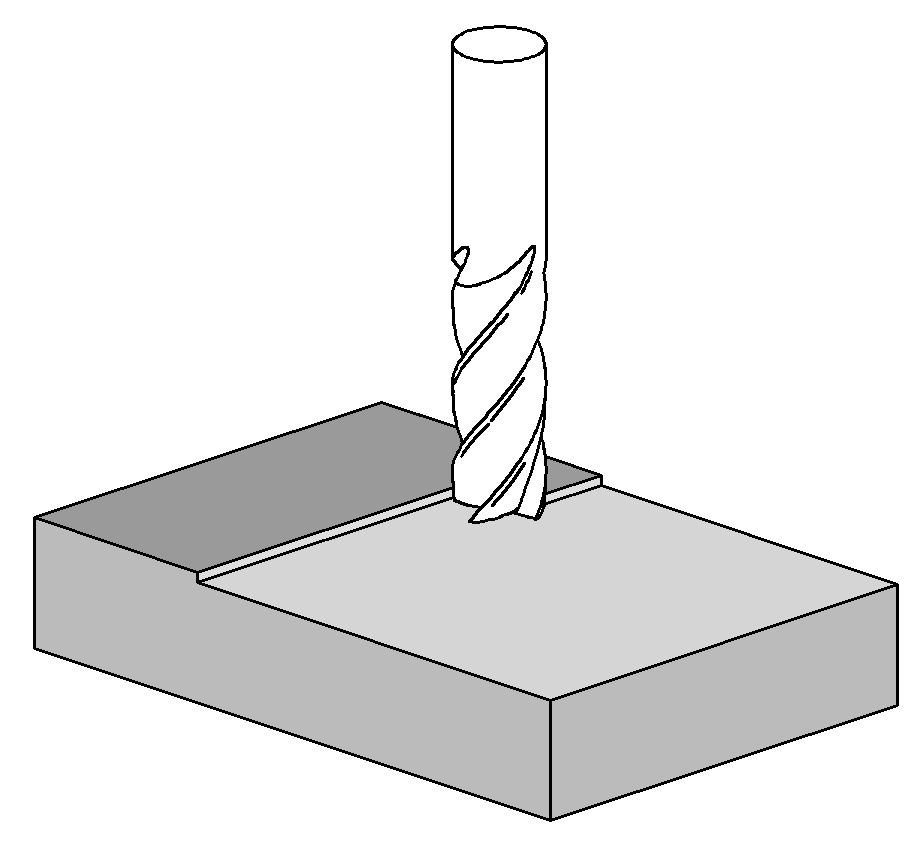

Face Milling Vs End Milling . One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. Choosing between a face mill and an end mill depends on your specific milling requirements. The difference between end and face milling is that a face mill can’t cut axially. In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. What is the significant difference between a face mill and an end mill? In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Understanding the differences in their design, properties, and applications. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. Understanding the primary configuration and.

from toolnotes.com

The difference between end and face milling is that a face mill can’t cut axially. In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. Understanding the primary configuration and. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. Choosing between a face mill and an end mill depends on your specific milling requirements. Understanding the differences in their design, properties, and applications. What is the significant difference between a face mill and an end mill?

Milling Operations ToolNotes

Face Milling Vs End Milling The difference between end and face milling is that a face mill can’t cut axially. Understanding the primary configuration and. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. The difference between end and face milling is that a face mill can’t cut axially. What is the significant difference between a face mill and an end mill? Understanding the differences in their design, properties, and applications. In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Choosing between a face mill and an end mill depends on your specific milling requirements.

From www.lathematters.com

Face Mill vs. End Mill Main Differences Explained! Face Milling Vs End Milling Choosing between a face mill and an end mill depends on your specific milling requirements. One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a. Face Milling Vs End Milling.

From www.easiahome.com

Face Milling vs. End Milling Which is Better for Your Project? Easiahome Face Milling Vs End Milling What is the significant difference between a face mill and an end mill? In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. One of. Face Milling Vs End Milling.

From finemetalworking.com

What is Milling? Climb vs. Conventional Milling Process Face Milling Vs End Milling In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. Choosing between a face mill and an end mill depends on your specific milling requirements. Understanding the differences in their design, properties, and applications. Understanding the primary configuration and. In face milling, the cutting edges are. Face Milling Vs End Milling.

From pre.unionfab.com

Face Mill vs. End Mill A Complete Comparison Guide Face Milling Vs End Milling Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Understanding the differences in their design, properties, and applications. Choosing between a face mill and an end mill depends. Face Milling Vs End Milling.

