Mig Welding Wire Help . Standard sizes range from 0.023. Joint design, position and other factors affect results and settings. The following basic mig welding settings are for welding steel with solid wire. This wire diameter is suitable for various material. Mig welding requires shielding the weld from the atmosphere. A mig wire size chart provides recommended wire diameters for different metal thicknesses. To do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. The letter l stands for the maximum carbon content of 0.03%, which. Here you can find articles, videos, webinars and all things. It is used with 75/25 ar/co2 or 100% co2. Whether you're new to mig welding or want to hone your skills, you're in the right place.

from www.icollector.com

It is used with 75/25 ar/co2 or 100% co2. Joint design, position and other factors affect results and settings. The following basic mig welding settings are for welding steel with solid wire. To do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. This wire diameter is suitable for various material. The letter l stands for the maximum carbon content of 0.03%, which. Standard sizes range from 0.023. Mig welding requires shielding the weld from the atmosphere. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. A mig wire size chart provides recommended wire diameters for different metal thicknesses.

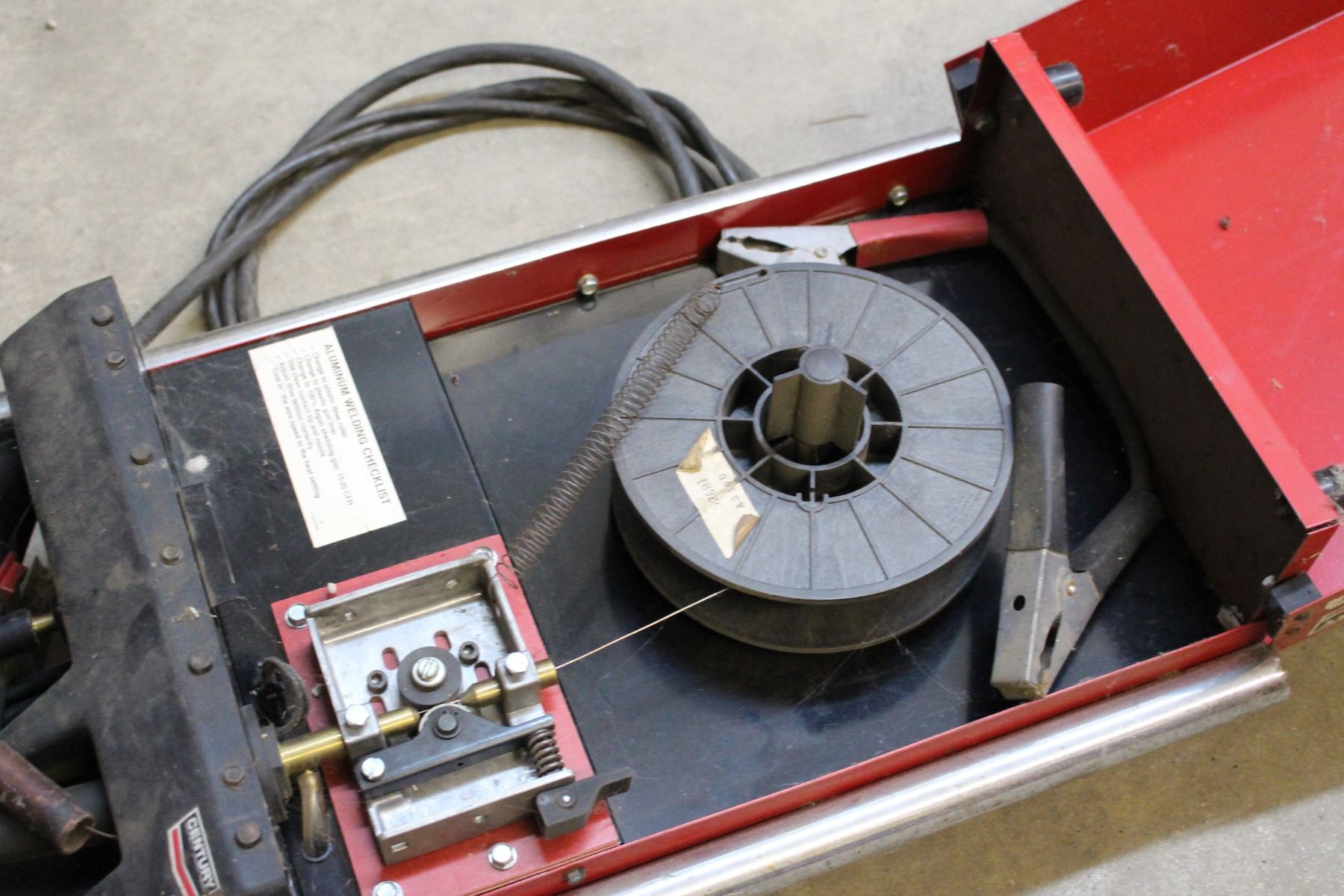

Century Portable MIG Wire Feed Welder, With Manual And Lots Of Accessories

Mig Welding Wire Help The following basic mig welding settings are for welding steel with solid wire. Whether you're new to mig welding or want to hone your skills, you're in the right place. Standard sizes range from 0.023. The following basic mig welding settings are for welding steel with solid wire. To do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. It is used with 75/25 ar/co2 or 100% co2. A mig wire size chart provides recommended wire diameters for different metal thicknesses. This wire diameter is suitable for various material. The letter l stands for the maximum carbon content of 0.03%, which. Mig welding requires shielding the weld from the atmosphere. Joint design, position and other factors affect results and settings. Here you can find articles, videos, webinars and all things.

From ar.inspiredpencil.com

Mig Welding Diagram Mig Welding Wire Help Joint design, position and other factors affect results and settings. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Mig welding requires shielding the weld from the atmosphere. The following basic mig welding settings are for welding steel with solid wire. Typically, the mig wire process is recognized as having very low hydrogen in the deposit.. Mig Welding Wire Help.

