A single tow can be pulled out of the fabric to cut a straight. Carbon Fiber Layup.

From formlabs.com

How to Manufacture Carbon Fiber Parts Carbon Fiber Layup Wet layup refers to draping carbon fiber fabric over a core or mold. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. Here’s how. Carbon Fiber Layup.

From harborinnboatworks.blogspot.com

Harbor Inn Boatworks Carbon Fiber Layup On Coaming Carbon Fiber Layup In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. Wet layup refers to draping carbon fiber fabric over a core or mold. Here’s how to use. Carbon Fiber Layup.

From jcsportline.com

How to lay carbon fiber clothJCsportline Co., Ltd. Carbon Fiber Layup First, cut the carbon fiber into sections. Wet layup refers to draping carbon fiber fabric over a core or mold. Here’s how to use this technique: Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic. Carbon Fiber Layup.

From www.hotrod.com

Carbon Fiber StepbyStep How to Lay Up Carbon Fiber Hot Rod Hot Carbon Fiber Layup Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. Wet layup refers to draping carbon fiber fabric over a core or mold. In this section, we focus on the crucial steps for. Carbon Fiber Layup.

From www.shutterstock.com

Carbon fiber layup 2 images, photos et images vectorielles de stock Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. Here’s how to use this technique: Wet layup refers to draping carbon fiber fabric over a core or mold. First, cut the carbon fiber into sections. Learn everything about carbon fiber design and application, from its properties and manufacturing to. Carbon Fiber Layup.

From bercella.it

Bercella first steps of carbon fiber layup process Carbon Fiber Layup In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create. Carbon Fiber Layup.

From www.hypetex.com

220gsm 3K 2x2 Twill Carbon Fibre Hypetex Carbon Fiber Layup A single tow can be pulled out of the fabric to cut a straight line to guide your cut. First, cut the carbon fiber into sections. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. Wet layup refers to draping carbon fiber fabric over a core or mold. We’ll detail the. Carbon Fiber Layup.

From www.talkcomposites.com

Carbon Fiber Layup with Mould 3D Printer Carbon Fiber Layup We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. Wet layup refers to draping carbon fiber fabric over a core or mold. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. A single tow can be pulled out of the. Carbon Fiber Layup.

From www.singletracks.com

How Carbon Fiber Layup Makes Bike Frames Stiff and Compliant in all the Carbon Fiber Layup A single tow can be pulled out of the fabric to cut a straight line to guide your cut. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses. Carbon Fiber Layup.

From abilitycomposites.com

Carbon Fiber Layup & Fiberglass Layup Services Colorado Carbon Fiber Layup A single tow can be pulled out of the fabric to cut a straight line to guide your cut. Wet layup refers to draping carbon fiber fabric over a core or mold. First, cut the carbon fiber into sections. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. In. Carbon Fiber Layup.

From www.hotrod.com

Carbon Fiber StepbyStep How to Lay Up Carbon Fiber Hot Rod Hot Carbon Fiber Layup Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. Here’s how to use this technique: Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. A single tow can be pulled out of the fabric to cut a straight line to guide your. Carbon Fiber Layup.

From bercella.it

Bercella first steps of carbon fiber layup process Carbon Fiber Layup In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. First, cut the carbon fiber into sections. We’ll detail the specific methods and materials used, ensuring clarity. Carbon Fiber Layup.

From www.youtube.com

How to Make a Carbon Fiber Panel Wet Lay Technique YouTube Carbon Fiber Layup Wet layup refers to draping carbon fiber fabric over a core or mold. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Here’s how to use. Carbon Fiber Layup.

From bercella.it

Bercella first steps of carbon fiber layup process Carbon Fiber Layup Wet layup refers to draping carbon fiber fabric over a core or mold. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. We’ll detail the specific. Carbon Fiber Layup.

From www.hotrod.com

Carbon Fiber StepbyStep How to Lay Up Carbon Fiber Hot Rod Hot Carbon Fiber Layup First, cut the carbon fiber into sections. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses. Carbon Fiber Layup.

