Plain Milling Cutter Is . In plain milling processing, the cutter is one of the most important elements defining the expected results. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. Peripheral milling, also known as plain milling, is a milling operation that uses a rotating milling cutter with an axis parallel to the workpiece. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being. Plain milling, or slab milling, is a machining process involving a cylindrical cutting tool known as a milling cutter. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. Plain milling cutter like many milling bits types, a plain milling cutter has helical or straight teeth on the disc or cylinder side. There are two foremost slab. Here the cutter is positioned so that its cutting edges on the periphery grind at the To function, the workpiece to be worked on should have a flat surface that runs parallel to the cutter’s

from www.mecholic.com

Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. To function, the workpiece to be worked on should have a flat surface that runs parallel to the cutter’s Plain milling cutter like many milling bits types, a plain milling cutter has helical or straight teeth on the disc or cylinder side. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. Here the cutter is positioned so that its cutting edges on the periphery grind at the Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. There are two foremost slab.

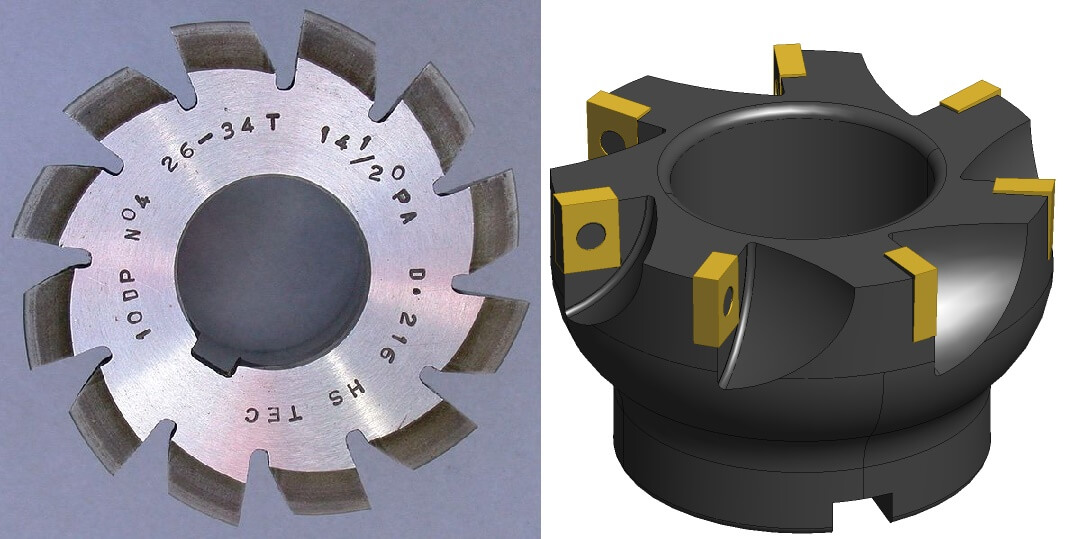

milling cutter

Plain Milling Cutter Is Plain milling, or slab milling, is a machining process involving a cylindrical cutting tool known as a milling cutter. Here the cutter is positioned so that its cutting edges on the periphery grind at the Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Peripheral milling, also known as plain milling, is a milling operation that uses a rotating milling cutter with an axis parallel to the workpiece. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Plain milling cutter like many milling bits types, a plain milling cutter has helical or straight teeth on the disc or cylinder side. Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being. There are two foremost slab. In plain milling processing, the cutter is one of the most important elements defining the expected results. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. To function, the workpiece to be worked on should have a flat surface that runs parallel to the cutter’s Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. Plain milling, or slab milling, is a machining process involving a cylindrical cutting tool known as a milling cutter.

From www.indiamart.com

Silver 25 mm Plain Milling Cutter at Rs 1890/piece in Patiala ID Plain Milling Cutter Is Peripheral milling, also known as plain milling, is a milling operation that uses a rotating milling cutter with an axis parallel to the workpiece. Here the cutter is positioned so that its cutting edges on the periphery grind at the Plain milling, or slab milling, is a machining process involving a cylindrical cutting tool known as a milling cutter. There. Plain Milling Cutter Is.

From www.youtube.com

Types of Milling Cutters Plain Milling Cutter YouTube Plain Milling Cutter Is Plain milling, or slab milling, is a machining process involving a cylindrical cutting tool known as a milling cutter. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. To function, the workpiece to be worked on should have a flat surface that runs parallel to the cutter’s Also known as slab. Plain Milling Cutter Is.

