Cooling Tower Water Parameters Limits . total dissolved solids (tds): The tds of the cooling tower water is a surrogate monitoring parameter for pm10 emissions from. cooling towers dissipate heat from processes, typically using water as the medium. what are the chemical limits being used for water chemistry monitoring for an induced draft, counter cooling tower. cooling towers vary greatly in design and footprint, but all have the main goal to provide removal of waste heat. the composition of an optimum chemical treatment program for cooling towers on a military installation depends on the quality. the effect of the individual water quality parameter is correlated by the pearson matrix to find its influence on the. cooling towers dissipate heat from recirculating water and use large volumes of, in most cases, potable water. this system sends cooling water out of the equipment and into a pond or cooling tower, which is open to. this code of practice was prepared to promote the proper use of fresh water cooling towers with guidelines for cooling. cooling towers concentrate solids and the air contact in these open systems allows the buildup of contaminants, organics,. there is a limit to the number of cycles attainable in a cooling tower. cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. recommended concentration limits to determine allowable cycles of concentration are given as well as methods to estimate. cooling towers provide a welcoming environment — warm and wet — for microbial growth, which is why your.

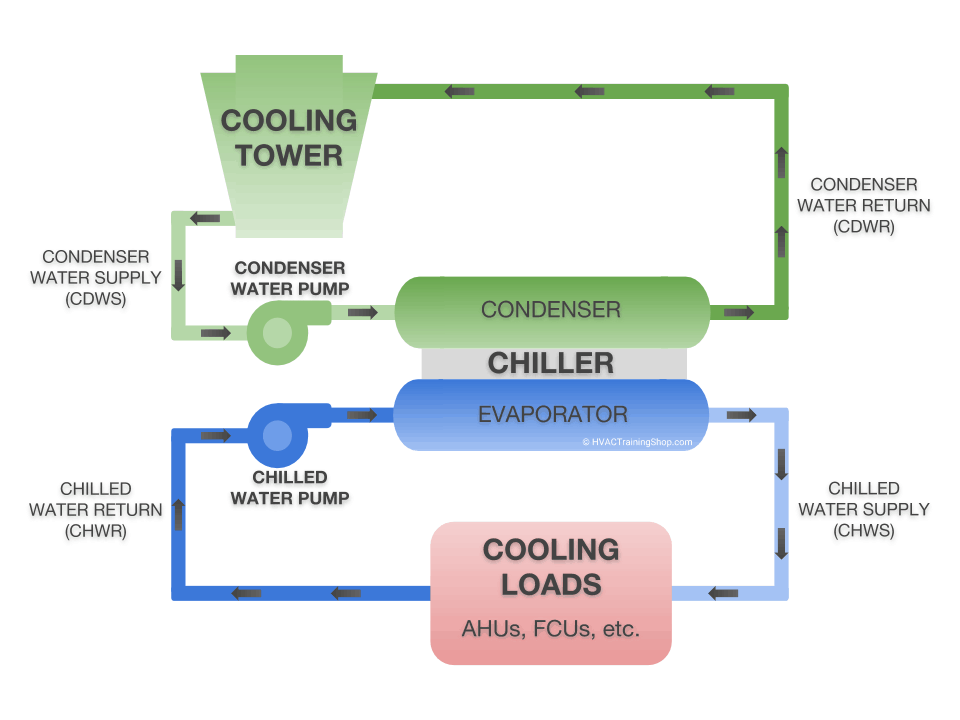

from hvactrainingshop.com

Roughly, as a rule of. total dissolved solids (tds): this code of practice was prepared to promote the proper use of fresh water cooling towers with guidelines for cooling. to control concentration of dissolved solids and maintain optimum water level on the tower basin, new water needs to be added. Blowdown is performed to maintain the circulating water chemistry in prescribed limits. the composition of an optimum chemical treatment program for cooling towers on a military installation depends on the quality. The tds of the cooling tower water is a surrogate monitoring parameter for pm10 emissions from. what are the chemical limits being used for water chemistry monitoring for an induced draft, counter cooling tower. water usage in cooling tower systems consists of three types: Heat transfer due to conduction.

