Step Drilling Taper Pin Holes . These reamers have a tapered cutting end that matches the taper of. The taper on all pins is 0.250 per foot (or 1.194°). These are designed for reaming holes so that standard taper pins will be able to fit properly. Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. The taper causes constant contact through the length of the pin as well as the. I drilled the hole out in about six steps to. Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. The table below provides an overview of the standard taper pin sizes. Stepped holes by drilling two holes. Taper pins are a highly precise locating pin. Determine the desired taper angle: First the larger diameter, then the smaller. This will depend on the. The first step is to decide on the angle of the taper hole.

from www.mdpi.com

Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. First the larger diameter, then the smaller. The table below provides an overview of the standard taper pin sizes. The taper causes constant contact through the length of the pin as well as the. I drilled the hole out in about six steps to. This will depend on the. The taper on all pins is 0.250 per foot (or 1.194°). These are designed for reaming holes so that standard taper pins will be able to fit properly. The first step is to decide on the angle of the taper hole. Determine the desired taper angle:

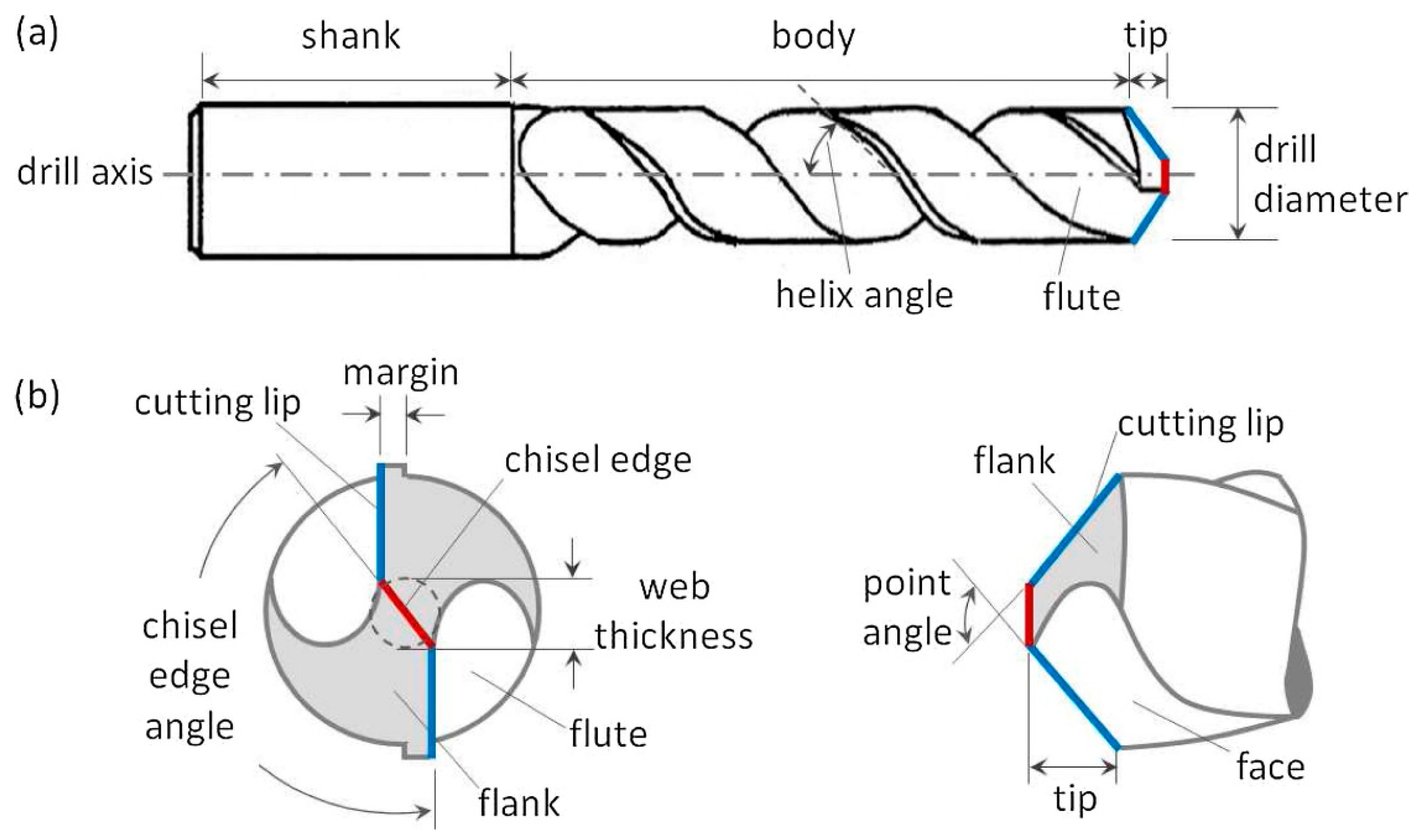

Metals Free FullText A Review of Surgical Bone Drilling and Drill

Step Drilling Taper Pin Holes The first step is to decide on the angle of the taper hole. I drilled the hole out in about six steps to. Stepped holes by drilling two holes. This will depend on the. Determine the desired taper angle: These reamers have a tapered cutting end that matches the taper of. Taper pins are a highly precise locating pin. These are designed for reaming holes so that standard taper pins will be able to fit properly. The first step is to decide on the angle of the taper hole. The taper on all pins is 0.250 per foot (or 1.194°). Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. First the larger diameter, then the smaller. Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. The table below provides an overview of the standard taper pin sizes. The taper causes constant contact through the length of the pin as well as the.

From www.dreamstime.com

Conical Step Drill for Drilling Holes of Different Diameters, Isolated Step Drilling Taper Pin Holes The first step is to decide on the angle of the taper hole. Determine the desired taper angle: Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. This will depend on the. Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. Stepped. Step Drilling Taper Pin Holes.

From www.aliexpress.com

Buy 3pc Hss Step Cone Taper Drill Bit Set Metal Hole Step Drilling Taper Pin Holes Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. These reamers have a tapered cutting end that matches the taper of. Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. The first step is to decide on the angle of the taper. Step Drilling Taper Pin Holes.

From www.dreamstime.com

Conical Step Drill for Drilling Holes of Different Diameters, Isolated Step Drilling Taper Pin Holes Stepped holes by drilling two holes. The taper on all pins is 0.250 per foot (or 1.194°). The taper causes constant contact through the length of the pin as well as the. These are designed for reaming holes so that standard taper pins will be able to fit properly. This will depend on the. Determine the desired taper angle: First. Step Drilling Taper Pin Holes.

