Tube Velocity Heat Exchanger . There are thus three heat transfer. Q the wall thickness of heat exchanger tubes is. The actual maximum velocity for this application varies with heat exchanger diameter and nozzle opening sizes. Some copper tube selections may have. Tube side velocity is between 0.9 to 2.4 m/s for liquid service; §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). One can increase the tube side heat transfer coefficient by increasing. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Setting shell side and tube side velocity limits. Setting shell side and tube side pressure drop design. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. Selection of heat transfer models and.

from www.chegg.com

The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. Selection of heat transfer models and. Setting shell side and tube side pressure drop design. Tube side velocity is between 0.9 to 2.4 m/s for liquid service; For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. One can increase the tube side heat transfer coefficient by increasing. Setting shell side and tube side velocity limits. Some copper tube selections may have. Q the wall thickness of heat exchanger tubes is. §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec).

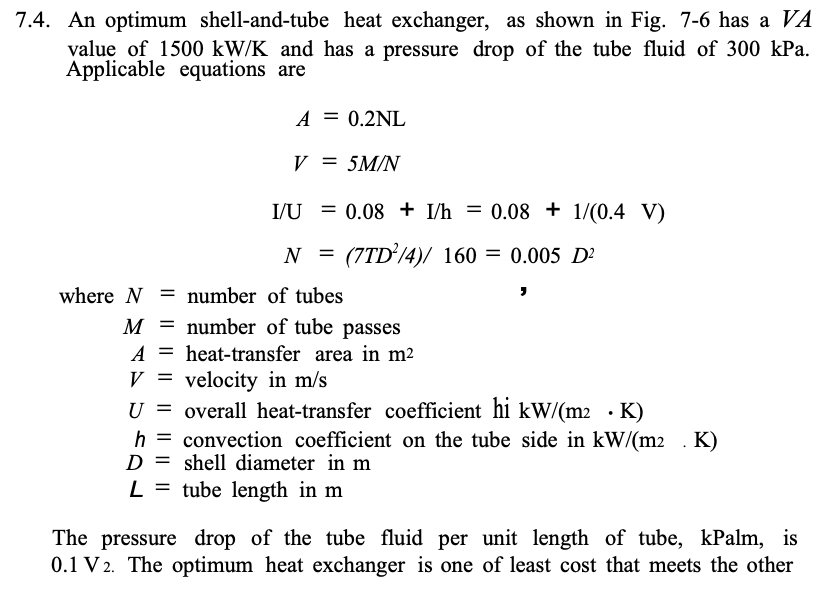

7.4. An optimum shellandtube heat exchanger, as

Tube Velocity Heat Exchanger Selection of heat transfer models and. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Q the wall thickness of heat exchanger tubes is. §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). Tube side velocity is between 0.9 to 2.4 m/s for liquid service; Selection of heat transfer models and. The actual maximum velocity for this application varies with heat exchanger diameter and nozzle opening sizes. Setting shell side and tube side velocity limits. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. There are thus three heat transfer. Some copper tube selections may have. One can increase the tube side heat transfer coefficient by increasing. Setting shell side and tube side pressure drop design.

From www.youtube.com

Calculating Fluid Contact Area and Tube Length for Counter Flow Heat Tube Velocity Heat Exchanger Tube side velocity is between 0.9 to 2.4 m/s for liquid service; Setting shell side and tube side velocity limits. There are thus three heat transfer. Selection of heat transfer models and. Setting shell side and tube side pressure drop design. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it. Tube Velocity Heat Exchanger.

From helecu.com

All About Shell And Tube Heat Exchangers What You Need To Know (2022) Tube Velocity Heat Exchanger Selection of heat transfer models and. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. Q the wall thickness of heat exchanger tubes is. Setting shell side and tube side pressure drop design. There are thus three heat transfer. The optimum thermal. Tube Velocity Heat Exchanger.

