Uniform Strain Definition . Takes the position vector z of any point in the undeformed. Generalizes the 1d concept of the map to 3d. General definition of strains in 1d: Engineering strain is defined as the ratio between the change in length and the original length. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. Normal strain occurs when the elongation of an object is in response to a normal stress. For each step during deformation,. Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. An object or medium under stress becomes deformed. 4.27 (b)) all elements in the block have been deformed the same amount. For example, if the gauge length at. The quantity that describes this deformation is called strain. State of uniform strain (see fig.

from engineeringdiscoveries.com

An object or medium under stress becomes deformed. State of uniform strain (see fig. Engineering strain is defined as the ratio between the change in length and the original length. Normal strain occurs when the elongation of an object is in response to a normal stress. Generalizes the 1d concept of the map to 3d. 4.27 (b)) all elements in the block have been deformed the same amount. For example, if the gauge length at. Takes the position vector z of any point in the undeformed. General definition of strains in 1d: In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length.

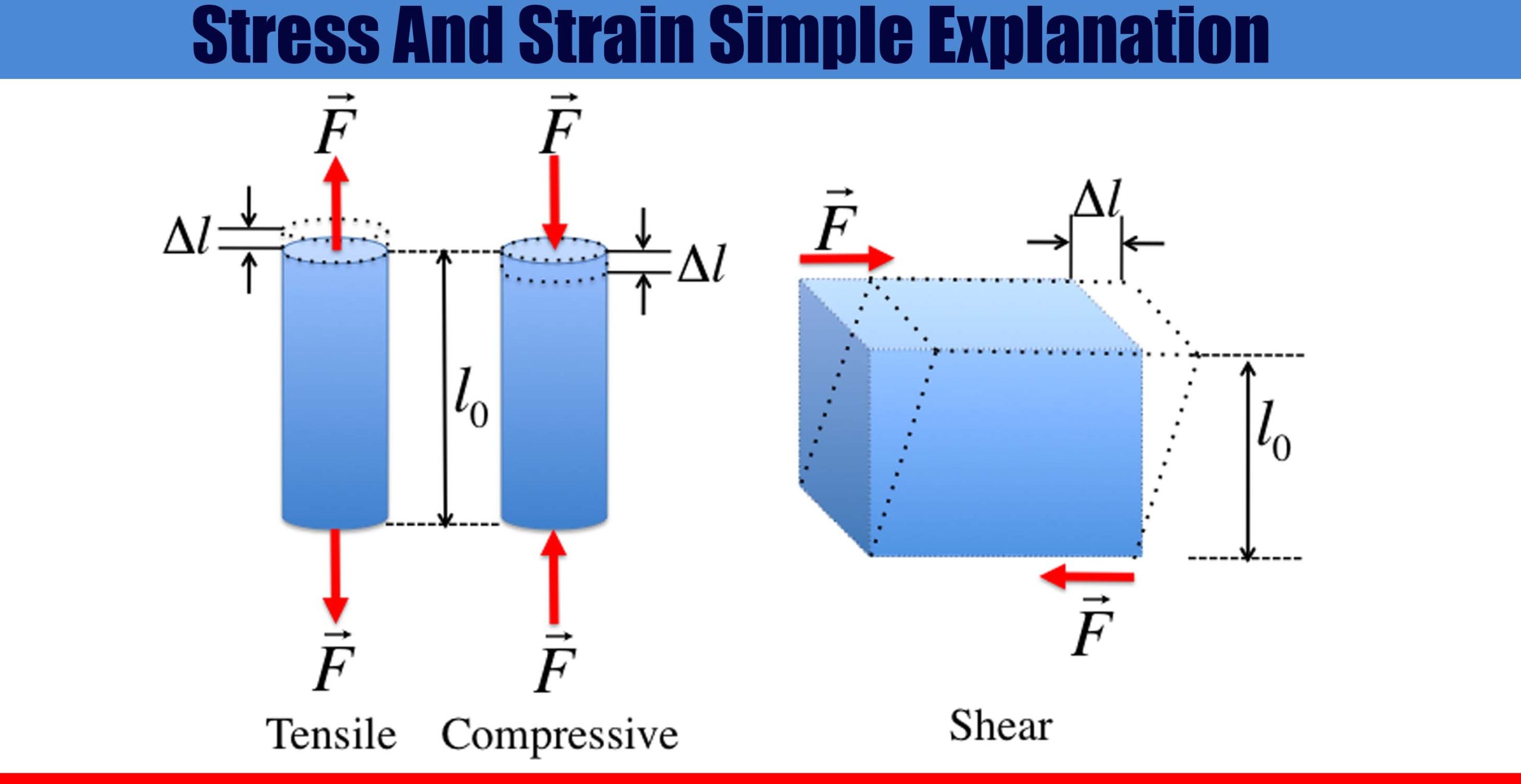

Stress And Strain Simple Explanation Engineering Discoveries

Uniform Strain Definition For example, if the gauge length at. Takes the position vector z of any point in the undeformed. Normal strain occurs when the elongation of an object is in response to a normal stress. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. For each step during deformation,. The quantity that describes this deformation is called strain. Engineering strain is defined as the ratio between the change in length and the original length. General definition of strains in 1d: For example, if the gauge length at. An object or medium under stress becomes deformed. Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. 4.27 (b)) all elements in the block have been deformed the same amount. State of uniform strain (see fig. Generalizes the 1d concept of the map to 3d.

From www.slideserve.com

PPT Stress/strain Relationship for Solids PowerPoint Presentation Uniform Strain Definition An object or medium under stress becomes deformed. The quantity that describes this deformation is called strain. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. 4.27 (b)) all elements in the block have been deformed the same amount. Engineering strain is defined as the ratio between. Uniform Strain Definition.

From www.researchgate.net

Schematic of characterizing uniform strain Download Scientific Diagram Uniform Strain Definition The quantity that describes this deformation is called strain. Takes the position vector z of any point in the undeformed. For example, if the gauge length at. Engineering strain is defined as the ratio between the change in length and the original length. Generalizes the 1d concept of the map to 3d. In a tensile test, uniform elongation is the. Uniform Strain Definition.