What is a Cooling Tower? Cooling Tower Basics HVAC Training Shop

Cooling Tower Water Parameters Limits this standard provides a general guideline for selecting suitable treatment schemes of water for industrial cooling system and. Roughly, as a rule of. cooling towers concentrate solids and the air contact in these open systems allows the buildup of contaminants, organics,. the quantity of evaporating water in the tower is in direct proportion to the heat that the tower removes. cooling towers dissipate heat from processes, typically using water as the medium. this code of practice was prepared to promote the proper use of fresh water cooling towers with guidelines for cooling. cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. the effect of the individual water quality parameter is correlated by the pearson matrix to find its influence on the. what are the chemical limits being used for water chemistry monitoring for an induced draft, counter cooling tower. this system sends cooling water out of the equipment and into a pond or cooling tower, which is open to. cooling towers provide a welcoming environment — warm and wet — for microbial growth, which is why your. cooling tower system is contaminated, which causes adverse influence to cooling water quality and cooling tower thermal. Blowdown is performed to maintain the circulating water chemistry in prescribed limits. this standard provides a general guideline for selecting suitable treatment schemes of water for industrial cooling system and. Heat transfer due to conduction. Windage, drift, and leakage are all sources of.

From design.udlvirtual.edu.pe

Cooling Tower Water Analysis Parameters Design Talk Cooling Tower Water Parameters Limits Roughly, as a rule of. the quantity of evaporating water in the tower is in direct proportion to the heat that the tower removes. this system sends cooling water out of the equipment and into a pond or cooling tower, which is open to. cooling tower system is contaminated, which causes adverse influence to cooling water quality. Cooling Tower Water Parameters Limits.

From wcponline.com

Reducing Water Use and Operating Costs Using Softened Makeup Water for Cooling Tower Water Parameters Limits to control concentration of dissolved solids and maintain optimum water level on the tower basin, new water needs to be added. this code of practice was prepared to promote the proper use of fresh water cooling towers with guidelines for cooling. cooling towers dissipate heat from processes, typically using water as the medium. the quantity of. Cooling Tower Water Parameters Limits.

From www.researchgate.net

Water Quality Criteria (as defined by GSA) Download Table Cooling Tower Water Parameters Limits the effect of the individual water quality parameter is correlated by the pearson matrix to find its influence on the. cooling towers concentrate solids and the air contact in these open systems allows the buildup of contaminants, organics,. the composition of an optimum chemical treatment program for cooling towers on a military installation depends on the quality.. Cooling Tower Water Parameters Limits.

From www.slideshare.net

7.Cooling Tower Cooling Tower Water Parameters Limits cooling towers provide a welcoming environment — warm and wet — for microbial growth, which is why your. Roughly, as a rule of. cooling towers concentrate solids and the air contact in these open systems allows the buildup of contaminants, organics,. the composition of an optimum chemical treatment program for cooling towers on a military installation depends. Cooling Tower Water Parameters Limits.

From www.researchgate.net

Operational characteristics of two industrial scale open cooling tower Cooling Tower Water Parameters Limits Heat transfer due to conduction. what are the chemical limits being used for water chemistry monitoring for an induced draft, counter cooling tower. this code of practice was prepared to promote the proper use of fresh water cooling towers with guidelines for cooling. there is a limit to the number of cycles attainable in a cooling tower.. Cooling Tower Water Parameters Limits.

From www.homeazing.com

Cooling Tower Water Parameters Limits what are the chemical limits being used for water chemistry monitoring for an induced draft, counter cooling tower. water usage in cooling tower systems consists of three types: cooling towers vary greatly in design and footprint, but all have the main goal to provide removal of waste heat. cooling towers dissipate heat from processes, typically using. Cooling Tower Water Parameters Limits.