From alisaleplus.com

Hss Taper Titanium Coated Step Drill Set (3pc) Step Drilling Taper Pin Holes The first step is to decide on the angle of the taper hole. First the larger diameter, then the smaller. The taper on all pins is 0.250 per foot (or 1.194°). This will depend on the. Determine the desired taper angle: Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. These. Step Drilling Taper Pin Holes.

From www.familyhandyman.com

12 Tips for Drilling Holes in Metal — The Family Handyman Step Drilling Taper Pin Holes Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. The taper on all pins is 0.250 per foot (or 1.194°). These reamers have a tapered cutting end that matches the taper of. Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. First. Step Drilling Taper Pin Holes.

From www.indiamart.com

Taper Shank Twist Drills For Taper Pin Holes at Rs 1500/piece Taper Step Drilling Taper Pin Holes This will depend on the. The table below provides an overview of the standard taper pin sizes. These reamers have a tapered cutting end that matches the taper of. I drilled the hole out in about six steps to. These are designed for reaming holes so that standard taper pins will be able to fit properly. First the larger diameter,. Step Drilling Taper Pin Holes.

From shuntool.com

Mastering The Art Of Drilling Taper Holes A Comprehensive Guide ShunTool Step Drilling Taper Pin Holes These are designed for reaming holes so that standard taper pins will be able to fit properly. The taper causes constant contact through the length of the pin as well as the. These reamers have a tapered cutting end that matches the taper of. Determine the desired taper angle: Stepped holes by drilling two holes. Always start drilling the large. Step Drilling Taper Pin Holes.

From www.joom.com

Buy Step Taper Drill Bit Set Multifunctional Cone Metal Hole Cutter Step Drilling Taper Pin Holes Stepped holes by drilling two holes. First the larger diameter, then the smaller. These reamers have a tapered cutting end that matches the taper of. I drilled the hole out in about six steps to. The first step is to decide on the angle of the taper hole. The table below provides an overview of the standard taper pin sizes.. Step Drilling Taper Pin Holes.

From www.aliexpress.com

4Pcs Drilling Bits Set taper 6mm Saw 8 20mm Taper 4 12mm Step Drill Bit Step Drilling Taper Pin Holes The taper on all pins is 0.250 per foot (or 1.194°). These are designed for reaming holes so that standard taper pins will be able to fit properly. These reamers have a tapered cutting end that matches the taper of. First the larger diameter, then the smaller. The taper causes constant contact through the length of the pin as well. Step Drilling Taper Pin Holes.

From www.aliexpress.com

13pcHSSStepDrillBitSetConeHoleCutterTaperMetric4122032mm.jpg Step Drilling Taper Pin Holes The first step is to decide on the angle of the taper hole. The taper on all pins is 0.250 per foot (or 1.194°). First the larger diameter, then the smaller. Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. Always start drilling the large diameter to ensure centering of the. Step Drilling Taper Pin Holes.

