Aluminum Connecting Rods Vs Steel . A steel connecting rod might last forever, depending on the application. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Steel connecting rods are known for their strength and durability but are heavier. An aluminum connecting rod could last only a handful of passes, too. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. Aluminum rods help reduce weight, making the engine more.

from www.semanticscholar.org

In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Steel connecting rods are known for their strength and durability but are heavier. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. An aluminum connecting rod could last only a handful of passes, too. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. A steel connecting rod might last forever, depending on the application. Aluminum rods help reduce weight, making the engine more.

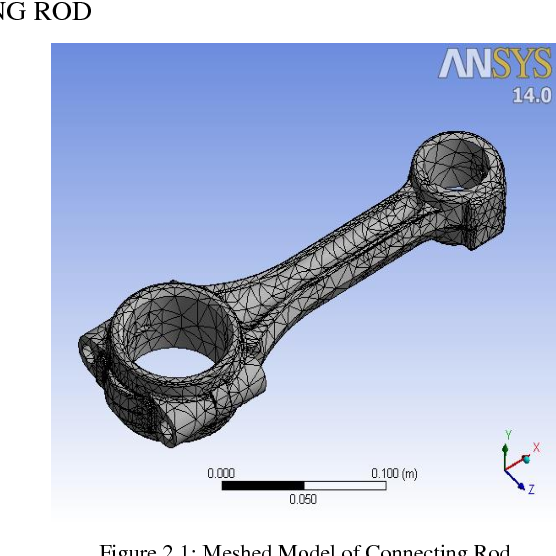

Figure 2.1 from Optimization of Steel connecting Rod by Aluminum

Aluminum Connecting Rods Vs Steel As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. An aluminum connecting rod could last only a handful of passes, too. A steel connecting rod might last forever, depending on the application. Aluminum rods help reduce weight, making the engine more. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. Steel connecting rods are known for their strength and durability but are heavier.

From www.enginelabs.com

Five Things You Need To Know About Aluminum Connecting Rods Aluminum Connecting Rods Vs Steel In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. An aluminum connecting rod could last only a handful of passes, too. Aluminum rods help reduce weight, making the engine more. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. A steel connecting. Aluminum Connecting Rods Vs Steel.

From pauter.com

Connecting Rods Pauter Aluminum Connecting Rods Vs Steel An aluminum connecting rod could last only a handful of passes, too. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Aluminum rods help reduce weight, making the engine more. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under. Aluminum Connecting Rods Vs Steel.

From blog.rrconnectingrods.com

Aluminum, Steel, or Titanium Connecting Rods? Aluminum Connecting Rods Vs Steel Steel connecting rods are known for their strength and durability but are heavier. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. An aluminum connecting rod could last only a handful of passes, too. Aluminum rods help reduce weight, making the engine more. As a general rule of thumb, aluminum rods. Aluminum Connecting Rods Vs Steel.

From www.theengineerspost.com

Connecting Rods Parts, Types, Functions, Applications [PDF] Aluminum Connecting Rods Vs Steel As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. Aluminum rods help reduce weight, making the engine more. A steel connecting rod might last forever, depending on the application. Steel connecting rods are known for their strength and durability but are heavier. Racers and engine builders chose an aluminum rod because. Aluminum Connecting Rods Vs Steel.

From www.semanticscholar.org

Figure 2.1 from Optimization of Steel connecting Rod by Aluminum Aluminum Connecting Rods Vs Steel Aluminum rods help reduce weight, making the engine more. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. An aluminum connecting rod could last only a handful of passes, too. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll. Aluminum Connecting Rods Vs Steel.

From www.tradeindia.com

Aluminum Connecting Rods at Best Price in Rajkot, Gujarat Uma Industries Aluminum Connecting Rods Vs Steel Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect. Aluminum Connecting Rods Vs Steel.

From www.dragzine.com

Five Things You Need To Know About Aluminum Connecting Rods Aluminum Connecting Rods Vs Steel Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. An aluminum connecting rod could last only a handful of passes, too. Steel connecting rods are known for their strength and durability but are heavier. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel. Aluminum Connecting Rods Vs Steel.

From www.nitto.com.au

4G63 Aluminium Connecting Rods Aluminum Connecting Rods Vs Steel Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Aluminum rods help reduce weight, making the engine more. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. An aluminum connecting rod could last only a handful of passes, too. As a general. Aluminum Connecting Rods Vs Steel.