From www.cibsejournal.com

Towering savings water conservation in cooling towers CIBSE Journal Cooling Tower Water Parameters Limits cooling towers provide a welcoming environment — warm and wet — for microbial growth, which is why your. cooling towers dissipate heat from processes, typically using water as the medium. Windage, drift, and leakage are all sources of. water usage in cooling tower systems consists of three types: Blowdown is performed to maintain the circulating water chemistry. Cooling Tower Water Parameters Limits.

From www.researchgate.net

Composition of Elsta and LHC3 cooling tower blowdown (raw water Cooling Tower Water Parameters Limits cooling towers dissipate heat from processes, typically using water as the medium. the effect of the individual water quality parameter is correlated by the pearson matrix to find its influence on the. Blowdown is performed to maintain the circulating water chemistry in prescribed limits. Windage, drift, and leakage are all sources of. this code of practice was. Cooling Tower Water Parameters Limits.

From www.evoqua.com

Leveraging Advanced Water Filtration to Maximize Cooling Tower Performance Cooling Tower Water Parameters Limits the effect of the individual water quality parameter is correlated by the pearson matrix to find its influence on the. recommended concentration limits to determine allowable cycles of concentration are given as well as methods to estimate. cooling towers vary greatly in design and footprint, but all have the main goal to provide removal of waste heat.. Cooling Tower Water Parameters Limits.

From www.researchgate.net

Initial design parameters of the industrial cooling tower and Cooling Tower Water Parameters Limits Blowdown is performed to maintain the circulating water chemistry in prescribed limits. the quantity of evaporating water in the tower is in direct proportion to the heat that the tower removes. water usage in cooling tower systems consists of three types: what are the chemical limits being used for water chemistry monitoring for an induced draft, counter. Cooling Tower Water Parameters Limits.

From chemicalengineeringsite.in

How to Calculate Cooling Tower Efficiency? Cooling Tower Water Parameters Limits Windage, drift, and leakage are all sources of. total dissolved solids (tds): cooling towers concentrate solids and the air contact in these open systems allows the buildup of contaminants, organics,. cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. cooling towers dissipate heat from recirculating water. Cooling Tower Water Parameters Limits.

From leeduser.buildinggreen.com

Cooling Tower Water Use LEEDuser Cooling Tower Water Parameters Limits cooling towers concentrate solids and the air contact in these open systems allows the buildup of contaminants, organics,. cooling towers provide a welcoming environment — warm and wet — for microbial growth, which is why your. this standard provides a general guideline for selecting suitable treatment schemes of water for industrial cooling system and. this system. Cooling Tower Water Parameters Limits.

From www.veoliawatertech.com

Cooling Tower Water Treatment Veolia Water Technologies Cooling Tower Water Parameters Limits this code of practice was prepared to promote the proper use of fresh water cooling towers with guidelines for cooling. Blowdown is performed to maintain the circulating water chemistry in prescribed limits. Windage, drift, and leakage are all sources of. to control concentration of dissolved solids and maintain optimum water level on the tower basin, new water needs. Cooling Tower Water Parameters Limits.

From hvacsimplified.in

COOLING TOWER Makeup Water Calculation Sheet hvacsimplified.in Cooling Tower Water Parameters Limits this code of practice was prepared to promote the proper use of fresh water cooling towers with guidelines for cooling. cooling towers dissipate heat from recirculating water and use large volumes of, in most cases, potable water. cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. . Cooling Tower Water Parameters Limits.

From www.coolingtechnology.org

Standard 163 Vibration Limits in Water Cooling Towers Cooling Tower Water Parameters Limits cooling tower system is contaminated, which causes adverse influence to cooling water quality and cooling tower thermal. cooling towers dissipate heat from recirculating water and use large volumes of, in most cases, potable water. The tds of the cooling tower water is a surrogate monitoring parameter for pm10 emissions from. water usage in cooling tower systems consists. Cooling Tower Water Parameters Limits.