From www.tlbox.com

5 Best Wire Feed Welder A tool comes in handy Tool Box Mig Welding Wire Help Whether you're new to mig welding or want to hone your skills, you're in the right place. The letter l stands for the maximum carbon content of 0.03%, which. The following basic mig welding settings are for welding steel with solid wire. It is used with 75/25 ar/co2 or 100% co2. To do this, direct shielding gas over the weld. Mig Welding Wire Help.

From www.nextmart.com.au

0.8mm Gasless Mig Welding Wire Dynamic Power Mig Welding Wire Help Whether you're new to mig welding or want to hone your skills, you're in the right place. The letter l stands for the maximum carbon content of 0.03%, which. Joint design, position and other factors affect results and settings. A mig wire size chart provides recommended wire diameters for different metal thicknesses. The following basic mig welding settings are for. Mig Welding Wire Help.

From www.twi-global.com

Metal Inert Gas (MIG) Welding Process and Applications TWI Mig Welding Wire Help Whether you're new to mig welding or want to hone your skills, you're in the right place. The letter l stands for the maximum carbon content of 0.03%, which. A mig wire size chart provides recommended wire diameters for different metal thicknesses. It is used with 75/25 ar/co2 or 100% co2. This wire diameter is suitable for various material. Typically,. Mig Welding Wire Help.

From www.aliexpress.com

IGBT MMA/MIG/Flux wire/Solid wire welding Machine Dual voltage 110V Mig Welding Wire Help To do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. The following basic mig welding settings are for welding steel with solid wire. This wire diameter is suitable for various material. Mig welding requires shielding the weld from the atmosphere. Standard sizes range from 0.023. Whether you're new. Mig Welding Wire Help.

From www.liveauctionworld.com

LINCOLN ELECTRIC 256 POWER MIG WELDER WITH SPOOL OF COPPER WIRE Mig Welding Wire Help Here you can find articles, videos, webinars and all things. This wire diameter is suitable for various material. Mig welding requires shielding the weld from the atmosphere. The letter l stands for the maximum carbon content of 0.03%, which. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. Whether you're new to mig welding. Mig Welding Wire Help.