From www.iqsdirectory.com

Shell and Tube Heat Exchanger What Is It? Types, Process Tube Velocity Heat Exchanger The actual maximum velocity for this application varies with heat exchanger diameter and nozzle opening sizes. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Selection of heat transfer models and. One. Tube Velocity Heat Exchanger.

From www.iqsdirectory.com

Shell and Tube Heat Exchanger What Is It? Types, Process Tube Velocity Heat Exchanger One can increase the tube side heat transfer coefficient by increasing. §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). Setting shell side and tube side pressure drop design. Some copper tube selections may have. Selection of heat transfer models and. The basic component of a heat exchanger can be viewed. Tube Velocity Heat Exchanger.

From engineerexcel.com

Parallel Heat Exchangers Explained EngineerExcel Tube Velocity Heat Exchanger There are thus three heat transfer. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. Q the wall thickness of heat exchanger tubes is. Some copper tube selections may have. One can increase the tube side heat transfer coefficient by increasing. The actual maximum velocity for this application. Tube Velocity Heat Exchanger.

From arvengtraining.com

Basics of Shell & Tube Heat Exchangers Arveng Training & Engineering Tube Velocity Heat Exchanger Selection of heat transfer models and. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Tube side velocity is between 0.9 to 2.4 m/s for liquid service; Some copper tube selections may have. Setting shell side and tube side velocity limits. §tube side velocity for water and similar liquids ranges from 0.9 to. Tube Velocity Heat Exchanger.

From www.flexachem.com

Heat Exchangersstatic mixers Tube Velocity Heat Exchanger Tube side velocity is between 0.9 to 2.4 m/s for liquid service; For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Selection of heat transfer models and. Some copper tube selections may have. The actual maximum velocity for this application varies with heat exchanger diameter and nozzle opening sizes. One can increase the. Tube Velocity Heat Exchanger.

From mavink.com

Types Of Heat Exchangers Tube Velocity Heat Exchanger Selection of heat transfer models and. Some copper tube selections may have. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Setting shell side and tube side pressure drop design. §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). Setting shell side and tube. Tube Velocity Heat Exchanger.

From www.grainger.com

STANDARD XCHANGE Shell and Tube Heat Exchanger, Brass, Length (In.) 30. Tube Velocity Heat Exchanger The actual maximum velocity for this application varies with heat exchanger diameter and nozzle opening sizes. Selection of heat transfer models and. Tube side velocity is between 0.9 to 2.4 m/s for liquid service; Setting shell side and tube side velocity limits. Q the wall thickness of heat exchanger tubes is. One can increase the tube side heat transfer coefficient. Tube Velocity Heat Exchanger.

From lasopaadvantage181.weebly.com

Velocity Of Fluid Number Of Tubes Heat Exchanger lasopaadvantage Tube Velocity Heat Exchanger Setting shell side and tube side velocity limits. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Selection of heat transfer models and. One can increase. Tube Velocity Heat Exchanger.

From mikaelabilrogers.blogspot.com

6 Pass Heat Exchanger MikaelabilRogers Tube Velocity Heat Exchanger There are thus three heat transfer. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). Some copper tube selections may have. Setting shell side and tube side pressure drop design.. Tube Velocity Heat Exchanger.

From www.chegg.com

7.4. An optimum shellandtube heat exchanger, as Tube Velocity Heat Exchanger The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. Some copper tube selections may have. Q the wall thickness of heat exchanger tubes is. There are thus three heat transfer. Tube side velocity is between 0.9 to 2.4 m/s for liquid service;. Tube Velocity Heat Exchanger.

From www.vrogue.co

Flow Arrangements In Heat Exchangers Types Of Flow In vrogue.co Tube Velocity Heat Exchanger Some copper tube selections may have. Q the wall thickness of heat exchanger tubes is. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec).. Tube Velocity Heat Exchanger.

From www.torq-n-seal.com

How Do Shell And Tube Heat Exchangers Work? Torq N' Seal® Tube Velocity Heat Exchanger Some copper tube selections may have. Setting shell side and tube side pressure drop design. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. §tube side. Tube Velocity Heat Exchanger.

