Worm Gear Calculations . The calculations use procedures, algorithms and. Define the center distance, c. Auxiliary calculations (heating, shaft design). The pitch line velocity is ideally up to 30 m/s. Define the number of starts. In principle, worm and worm gear work like a pair of helical gears in crossed configuration. L = lead of a worm which is the distance any one thread. An outline design procedure for a worm and wheel gear set using the agma equations is: Worm and wormgear design equations and calculator. The worm gear ratio calculator is a valuable tool designed to determine the gear ratio between a worm gear and a worm wheel (or gear) in mechanical systems. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. This calculator provides the calculation of worm gears for mechanical engineering applications. Support of 2d and 3d cad systems. The efficiency of a worm gear. The worm and worm gear have helices of the same.

from www.chegg.com

Worm and wormgear design equations and calculator. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Auxiliary calculations (heating, shaft design). Define the number of starts. The calculations use procedures, algorithms and. An outline design procedure for a worm and wheel gear set using the agma equations is: In principle, worm and worm gear work like a pair of helical gears in crossed configuration. Define the center distance, c. Support of 2d and 3d cad systems. The pitch line velocity is ideally up to 30 m/s.

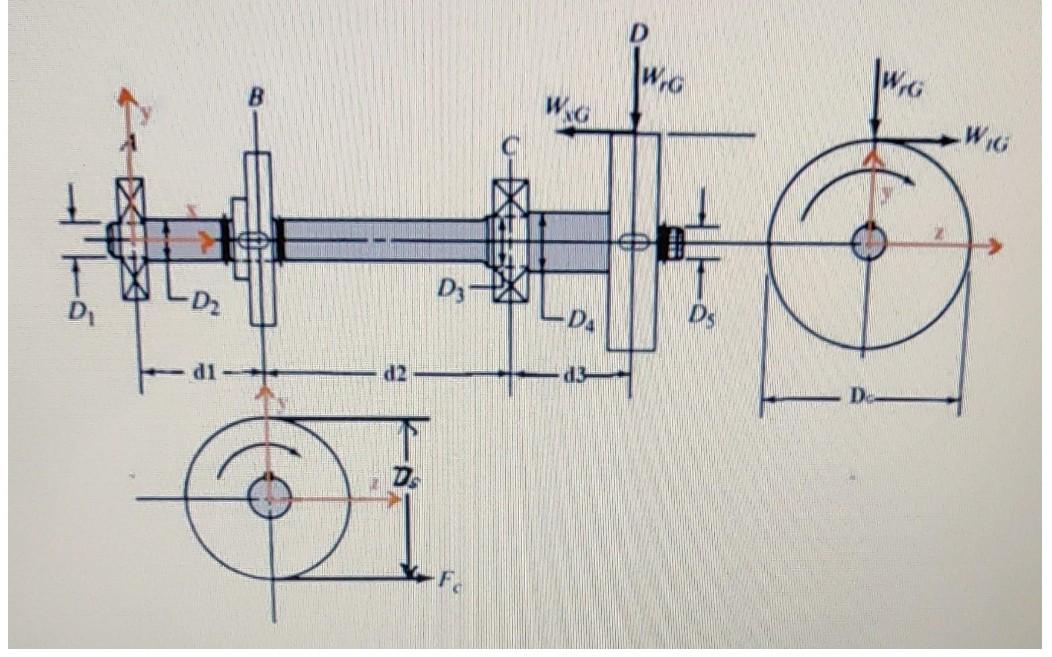

Solved A worm gear is mounted on the end of the shaft,

Worm Gear Calculations The worm and worm gear have helices of the same. L = lead of a worm which is the distance any one thread. The calculations use procedures, algorithms and. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the number of starts. The worm and worm gear have helices of the same. The efficiency of a worm gear. This calculator provides the calculation of worm gears for mechanical engineering applications. Define the center distance, c. Worm and wormgear design equations and calculator. In principle, worm and worm gear work like a pair of helical gears in crossed configuration. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Auxiliary calculations (heating, shaft design). The pitch line velocity is ideally up to 30 m/s. Support of 2d and 3d cad systems. The worm gear ratio calculator is a valuable tool designed to determine the gear ratio between a worm gear and a worm wheel (or gear) in mechanical systems.

From www.chegg.com

Solved A worm gear is mounted on the end of the shaft, Worm Gear Calculations Worm and wormgear design equations and calculator. L = lead of a worm which is the distance any one thread. The pitch line velocity is ideally up to 30 m/s. This calculator provides the calculation of worm gears for mechanical engineering applications. Define the center distance, c. The worm and worm gear have helices of the same. An outline design. Worm Gear Calculations.

