Countersinking Holes . Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Its purpose is to allow fasteners, like flathead screws, to sit flush or. Once the screw is in place, you can either leave it exposed or conceal it using wood putty! After that, you can use a countersink cutter to drill a larger hole for the screw head. Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother.

from www.protoexpress.com

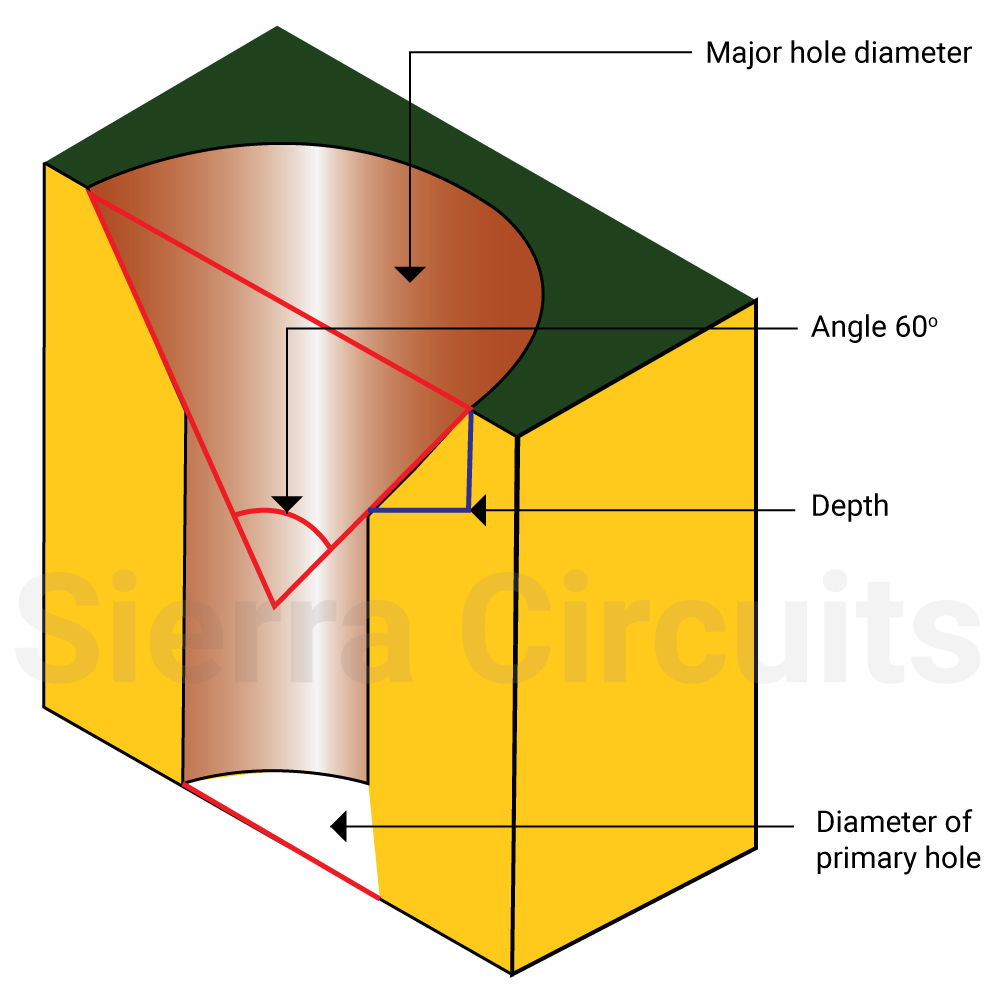

Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Once the screw is in place, you can either leave it exposed or conceal it using wood putty! After that, you can use a countersink cutter to drill a larger hole for the screw head. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. Its purpose is to allow fasteners, like flathead screws, to sit flush or.

Countersink Holes in PCBs Sierra Circuits

Countersinking Holes Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Its purpose is to allow fasteners, like flathead screws, to sit flush or. Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. Once the screw is in place, you can either leave it exposed or conceal it using wood putty! Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. After that, you can use a countersink cutter to drill a larger hole for the screw head. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother.

From www.dreamstime.com

Countersinking holes. stock photo. Image of countersink 14454796 Countersinking Holes Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. Once the screw is in place, you can either leave it exposed or conceal it. Countersinking Holes.

From www.diydoctor.org.uk

How to Drill Countersink Holes and Pilot Holes DIY Doctor Countersinking Holes Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the. Countersinking Holes.

From www.scribd.com

Guidelines for Punching and Countersinking Holes for Various Screw Countersinking Holes Once the screw is in place, you can either leave it exposed or conceal it using wood putty! After that, you can use a countersink cutter to drill a larger hole for the screw head. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with,. Countersinking Holes.

From www.wikihow.com

How to Countersink 13 Steps (with Pictures) wikiHow Countersinking Holes Once the screw is in place, you can either leave it exposed or conceal it using wood putty! Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to. Countersinking Holes.

From www.researchgate.net

The cutting tool and the nominal countersink hole Download Scientific Countersinking Holes They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. Start by drilling a pilot. Countersinking Holes.

From www.dreamstime.com

Drilling Holes in a Piece of Wood. Countersinking the Hole for Wood Countersinking Holes Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. Countersink holes are conical recesses created on the surface of a material to accommodate the heads. Countersinking Holes.

From ar.inspiredpencil.com

Standard Countersink Hole Countersinking Holes Its purpose is to allow fasteners, like flathead screws, to sit flush or. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. Once the screw. Countersinking Holes.

From forums.sketchup.com

Help needed on countersinking holes SketchUp SketchUp Community Countersinking Holes Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the. Countersinking Holes.