From www.slideserve.com

PPT Mechanics PowerPoint Presentation, free download ID3293543 Uniform Strain Definition 4.27 (b)) all elements in the block have been deformed the same amount. Normal strain occurs when the elongation of an object is in response to a normal stress. The quantity that describes this deformation is called strain. State of uniform strain (see fig. Engineering strain is defined as the ratio between the change in length and the original length.. Uniform Strain Definition.

From www.researchgate.net

Definition of strain and strain rate. A Strain (ε) is defined as the Uniform Strain Definition General definition of strains in 1d: 4.27 (b)) all elements in the block have been deformed the same amount. Takes the position vector z of any point in the undeformed. An object or medium under stress becomes deformed. For each step during deformation,. Generalizes the 1d concept of the map to 3d. Engineering strain is defined as the ratio between. Uniform Strain Definition.

From learnvikash.com

stress strain definition of both in very easy language check Uniform Strain Definition For each step during deformation,. An object or medium under stress becomes deformed. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. Takes the position vector z of any point in the undeformed. Generalizes the 1d concept of the map to 3d. State of uniform strain (see. Uniform Strain Definition.

From luceo.co.jp

What is Strain? Luceo Co., Ltd. Uniform Strain Definition Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. An object or medium under stress becomes deformed. 4.27 (b)) all elements in the block have been deformed the same amount. For each step during deformation,. The quantity that describes this deformation is called strain. Normal strain occurs when the elongation of. Uniform Strain Definition.

From aslcore.org

Strain ASLCORE Physics Uniform Strain Definition Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. 4.27 (b)) all elements in the block have been deformed the same amount. The quantity that describes this deformation is called strain. Generalizes the 1d concept of the map to 3d. For each step during deformation,. An object or medium under stress. Uniform Strain Definition.

From fractory.com

StressStrain Curve How to Read the Graph? Uniform Strain Definition For example, if the gauge length at. Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. 4.27 (b)) all elements in the block have been deformed the same amount. An object or medium under stress becomes deformed. In a tensile test, uniform elongation is the percentage the gauge length elongated at. Uniform Strain Definition.

From www.mdpi.com

Metals Free FullText An Evaluation of Mechanical Properties with Uniform Strain Definition Takes the position vector z of any point in the undeformed. 4.27 (b)) all elements in the block have been deformed the same amount. Engineering strain is defined as the ratio between the change in length and the original length. The quantity that describes this deformation is called strain. Generalizes the 1d concept of the map to 3d. State of. Uniform Strain Definition.

