How To Cut Gear Teeth . Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like the final gear shape). As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. These are from 1/8” thick flat brass bar. By this method, it cuts regular teeth into the full. For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. The method of action is simple. This is about the simplest way to make an accurate gear with the minimum of equipment, just a milling machine and a rotary. One of the most common ways of making spur gears is by using a dividing head on a milling machine.

from teethwalls.blogspot.com

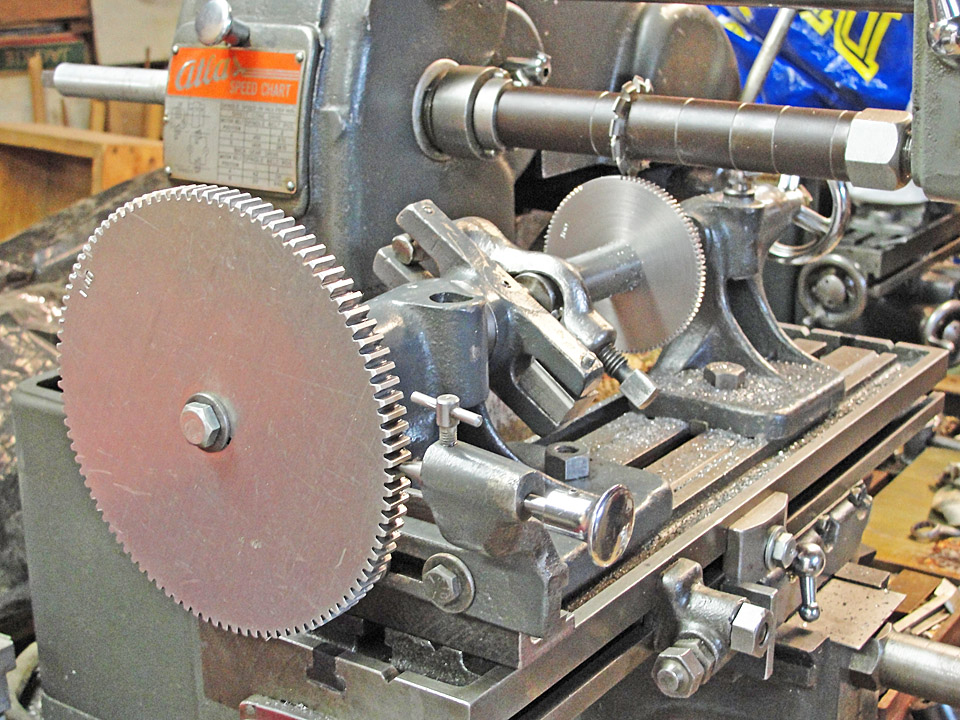

These are from 1/8” thick flat brass bar. One of the most common ways of making spur gears is by using a dividing head on a milling machine. Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like the final gear shape). As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. By this method, it cuts regular teeth into the full. Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. This is about the simplest way to make an accurate gear with the minimum of equipment, just a milling machine and a rotary. The method of action is simple.

Cutting Gear Teeth On Milling Machine TeethWalls

How To Cut Gear Teeth As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. One of the most common ways of making spur gears is by using a dividing head on a milling machine. By this method, it cuts regular teeth into the full. Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. These are from 1/8” thick flat brass bar. This is about the simplest way to make an accurate gear with the minimum of equipment, just a milling machine and a rotary. The method of action is simple. The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like the final gear shape). As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make.

From www.dreamstime.com

Cutting the Teeth with a Cutter and Gear for Gear on the Inner Surface, with Oil Cooling Stock How To Cut Gear Teeth For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. These are from 1/8” thick flat brass bar. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. The term “gear cutting” refers to. How To Cut Gear Teeth.

From www.youtube.com

Gear Tooth Vernier Caliper Working Gear Tooth Thickness Measurement Metrology Shubham Kola How To Cut Gear Teeth This is about the simplest way to make an accurate gear with the minimum of equipment, just a milling machine and a rotary. One of the most common ways of making spur gears is by using a dividing head on a milling machine. These are from 1/8” thick flat brass bar. To use an involute gear cutter effectively, you need. How To Cut Gear Teeth.

From www.youtube.com

DIY Internal Gear Teeth Cutting Process in Slotting machine Machining Gear Cutting YouTube How To Cut Gear Teeth One of the most common ways of making spur gears is by using a dividing head on a milling machine. For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of. How To Cut Gear Teeth.