From themechanicalengineering.com

Milling Cutter Definition, Types in detail, Geometry Material [Notes Plain Milling Cutter Is It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. There are two foremost slab. Plain milling cutter like many milling bits types, a plain milling cutter. Plain Milling Cutter Is.

From engineeringlearn.com

End Mill Cutter Archives Engineering Learn Plain Milling Cutter Is Plain milling, or slab milling, is a machining process involving a cylindrical cutting tool known as a milling cutter. Here the cutter is positioned so that its cutting edges on the periphery grind at the Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. Plain milling, also known as slab. Plain Milling Cutter Is.

From www.mscdirect.com

Keo 21/2" Cut Diam x 4" Cut Width High Speed Steel Plain Milling Plain Milling Cutter Is The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling, or slab milling, is a machining process involving a cylindrical cutting tool known as a milling cutter. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Here the cutter is positioned so that. Plain Milling Cutter Is.

From www.victornet.com

4 X 6 X 11/2 Heavy Duty Plain Milling Cutter, High Speed Steel Plain Milling Cutter Is Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. Here the cutter is positioned so that. Plain Milling Cutter Is.

From www.beaverdrillstore.com

Plain High Speed Steel Milling Cutter Beaver Drill Store Plain Milling Cutter Is There are two foremost slab. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being. Here the cutter is positioned so that its cutting edges on the periphery grind at the Plain milling is the process of removing material from a flat surface. Plain Milling Cutter Is.

From www.kbctools.com

Side Milling Cutters Results Page 1 KBC Tools & Machinery Plain Milling Cutter Is Here the cutter is positioned so that its cutting edges on the periphery grind at the Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. It involves using a milling cutter which rotates on an. Plain Milling Cutter Is.

From www.indiamart.com

Slab Milling Cutters, CNC Milling Cutter, Computer Numerical Control Plain Milling Cutter Is Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Peripheral milling, also known as plain milling, is a milling operation that uses a. Plain Milling Cutter Is.

From en.mrt-metalsaw.com

Plain Milling Cutter MRT Co.,Ltd Plain Milling Cutter Is Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being. There are two foremost slab. Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. Plain milling, or slab milling, is a machining process. Plain Milling Cutter Is.

From fractory.com

Milling Cutters & Tools Types and Their Purposes (with Images) Plain Milling Cutter Is There are two foremost slab. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. To function, the workpiece to be worked on should have a flat surface that runs parallel to the cutter’s Plain milling, also known as slab milling or surface milling, the. Plain Milling Cutter Is.

From www.indiamart.com

Plain Milling Cutter, CNC Milling Cutter, Computer Numerical Control Plain Milling Cutter Is Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. Here the cutter is positioned so that its cutting edges on the periphery grind at the Plain milling, or slab milling, is a machining process involving. Plain Milling Cutter Is.

From www.keocutters.com

81509 Plain Milling Cutter TiAlN KEO Plain Milling Cutter Is To function, the workpiece to be worked on should have a flat surface that runs parallel to the cutter’s There are two foremost slab. Plain milling, or slab milling, is a machining process involving a cylindrical cutting tool known as a milling cutter. Plain milling cutter like many milling bits types, a plain milling cutter has helical or straight teeth. Plain Milling Cutter Is.

From www.youtube.com

Plain Milling Cutter DIC Tools Milling Cutter Dedicated Impex Co Plain Milling Cutter Is Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. To function, the workpiece to be worked on. Plain Milling Cutter Is.

From www.victornet.com

41/2 X 6 X 2 Helical Plain Milling Cutter, High Speed Steel (sale) Plain Milling Cutter Is Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface. Plain Milling Cutter Is.

From www.amazon.com

F&D Tool Company 10531A153 Plain Milling Cutter, Light Duty, High Plain Milling Cutter Is Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. Also known as slab milling or surface milling, the process involves fixing the workpiece to the. Plain Milling Cutter Is.

From www.keocutters.com

81570 Plain Milling Cutter TiAlN KEO Plain Milling Cutter Is To function, the workpiece to be worked on should have a flat surface that runs parallel to the cutter’s Peripheral milling, also known as plain milling, is a milling operation that uses a rotating milling cutter with an axis parallel to the workpiece. Here the cutter is positioned so that its cutting edges on the periphery grind at the There. Plain Milling Cutter Is.

From www.indiamart.com

Surya 200 MM Side And Face Milling Cutter., 55 Hrc, 40 MM at Rs 1800 in Plain Milling Cutter Is Plain milling cutter like many milling bits types, a plain milling cutter has helical or straight teeth on the disc or cylinder side. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface.. Plain Milling Cutter Is.