From www.walmart.com

3Pc Hss Step Cone Taper Drill Bit Set Hole Cutter Metric 412/20/32Mm 1 Step Drilling Taper Pin Holes First the larger diameter, then the smaller. I drilled the hole out in about six steps to. The taper on all pins is 0.250 per foot (or 1.194°). Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. The first step is to decide on the angle of the taper hole. The. Step Drilling Taper Pin Holes.

From www.dreamstime.com

Conical Step Drill for Drilling Holes of Different Diameters, Isolated Step Drilling Taper Pin Holes The taper causes constant contact through the length of the pin as well as the. The table below provides an overview of the standard taper pin sizes. The taper on all pins is 0.250 per foot (or 1.194°). Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. These are designed for. Step Drilling Taper Pin Holes.

From www.aliexpress.com

3pcs Hss Step Cone Taper Drill Bit Set Hole Cutter Metric 4 12/20/32mm Step Drilling Taper Pin Holes Taper pins are a highly precise locating pin. First the larger diameter, then the smaller. Determine the desired taper angle: Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. The table below provides. Step Drilling Taper Pin Holes.

From www.walmart.com

Adjustable Counterbore Drilling Taper Hole Drilling Drilling Step Screw Step Drilling Taper Pin Holes Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. These reamers have a tapered cutting end that matches the taper of. Stepped holes by drilling two holes. I drilled the hole out in. Step Drilling Taper Pin Holes.

From www.dreamstime.com

Conical Step Drill for Drilling Holes of Different Diameters, Isolated Step Drilling Taper Pin Holes Stepped holes by drilling two holes. The table below provides an overview of the standard taper pin sizes. These reamers have a tapered cutting end that matches the taper of. This will depend on the. Determine the desired taper angle: Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. These are. Step Drilling Taper Pin Holes.

From www.alamy.com

Conical step drill for drilling holes of different diameters, isolated Step Drilling Taper Pin Holes The table below provides an overview of the standard taper pin sizes. I drilled the hole out in about six steps to. Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. These reamers have a tapered cutting end that matches the taper of. Taper pins are a highly precise locating pin.. Step Drilling Taper Pin Holes.

From www.dreamstime.com

Conical Step Drill for Drilling Holes of Different Diameters, Isolated Step Drilling Taper Pin Holes The first step is to decide on the angle of the taper hole. First the larger diameter, then the smaller. The table below provides an overview of the standard taper pin sizes. The taper causes constant contact through the length of the pin as well as the. Stepped holes by drilling two holes. These are designed for reaming holes so. Step Drilling Taper Pin Holes.

From www.youtube.com

Transferring Hole Locations using gauge pins match holes for drilling Step Drilling Taper Pin Holes First the larger diameter, then the smaller. Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. The taper causes constant contact through the length of the pin as well as the. The first step is to decide on the angle of the taper hole. Taper pin reamers are specialized tools used. Step Drilling Taper Pin Holes.

From www.aliexpress.com

10 45mm HSS Step Cone Drill Bit Titanium Hole Saw Cutter Tool Metal Step Drilling Taper Pin Holes Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. These reamers have a tapered cutting end that matches the taper of. The taper on all pins is 0.250 per foot (or 1.194°). Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. The. Step Drilling Taper Pin Holes.

From www.dreamstime.com

Conical Step Drill for Drilling Holes of Different Diameters, Isolated Step Drilling Taper Pin Holes Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. These are designed for reaming holes so that standard taper pins will be able to fit properly. The table below provides an overview of the standard taper pin sizes. Taper pins are a highly precise locating pin. Stepped holes by drilling two. Step Drilling Taper Pin Holes.

From www.youtube.com

Taper Pin Hole Drilling and Reaming PART 3 YouTube Step Drilling Taper Pin Holes Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. The first step is to decide on the angle of the taper hole. Stepped holes by drilling two holes. These are designed for reaming. Step Drilling Taper Pin Holes.

From shopee.ph

Drill Bit HSS Titanium Coated Hex Shank Step Drill bit set cone hole Step Drilling Taper Pin Holes I drilled the hole out in about six steps to. Stepped holes by drilling two holes. This will depend on the. Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. The table below provides an overview of the standard taper pin sizes. First the larger diameter, then the smaller. The first. Step Drilling Taper Pin Holes.

From www.thehandymansdaughter.com

How to Drill Shelf Pin Holes [Two Different Ways] The Handyman's Daughter Step Drilling Taper Pin Holes This will depend on the. Taper pins are a highly precise locating pin. The taper on all pins is 0.250 per foot (or 1.194°). I drilled the hole out in about six steps to. Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. The table below provides an overview of the. Step Drilling Taper Pin Holes.

From www.dreamstime.com

Conical Step Drill for Drilling Holes of Different Diameters, Isolated Step Drilling Taper Pin Holes These are designed for reaming holes so that standard taper pins will be able to fit properly. I drilled the hole out in about six steps to. Determine the desired taper angle: Stepped holes by drilling two holes. The table below provides an overview of the standard taper pin sizes. Taper pin reamers are specialized tools used to enlarge tapered. Step Drilling Taper Pin Holes.

