Foam Concrete Density And Strength . Consequently, this will effect a. In general, foam concrete with. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained into the plastic. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. Typically, there are two main “driving” factors to a material technical specification: Often, one requirement will define the mix design. Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. Its distinctive qualities include “low aggregate consumption, high. The compressive strength of foam concrete is found to be. Density of foam concrete varies from 300 to 1600 kg/m 3.

from engineeringdiscoveries.com

Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained into the plastic. Density of foam concrete varies from 300 to 1600 kg/m 3. Typically, there are two main “driving” factors to a material technical specification: Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. Often, one requirement will define the mix design. The compressive strength of foam concrete is found to be. Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. In general, foam concrete with. Its distinctive qualities include “low aggregate consumption, high. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to.

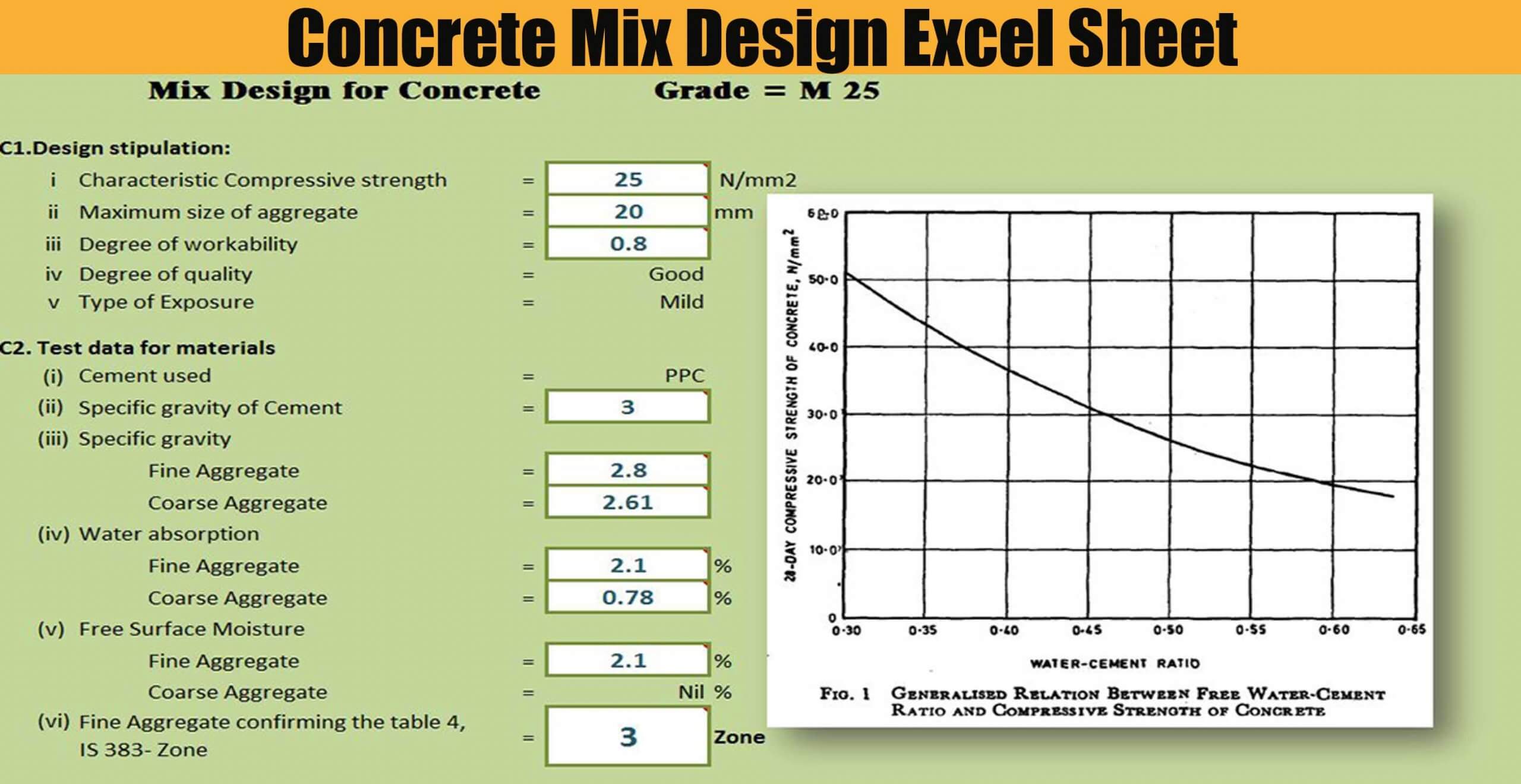

Concrete Mix Design Excel Sheet Engineering Discoveries

Foam Concrete Density And Strength Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. Often, one requirement will define the mix design. Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained into the plastic. Typically, there are two main “driving” factors to a material technical specification: Density of foam concrete varies from 300 to 1600 kg/m 3. Consequently, this will effect a. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. The compressive strength of foam concrete is found to be. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. Its distinctive qualities include “low aggregate consumption, high. In general, foam concrete with.

From www.foamedconcrete.co.uk

What is Foam Concrete? Propump Engineering Limited Foam Concrete Density And Strength Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. Often, one requirement will define the mix design. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. The compressive strength of foam concrete is found to be. Pore distribution is. Foam Concrete Density And Strength.

From www.foamedconcrete.co.uk

High Density Foamed Concretes Foamed Concrete Specialists Propump Foam Concrete Density And Strength Often, one requirement will define the mix design. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. Its distinctive qualities include “low aggregate consumption, high. In general, foam concrete with. Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is. Foam Concrete Density And Strength.

From www.researchgate.net

Compressive strength vs. apparent density of foam concrete. Sstandard Foam Concrete Density And Strength Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. In general, foam concrete with. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. Consequently, this will effect a. Pore distribution is one of the important microscopic. Foam Concrete Density And Strength.

From www.researchgate.net

