Kiss Cut Process . What is a kiss cut? Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. Kiss cut sticker sheet printing is when the adhesive top layer of a sticker sheet is “kissed” by a kiss vinyls. The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is “kissed” by the blade so it only cuts through the topmost layer. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any backing material intact. Most often, this is used to create a roll of parts, where. Kiss cutting is a process of cutting sticker paper or vinyl. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. A kiss cut is a “light” cut that can be made with a die or laser. If you need to cut specific layers of material, kiss cutting.

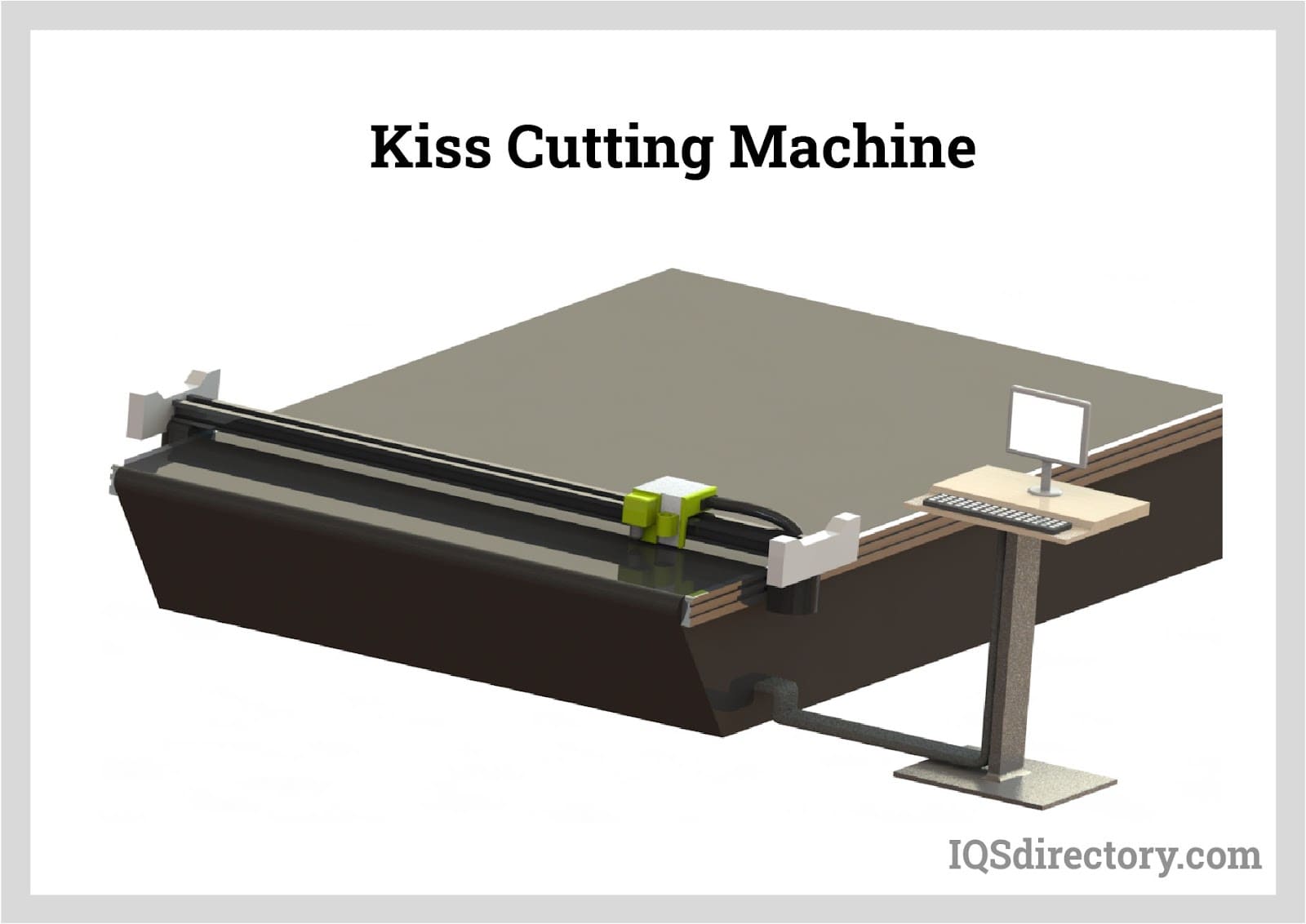

from www.iqsdirectory.com

Kiss cutting is a process of cutting sticker paper or vinyl. A kiss cut is a “light” cut that can be made with a die or laser. Kiss cut sticker sheet printing is when the adhesive top layer of a sticker sheet is “kissed” by a kiss vinyls. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is “kissed” by the blade so it only cuts through the topmost layer. If you need to cut specific layers of material, kiss cutting. Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. What is a kiss cut?

Kiss Cutting What Is It? How Does It Work? Types, Products

Kiss Cut Process Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. Kiss cut sticker sheet printing is when the adhesive top layer of a sticker sheet is “kissed” by a kiss vinyls. Most often, this is used to create a roll of parts, where. A kiss cut is a “light” cut that can be made with a die or laser. The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is “kissed” by the blade so it only cuts through the topmost layer. What is a kiss cut? Kiss cutting is a process of cutting sticker paper or vinyl. Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any backing material intact. If you need to cut specific layers of material, kiss cutting. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting.