From wiringdiagram.2bitboer.com

Ya205 Mig Welder Wiring Diagram Wiring Diagram Mig Welding Wire Help Whether you're new to mig welding or want to hone your skills, you're in the right place. This wire diameter is suitable for various material. The following basic mig welding settings are for welding steel with solid wire. Standard sizes range from 0.023. Joint design, position and other factors affect results and settings. A mig wire size chart provides recommended. Mig Welding Wire Help.

From www.amcoweld.com.sg

Kemppi Welding Machine Amcoweld Inc Pte Ltd Mig Welding Wire Help Typically, the mig wire process is recognized as having very low hydrogen in the deposit. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Whether you're new to mig welding or want to hone your skills, you're in the right place. To do this, direct shielding gas over the weld area, and control the flow of. Mig Welding Wire Help.

From www.millerwelds.com

Tips for Welding Sheet Metal With MIG or TIG MillerWelds Mig Welding Wire Help It is used with 75/25 ar/co2 or 100% co2. To do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. The following basic mig welding settings are for welding steel with solid wire. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. Here. Mig Welding Wire Help.

From www.homedepot.com

Lincoln Electric 140 Amp Weld Pak 140 HD MIG Wire Feed Welder with Mig Welding Wire Help The following basic mig welding settings are for welding steel with solid wire. Here you can find articles, videos, webinars and all things. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. Joint design, position and other factors affect results and settings. A mig wire size chart provides recommended wire diameters for different metal. Mig Welding Wire Help.

From www.thefabricator.com

Twinwire GMAW meets the pipe welding cobot Mig Welding Wire Help It is used with 75/25 ar/co2 or 100% co2. Joint design, position and other factors affect results and settings. Whether you're new to mig welding or want to hone your skills, you're in the right place. Mig welding requires shielding the weld from the atmosphere. This wire diameter is suitable for various material. Here you can find articles, videos, webinars. Mig Welding Wire Help.

From www.aliexpress.com

Buy 1PC Mig Welder Wire Feed Drive Roller 25mm Mig Welding Wire Help The letter l stands for the maximum carbon content of 0.03%, which. Here you can find articles, videos, webinars and all things. This wire diameter is suitable for various material. To do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. The following basic mig welding settings are for. Mig Welding Wire Help.

From angola.desertcart.com

HITBOX 5 in 1 Aluminum Mig Welder 200Amp 240V Smart Control Gas Mig Welding Wire Help Joint design, position and other factors affect results and settings. Here you can find articles, videos, webinars and all things. The letter l stands for the maximum carbon content of 0.03%, which. It is used with 75/25 ar/co2 or 100% co2. Whether you're new to mig welding or want to hone your skills, you're in the right place. The following. Mig Welding Wire Help.

From makemoneywelding.com

MIG Welding Wire Essentials A Guide to Types & Uses Mig Welding Wire Help Joint design, position and other factors affect results and settings. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. It is used with 75/25 ar/co2 or 100% co2. The following basic mig welding settings are for welding steel with solid wire. This wire diameter is suitable for various material. A mig wire size chart. Mig Welding Wire Help.

From www.icollector.com

Century Portable MIG Wire Feed Welder, With Manual And Lots Of Accessories Mig Welding Wire Help The following basic mig welding settings are for welding steel with solid wire. A mig wire size chart provides recommended wire diameters for different metal thicknesses. It is used with 75/25 ar/co2 or 100% co2. This wire diameter is suitable for various material. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. Mig welding. Mig Welding Wire Help.

From www.bidspotter.com

SOLAR 2114 TOTE MIG II WIRE FEED WELDER, 75 AMP, MDL. 117045000, S/N Mig Welding Wire Help The following basic mig welding settings are for welding steel with solid wire. Standard sizes range from 0.023. Whether you're new to mig welding or want to hone your skills, you're in the right place. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Mig welding requires shielding the weld from the atmosphere. Typically, the mig. Mig Welding Wire Help.