Correlation between compressive strength at 28day and dry density of Foam Concrete Density And Strength Density of foam concrete varies from 300 to 1600 kg/m 3. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. The compressive strength of foam concrete is found to be. Often, one requirement will define the mix design. Consequently, this will effect a. Typically, there are two main “driving”. Foam Concrete Density And Strength.

From www.slideserve.com

PPT Foam concrete block PowerPoint Presentation ID6959805 Foam Concrete Density And Strength The compressive strength of foam concrete is found to be. Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. Pore distribution is one of the important microscopic parameters affecting the. Foam Concrete Density And Strength.

From www.google.com

WO2010076565A1 Foaming agent Google Patents Foam Concrete Density And Strength Its distinctive qualities include “low aggregate consumption, high. Often, one requirement will define the mix design. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. The compressive strength of foam concrete is found to be. Foam concrete can be defined as a cementitious material that consists. Foam Concrete Density And Strength.

From www.thethamesconcrete.co.uk

Essential Steps to Make Foam Concrete Blocks Foam Concrete Density And Strength Its distinctive qualities include “low aggregate consumption, high. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. Consequently, this will effect a. Typically, there are two main “driving” factors to a material technical specification:. Foam Concrete Density And Strength.

From www.totalconcrete.co.uk

What is Foamed Concrete? Total Concrete Foam Concrete Density And Strength Often, one requirement will define the mix design. Its distinctive qualities include “low aggregate consumption, high. Density of foam concrete varies from 300 to 1600 kg/m 3. Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. In general, foam concrete with. Foam concrete can be defined as a cementitious material. Foam Concrete Density And Strength.

From giomtuybt.blob.core.windows.net

Foam Concrete Design at Russell Mccabe blog Foam Concrete Density And Strength Its distinctive qualities include “low aggregate consumption, high. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. In general, foam concrete with. Often, one requirement will define. Foam Concrete Density And Strength.

From civilstring.com

Foam Concrete Or Lightweight Concrete Advantages And Disadvantages Of Foam Concrete Density And Strength The compressive strength of foam concrete is found to be. Typically, there are two main “driving” factors to a material technical specification: After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity. Foam Concrete Density And Strength.

From www.foamedconcrete.co.uk

Low Density Light Weight Foamed Concretes Foamed Concrete Specialists Foam Concrete Density And Strength Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained into the plastic. Density of foam concrete varies from 300 to 1600 kg/m 3. Typically, there are two main “driving” factors to a material technical specification: Foam concrete (fc) is one among the lightweight concrete, which is usually considered. Foam Concrete Density And Strength.