From www.transtutors.com

(Solved) Question 1 By using a labelled diagram describe the function Face Milling Vs End Milling Choosing between a face mill and an end mill depends on your specific milling requirements. The difference between end and face milling is that a face mill can’t cut axially. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. Understanding the differences in their design, properties, and applications.. Face Milling Vs End Milling.

From www.3qmachining.com

What Is Face Milling Cutter 3Q Machining Face Milling Vs End Milling In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Choosing between a face mill and an end mill depends on your specific milling requirements. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. The difference between end. Face Milling Vs End Milling.

From www.slideserve.com

PPT ME 350 Lecture 5 Chapter 22 & 23 PowerPoint Presentation ID Face Milling Vs End Milling Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. Understanding the differences in their design, properties, and applications. What is the significant difference between a face mill and an end mill? One of the reasons is that its cutting edges or cutting teeth are located in its cutting. Face Milling Vs End Milling.

From www.lathematters.com

Face Mill vs. End Mill Main Differences Explained! Face Milling Vs End Milling Choosing between a face mill and an end mill depends on your specific milling requirements. One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Understanding the. Face Milling Vs End Milling.

From www.autodesk.com

6face milling Fusion Blog Face Milling Vs End Milling Understanding the differences in their design, properties, and applications. In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. What is the significant difference between a face mill and an end mill? Choosing between a face mill and an end mill depends on your specific milling. Face Milling Vs End Milling.

From topsbest-precision.com

Face Milling vs End Milling:What’s the Difference? Custom Precision Face Milling Vs End Milling In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Choosing between a face mill and an end mill depends on your specific milling requirements. Understanding. Face Milling Vs End Milling.

From www.slideserve.com

PPT Chapter 23 Machining Processes Used to Produce Various Shapes Face Milling Vs End Milling Understanding the differences in their design, properties, and applications. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. What is the significant difference between a face mill and an end mill? One of the reasons is that its cutting edges or cutting teeth are located in its cutting head. Face Milling Vs End Milling.

From atelier-yuwa.ciao.jp

What Is Face Milling Operation Tips Face Milling Vs Peripheral Milling Face Milling Vs End Milling In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. The difference between end and face milling is that a face mill can’t cut axially. Understanding the differences in their design, properties, and applications. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while. Face Milling Vs End Milling.

From proleantech.com

Understanding Milling Cutters in CNC Machining Face Milling Vs End Milling Understanding the primary configuration and. Choosing between a face mill and an end mill depends on your specific milling requirements. Understanding the differences in their design, properties, and applications. In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. In face milling, the cutting edges are. Face Milling Vs End Milling.

From www.china-machining.com

Face Milling 101 Here is What You Need to Know Face Milling Vs End Milling One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. Choosing between a face mill and an end mill depends on your specific milling requirements. Understanding. Face Milling Vs End Milling.

From dusan.sts.si

Frezanje Tehnologija na Face Milling Vs End Milling One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. Understanding the differences in their design, properties, and applications. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. In face milling, the cutting edges are. Face Milling Vs End Milling.

From www.rtprototype.com

End Milling vs Face Milling What's the Difference? Ruitai Mould Face Milling Vs End Milling In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Choosing between a face mill and an end mill depends on your specific milling requirements. The difference between end and face milling is that a face mill can’t cut axially. In addition, the coarse and fine teeth are also replaceable,. Face Milling Vs End Milling.

From www.slideserve.com

PPT Machining and Machine Tools PowerPoint Presentation ID5722287 Face Milling Vs End Milling The difference between end and face milling is that a face mill can’t cut axially. One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. What is the significant difference between a face mill and an end mill? Face milling uses the cutter’s face to create flat. Face Milling Vs End Milling.

From www.slideserve.com

PPT Lecture 8 THEORY OF METAL MACHINING PowerPoint Presentation Face Milling Vs End Milling What is the significant difference between a face mill and an end mill? Understanding the primary configuration and. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. Choosing between a face mill and an end mill depends on your specific milling requirements. The difference between end and face. Face Milling Vs End Milling.

From www.youtube.com

Differences between Drilling and End Milling (Drill Vs End Mill) YouTube Face Milling Vs End Milling The difference between end and face milling is that a face mill can’t cut axially. In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the. Face Milling Vs End Milling.

