Purpose Of Abrasive Flow Machine . Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. Abrasive flow machining (afm) is also known as extrude honing. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. What is abrasive flow machining (afm) and how does it work in manufacturing? Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. This is an interior surface finishing process that involves an abrasive. Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries.

from www.thefabricator.com

What is abrasive flow machining (afm) and how does it work in manufacturing? Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. This is an interior surface finishing process that involves an abrasive. Abrasive flow machining (afm) is also known as extrude honing.

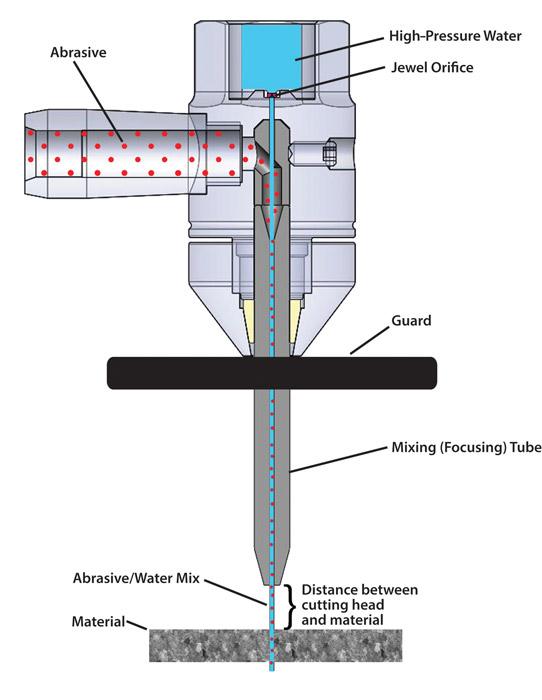

Pressure matters in abrasive waterjet cutting The Fabricator

Purpose Of Abrasive Flow Machine Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. Abrasive flow machining (afm) is also known as extrude honing. Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. What is abrasive flow machining (afm) and how does it work in manufacturing? This is an interior surface finishing process that involves an abrasive.

From www.mdpi.com

Study on Elucidation of the Roundness Improvement Mechanism of the Purpose Of Abrasive Flow Machine This is an interior surface finishing process that involves an abrasive. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. Abrasive flow machining (afm) is also. Purpose Of Abrasive Flow Machine.

From www.researchgate.net

27 Schematic illustration of one abrasive flow machining setup. The Purpose Of Abrasive Flow Machine Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. This is an interior surface finishing process that involves an abrasive. Abrasive machining is. Purpose Of Abrasive Flow Machine.

From www.researchgate.net

Schematic diagram of the precision machining of abrasive flow Purpose Of Abrasive Flow Machine What is abrasive flow machining (afm) and how does it work in manufacturing? Abrasive flow machining (afm) is also known as extrude honing. Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing,. Purpose Of Abrasive Flow Machine.

From www.flowgrinding.com

Abrasive Flow Machining Systems Winbro Flow Grinding Purpose Of Abrasive Flow Machine Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. Abrasive flow machining (afm) is also known as extrude honing. Abrasive flow machining (afm),. Purpose Of Abrasive Flow Machine.

From swaterjet.com

abrasive water jet machining Same Waterjet Purpose Of Abrasive Flow Machine The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. Abrasive flow machining (afm) is also known as extrude honing. This is an interior surface finishing process that involves an abrasive. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish,. Purpose Of Abrasive Flow Machine.

From finemetalworking.com

Abrasive Water Jet Machining. How Water Jet Cutter Works? Purpose Of Abrasive Flow Machine This is an interior surface finishing process that involves an abrasive. The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. What is abrasive flow machining (afm) and how does it work in manufacturing? Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing,. Purpose Of Abrasive Flow Machine.

From finemetalworking.com

Abrasive Water Jet Machining. How Water Jet Cutter Works? Purpose Of Abrasive Flow Machine Abrasive flow machining (afm) is also known as extrude honing. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. What is abrasive flow machining (afm) and how does it work in manufacturing? Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve. Purpose Of Abrasive Flow Machine.

From www.researchgate.net

Abrasive flow machine [23] Download Scientific Diagram Purpose Of Abrasive Flow Machine This is an interior surface finishing process that involves an abrasive. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. The abrasive flow machine, available in. Purpose Of Abrasive Flow Machine.