From www.engineerknow.com

How to calculate gear ratio of Worm gear Worm Gear Calculations The efficiency of a worm gear. An outline design procedure for a worm and wheel gear set using the agma equations is: Worm and wormgear design equations and calculator. The worm gear ratio calculator is a valuable tool designed to determine the gear ratio between a worm gear and a worm wheel (or gear) in mechanical systems. Define the center. Worm Gear Calculations.

From gasesaver.weebly.com

Worm gear design calculation pdf editor gasesaver Worm Gear Calculations In principle, worm and worm gear work like a pair of helical gears in crossed configuration. Auxiliary calculations (heating, shaft design). An outline design procedure for a worm and wheel gear set using the agma equations is: Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The pitch line. Worm Gear Calculations.

From khkgears.net

Surface Durability of Worm Gear KHK Gears Worm Gear Calculations The pitch line velocity is ideally up to 30 m/s. Define the center distance, c. The calculations use procedures, algorithms and. In principle, worm and worm gear work like a pair of helical gears in crossed configuration. L = lead of a worm which is the distance any one thread. Support of 2d and 3d cad systems. An outline design. Worm Gear Calculations.

From platformerogon.weebly.com

Worm Gear Design Calculation Pdf Free platformerogon Worm Gear Calculations Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The pitch line velocity is ideally up to 30 m/s. Support of 2d and 3d cad systems. Define the number of starts. The worm and worm gear have helices of the same. An outline design procedure for a worm and. Worm Gear Calculations.

From calculatorshub.net

Worm Gear Ratio Calculator Online Worm Gear Calculations L = lead of a worm which is the distance any one thread. The calculations use procedures, algorithms and. Auxiliary calculations (heating, shaft design). This calculator provides the calculation of worm gears for mechanical engineering applications. Support of 2d and 3d cad systems. Define the center distance, c. The worm gear ratio calculator is a valuable tool designed to determine. Worm Gear Calculations.

From www.youtube.com

Worm Gear Calculation and Design (MITCalc12) YouTube Worm Gear Calculations The pitch line velocity is ideally up to 30 m/s. L = lead of a worm which is the distance any one thread. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. An outline design procedure for a worm and wheel gear set using the agma equations is: The. Worm Gear Calculations.

From www.hexagon.de

ZAR3 Worm Gear Calculation Worm Gear Calculations Support of 2d and 3d cad systems. L = lead of a worm which is the distance any one thread. Worm and wormgear design equations and calculator. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. An outline design procedure for a worm and wheel gear set using the. Worm Gear Calculations.

From www.hexagon.de

ZAR3 Worm Gear Calculation Worm Gear Calculations The pitch line velocity is ideally up to 30 m/s. L = lead of a worm which is the distance any one thread. Define the center distance, c. The calculations use procedures, algorithms and. Worm and wormgear design equations and calculator. The worm gear ratio calculator is a valuable tool designed to determine the gear ratio between a worm gear. Worm Gear Calculations.

From www.youtube.com

WORM GEARS Forces and Speed Relations in Just Under 15 Minutes! YouTube Worm Gear Calculations In principle, worm and worm gear work like a pair of helical gears in crossed configuration. L = lead of a worm which is the distance any one thread. Define the number of starts. Worm and wormgear design equations and calculator. This calculator provides the calculation of worm gears for mechanical engineering applications. Define the center distance, c. Auxiliary calculations. Worm Gear Calculations.

From grabcad.com

How to Calculate the Centre to CentreDistance between Worm and Wrom Worm Gear Calculations The efficiency of a worm gear. The pitch line velocity is ideally up to 30 m/s. The calculations use procedures, algorithms and. Support of 2d and 3d cad systems. In principle, worm and worm gear work like a pair of helical gears in crossed configuration. The worm and worm gear have helices of the same. The worm gear ratio calculator. Worm Gear Calculations.

From brainsherof.weebly.com

Worm gear design calculation download brainsherofMy Site Worm Gear Calculations L = lead of a worm which is the distance any one thread. Define the number of starts. Auxiliary calculations (heating, shaft design). The efficiency of a worm gear. The calculations use procedures, algorithms and. The worm and worm gear have helices of the same. An outline design procedure for a worm and wheel gear set using the agma equations. Worm Gear Calculations.