From airgasthinks.com

MIG Busters Are You Using the Wrong Size MIG Wire? Mig Welding Wire Help Here you can find articles, videos, webinars and all things. Standard sizes range from 0.023. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. The letter l stands for the maximum carbon content of 0.03%, which. Joint design, position and other factors affect results and settings. Mig welding requires shielding the weld from the. Mig Welding Wire Help.

From amico.welderguide.biz

MTS205 Amp MIG Wire Feed Welder Flux Cored Mig Welding Wire Help Here you can find articles, videos, webinars and all things. Mig welding requires shielding the weld from the atmosphere. Standard sizes range from 0.023. Whether you're new to mig welding or want to hone your skills, you're in the right place. A mig wire size chart provides recommended wire diameters for different metal thicknesses. The letter l stands for the. Mig Welding Wire Help.

From www.aliexpress.com

120SN C1 double drive weld feeder assembly co2 mig welding wire feeder Mig Welding Wire Help Joint design, position and other factors affect results and settings. This wire diameter is suitable for various material. A mig wire size chart provides recommended wire diameters for different metal thicknesses. The following basic mig welding settings are for welding steel with solid wire. Here you can find articles, videos, webinars and all things. It is used with 75/25 ar/co2. Mig Welding Wire Help.

From www.gz-supplies.com

Buy Online MIG/MAG Gasless welding wire 1mm (gaslessWeld1mm) Mig Welding Wire Help It is used with 75/25 ar/co2 or 100% co2. To do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. Mig welding requires shielding the weld from the atmosphere. Here you can find articles, videos, webinars and all things. The following basic mig welding settings are for welding steel. Mig Welding Wire Help.

From klaoeyttq.blob.core.windows.net

How To Use A Mig Welder Step By Step at Thomas Moose blog Mig Welding Wire Help This wire diameter is suitable for various material. Joint design, position and other factors affect results and settings. A mig wire size chart provides recommended wire diameters for different metal thicknesses. It is used with 75/25 ar/co2 or 100% co2. The letter l stands for the maximum carbon content of 0.03%, which. Typically, the mig wire process is recognized as. Mig Welding Wire Help.

From www.aliexpress.com

Buy 1 Roll 1kg 0.8mm Gasless Mig Welding Wire Flux Mig Welding Wire Help This wire diameter is suitable for various material. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. It is used with 75/25 ar/co2 or 100% co2. Here you can find articles, videos, webinars and all things. To do this, direct shielding. Mig Welding Wire Help.

From www.grainger.com

WESTWARD 550 lb Carbon Steel Drum Mig Welding Wire with 0.045 in Mig Welding Wire Help Joint design, position and other factors affect results and settings. To do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. It is used with 75/25 ar/co2 or 100% co2. The letter l stands for the maximum carbon content of 0.03%, which. Here you can find articles, videos, webinars. Mig Welding Wire Help.

From www.mig-welding.co.uk

Installing MIG Wire and Setting Wire Feed Tension Mig Welding Wire Help Joint design, position and other factors affect results and settings. Whether you're new to mig welding or want to hone your skills, you're in the right place. This wire diameter is suitable for various material. Standard sizes range from 0.023. Mig welding requires shielding the weld from the atmosphere. The following basic mig welding settings are for welding steel with. Mig Welding Wire Help.

From bid.ableauctions.ca

CRAFTSMAN WIREFEED MIG WELDER Able Auctions Mig Welding Wire Help Whether you're new to mig welding or want to hone your skills, you're in the right place. Here you can find articles, videos, webinars and all things. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. This wire diameter is suitable for various material. The letter l stands for the maximum carbon content of. Mig Welding Wire Help.