From www.youtube.com

[Hindi] Range Of Cooling Tower Water Parameters/ Importance of Cooling Cooling Tower Water Parameters Limits Roughly, as a rule of. the effect of the individual water quality parameter is correlated by the pearson matrix to find its influence on the. to control concentration of dissolved solids and maintain optimum water level on the tower basin, new water needs to be added. cooling towers can cycle water numerous times before the water becomes. Cooling Tower Water Parameters Limits.

From www.cibsejournal.com

Towering savings water conservation in cooling towers CIBSE Journal Cooling Tower Water Parameters Limits cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. there is a limit to the number of cycles attainable in a cooling tower. cooling towers dissipate heat from recirculating water and use large volumes of, in most cases, potable water. cooling towers dissipate heat from processes,. Cooling Tower Water Parameters Limits.

From coolingtowerbeteizu.blogspot.com

Cooling Tower Cooling Tower Approach Temperature Cooling Tower Water Parameters Limits water usage in cooling tower systems consists of three types: there is a limit to the number of cycles attainable in a cooling tower. cooling towers vary greatly in design and footprint, but all have the main goal to provide removal of waste heat. this code of practice was prepared to promote the proper use of. Cooling Tower Water Parameters Limits.

From www.semanticscholar.org

Table 1 from Assessing the Treatment of Cooling Tower Water Using the Cooling Tower Water Parameters Limits the composition of an optimum chemical treatment program for cooling towers on a military installation depends on the quality. Windage, drift, and leakage are all sources of. total dissolved solids (tds): cooling tower system is contaminated, which causes adverse influence to cooling water quality and cooling tower thermal. the effect of the individual water quality parameter. Cooling Tower Water Parameters Limits.

From www.researchgate.net

Characteristic of cooling tower blowdown water were collect from Cooling Tower Water Parameters Limits cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. this standard provides a general guideline for selecting suitable treatment schemes of water for industrial cooling system and. the composition of an optimum chemical treatment program for cooling towers on a military installation depends on the quality. . Cooling Tower Water Parameters Limits.

From www.powermag.com

Using Reclaimed Water in Power Plant Cooling Applications Cooling Tower Water Parameters Limits cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. water usage in cooling tower systems consists of three types: to control concentration of dissolved solids and maintain optimum water level on the tower basin, new water needs to be added. this standard provides a general guideline. Cooling Tower Water Parameters Limits.

From mechanicalgalaxy.blogspot.com

Mechanical Engineering An overview of a Cooling Tower indicating flow Cooling Tower Water Parameters Limits water usage in cooling tower systems consists of three types: Heat transfer due to conduction. cooling towers vary greatly in design and footprint, but all have the main goal to provide removal of waste heat. cooling tower system is contaminated, which causes adverse influence to cooling water quality and cooling tower thermal. total dissolved solids (tds):. Cooling Tower Water Parameters Limits.

From www.researchgate.net

Composition of Elsta and LHC3 cooling tower blowdown (raw water Cooling Tower Water Parameters Limits this system sends cooling water out of the equipment and into a pond or cooling tower, which is open to. cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. cooling tower system is contaminated, which causes adverse influence to cooling water quality and cooling tower thermal. . Cooling Tower Water Parameters Limits.

From visipraxis.com

Cooling Tower Water Treatment VisiPraxis Cooling Tower Water Parameters Limits this system sends cooling water out of the equipment and into a pond or cooling tower, which is open to. cooling towers vary greatly in design and footprint, but all have the main goal to provide removal of waste heat. total dissolved solids (tds): what are the chemical limits being used for water chemistry monitoring for. Cooling Tower Water Parameters Limits.

From coolingtowerbeteizu.blogspot.com

Cooling Tower Cooling Tower Water Quality Parameters Cooling Tower Water Parameters Limits the effect of the individual water quality parameter is correlated by the pearson matrix to find its influence on the. the quantity of evaporating water in the tower is in direct proportion to the heat that the tower removes. what are the chemical limits being used for water chemistry monitoring for an induced draft, counter cooling tower.. Cooling Tower Water Parameters Limits.