From pec.ac.in

Abrasive Flow Machine / Hydraulic Press Punjab Engineering College Purpose Of Abrasive Flow Machine The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. Abrasive flow machining (afm) is also known as extrude honing. This is an interior surface finishing process that involves an abrasive. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to. Purpose Of Abrasive Flow Machine.

From www.sandblastequipment.com

Manus Abrasive Systems, Inc. Sandblast Equipment Purpose Of Abrasive Flow Machine Abrasive flow machining (afm) is also known as extrude honing. Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Abrasive flow machining (afm), also. Purpose Of Abrasive Flow Machine.

From libertymachinery.com

Watch HL20 Abrasive Flow Machine Walkthrough — Liberty Machinery Purpose Of Abrasive Flow Machine Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Abrasive flow machining (afm) is also known as extrude honing. What is abrasive flow machining (afm) and how does it. Purpose Of Abrasive Flow Machine.

From mungfali.com

Machining Process Flow Chart Purpose Of Abrasive Flow Machine Abrasive flow machining (afm) is also known as extrude honing. The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. This is an interior surface finishing process that involves an abrasive. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that. Purpose Of Abrasive Flow Machine.

From www.cottandco.com

Extrude Hone Easyflow 200 Abrasive Flow Machine (2018) Purpose Of Abrasive Flow Machine Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. What is abrasive flow machining (afm) and how does it work in manufacturing? This is an interior surface finishing process that involves an abrasive. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or. Purpose Of Abrasive Flow Machine.

From www.mecholic.com

abrasive_machining_schematic_diagram Purpose Of Abrasive Flow Machine Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. Abrasive flow machining (afm) is also known as extrude honing. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. Abrasive machining. Purpose Of Abrasive Flow Machine.

From www.researchgate.net

(PDF) Design and Fabrication of advanced Abrasive flow machine for Purpose Of Abrasive Flow Machine What is abrasive flow machining (afm) and how does it work in manufacturing? This is an interior surface finishing process that involves an abrasive. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Abrasive flow machining (afm) is also known as extrude honing. Abrasive flow machining (afm), also. Purpose Of Abrasive Flow Machine.

From libertymachinery.com

Extrude Hone Abrasive Flow Machine WalkThru — Liberty Machinery Purpose Of Abrasive Flow Machine What is abrasive flow machining (afm) and how does it work in manufacturing? Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Abrasive flow machining (afm) is also known. Purpose Of Abrasive Flow Machine.

From www.youtube.com

Working principle of Abrasive Flow Machining (AFM) YouTube Purpose Of Abrasive Flow Machine What is abrasive flow machining (afm) and how does it work in manufacturing? Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Abrasive flow. Purpose Of Abrasive Flow Machine.

From www.waterjet-cutting.com

Abrasive Flow Machining Companies Services Purpose Of Abrasive Flow Machine Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. This is an interior surface finishing process that involves an abrasive. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. What is abrasive flow. Purpose Of Abrasive Flow Machine.

From www.flowgrinding.com

Abrasive Flow Machining Systems Winbro Flow Grinding Purpose Of Abrasive Flow Machine Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. Abrasive flow machining (afm) is also known as extrude honing. Unlike traditional machining methods that rely on mechanical cutting, abrasive. Purpose Of Abrasive Flow Machine.

From www.waterjet-cutting.com

Abrasive Flow Machining Companies Services Purpose Of Abrasive Flow Machine Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. Abrasive flow machining (afm) is also known as extrude honing. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. What is. Purpose Of Abrasive Flow Machine.

From electricalworkbook.com

What is Abrasive Flow Finishing (AFF)? Process, Diagram, Working Purpose Of Abrasive Flow Machine Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. What is abrasive flow machining (afm) and how does it work in manufacturing? Abrasive machining is a. Purpose Of Abrasive Flow Machine.

From www.skyfilabs.com

Develop a project using the Abrasive Jet Machine process Purpose Of Abrasive Flow Machine What is abrasive flow machining (afm) and how does it work in manufacturing? Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. This is an interior surface finishing process that involves an abrasive. The abrasive flow machine, available in a variety of sizes, contains two. Purpose Of Abrasive Flow Machine.