From www.geofoamamerica.com

Information Density and Ratings of foam logs, blocks and billets Foam Concrete Density And Strength Its distinctive qualities include “low aggregate consumption, high. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. The compressive strength of foam concrete is found to be. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. Foam concrete can be. Foam Concrete Density And Strength.

From civiconcepts.com

Light Weight Concrete Types, Uses & Properties Civiconcepts Foam Concrete Density And Strength Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. The compressive strength of foam concrete is found to be. Often, one requirement will define the mix design. Foam concrete (fc) is. Foam Concrete Density And Strength.

From www.novotek.co

CLC Block Plant Foam concrete production line Novotek Machinery Co Foam Concrete Density And Strength Consequently, this will effect a. Often, one requirement will define the mix design. Its distinctive qualities include “low aggregate consumption, high. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. Typically, there are two main “driving” factors to a material technical specification: Pore distribution is one of the important. Foam Concrete Density And Strength.

From giomtuybt.blob.core.windows.net

Foam Concrete Design at Russell Mccabe blog Foam Concrete Density And Strength Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained into the plastic. Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. After 28. Foam Concrete Density And Strength.

From www.mdpi.com

Crystals Free FullText A Taguchi Approach for Optimizing Design Foam Concrete Density And Strength Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained into the plastic. Consequently, this will effect a. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Its distinctive qualities include “low aggregate consumption, high. Typically, there are two main “driving” factors to. Foam Concrete Density And Strength.

From br.pinterest.com

Foam Concrete Manufacturing, Advantages and Disadvantages Concrete Foam Concrete Density And Strength Its distinctive qualities include “low aggregate consumption, high. Typically, there are two main “driving” factors to a material technical specification: Density of foam concrete varies from 300 to 1600 kg/m 3. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. Often, one requirement will define the. Foam Concrete Density And Strength.

From www.mdpi.com

Research on the Improving Performance of Foam Concrete Applied to the Foam Concrete Density And Strength Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained into the plastic. Density of foam concrete varies from 300 to 1600 kg/m 3. The compressive strength of foam concrete is found to be. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete.. Foam Concrete Density And Strength.

From www.researchgate.net

Test Results of Split Tensile Strength of foam Concrete Download Foam Concrete Density And Strength Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. Consequently, this will effect a. Often, one requirement will define the mix design. The compressive strength of foam concrete is found to be. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and. Foam Concrete Density And Strength.

From www.specifyconcrete.org

What Exactly Is Lightweight Concrete? Specify Concrete Foam Concrete Density And Strength Consequently, this will effect a. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. Typically, there are two main “driving” factors to a material technical specification: Often, one requirement will define the mix design. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete.. Foam Concrete Density And Strength.

From www.researchgate.net

Relationship between density and compressive strength of hardened Foam Concrete Density And Strength Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. Consequently, this will effect a. Typically, there are two main “driving” factors to a material technical specification: In general, foam concrete with. Often, one requirement will define the mix design. Its distinctive qualities include “low aggregate consumption, high. Pore distribution. Foam Concrete Density And Strength.

From www.scribd.com

Characteristics of Foam Concrete With Usage of Foam Agent Which Varies Foam Concrete Density And Strength Consequently, this will effect a. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Often, one requirement will define the mix design. Density of foam concrete varies from 300 to 1600 kg/m 3. Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained. Foam Concrete Density And Strength.

From www.frontiersin.org

Frontiers Optimization of Preparation of Foamed Concrete Based on Foam Concrete Density And Strength In general, foam concrete with. Its distinctive qualities include “low aggregate consumption, high. Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained into the plastic. Density of foam concrete varies from 300 to 1600 kg/m 3. Bulk density of foam concrete is obtained to be 250 kg/m3 and. Foam Concrete Density And Strength.

From www.azobuild.com

How is Foam Concrete Used in Construction? Foam Concrete Density And Strength Consequently, this will effect a. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. Typically, there are two main “driving” factors to a material technical specification: Foam concrete (fc) is one. Foam Concrete Density And Strength.