From www.bigstockphoto.com

Countersinking Holes Image & Photo (Free Trial) Bigstock Countersinking Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. A countersink is an angled taper applied to a. Countersinking Holes.

From www.youtube.com

Countersinking Holes on the CNC YouTube Countersinking Holes After that, you can use a countersink cutter to drill a larger hole for the screw head. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. They serve the purpose of allowing the fasteners to sit flush or below the material surface,. Countersinking Holes.

From okdor.com

Countersink Holes From Basics to Advanced Techniques Countersinking Holes They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Start by drilling a pilot hole for your screw so you can thread it. Countersinking Holes.

From www.youtube.com

How to make Countersink Holes in SolidWorks by Hole Wizard Command Countersinking Holes Once the screw is in place, you can either leave it exposed or conceal it using wood putty! Its purpose is to allow fasteners, like flathead screws, to sit flush or. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Countersink. Countersinking Holes.

From okdor.com

How to countersink a hole? Countersinking Holes Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Its purpose is to allow fasteners, like flathead screws, to. Countersinking Holes.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersinking Holes Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Once the screw is in place, you can either leave it exposed or conceal it using wood putty!. Countersinking Holes.

From be-cu.com

Countersink Holes An Essential Guide To Precision And Functionality Countersinking Holes Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and. Countersinking Holes.

From forum.onshape.com

Countersink Screws and Holes Mating — Onshape Countersinking Holes Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. After that, you can use a countersink cutter to drill a larger hole for the screw head. Its purpose is to allow fasteners, like flathead screws, to sit flush or. They serve the purpose of allowing. Countersinking Holes.

From ar.inspiredpencil.com

Standard Countersink Hole Countersinking Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. Its purpose is to allow fasteners, like flathead screws, to sit flush or. Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood.. Countersinking Holes.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersinking Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. After that, you can use a countersink cutter to drill a larger hole for the screw head. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting. Countersinking Holes.

From be-cu.com

Countersink Holes An Essential Guide To Precision And Functionality Countersinking Holes Once the screw is in place, you can either leave it exposed or conceal it using wood putty! A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersink holes are conical recesses created on the surface of a material to accommodate the heads. Countersinking Holes.

From www.dreamstime.com

Drilling Holes in a Piece of Wood. Countersinking the Hole for Wood Countersinking Holes Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Start by drilling a pilot hole for your screw so you can thread it in easily without splitting. Countersinking Holes.

From be-cu.com

Countersink Holes An Essential Guide To Precision And Functionality Countersinking Holes Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. After that, you can use a countersink cutter to drill a larger hole for the screw head. Its purpose is to allow fasteners, like flathead screws, to sit flush or. Countersink holes, characterized by their conical shape, are designed to. Countersinking Holes.

From www.slideserve.com

PPT Holes PowerPoint Presentation, free download ID2107959 Countersinking Holes Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. They serve the purpose of allowing the fasteners to sit flush or below. Countersinking Holes.

From ar.inspiredpencil.com

Standard Countersink Hole Countersinking Holes Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Its purpose is to allow fasteners, like flathead screws, to sit flush or. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit. Countersinking Holes.

From www.theengineeringknowledge.com

What are Countersink Holes in Engineering? The Engineering Knowledge Countersinking Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. Once the screw is in place, you can either leave it exposed or conceal it using wood putty! A countersink is an angled taper applied to a hole that allows a fastener (usually. Countersinking Holes.

From www.csfabs.co.uk

Countersunk Holes in Sheet Metal C&S Fabrications Countersinking Holes Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. After that, you can use a countersink cutter to drill a larger hole for the screw head. A. Countersinking Holes.

From www.thehandymansdaughter.com

How to Countersink Screws The Handyman's Daughter Countersinking Holes Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Once the screw is in place, you can either leave it exposed or conceal it using wood putty!. Countersinking Holes.

From www.dreamstime.com

Drilling Holes in a Piece of Wood. Countersinking the Hole for Wood Countersinking Holes Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners. Countersinking Holes.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersinking Holes After that, you can use a countersink cutter to drill a larger hole for the screw head. Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a. Countersinking Holes.

From www.youtube.com

How to Make Countersink Holes in SolidWorks using Hole Wizard Command Countersinking Holes Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Countersink holes are conical recesses created on the surface of a material to accommodate the heads. Countersinking Holes.

From www.dreamstime.com

Countersinking holes. stock image. Image of motion, mill 5455931 Countersinking Holes They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. After that, you can use a countersink cutter to drill a larger. Countersinking Holes.

From www.theengineeringknowledge.com

What are Countersink Holes in Engineering? The Engineering Knowledge Countersinking Holes Its purpose is to allow fasteners, like flathead screws, to sit flush or. Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood,. Countersinking Holes.

From www.pinterest.de

The best way to get a nice, smooth countersunk hole in your workpiece Countersinking Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Join us as we delve into the intricacies of. Countersinking Holes.

From www.dreamstime.com

Countersinking Holes Stock Photos Free & RoyaltyFree Stock Photos Countersinking Holes Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersink holes are conical recesses created on the surface of. Countersinking Holes.

From www.protoexpress.com

Countersink Holes in PCBs Sierra Circuits Countersinking Holes Countersink holes, characterized by their conical shape, are designed to accommodate flush or below flush fasteners in various materials, from metal to wood, enhancing aesthetics and functionality. Start by drilling a pilot hole for your screw so you can thread it in easily without splitting the wood. Join us as we delve into the intricacies of countersink holes, exploring their. Countersinking Holes.

From ar.inspiredpencil.com

Standard Countersink Hole Countersinking Holes They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Join us as we delve into the intricacies of countersink holes, exploring their types, uses, and how to create them in different materials perfectly. Countersink holes are conical recesses created on the. Countersinking Holes.