From www.researchgate.net

EPRI Water Chemistry Limits for Cooling Water Download Table Cooling Tower Water Parameters Limits water usage in cooling tower systems consists of three types: cooling towers vary greatly in design and footprint, but all have the main goal to provide removal of waste heat. cooling towers provide a welcoming environment — warm and wet — for microbial growth, which is why your. what are the chemical limits being used for. Cooling Tower Water Parameters Limits.

From www.youtube.com

Cooling tower water parameters limits Cooling water parameter Cooling Tower Water Parameters Limits the effect of the individual water quality parameter is correlated by the pearson matrix to find its influence on the. Windage, drift, and leakage are all sources of. to control concentration of dissolved solids and maintain optimum water level on the tower basin, new water needs to be added. total dissolved solids (tds): cooling towers concentrate. Cooling Tower Water Parameters Limits.

From www.kuritaamerica.com

Automation in Cooling Towers Reduces Water & Saves Hospital Thousands Cooling Tower Water Parameters Limits the composition of an optimum chemical treatment program for cooling towers on a military installation depends on the quality. cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. recommended concentration limits to determine allowable cycles of concentration are given as well as methods to estimate. this. Cooling Tower Water Parameters Limits.

From mycoolingtower.com.au

Water Calculator My Cooling Tower Cooling Tower Water Parameters Limits cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. to control concentration of dissolved solids and maintain optimum water level on the tower basin, new water needs to be added. recommended concentration limits to determine allowable cycles of concentration are given as well as methods to estimate.. Cooling Tower Water Parameters Limits.

From www.tempco.it

Cooling tower, water parameters Tempco Blog Cooling Tower Water Parameters Limits cooling towers vary greatly in design and footprint, but all have the main goal to provide removal of waste heat. cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. cooling tower system is contaminated, which causes adverse influence to cooling water quality and cooling tower thermal. . Cooling Tower Water Parameters Limits.

From hvactrainingshop.com

What is a Cooling Tower? Cooling Tower Basics HVAC Training Shop Cooling Tower Water Parameters Limits water usage in cooling tower systems consists of three types: there is a limit to the number of cycles attainable in a cooling tower. The tds of the cooling tower water is a surrogate monitoring parameter for pm10 emissions from. recommended concentration limits to determine allowable cycles of concentration are given as well as methods to estimate.. Cooling Tower Water Parameters Limits.

From www.saubhaya.com

Cooling Tower Makeup Water Rate Saubhaya Makeup Cooling Tower Water Parameters Limits this standard provides a general guideline for selecting suitable treatment schemes of water for industrial cooling system and. cooling towers dissipate heat from recirculating water and use large volumes of, in most cases, potable water. Roughly, as a rule of. cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out. Cooling Tower Water Parameters Limits.

From www.powermag.com

Using Reclaimed Water in Power Plant Cooling Applications Cooling Tower Water Parameters Limits cooling towers provide a welcoming environment — warm and wet — for microbial growth, which is why your. the effect of the individual water quality parameter is correlated by the pearson matrix to find its influence on the. this standard provides a general guideline for selecting suitable treatment schemes of water for industrial cooling system and. . Cooling Tower Water Parameters Limits.

From www.processtechacademy.com

Process Tech & Oper Academy Hyperbolic Cooling Towers Cooling Tower Water Parameters Limits to control concentration of dissolved solids and maintain optimum water level on the tower basin, new water needs to be added. cooling towers can cycle water numerous times before the water becomes saturated and must be discharged out of the. cooling towers dissipate heat from recirculating water and use large volumes of, in most cases, potable water.. Cooling Tower Water Parameters Limits.

From www.saubhaya.com

Cooling Tower Makeup Water Quality Saubhaya Makeup Cooling Tower Water Parameters Limits cooling towers concentrate solids and the air contact in these open systems allows the buildup of contaminants, organics,. this standard provides a general guideline for selecting suitable treatment schemes of water for industrial cooling system and. the composition of an optimum chemical treatment program for cooling towers on a military installation depends on the quality. there. Cooling Tower Water Parameters Limits.