From butlerperformance.com

GRP GRP 5500 Series Custom Aluminum Connecting Rods Image 2 Aluminum Connecting Rods Vs Steel Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Aluminum rods help reduce weight, making the engine more. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. Steel connecting rods are known for their strength and durability but are. Aluminum Connecting Rods Vs Steel.

From hmaking.com

Custom Aluminum Connecting Rods Supplier HM Aluminum Connecting Rods Vs Steel An aluminum connecting rod could last only a handful of passes, too. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. A steel connecting rod might last forever, depending on the application. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more. Aluminum Connecting Rods Vs Steel.

From www.mdpi.com

Materials Free FullText The New Technology of Die of Aluminum Connecting Rods Vs Steel Steel connecting rods are known for their strength and durability but are heavier. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. A steel connecting rod might last forever, depending on the application.. Aluminum Connecting Rods Vs Steel.

From pauter.com

Aluminum Connecting Rods Pauter Aluminum Connecting Rods Vs Steel An aluminum connecting rod could last only a handful of passes, too. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. Aluminum rods help reduce weight, making the engine more. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints.. Aluminum Connecting Rods Vs Steel.

From www.youtube.com

STEEL vs ALUMINUM vs TITANIUM Connecting Rods YouTube Aluminum Connecting Rods Vs Steel Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals. Aluminum Connecting Rods Vs Steel.

From www.youtube.com

Aluminium Conrod Pros and Cons GRP Connecting Rods [TECH TALK] YouTube Aluminum Connecting Rods Vs Steel As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. A steel connecting rod might last forever, depending on the application. An aluminum connecting rod could last only a handful of passes, too. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect. Aluminum Connecting Rods Vs Steel.

From www.bossgoo.com

Nitoyo Racing I Beam Aluminum Connecting Rod, High Quality Nitoyo Aluminum Connecting Rods Vs Steel As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Aluminum rods help reduce weight, making. Aluminum Connecting Rods Vs Steel.

From www.kingtecjetski.com

STEEL vs ALUMINUM vs TITANIUM Connecting Rods KingTec Jet Ski Aluminum Connecting Rods Vs Steel Steel connecting rods are known for their strength and durability but are heavier. An aluminum connecting rod could last only a handful of passes, too. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Aluminum rods help reduce weight, making the engine more. Learn about the pros and cons of steel. Aluminum Connecting Rods Vs Steel.

From www.youtube.com

CNC Machining of Billet Aluminum 7075 Connecting Rod! Part 1 of 2 YouTube Aluminum Connecting Rods Vs Steel Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Aluminum rods help reduce weight, making the engine more. An aluminum connecting rod could last only a handful of passes, too. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under. Aluminum Connecting Rods Vs Steel.

From pauter.com

Aluminum Connecting Rods Pauter Aluminum Connecting Rods Vs Steel A steel connecting rod might last forever, depending on the application. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. In short, the choice between steel, aluminum, and. Aluminum Connecting Rods Vs Steel.

From www.kingtecracing.com

Steel vs Aluminum vs Titanium connecting rods, how to choose the right Aluminum Connecting Rods Vs Steel Steel connecting rods are known for their strength and durability but are heavier. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Learn about the pros and cons of steel and aluminum connecting. Aluminum Connecting Rods Vs Steel.

From www.dragzine.com

Five Things You Need To Know About Aluminum Connecting Rods Aluminum Connecting Rods Vs Steel A steel connecting rod might last forever, depending on the application. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Thus, if you’re setting the deck of a. Aluminum Connecting Rods Vs Steel.

From www.enginelabs.com

MGP 2500 Pro Series Lightweight Billet Aluminum LS Connecting Rods Aluminum Connecting Rods Vs Steel Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. Aluminum rods help reduce weight, making the engine more. An aluminum connecting rod could last only a handful of passes, too. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod.. Aluminum Connecting Rods Vs Steel.

From www.youtube.com

Aluminum Connecting Rods, GRP v/s MGP YouTube Aluminum Connecting Rods Vs Steel Aluminum rods help reduce weight, making the engine more. A steel connecting rod might last forever, depending on the application. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. An aluminum connecting rod. Aluminum Connecting Rods Vs Steel.