From blog.ar-cad.com

Worm Gear Assembly and Simulation in SpaceClaim ARCAD Blog Worm Gear Calculations Define the number of starts. L = lead of a worm which is the distance any one thread. Define the center distance, c. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The efficiency of a worm gear. An outline design procedure for a worm and wheel gear set. Worm Gear Calculations.

From mvg99.narod.ru

Click to enlarge image Worm Gear Calculations Worm and wormgear design equations and calculator. L = lead of a worm which is the distance any one thread. Define the number of starts. The pitch line velocity is ideally up to 30 m/s. Auxiliary calculations (heating, shaft design). The worm gear ratio calculator is a valuable tool designed to determine the gear ratio between a worm gear and. Worm Gear Calculations.

From www.pinterest.com

A worm gear box is used for higher reduction ratios. This Worm gear Worm Gear Calculations Define the number of starts. In principle, worm and worm gear work like a pair of helical gears in crossed configuration. This calculator provides the calculation of worm gears for mechanical engineering applications. The pitch line velocity is ideally up to 30 m/s. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z),. Worm Gear Calculations.

From rangmillionaire.weebly.com

Worm Gear Design Calculation Pdf File rangmillionaire Worm Gear Calculations L = lead of a worm which is the distance any one thread. This calculator provides the calculation of worm gears for mechanical engineering applications. The calculations use procedures, algorithms and. The efficiency of a worm gear. Worm and wormgear design equations and calculator. The worm and worm gear have helices of the same. An outline design procedure for a. Worm Gear Calculations.

From dpoksystems.weebly.com

Worm gear design calculation pdf to excel dpoksystems Worm Gear Calculations The efficiency of a worm gear. L = lead of a worm which is the distance any one thread. An outline design procedure for a worm and wheel gear set using the agma equations is: The pitch line velocity is ideally up to 30 m/s. Define the number of starts. The calculations use procedures, algorithms and. Worm and wormgear design. Worm Gear Calculations.

From supernewselect.bitballoon.com

Worm Gear Module Calculation Software Worm Gear Calculations L = lead of a worm which is the distance any one thread. Define the center distance, c. Worm and wormgear design equations and calculator. This calculator provides the calculation of worm gears for mechanical engineering applications. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the number of starts. Support of. Worm Gear Calculations.

From heremup766.weebly.com

Worm Gear Design Calculation Pdf heremup Worm Gear Calculations Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Support of 2d and 3d cad systems. In principle, worm and worm gear work like a pair of helical gears in crossed configuration. An outline design procedure for a worm and wheel gear set using the agma equations is: Define. Worm Gear Calculations.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Worm Gear Calculations An outline design procedure for a worm and wheel gear set using the agma equations is: Worm and wormgear design equations and calculator. Support of 2d and 3d cad systems. The worm and worm gear have helices of the same. The pitch line velocity is ideally up to 30 m/s. The worm gear ratio calculator is a valuable tool designed. Worm Gear Calculations.

From www.youtube.com

Gear Force Components Example 3 Worm Gears YouTube Worm Gear Calculations Worm and wormgear design equations and calculator. Auxiliary calculations (heating, shaft design). Support of 2d and 3d cad systems. The calculations use procedures, algorithms and. The worm gear ratio calculator is a valuable tool designed to determine the gear ratio between a worm gear and a worm wheel (or gear) in mechanical systems. The worm and worm gear have helices. Worm Gear Calculations.

From www.engineersedge.com

Worm Gear Sizing Calculator Worm Gear Calculations The worm and worm gear have helices of the same. The calculations use procedures, algorithms and. This calculator provides the calculation of worm gears for mechanical engineering applications. Support of 2d and 3d cad systems. L = lead of a worm which is the distance any one thread. Gear dimensions are determined in accordance with their specifications, such as module. Worm Gear Calculations.

From www.scribd.com

Analysis of Worm Gears Geometry, Force Calculations, Stress Analysis Worm Gear Calculations Worm and wormgear design equations and calculator. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The pitch line velocity is ideally up to 30 m/s. An outline design procedure for a worm and wheel gear set using the agma equations is: In principle, worm and worm gear work. Worm Gear Calculations.

From crownmarbl.web.fc2.com

Worm Gear Design Calculation Pdf Creator Worm Gear Calculations Define the center distance, c. The pitch line velocity is ideally up to 30 m/s. In principle, worm and worm gear work like a pair of helical gears in crossed configuration. Auxiliary calculations (heating, shaft design). Worm and wormgear design equations and calculator. The worm gear ratio calculator is a valuable tool designed to determine the gear ratio between a. Worm Gear Calculations.