From www.researchgate.net

1.3.1 A shellandtube [11] heat exchanger one shell pass and one tube Tube Velocity Heat Exchanger Tube side velocity is between 0.9 to 2.4 m/s for liquid service; Setting shell side and tube side pressure drop design. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Q the wall thickness of heat exchanger tubes is. The optimum thermal design of a shell and tube heat exchanger involves the consideration. Tube Velocity Heat Exchanger.

From www.researchgate.net

Pressure drop with velocity in the finnedtube heat exchanger Tube Velocity Heat Exchanger Some copper tube selections may have. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. Selection of heat transfer models and. Q the wall thickness of heat exchanger tubes is. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. The actual. Tube Velocity Heat Exchanger.

From hassanelbanhawi.com

Heat Exchangers Classification, governing Equations and Calculation Tools. Tube Velocity Heat Exchanger The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. Tube side velocity is between 0.9 to 2.4 m/s for liquid service; One can increase the tube side heat transfer coefficient by increasing. There are thus three heat transfer. Setting shell side and. Tube Velocity Heat Exchanger.

From www.myxxgirl.com

Heat Exchanger Piping Schematic My XXX Hot Girl Tube Velocity Heat Exchanger Setting shell side and tube side velocity limits. The actual maximum velocity for this application varies with heat exchanger diameter and nozzle opening sizes. One can increase the tube side heat transfer coefficient by increasing. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. Tube side velocity is. Tube Velocity Heat Exchanger.

From fasrmodels239.weebly.com

Velocity Of Fluid Number Of Tubes Heat Exchanger fasrmodels Tube Velocity Heat Exchanger Setting shell side and tube side velocity limits. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Selection of heat transfer models and. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. Some copper tube. Tube Velocity Heat Exchanger.

From savree.com

Shell and Tube Heat Exchanger Explained saVRee saVRee Tube Velocity Heat Exchanger There are thus three heat transfer. Some copper tube selections may have. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Setting shell side and tube side pressure drop design. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing. Tube Velocity Heat Exchanger.

From www.pinterest.com

Industrial Enerquip Shell & Tube Heat Exchangers Heat exchanger Tube Velocity Heat Exchanger The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. Selection of heat transfer models and. Setting shell side and tube side pressure drop design. Setting shell side and tube side velocity limits. There are thus three heat transfer. Q the wall thickness of heat exchanger tubes is. The. Tube Velocity Heat Exchanger.

From www.chegg.com

1. (20 points) A shellandtube heat exchanger (1 Tube Velocity Heat Exchanger Setting shell side and tube side pressure drop design. One can increase the tube side heat transfer coefficient by increasing. §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). Tube side velocity is between 0.9 to 2.4 m/s for liquid service; The optimum thermal design of a shell and tube heat. Tube Velocity Heat Exchanger.

From thepipingtalk.com

Types of Heat Exchanger according to construction The piping talk Tube Velocity Heat Exchanger §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). Some copper tube selections may have. Selection of heat transfer models and. One can increase the tube side heat transfer coefficient by increasing. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. Tube side velocity. Tube Velocity Heat Exchanger.

From www.youtube.com

How to find out the maximum effectiveness of a heat exchanger YouTube Tube Velocity Heat Exchanger Setting shell side and tube side velocity limits. Tube side velocity is between 0.9 to 2.4 m/s for liquid service; Some copper tube selections may have. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. Setting shell side and tube side pressure drop design. Selection of heat transfer. Tube Velocity Heat Exchanger.

From www.researchgate.net

The configurations of finned round and flat tube heat exchanger Tube Velocity Heat Exchanger Setting shell side and tube side velocity limits. Some copper tube selections may have. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can. Q the wall thickness of heat exchanger tubes is. One can increase the tube side heat transfer coefficient by increasing. §tube side velocity for water. Tube Velocity Heat Exchanger.