From www.youtube.com

What are Flexural Stresses / Bending Stresses YouTube Uniform Strain Definition Engineering strain is defined as the ratio between the change in length and the original length. General definition of strains in 1d: For each step during deformation,. An object or medium under stress becomes deformed. For example, if the gauge length at. Normal strain occurs when the elongation of an object is in response to a normal stress. Generalizes the. Uniform Strain Definition.

From www.researchgate.net

Definition of the inherent strain (a) standard state, (b) stressed Uniform Strain Definition State of uniform strain (see fig. Engineering strain is defined as the ratio between the change in length and the original length. The quantity that describes this deformation is called strain. Normal strain occurs when the elongation of an object is in response to a normal stress. 4.27 (b)) all elements in the block have been deformed the same amount.. Uniform Strain Definition.

From www.admet.com

Sheet Metal Tension Testing ADMET Uniform Strain Definition Generalizes the 1d concept of the map to 3d. General definition of strains in 1d: For each step during deformation,. An object or medium under stress becomes deformed. Engineering strain is defined as the ratio between the change in length and the original length. Strain is a unitless measure of how much an object gets bigger or smaller from an. Uniform Strain Definition.

From structures-explained.com

Shear Forces and Shear Stresses in Structures Structures Explained Uniform Strain Definition The quantity that describes this deformation is called strain. Takes the position vector z of any point in the undeformed. For each step during deformation,. Engineering strain is defined as the ratio between the change in length and the original length. Normal strain occurs when the elongation of an object is in response to a normal stress. State of uniform. Uniform Strain Definition.

From ar.inspiredpencil.com

Mild Steel Stress Strain Diagram Uniform Strain Definition Normal strain occurs when the elongation of an object is in response to a normal stress. 4.27 (b)) all elements in the block have been deformed the same amount. For each step during deformation,. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. Takes the position vector. Uniform Strain Definition.

From engineeringdiscoveries.com

Stress And Strain Simple Explanation Engineering Discoveries Uniform Strain Definition An object or medium under stress becomes deformed. The quantity that describes this deformation is called strain. Engineering strain is defined as the ratio between the change in length and the original length. State of uniform strain (see fig. General definition of strains in 1d: Generalizes the 1d concept of the map to 3d. 4.27 (b)) all elements in the. Uniform Strain Definition.

From www.slideserve.com

PPT Strain PowerPoint Presentation, free download ID2608772 Uniform Strain Definition Generalizes the 1d concept of the map to 3d. For example, if the gauge length at. General definition of strains in 1d: Engineering strain is defined as the ratio between the change in length and the original length. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length.. Uniform Strain Definition.

From www.researchgate.net

5. Nonuniform strain and stress distribution in a thickwalled blood Uniform Strain Definition In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. Generalizes the 1d concept of the map to 3d. Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. For each step during deformation,. State of uniform strain (see fig.. Uniform Strain Definition.

From blog.naver.com

XRD 회절시험 응용 네이버 블로그 Uniform Strain Definition Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. Generalizes the 1d concept of the map to 3d. State of uniform strain (see fig. An object or medium under stress becomes deformed. Takes the position vector z of any point in the undeformed. Engineering strain is defined as the ratio between. Uniform Strain Definition.

From collegedunia.com

Strain Definition, Formula and Derivation Uniform Strain Definition Normal strain occurs when the elongation of an object is in response to a normal stress. An object or medium under stress becomes deformed. The quantity that describes this deformation is called strain. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. 4.27 (b)) all elements in. Uniform Strain Definition.

From www.hardwareinterviews.fyi

What's the difference between a true stressstrain curve and a Uniform Strain Definition For each step during deformation,. Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. General definition of strains in 1d: The quantity that describes this deformation is called strain. Takes the position vector z of any point in the undeformed. An object or medium under stress becomes deformed. For example, if. Uniform Strain Definition.

From themechanicalengineering.com

Stress and Strain Definition, Formula,Types in detail, [Notes & PDF] Uniform Strain Definition Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. 4.27 (b)) all elements in the block have been deformed the same amount. For example, if the gauge length at. Engineering strain is defined as the ratio between the change in length and the original length. An object or medium under stress. Uniform Strain Definition.

From material-properties.org

What is Stressstrain Curve Stressstrain Diagram Definition Uniform Strain Definition Takes the position vector z of any point in the undeformed. 4.27 (b)) all elements in the block have been deformed the same amount. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. Generalizes the 1d concept of the map to 3d. Normal strain occurs when the. Uniform Strain Definition.