From www.pinterest.co.uk

Robotic Mechanisms WORM GEARS 51038 Eğitim Worm Gear Calculations Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The worm gear ratio calculator is a valuable tool designed to determine the gear ratio between a worm gear and a worm wheel (or gear) in mechanical systems. In principle, worm and worm gear work like a pair of helical. Worm Gear Calculations.

From www.youtube.com

Worm and Wheel Gearbox Gear ratio Calculation How to calculate worm Worm Gear Calculations The worm and worm gear have helices of the same. Define the center distance, c. The pitch line velocity is ideally up to 30 m/s. In principle, worm and worm gear work like a pair of helical gears in crossed configuration. Support of 2d and 3d cad systems. The worm gear ratio calculator is a valuable tool designed to determine. Worm Gear Calculations.

From www.researchgate.net

(a) Details of the worm gear [20], and (b) worm gear profile and bull Worm Gear Calculations The worm and worm gear have helices of the same. L = lead of a worm which is the distance any one thread. Define the center distance, c. Worm and wormgear design equations and calculator. The calculations use procedures, algorithms and. In principle, worm and worm gear work like a pair of helical gears in crossed configuration. The pitch line. Worm Gear Calculations.

From www.engineersedge.com

Worm and WormGear Design Equations and Calculator Worm Gear Calculations The efficiency of a worm gear. The calculations use procedures, algorithms and. This calculator provides the calculation of worm gears for mechanical engineering applications. Worm and wormgear design equations and calculator. Support of 2d and 3d cad systems. The pitch line velocity is ideally up to 30 m/s. Define the number of starts. The worm gear ratio calculator is a. Worm Gear Calculations.

From goodtextmoto.web.fc2.com

Worm Gear Design Calculation Pdf Files Worm Gear Calculations An outline design procedure for a worm and wheel gear set using the agma equations is: Worm and wormgear design equations and calculator. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The efficiency of a worm gear. The calculations use procedures, algorithms and. The pitch line velocity is. Worm Gear Calculations.

From www.hexagon.de

ZAR3 Worm Gear Calculation Worm Gear Calculations The efficiency of a worm gear. Define the number of starts. An outline design procedure for a worm and wheel gear set using the agma equations is: In principle, worm and worm gear work like a pair of helical gears in crossed configuration. The pitch line velocity is ideally up to 30 m/s. Worm and wormgear design equations and calculator.. Worm Gear Calculations.

From www.youtube.com

Worm Gear Calculation Reverse Engineering YouTube Worm Gear Calculations Define the number of starts. Auxiliary calculations (heating, shaft design). The calculations use procedures, algorithms and. The worm and worm gear have helices of the same. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The pitch line velocity is ideally up to 30 m/s. Worm and wormgear design. Worm Gear Calculations.

From www.hexagon.de

ZAR3 Worm Gear Calculation Worm Gear Calculations The efficiency of a worm gear. Define the center distance, c. The calculations use procedures, algorithms and. An outline design procedure for a worm and wheel gear set using the agma equations is: Auxiliary calculations (heating, shaft design). The pitch line velocity is ideally up to 30 m/s. L = lead of a worm which is the distance any one. Worm Gear Calculations.

From www.youtube.com

Worm Gear Worm Gear Calculation Different Calculations of Worm Gear Worm Gear Calculations Auxiliary calculations (heating, shaft design). The calculations use procedures, algorithms and. Define the number of starts. Worm and wormgear design equations and calculator. In principle, worm and worm gear work like a pair of helical gears in crossed configuration. The efficiency of a worm gear. Support of 2d and 3d cad systems. The pitch line velocity is ideally up to. Worm Gear Calculations.

From www.degruyter.com

Mathematical description of tooth flank surface of globoidal worm gear Worm Gear Calculations Define the number of starts. The worm and worm gear have helices of the same. Support of 2d and 3d cad systems. An outline design procedure for a worm and wheel gear set using the agma equations is: Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The efficiency. Worm Gear Calculations.

From www.tec-science.com

Worms and worm gears tecscience Worm Gear Calculations The efficiency of a worm gear. This calculator provides the calculation of worm gears for mechanical engineering applications. The worm gear ratio calculator is a valuable tool designed to determine the gear ratio between a worm gear and a worm wheel (or gear) in mechanical systems. The worm and worm gear have helices of the same. In principle, worm and. Worm Gear Calculations.