From www.flowgrinding.com

Abrasive Flow Machining Systems Winbro Flow Grinding Purpose Of Abrasive Flow Machine This is an interior surface finishing process that involves an abrasive. The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Abrasive flow grinding, also known as. Purpose Of Abrasive Flow Machine.

From www.scribd.com

Abrasive Flow Machining Machining Abrasive Purpose Of Abrasive Flow Machine Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish,. Purpose Of Abrasive Flow Machine.

From journals.sagepub.com

Experimental Research into Technology of Abrasive Flow Machining Purpose Of Abrasive Flow Machine This is an interior surface finishing process that involves an abrasive. The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. What is abrasive flow machining (afm) and how. Purpose Of Abrasive Flow Machine.

From www.slideserve.com

PPT ABRASIVE FLOW MACHINING PowerPoint Presentation, free Purpose Of Abrasive Flow Machine What is abrasive flow machining (afm) and how does it work in manufacturing? The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. Abrasive. Purpose Of Abrasive Flow Machine.

From www.researchgate.net

Abrasive flow finishing process setup with various finishing forces on Purpose Of Abrasive Flow Machine Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. Abrasive flow machining (afm) is also known as extrude honing. Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. Unlike traditional machining methods that rely on. Purpose Of Abrasive Flow Machine.

From libertymachinery.com

Extrude Hone Profile 100 Abrasive Flow Machine — Liberty Purpose Of Abrasive Flow Machine Abrasive flow machining (afm) is also known as extrude honing. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. This is an interior surface finishing process that involves an abrasive. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a. Purpose Of Abrasive Flow Machine.

From www.researchgate.net

Polishing sketch of abrasive flow machining. Download Scientific Diagram Purpose Of Abrasive Flow Machine Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. What is abrasive flow machining (afm) and how does it work in manufacturing? Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Abrasive flow machining (afm) is also known. Purpose Of Abrasive Flow Machine.

From www.gtusun-machinery.com

Efficient abrasive flow finishing solution provider GTusun Purpose Of Abrasive Flow Machine Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing technology used in a variety of industries. Abrasive flow machining (afm) is also known as extrude honing. This is an interior surface finishing process that involves an abrasive. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to. Purpose Of Abrasive Flow Machine.

From www.thefabricator.com

Pressure matters in abrasive waterjet cutting The Fabricator Purpose Of Abrasive Flow Machine Abrasive flow machining (afm) is also known as extrude honing. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. What is abrasive flow machining (afm) and how does it work in manufacturing? The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders. Purpose Of Abrasive Flow Machine.

From www.youtube.com

Abrasive Flow Machining Companies YouTube Purpose Of Abrasive Flow Machine Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Abrasive flow machining (afm) is also known as extrude honing. Abrasive flow machining (afm), also. Purpose Of Abrasive Flow Machine.

From www.alu.com.cn

Multicut Flowgrind Media for Abrasive Flow MachineAluminium products Purpose Of Abrasive Flow Machine The abrasive flow machine, available in a variety of sizes, contains two vertically opposed media cylinders which hydraulically close to hold a. Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. Abrasive flow machining (afm) is also known as extrude honing. Abrasive machining is a material removal process that uses. Purpose Of Abrasive Flow Machine.

From www.researchgate.net

Schematic diagram of abrasive flow machining Download Scientific Diagram Purpose Of Abrasive Flow Machine Abrasive flow machining (afm), also known as abrasive flow deburring or extrude honing, is a process that finishes interior. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve the desired surface finish or geometry. Abrasive flow grinding, also known as abrasive flow machining (afm) or extrude honing®, is a precision finishing. Purpose Of Abrasive Flow Machine.

From www.researchgate.net

Schematic diagram of abrasive flow machining. Download Scientific Diagram Purpose Of Abrasive Flow Machine Abrasive flow machining (afm) is also known as extrude honing. This is an interior surface finishing process that involves an abrasive. Abrasive machining is a material removal process that uses hard particles, known as abrasives, to shape, finish, or cut a workpiece. Unlike traditional machining methods that rely on mechanical cutting, abrasive machining employs grinding, honing, or lapping to achieve. Purpose Of Abrasive Flow Machine.