From www.aliexpress.com

Wire Feeder DC 24V Double Drive Welding Wire Feeding Assembly ZK 76ZY Mig Welding Wire Help Joint design, position and other factors affect results and settings. It is used with 75/25 ar/co2 or 100% co2. Mig welding requires shielding the weld from the atmosphere. This wire diameter is suitable for various material. A mig wire size chart provides recommended wire diameters for different metal thicknesses. The following basic mig welding settings are for welding steel with. Mig Welding Wire Help.

From www.dragzine.com

MIGWelding Basics To Help You Correctly Melt Metal Mig Welding Wire Help To do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. The following basic mig welding settings are for welding steel with solid wire. Joint design, position and other factors affect results and settings. Here you can find articles, videos, webinars and all things. Whether you're new to mig. Mig Welding Wire Help.

From www.amazon.com

PrimeWeld MIG180 Mig Welder, 180 Amp Wire Feed Welding Machine With Mig Welding Wire Help The letter l stands for the maximum carbon content of 0.03%, which. This wire diameter is suitable for various material. Standard sizes range from 0.023. Mig welding requires shielding the weld from the atmosphere. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Joint design, position and other factors affect results and settings. The following basic. Mig Welding Wire Help.

From www.homedepot.com

Lincoln Electric 216 Amp Power MIG 216 MIG Wire Feed Welder with Magnum Mig Welding Wire Help Whether you're new to mig welding or want to hone your skills, you're in the right place. Joint design, position and other factors affect results and settings. This wire diameter is suitable for various material. Standard sizes range from 0.023. It is used with 75/25 ar/co2 or 100% co2. Mig welding requires shielding the weld from the atmosphere. The letter. Mig Welding Wire Help.

From wiringdiagram.2bitboer.com

Ya205 Mig Welder Wiring Diagram Wiring Diagram Mig Welding Wire Help Whether you're new to mig welding or want to hone your skills, you're in the right place. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Here you can find articles, videos, webinars and all things. Standard sizes range from 0.023. Joint design, position and other factors affect results and settings. To do this, direct shielding. Mig Welding Wire Help.

From www.lsxmag.com

MIGWelding Basics To Help You Correctly Melt Metal Mig Welding Wire Help The following basic mig welding settings are for welding steel with solid wire. Joint design, position and other factors affect results and settings. Whether you're new to mig welding or want to hone your skills, you're in the right place. Here you can find articles, videos, webinars and all things. To do this, direct shielding gas over the weld area,. Mig Welding Wire Help.

From www.hollyfab.com

Common Welding Methods Mig Welding Wire Help Typically, the mig wire process is recognized as having very low hydrogen in the deposit. Standard sizes range from 0.023. This wire diameter is suitable for various material. Mig welding requires shielding the weld from the atmosphere. The following basic mig welding settings are for welding steel with solid wire. To do this, direct shielding gas over the weld area,. Mig Welding Wire Help.

From www.ljwelding.com

MIG Welding Boom Mount Mig Welding Wire Help The following basic mig welding settings are for welding steel with solid wire. Here you can find articles, videos, webinars and all things. Mig welding requires shielding the weld from the atmosphere. Standard sizes range from 0.023. Whether you're new to mig welding or want to hone your skills, you're in the right place. Joint design, position and other factors. Mig Welding Wire Help.

From weldguru.com

What is GMAW (MIG Welding) & How Does it Work? Weld Guru Mig Welding Wire Help The letter l stands for the maximum carbon content of 0.03%, which. To do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. Mig welding requires shielding the weld from the atmosphere. Joint design, position and other factors affect results and settings. Here you can find articles, videos, webinars. Mig Welding Wire Help.

From www.liveauctionworld.com

Lincoln Electric Wire Feed MIG Welder SP100 Mig Welding Wire Help Standard sizes range from 0.023. The following basic mig welding settings are for welding steel with solid wire. The letter l stands for the maximum carbon content of 0.03%, which. Typically, the mig wire process is recognized as having very low hydrogen in the deposit. Mig welding requires shielding the weld from the atmosphere. Whether you're new to mig welding. Mig Welding Wire Help.