From topsbest-precision.com

Face Milling vs End Milling:What’s the Difference? Custom Precision Face Milling Vs End Milling In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. The difference between end and face milling is that a face mill can’t cut axially. Choosing between a face mill and an end mill depends on your specific milling requirements. What is the significant difference between a face mill and. Face Milling Vs End Milling.

From www.lathematters.com

Face Mill vs. End Mill Main Differences Explained! Face Milling Vs End Milling Understanding the primary configuration and. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Understanding the differences in their design, properties, and applications. What is the significant difference between a face mill and an end mill? One of the reasons is that its cutting edges or cutting teeth are. Face Milling Vs End Milling.

From www.slideserve.com

PPT Machining Operations by Ed Red PowerPoint Presentation, free Face Milling Vs End Milling Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. Choosing between a face mill and an end mill depends on your specific milling requirements. The difference between end and face milling is that a face mill can’t cut axially. Understanding the primary configuration and. In addition, the coarse. Face Milling Vs End Milling.

From www.rtprototype.com

End Milling vs Face Milling What's the Difference? Ruitai Mould Face Milling Vs End Milling Understanding the primary configuration and. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. Understanding the differences in their design, properties, and applications. What is the significant difference. Face Milling Vs End Milling.

From www.cnclathing.com

China Top CNC Machining Service OEM Supplier & Manufacturer Junying Face Milling Vs End Milling What is the significant difference between a face mill and an end mill? Understanding the primary configuration and. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. The difference between end and face milling is that a face mill can’t cut axially. One of the reasons is that its. Face Milling Vs End Milling.

From www.slideserve.com

PPT Chapter4 MILLING PROCESS PowerPoint Presentation, free download Face Milling Vs End Milling In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. Understanding the differences in their design, properties, and applications. One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. Face milling uses the. Face Milling Vs End Milling.

From www.manufacturingguide.com

Face milling Find suppliers, processes & material Face Milling Vs End Milling What is the significant difference between a face mill and an end mill? Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Understanding the differences in their design,. Face Milling Vs End Milling.

From toolnotes.com

Milling Operations ToolNotes Face Milling Vs End Milling Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. Understanding the differences in their design, properties, and applications. In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. Choosing between a face mill and. Face Milling Vs End Milling.

From mellowpine.com

Face Milling in Machining How's it Done? MellowPine Face Milling Vs End Milling What is the significant difference between a face mill and an end mill? One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. Understanding the primary configuration and. Understanding the differences in their design, properties, and applications. In face milling, the cutting edges are positioned perpendicular to. Face Milling Vs End Milling.

From www.easiahome.com

Face Milling vs. End Milling Which is Better for Your Project? Easiahome Face Milling Vs End Milling What is the significant difference between a face mill and an end mill? One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time.. Face Milling Vs End Milling.

From autoplasticsworld.com

Exploring Milling Operations Types and Applications Face Milling Vs End Milling Choosing between a face mill and an end mill depends on your specific milling requirements. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. Understanding the differences in their design, properties, and applications. One of the reasons is that its cutting edges or cutting teeth are located in its. Face Milling Vs End Milling.

From www.lathematters.com

Face Milling vs Peripheral Milling What's The Difference? Face Milling Vs End Milling The difference between end and face milling is that a face mill can’t cut axially. One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a. Face Milling Vs End Milling.

From www.rtprototype.com

End Milling vs Face Milling What's the Difference? Ruitai Mould Face Milling Vs End Milling Understanding the primary configuration and. In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. What is the significant difference between a face mill and an end mill? One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end. Face Milling Vs End Milling.

From www.slideshare.net

Week 1 mill 1 Face Milling Vs End Milling In face milling, the cutting edges are positioned perpendicular to the workpiece surface, while in end milling, the cutting edges. One of the reasons is that its cutting edges or cutting teeth are located in its cutting head or at the end face. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end. Face Milling Vs End Milling.

From slideplayer.com

Material Removal Processes Cutting ppt download Face Milling Vs End Milling Understanding the primary configuration and. The difference between end and face milling is that a face mill can’t cut axially. Understanding the differences in their design, properties, and applications. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. In addition, the coarse and fine teeth are also replaceable,. Face Milling Vs End Milling.

From www.mdpi.com

Materials Free FullText HighPerformance Face Milling of 42CrMo4 Face Milling Vs End Milling In addition, the coarse and fine teeth are also replaceable, which plays an important role in using the milling cutter for a long time. Face milling uses the cutter’s face to create flat surfaces and remove large material amounts, while end milling uses the cutter’s. Understanding the differences in their design, properties, and applications. One of the reasons is that. Face Milling Vs End Milling.