From www.mdpi.com

Energies Free FullText Influence of Perforated Fin on Flow Tube Velocity Heat Exchanger §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). One can increase the tube side heat transfer coefficient by increasing. Setting shell side and tube side velocity limits. Setting shell side and tube side pressure drop design. The optimum thermal design of a shell and tube heat exchanger involves the consideration. Tube Velocity Heat Exchanger.

From www.nexson-group.com

Spiral plate heat exchanger for liquid duties with high pressure and Tube Velocity Heat Exchanger Setting shell side and tube side velocity limits. Q the wall thickness of heat exchanger tubes is. Setting shell side and tube side pressure drop design. There are thus three heat transfer. One can increase the tube side heat transfer coefficient by increasing. The basic component of a heat exchanger can be viewed as a tube with one fluid running. Tube Velocity Heat Exchanger.

From kegero.com

What Is It? Types, Process (2024) Tube Velocity Heat Exchanger Setting shell side and tube side pressure drop design. Q the wall thickness of heat exchanger tubes is. Setting shell side and tube side velocity limits. There are thus three heat transfer. §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). For single phase heat transfer coefficients, higher fluid velocity increases. Tube Velocity Heat Exchanger.

From www.researchgate.net

(PDF) Analysis of FlowInduced Vibrations in a Heat Exchanger Tube Tube Velocity Heat Exchanger Setting shell side and tube side pressure drop design. The actual maximum velocity for this application varies with heat exchanger diameter and nozzle opening sizes. Selection of heat transfer models and. Setting shell side and tube side velocity limits. Tube side velocity is between 0.9 to 2.4 m/s for liquid service; Q the wall thickness of heat exchanger tubes is.. Tube Velocity Heat Exchanger.

From www.myhvaccoach.com

shellandtubeheatexchangermodel Tube Velocity Heat Exchanger For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. There are thus three heat transfer. Some copper tube selections may have. Selection of heat transfer models and. Setting shell side and tube side pressure drop design. Setting shell side and tube side velocity limits. The actual maximum velocity for this application varies with. Tube Velocity Heat Exchanger.

From www.chegg.com

Solved Question 3 (30) A counterflow doublepipe heat Tube Velocity Heat Exchanger §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). There are thus three heat transfer. Some copper tube selections may have. One can increase the tube side heat transfer coefficient by increasing. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it. Tube Velocity Heat Exchanger.

From ormandygroup.com

Shell and tube heat exchangers Ormandy Rycroft Engineering Tube Velocity Heat Exchanger Q the wall thickness of heat exchanger tubes is. There are thus three heat transfer. Some copper tube selections may have. Selection of heat transfer models and. Tube side velocity is between 0.9 to 2.4 m/s for liquid service; The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another. Tube Velocity Heat Exchanger.

From savree.com

Shell and Tube Heat Exchanger Explained saVRee saVRee Tube Velocity Heat Exchanger Selection of heat transfer models and. §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). Some copper tube selections may have. The basic component of a heat exchanger can be viewed as a tube with one fluid running through it and another fluid flowing by on the outside. The optimum thermal. Tube Velocity Heat Exchanger.

From www.slideserve.com

PPT Heat exchangers PowerPoint Presentation, free download ID3345466 Tube Velocity Heat Exchanger There are thus three heat transfer. Setting shell side and tube side velocity limits. One can increase the tube side heat transfer coefficient by increasing. Selection of heat transfer models and. Tube side velocity is between 0.9 to 2.4 m/s for liquid service; For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. §tube. Tube Velocity Heat Exchanger.

From thepipingtalk.com

Types of Heat Exchanger according to construction The piping talk Tube Velocity Heat Exchanger §tube side velocity for water and similar liquids ranges from 0.9 to 2.4 m/s (3 to 8 ft/sec). Q the wall thickness of heat exchanger tubes is. Selection of heat transfer models and. For single phase heat transfer coefficients, higher fluid velocity increases heat transfer coefficients and pressure drop. The optimum thermal design of a shell and tube heat exchanger. Tube Velocity Heat Exchanger.