From www.researchgate.net

, Design and mix proportion of lightweight foamed concrete (LFC Foam Concrete Density And Strength After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Its distinctive qualities include “low aggregate consumption, high. The compressive strength of foam concrete is found to be. Foam concrete can be. Foam Concrete Density And Strength.

From www.dpcanada.com

Dense Foam Riser Pad Concrete Floor Diamond Productions Foam Concrete Density And Strength Consequently, this will effect a. Its distinctive qualities include “low aggregate consumption, high. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Often, one requirement will define the mix design. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. Foam concrete can be. Foam Concrete Density And Strength.

From www.eppconcrete.com

Leveling Concrete Slabs Using Polyurethane Foam Injection Foam Concrete Density And Strength Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. Its distinctive qualities include “low aggregate consumption, high. Pore distribution is one of the important microscopic parameters. Foam Concrete Density And Strength.

From theoryanalysis.netlify.app

Relation between tensile strength and shear strength Foam Concrete Density And Strength The compressive strength of foam concrete is found to be. In general, foam concrete with. Often, one requirement will define the mix design. Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained into the plastic. Typically, there are two main “driving” factors to a material technical specification: Bulk. Foam Concrete Density And Strength.

From engineeringdiscoveries.com

Concrete Mix Design Excel Sheet Engineering Discoveries Foam Concrete Density And Strength Consequently, this will effect a. Density of foam concrete varies from 300 to 1600 kg/m 3. Often, one requirement will define the mix design. The compressive strength of foam concrete is found to be. In general, foam concrete with. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from. Foam Concrete Density And Strength.

From www.mdpi.com

Applied Sciences Free FullText A Detailed Review on Foam Concrete Foam Concrete Density And Strength Typically, there are two main “driving” factors to a material technical specification: Often, one requirement will define the mix design. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Its distinctive qualities include “low aggregate consumption, high. The compressive strength of foam concrete is found to be. Bulk density of foam concrete is obtained. Foam Concrete Density And Strength.

From www.researchgate.net

Compressive strengths of foamed concrete and normal concrete Download Foam Concrete Density And Strength In general, foam concrete with. Its distinctive qualities include “low aggregate consumption, high. Often, one requirement will define the mix design. Consequently, this will effect a. After 28 days, the plastic density of foam concrete is between 1800 and 280 kg/m3, and its compressive strength ranges from 43 to. Bulk density of foam concrete is obtained to be 250 kg/m3. Foam Concrete Density And Strength.

From api.gharpedia.com

Foamed Cellular Light Weight Concrete Applications and Advantages Foam Concrete Density And Strength Its distinctive qualities include “low aggregate consumption, high. Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. The compressive strength of foam concrete is found to be. In general, foam concrete with. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Foam concrete can. Foam Concrete Density And Strength.

From www.researchgate.net

Compressive Strength Concrete VS Density Download Scientific Diagram Foam Concrete Density And Strength Its distinctive qualities include “low aggregate consumption, high. Density of foam concrete varies from 300 to 1600 kg/m 3. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Foam concrete (fc) is one among the lightweight concrete, which is usually considered for its low strength and therefore it. Bulk density of foam concrete is. Foam Concrete Density And Strength.

From engineeringdiscoveries.com

Density Of Construction Materials In Kg/m3 And Ib/ft3 Engineering Foam Concrete Density And Strength Density of foam concrete varies from 300 to 1600 kg/m 3. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. Bulk density of foam concrete is obtained to be 250 kg/m3 and its heat conductivity to be 0,075 w/mk. The compressive strength of foam concrete is found to be. Consequently, this will effect a.. Foam Concrete Density And Strength.

From www.mdpi.com

Buildings Free FullText Effect of Foaming Agent, Binder and Foam Concrete Density And Strength Often, one requirement will define the mix design. In general, foam concrete with. Typically, there are two main “driving” factors to a material technical specification: Its distinctive qualities include “low aggregate consumption, high. Pore distribution is one of the important microscopic parameters affecting the strength of foam concrete. After 28 days, the plastic density of foam concrete is between 1800. Foam Concrete Density And Strength.