From www.archcuttingtools.com

81463 Plain Milling Cutter TiCN ARCH Cutting Tools Plain Milling Cutter Is It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. Plain milling cutter like many milling bits types,. Plain Milling Cutter Is.

From toolnotes.com

Milling Operations ToolNotes Plain Milling Cutter Is Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. The. Plain Milling Cutter Is.

From dictoolsindia.com

Plain Milling Cutters Plain Milling Cutters Manufacturers DIC Tools Plain Milling Cutter Is Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. It involves using a milling cutter which rotates on an axis that is parallel to the. Plain Milling Cutter Is.

From shopee.ph

HSS M2 fine teeth cylindrical milling cutter hss spiral plain milling Plain Milling Cutter Is Plain milling cutter like many milling bits types, a plain milling cutter has helical or straight teeth on the disc or cylinder side. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. There are two foremost slab. In plain milling processing, the cutter is. Plain Milling Cutter Is.

From www.victornet.com

3 x 3/4 x 11/4 USA HSS Plain Milling Cutter Plain Milling Cutter Is Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. There are two foremost slab. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. To function, the workpiece to be worked on should have a flat surface that runs parallel to. Plain Milling Cutter Is.

From www.scharptools.com

Plain milling cutter Plain Milling Cutter Is The movement of the cutter removes unwanted material from the workpiece creating the desired end product. To function, the workpiece to be worked on should have a flat surface that runs parallel to the cutter’s Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the. Plain Milling Cutter Is.

From learnmech.com

Milling Cutter Types Of Milling Cutter used For Machining Plain Milling Cutter Is Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. In plain milling processing, the cutter is one. Plain Milling Cutter Is.

From zhenjiangscharptools.en.made-in-china.com

High Speed Steel Plain Milling Cutters China Plain Milling Cutters Plain Milling Cutter Is The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. In plain milling processing, the cutter is one of the. Plain Milling Cutter Is.

From www.maxwelltools.com

Paper Milling Cutters Maxwell Tools Company Plain Milling Cutter Is Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Here the cutter is positioned so that its cutting edges on the periphery grind at the The movement of the cutter removes. Plain Milling Cutter Is.

From www.ebay.com

PLAIN MILLING CUTTER 16T 229/32 x 13/16 x 11/4 eBay Plain Milling Cutter Is In plain milling processing, the cutter is one of the most important elements defining the expected results. Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. Plain milling, or slab milling, is a machining process. Plain Milling Cutter Is.

From dizz.com

Plain Milling Cutter Nomenclature Design Engineering Plain Milling Cutter Is To function, the workpiece to be worked on should have a flat surface that runs parallel to the cutter’s Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. There are two foremost. Plain Milling Cutter Is.

From en.mrt-metalsaw.com

Plain Milling Cutter MRT Co.,Ltd Plain Milling Cutter Is Here the cutter is positioned so that its cutting edges on the periphery grind at the The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Peripheral milling, also known as plain milling, is a milling operation that uses a rotating milling cutter with an axis parallel to the workpiece. Plain milling involves a. Plain Milling Cutter Is.

From www.archcuttingtools.com

81509 Plain Milling Cutter TiAlN ARCH Cutting Tools Plain Milling Cutter Is Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Also known as slab. Plain Milling Cutter Is.

From www.china-machining.com

Plain Milling Understanding this Fascinating Production Process Plain Milling Cutter Is Also known as slab milling or surface milling, the process involves fixing the workpiece to the bed of the machine while a spinning axis removes the material from the top face of the material. Peripheral milling, also known as plain milling, is a milling operation that uses a rotating milling cutter with an axis parallel to the workpiece. Plain milling. Plain Milling Cutter Is.

From caddesignr.com

Milling machine operations photos Cad Designer Plain Milling Cutter Is Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being. Plain milling cutter like many milling bits types, a plain milling cutter has helical. Plain Milling Cutter Is.

From epromachining.com

What is CNC Milling? Learn About This Useful Manufacturing Method Plain Milling Cutter Is There are two foremost slab. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being. To function, the. Plain Milling Cutter Is.

From www.mecholic.com

milling cutter Plain Milling Cutter Is Plain milling involves a process that machines a flat or horizontal surface on components by utilizing a milling cutter. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being. Also known as slab milling or surface milling, the process involves fixing the workpiece. Plain Milling Cutter Is.