From www.dreamstime.com

Conical Step Drill for Drilling Holes of Different Diameters, Isolated Step Drilling Taper Pin Holes Taper pins are a highly precise locating pin. The taper causes constant contact through the length of the pin as well as the. These are designed for reaming holes so that standard taper pins will be able to fit properly. These reamers have a tapered cutting end that matches the taper of. I drilled the hole out in about six. Step Drilling Taper Pin Holes.

From www.faithfulltools.com

HSS Taper Drills Step Drilling Taper Pin Holes Stepped holes by drilling two holes. The taper on all pins is 0.250 per foot (or 1.194°). The taper causes constant contact through the length of the pin as well as the. These reamers have a tapered cutting end that matches the taper of. Always start drilling the large diameter to ensure centering of the drill point and avoid chipping. Step Drilling Taper Pin Holes.

From www.woodworkingtalk.com

Drill driven bits for large tapered holes in thick wood. Woodworking Talk Step Drilling Taper Pin Holes I drilled the hole out in about six steps to. The table below provides an overview of the standard taper pin sizes. This will depend on the. The first step is to decide on the angle of the taper hole. These reamers have a tapered cutting end that matches the taper of. These are designed for reaming holes so that. Step Drilling Taper Pin Holes.

From medium.com

The Ins and Outs of Taper Pins Design, Installation, and Advantages Step Drilling Taper Pin Holes These reamers have a tapered cutting end that matches the taper of. Stepped holes by drilling two holes. Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. The taper on all pins is 0.250 per foot (or 1.194°). This will depend on the. The taper causes constant contact through the length. Step Drilling Taper Pin Holes.

From www.dreamstime.com

Conical Step Drill for Drilling Holes of Different Diameters, Isolated Step Drilling Taper Pin Holes This will depend on the. These reamers have a tapered cutting end that matches the taper of. These are designed for reaming holes so that standard taper pins will be able to fit properly. The table below provides an overview of the standard taper pin sizes. Always start drilling the large diameter to ensure centering of the drill point and. Step Drilling Taper Pin Holes.

From www.mdpi.com

Metals Free FullText A Review of Surgical Bone Drilling and Drill Step Drilling Taper Pin Holes These are designed for reaming holes so that standard taper pins will be able to fit properly. This will depend on the. First the larger diameter, then the smaller. The table below provides an overview of the standard taper pin sizes. Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. The. Step Drilling Taper Pin Holes.

From www.aliexpress.com

Hss Step Cone Taper Drills for Metal Plastic Hole Cutter 1/4" Hex Shank Step Drilling Taper Pin Holes Always start drilling the large diameter to ensure centering of the drill point and avoid chipping cutting edges. The taper on all pins is 0.250 per foot (or 1.194°). The first step is to decide on the angle of the taper hole. Determine the desired taper angle: This will depend on the. The table below provides an overview of the. Step Drilling Taper Pin Holes.

From www.youtube.com

Taper Pin Drill and Ream Part 1 YouTube Step Drilling Taper Pin Holes These are designed for reaming holes so that standard taper pins will be able to fit properly. Stepped holes by drilling two holes. The table below provides an overview of the standard taper pin sizes. These reamers have a tapered cutting end that matches the taper of. Determine the desired taper angle: The taper on all pins is 0.250 per. Step Drilling Taper Pin Holes.

From www.aliexpress.com

HSS 4241 Hss Step Drill Bit Set Cone Hole Cutter Taper Metric 4 12/20 Step Drilling Taper Pin Holes These are designed for reaming holes so that standard taper pins will be able to fit properly. This will depend on the. These reamers have a tapered cutting end that matches the taper of. The taper causes constant contact through the length of the pin as well as the. The first step is to decide on the angle of the. Step Drilling Taper Pin Holes.

From www.alamy.com

Conical step drill for drilling holes of different diameters, isolated Step Drilling Taper Pin Holes These reamers have a tapered cutting end that matches the taper of. Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. The first step is to decide on the angle of the taper hole. First the larger diameter, then the smaller. The table below provides an overview of the standard taper. Step Drilling Taper Pin Holes.

From www.aliexpress.com

PEGASI 3pc Hss Step Cone Taper Drill Bit Set Metal Hole Cutter Metric 4 Step Drilling Taper Pin Holes I drilled the hole out in about six steps to. The taper causes constant contact through the length of the pin as well as the. The taper on all pins is 0.250 per foot (or 1.194°). Determine the desired taper angle: Taper pin reamers are specialized tools used to enlarge tapered holes for a precise fit with taper pins. Always. Step Drilling Taper Pin Holes.