From www.tec-science.com

Gear cutting (gear manufacturing) tecscience How To Cut Gear Teeth As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. The method of action is simple. These are from 1/8” thick flat brass bar. The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like the final gear. How To Cut Gear Teeth.

From teethwalls.blogspot.com

Cutting Gear Teeth On Milling Machine TeethWalls How To Cut Gear Teeth These are from 1/8” thick flat brass bar. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like. How To Cut Gear Teeth.

From www.jeffree.co.uk

Gear cutting with a rack form multitooth cutter How To Cut Gear Teeth By this method, it cuts regular teeth into the full. Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. For an. How To Cut Gear Teeth.

From www.youtube.com

Gear Cutting on Milling Machine YouTube How To Cut Gear Teeth To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. By this method, it cuts regular teeth into the full. Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. The term. How To Cut Gear Teeth.

From ozarktoolmanuals.com

How to Cut/Make Gear Teeth on a Milling Machine by Cincinnati for Rack, Spur, Bevel, Helical How To Cut Gear Teeth Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. These are from 1/8” thick flat brass bar. The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like the. How To Cut Gear Teeth.

From www.youtube.com

How to repair differential gear teeth repairing rear wheel gear broken teeth Truck broken How To Cut Gear Teeth The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like the final gear shape). As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. By this method, it cuts regular teeth into the full. This is about. How To Cut Gear Teeth.

From www.youtube.com

Huge Gear teeth cutting on milling machine. YouTube How To Cut Gear Teeth These are from 1/8” thick flat brass bar. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. This is about the. How To Cut Gear Teeth.

From danielbusby.com

Gear Cutting on the Bridgeport Mill Daniel Busby How To Cut Gear Teeth One of the most common ways of making spur gears is by using a dividing head on a milling machine. These are from 1/8” thick flat brass bar. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. This is about the. How To Cut Gear Teeth.

From www.youtube.com

Construction of teeth profile Problem Spur gear Drawing Involute Profile YouTube How To Cut Gear Teeth For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. By this method, it cuts regular teeth into the full. The term “gear cutting” refers. How To Cut Gear Teeth.

From www.youtube.com

Cutting Wood Gear & Clock Wheel Teeth YouTube How To Cut Gear Teeth By this method, it cuts regular teeth into the full. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the. How To Cut Gear Teeth.

From www.amazon.com

How to Cut Gear Teeth on a Milling Machine by Cincinnati for Rack, Spur, Bevel, Helical, & Worm How To Cut Gear Teeth For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. The method of action is simple. Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term. How To Cut Gear Teeth.

From www.youtube.com

Cutting the gear teeth YouTube How To Cut Gear Teeth The method of action is simple. Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. By this method, it cuts regular teeth. How To Cut Gear Teeth.

From autopickles.com

How Do Straight Cut Gears Work? Autopickles How To Cut Gear Teeth Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. These are from 1/8” thick flat brass bar. For an upcoming project i. How To Cut Gear Teeth.

From www.youtube.com

cutting gear teeth on the shaper machine. YouTube How To Cut Gear Teeth As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like the final gear shape). One of the most common ways of making spur gears is by using. How To Cut Gear Teeth.

From www.youtube.com

Camelback Drill Press Gears 2 Cutting Gear Teeth on the First Gear YouTube How To Cut Gear Teeth These are from 1/8” thick flat brass bar. Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. The term “gear cutting”. How To Cut Gear Teeth.

From www.sculpteo.com

Design Your Own Gear Mechanism for Laser Cutting How To Cut Gear Teeth These are from 1/8” thick flat brass bar. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. By this method, it cuts regular teeth into the full. The method of action is simple. As the tap turns it not only cuts. How To Cut Gear Teeth.

From www.youtube.com

How to Cut Gears Detailed Version gearcutting YouTube How To Cut Gear Teeth Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like the final gear shape). To use an involute gear. How To Cut Gear Teeth.

From teethwalls.blogspot.com

Cutting Gear Teeth On Milling Machine TeethWalls How To Cut Gear Teeth One of the most common ways of making spur gears is by using a dividing head on a milling machine. The method of action is simple. These are from 1/8” thick flat brass bar. Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. Gear hobbing produces gear teeth by. How To Cut Gear Teeth.