From www.youtube.com

Normal strain YouTube Uniform Strain Definition State of uniform strain (see fig. Engineering strain is defined as the ratio between the change in length and the original length. An object or medium under stress becomes deformed. Normal strain occurs when the elongation of an object is in response to a normal stress. General definition of strains in 1d: Strain is a unitless measure of how much. Uniform Strain Definition.

From www.degreetutors.com

The StressStrain Curve & Plastic Hinges in Beams Uniform Strain Definition Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. General definition of strains in 1d: The quantity that describes this deformation is called strain. For each step during deformation,.. Uniform Strain Definition.

From ahssinsights.org

Uniform Elongation AHSS Guidelines Uniform Strain Definition State of uniform strain (see fig. An object or medium under stress becomes deformed. Normal strain occurs when the elongation of an object is in response to a normal stress. For example, if the gauge length at. Engineering strain is defined as the ratio between the change in length and the original length. For each step during deformation,. Generalizes the. Uniform Strain Definition.

From www.linearmotiontips.com

Stress and strain Mechanical properties of materials Uniform Strain Definition In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. 4.27 (b)) all elements in the block have been deformed the same amount. General definition of strains in 1d: State of uniform strain (see fig. Engineering strain is defined as the ratio between the change in length and. Uniform Strain Definition.

From www.researchgate.net

Tensile stressstrain curve of the Ti11Mo5Sn5Nb alloy and the Uniform Strain Definition 4.27 (b)) all elements in the block have been deformed the same amount. General definition of strains in 1d: The quantity that describes this deformation is called strain. For example, if the gauge length at. Takes the position vector z of any point in the undeformed. Generalizes the 1d concept of the map to 3d. In a tensile test, uniform. Uniform Strain Definition.

From www.slideserve.com

PPT ME 350 Lecture 2 Chapter 3 PowerPoint Presentation, free Uniform Strain Definition For each step during deformation,. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. General definition of strains in 1d: Normal strain occurs when the elongation of an object is in response to a normal stress. For example, if the gauge length at. Strain is a unitless. Uniform Strain Definition.

From ahssinsights.org

StressStrain Curve Archives AHSS Guidelines Uniform Strain Definition Takes the position vector z of any point in the undeformed. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. Normal strain occurs when the elongation of an object is in response to a normal stress. Engineering strain is defined as the ratio between the change in. Uniform Strain Definition.

From www.scienceabc.com

Yield Strength Defintion, Examples And A Simplified Explanation Uniform Strain Definition General definition of strains in 1d: The quantity that describes this deformation is called strain. For example, if the gauge length at. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. An object or medium under stress becomes deformed. For each step during deformation,. Generalizes the 1d. Uniform Strain Definition.

From www.thefabricator.com

Getting to know more about the metal you are forming Uniform Strain Definition General definition of strains in 1d: 4.27 (b)) all elements in the block have been deformed the same amount. An object or medium under stress becomes deformed. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. The quantity that describes this deformation is called strain. For example,. Uniform Strain Definition.

From www.youtube.com

What is Strain? Types of Strain Tensile Compressive Shear Uniform Strain Definition General definition of strains in 1d: State of uniform strain (see fig. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. 4.27 (b)) all elements in the block have been deformed the same amount. For example, if the gauge length at. An object or medium under stress. Uniform Strain Definition.

From www.tec-science.com

Tensile test tecscience Uniform Strain Definition Takes the position vector z of any point in the undeformed. An object or medium under stress becomes deformed. Strain is a unitless measure of how much an object gets bigger or smaller from an applied load. Normal strain occurs when the elongation of an object is in response to a normal stress. Engineering strain is defined as the ratio. Uniform Strain Definition.

From www.researchgate.net

1 Definition of transition strain. Download Scientific Diagram Uniform Strain Definition For example, if the gauge length at. In a tensile test, uniform elongation is the percentage the gauge length elongated at peak load relative to the initial gauge length. General definition of strains in 1d: 4.27 (b)) all elements in the block have been deformed the same amount. Strain is a unitless measure of how much an object gets bigger. Uniform Strain Definition.

From material-properties.org

What is Ductility and Toughness Definition Material Properties Uniform Strain Definition Engineering strain is defined as the ratio between the change in length and the original length. State of uniform strain (see fig. Takes the position vector z of any point in the undeformed. For example, if the gauge length at. 4.27 (b)) all elements in the block have been deformed the same amount. For each step during deformation,. Strain is. Uniform Strain Definition.