From magnusmotorsports.com

Magnus 4G63 Billet Aluminum Connecting Rods Magnus Motorsports Aluminum Connecting Rods Vs Steel Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect. Aluminum Connecting Rods Vs Steel.

From butlerperformance.com

GRP GRP PRO 5500 Series Custom Aluminum Connecting Rods Aluminum Connecting Rods Vs Steel Aluminum rods help reduce weight, making the engine more. A steel connecting rod might last forever, depending on the application. Steel connecting rods are known for their strength and durability but are heavier. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. An aluminum connecting rod could last only a handful. Aluminum Connecting Rods Vs Steel.

From pauter.com

Aluminum Connecting Rods Pauter Aluminum Connecting Rods Vs Steel Steel connecting rods are known for their strength and durability but are heavier. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Aluminum rods help reduce weight, making the engine more. Racers and. Aluminum Connecting Rods Vs Steel.

From hmaking.com

Custom Aluminum Connecting Rods Supplier HM Aluminum Connecting Rods Vs Steel As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. An aluminum connecting rod could last only a handful of passes, too. A steel connecting rod might last forever, depending on the application. Aluminum rods help reduce weight, making the engine more. Thus, if you’re setting the deck of a big block. Aluminum Connecting Rods Vs Steel.

From shop.boostinperformance.com

Rods R&R Aluminum Connecting Rods (DSM / Evo) Boostin Performance Aluminum Connecting Rods Vs Steel Aluminum rods help reduce weight, making the engine more. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. An aluminum connecting rod could last only a handful of. Aluminum Connecting Rods Vs Steel.

From www.stangtv.com

Connecting Rod Tech And Billet Steel Rods StangTV Aluminum Connecting Rods Vs Steel Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Aluminum rods help reduce weight, making the engine more. As a general rule of thumb, aluminum rods tend to. Aluminum Connecting Rods Vs Steel.

From www.dragzine.com

Five Things You Need To Know About Aluminum Connecting Rods Aluminum Connecting Rods Vs Steel A steel connecting rod might last forever, depending on the application. In short, the choice between steel, aluminum, and titanium connecting rods depends on your specific goals and constraints. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. Aluminum rods help reduce weight, making the engine more. An. Aluminum Connecting Rods Vs Steel.

From blog.rrconnectingrods.com

Aluminum, Steel, or Titanium Connecting Rods? Aluminum Connecting Rods Vs Steel Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Aluminum rods help reduce weight, making the engine more. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. Steel connecting rods are known for their strength and durability. Aluminum Connecting Rods Vs Steel.

From www.youtube.com

CPCarrillo BBC Aluminum Connecting rod YouTube Aluminum Connecting Rods Vs Steel Steel connecting rods are known for their strength and durability but are heavier. An aluminum connecting rod could last only a handful of passes, too. Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Aluminum rods help reduce weight, making the engine more. Learn about the pros and cons of steel. Aluminum Connecting Rods Vs Steel.

From pauter.com

Aluminum Connecting Rods Pauter Aluminum Connecting Rods Vs Steel Steel connecting rods are known for their strength and durability but are heavier. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. A steel connecting rod might last forever, depending on the application. Aluminum rods help reduce weight, making the engine more. An aluminum connecting rod could last only a handful. Aluminum Connecting Rods Vs Steel.

From hmaking.com

Custom Aluminum Connecting Rods Supplier HM Aluminum Connecting Rods Vs Steel Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under high loads. Aluminum rods help reduce weight, making the engine more. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. A steel connecting rod might last forever,. Aluminum Connecting Rods Vs Steel.

From hmaking.com

Custom Aluminum Connecting Rods Supplier HM Aluminum Connecting Rods Vs Steel Thus, if you’re setting the deck of a big block for.050″ total piston to head, you’ll want to. Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. Racers and engine builders chose an aluminum rod because of the deformation, which is easier on the piston and crank under. Aluminum Connecting Rods Vs Steel.

From pauter.com

Aluminum Connecting Rods Pauter Aluminum Connecting Rods Vs Steel Learn about the pros and cons of steel and aluminum connecting rods for racing engines, and how they affect compression ratio,. As a general rule of thumb, aluminum rods tend to stretch less than.010″ more than a steel rod. A steel connecting rod might last forever, depending on the application. Thus, if you’re setting the deck of a big block. Aluminum Connecting Rods Vs Steel.