From www.youtube.com

Setting up the tool to cut the gear teeth / Réglage de l'appareil à fraiser les dents YouTube How To Cut Gear Teeth These are from 1/8” thick flat brass bar. As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. The term “gear cutting” refers to the various methods that are used to make gears. How To Cut Gear Teeth.

From www.youtube.com

Horizontal Milling Machine Gear Teeth Cutting YouTube How To Cut Gear Teeth By this method, it cuts regular teeth into the full. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. As the tap turns. How To Cut Gear Teeth.

From mechanicstips.blogspot.com

Terminology of Gear Tooth MechanicsTips How To Cut Gear Teeth Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. This is about the simplest way to make an accurate gear with the. How To Cut Gear Teeth.

From www.youtube.com

How Cutting Gear Teeth On The Lathe Amazing Manufacturing process of Gearbox YouTube How To Cut Gear Teeth As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. One of the most common ways of making spur gears is by using a dividing head on a milling machine. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth. How To Cut Gear Teeth.

From ozarktoolmanuals.com

How to Cut Gear Teeth on a Milling Machine by Cincinnati for Rack, Spur, Bevel, Helical, & Worm How To Cut Gear Teeth Gear cutters work great in mills, and often times allow you to expand the capabilities of machines you already own. The method of action is simple. As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. For an upcoming project i want to cut some 48 diametral pitch gears with 52,. How To Cut Gear Teeth.

From www.youtube.com

How to cut a gear with 12.5 teeth YouTube How To Cut Gear Teeth The method of action is simple. One of the most common ways of making spur gears is by using a dividing head on a milling machine. The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like the final gear shape). These are from 1/8” thick flat. How To Cut Gear Teeth.

From dokumen.tips

(PDF) Cutting Gear Teeth DOKUMEN.TIPS How To Cut Gear Teeth By this method, it cuts regular teeth into the full. This is about the simplest way to make an accurate gear with the minimum of equipment, just a milling machine and a rotary. For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. The method of action is simple. One of the. How To Cut Gear Teeth.

From www.practicalmachinist.com

Cutting gear teeth....I need the basics Page 2 How To Cut Gear Teeth The term “gear cutting” refers to the various methods that are used to make gears out of gear blanks (a block that looks like the final gear shape). This is about the simplest way to make an accurate gear with the minimum of equipment, just a milling machine and a rotary. By this method, it cuts regular teeth into the. How To Cut Gear Teeth.

From www.youtube.com

Gear teeth cutting at SolidWorks YouTube How To Cut Gear Teeth The method of action is simple. For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. This is about the simplest way to make an accurate gear with the minimum of equipment, just a milling machine and a rotary. One of the most common ways of making spur gears is by using. How To Cut Gear Teeth.

From www.youtube.com

HOW TO CUT GEAR TEETH AT VMC SIEMENS CONTROL cncprogramming2dTITANSofCNC YouTube How To Cut Gear Teeth These are from 1/8” thick flat brass bar. To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. By this method, it cuts regular teeth into the full. Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob”. How To Cut Gear Teeth.

From www.youtube.com

DIY Internal Gear Teeth Cutting Process in Slotting machine Machining Gear Number of Teeth How To Cut Gear Teeth For an upcoming project i want to cut some 48 diametral pitch gears with 52, and 16 teeth. This is about the simplest way to make an accurate gear with the minimum of equipment, just a milling machine and a rotary. As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well.. How To Cut Gear Teeth.

From www.youtube.com

Gears Cutting my teeth. YouTube How To Cut Gear Teeth These are from 1/8” thick flat brass bar. Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” (hence the term gear hobbing) depicted in the gear hobbing machine interface below. As the tap turns it not only cuts into the workpiece, but rotates it on a bearing as well. The method of action is simple.. How To Cut Gear Teeth.

From www.youtube.com

Cutting Gear Teeth On The Lathe YouTube How To Cut Gear Teeth To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. One of the most common ways of making spur gears is by using a dividing head on a milling machine. This is about the simplest way to make an accurate gear with. How To Cut Gear Teeth.

From www.youtube.com

BIG SPUR GEAR TEETH CUTTING YouTube How To Cut Gear Teeth To use an involute gear cutter effectively, you need to know the pitch (or module), pressure angle, and number of teeth of the gear you're trying to make. One of the most common ways of making spur gears is by using a dividing head on a milling machine. For an upcoming project i want to cut some 48 diametral pitch. How To Cut Gear Teeth.