From www.easycomposites.co.uk

Introduction to OutofAutoclave Prepreg Carbon Fibre Easy Composites Carbon Fiber Layup Here’s how to use this technique: Wet layup refers to draping carbon fiber fabric over a core or mold. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process. Carbon Fiber Layup.

From www.pentapatterns.co.uk

Different Carbon Fibre Weave Patterns Penta Patterns Carbon Fiber Layup Wet layup refers to draping carbon fiber fabric over a core or mold. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. First, cut the carbon fiber into sections. Here’s how to use this technique: A single tow can be pulled out of the fabric to cut a straight line to. Carbon Fiber Layup.

From bigrep-3d.cn

Carbon Fiber Molds & Patterns BigRep China Carbon Fiber Layup Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. Here’s how to use this technique: First, cut the carbon fiber into sections. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. We’ll detail the specific methods and materials used, ensuring clarity. Carbon Fiber Layup.

From aerospaceamerica.aiaa.org

Modeling structural strength Aerospace America Carbon Fiber Layup Wet layup refers to draping carbon fiber fabric over a core or mold. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Learn everything. Carbon Fiber Layup.

From www.easycomposites.co.uk

Complex Moulding Using Prepreg Carbon Fibre Video Tutorial Easy Carbon Fiber Layup First, cut the carbon fiber into sections. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber. Carbon Fiber Layup.

From meechcustombikes.blogspot.com

MEECH Custom Bicycles How is this for some sweet carbon fiber layup? Carbon Fiber Layup First, cut the carbon fiber into sections. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. Wet layup refers to draping carbon fiber fabric over a core or mold. Here’s. Carbon Fiber Layup.

From www.youtube.com

Flat Carbon Fiber Layup YouTube Carbon Fiber Layup Wet layup refers to draping carbon fiber fabric over a core or mold. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. A single. Carbon Fiber Layup.

From bercella.it

Bercella first steps of carbon fiber layup process Carbon Fiber Layup Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. We’ll detail the specific methods. Carbon Fiber Layup.

From www.reddit.com

Carbon Fiber Hand Wet LayUp . r/CarbonFiber Carbon Fiber Layup Here’s how to use this technique: Wet layup refers to draping carbon fiber fabric over a core or mold. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. First, cut the carbon fiber into sections. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to. Carbon Fiber Layup.

From argonautcycles.com

The Layup Argonaut Cycles Carbon Fiber Layup In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. Wet layup refers to draping carbon fiber fabric over a core or mold. Learn how carbon. Carbon Fiber Layup.

From www.youtube.com

Making Complex Carbon Fibre Tubes Using a SplitMould YouTube Carbon Fiber Layup First, cut the carbon fiber into sections. We’ll detail the specific methods and materials used, ensuring clarity and precision in our approach to create strong, lightweight components. A single tow can be pulled out of the fabric to cut a straight line to guide your cut. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber. Carbon Fiber Layup.

From www.reddit.com

Wet layup in a mold, no resin on elevated edges. Any suggestions? r Carbon Fiber Layup In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. Here’s how to use this technique: A single tow can be pulled out of the fabric to. Carbon Fiber Layup.

From www.easycomposites.co.uk

Introduction to OutofAutoclave Prepreg Carbon Fibre Easy Composites Carbon Fiber Layup Here’s how to use this technique: In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing methods. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. First, cut the carbon fiber into sections. Wet layup refers to. Carbon Fiber Layup.

From www.esa.int

ESA ESA BIC 9T Labs 3D CLF printing in carbon fiber materials Carbon Fiber Layup First, cut the carbon fiber into sections. Learn everything about carbon fiber design and application, from its properties and manufacturing to its uses and engineering. Learn how carbon fiber orientation affects the strength and stiffness of a carbon fiber reinforced plastic (cfrp) laminate. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds. Carbon Fiber Layup.