From www.polarseal.net

Kiss cutting PolarSeal Kiss Cut Process Kiss cut sticker sheet printing is when the adhesive top layer of a sticker sheet is “kissed” by a kiss vinyls. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. What is a kiss. Kiss Cut Process.

From www.ljamiers.co.uk

Kiss Cutting Processes from LJA Miers Kiss Cut Process A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any backing material intact. What is a kiss cut? It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. The reason it is referred to as “kiss” cutting is because when the material is. Kiss Cut Process.

From www.youtube.com

Kiss Cutting Laser Marking Adhesive Paper by SCHMIDT YouTube Kiss Cut Process What is a kiss cut? Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. If you need to cut specific layers of material, kiss cutting. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. However, it. Kiss Cut Process.

From www.scoopearth.com

Kiss Cutting Services And When They're Useful Kiss Cut Process What is a kiss cut? However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. Kiss cut sticker sheet printing is when the adhesive top layer of a sticker sheet. Kiss Cut Process.

From www.youtube.com

Kiss Cutting Process For Custom Gaskets YouTube Kiss Cut Process A kiss cut is a “light” cut that can be made with a die or laser. A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any backing material intact. The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is. Kiss Cut Process.

From masterfoam.com

Kiss Cutting MASTERFOAM Kiss Cut Process The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is “kissed” by the blade so it only cuts through the topmost layer. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. Kiss cutting is a process of cutting sticker paper or vinyl. What. Kiss Cut Process.

From www.gfcole.com

Kiss Cutting G.F. Cole Corporation Kiss Cut Process Kiss cutting is a process of cutting sticker paper or vinyl. Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. If you need to cut specific layers. Kiss Cut Process.

From www.youtube.com

Get to know The Summa KissCut Tool. YouTube Kiss Cut Process Most often, this is used to create a roll of parts, where. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. If you need to cut specific layers of material, kiss cutting. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. It. Kiss Cut Process.

From www.youtube.com

Zünd Kiss cut YouTube Kiss Cut Process It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. A kiss cut is a “light” cut that can be made with a die or laser. The reason it is referred to as “kiss” cutting is because. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process Most often, this is used to create a roll of parts, where. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is “kissed” by the blade so it only cuts through the topmost. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process Kiss cut sticker sheet printing is when the adhesive top layer of a sticker sheet is “kissed” by a kiss vinyls. A kiss cut is a “light” cut that can be made with a die or laser. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. Kiss cutting is a process of cutting. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process A kiss cut is a “light” cut that can be made with a die or laser. What is a kiss cut? Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. Kiss cut sticker sheet printing is when the adhesive top layer of a sticker sheet is. Kiss Cut Process.

From www.youtube.com

Kiss Cutting For Peel & Stick Applications YouTube Kiss Cut Process Kiss cutting is a process of cutting sticker paper or vinyl. Most often, this is used to create a roll of parts, where. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. A kiss cut is a type of cut that only cuts through the first layer of a material and leaves. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process A kiss cut is a “light” cut that can be made with a die or laser. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. If you need to cut specific layers of material, kiss cutting. Kiss cutting is a process of cutting sticker paper or vinyl. A kiss cut is a. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process If you need to cut specific layers of material, kiss cutting. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. What is a kiss cut? The reason it is referred to as “kiss” cutting is because. Kiss Cut Process.

From quality-industrial.com

Die Cut Vs. Kiss Cut Quality Industrial Products, Inc. Kiss Cut Process It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. Kiss cut sticker sheet printing is when the adhesive top layer of a sticker sheet is “kissed” by a kiss vinyls. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. What is a kiss cut? Kiss. Kiss Cut Process.

From www.gfcole.com

Kiss Cutting G.F. Cole Corporation Kiss Cut Process A kiss cut is a “light” cut that can be made with a die or laser. Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any. Kiss Cut Process.

From www.temizserigrafi.com

Die Cutting and Kiss Cutting Temiz Serigrafi Kiss Cut Process Most often, this is used to create a roll of parts, where. Kiss cutting is a process of cutting sticker paper or vinyl. A kiss cut is a “light” cut that can be made with a die or laser. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. It only. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process Kiss cutting is a process of cutting sticker paper or vinyl. If you need to cut specific layers of material, kiss cutting. What is a kiss cut? A kiss cut is a “light” cut that can be made with a die or laser. A kiss cut is a type of cut that only cuts through the first layer of a. Kiss Cut Process.

From www.dexcakft.com

Kiss Cutting Dexca Kiss Cut Process A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any backing material intact. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is. Kiss Cut Process.

From www.youtube.com

Laser kiss cutting process (StartStop Mode)/Процесс лазерной надсечки Kiss Cut Process Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any backing material intact. If you need to cut specific layers of material, kiss cutting. The reason it is referred to. Kiss Cut Process.

From www.gfcole.com

Kiss Cutting G.F. Cole Corporation Kiss Cut Process Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. Kiss cutting is a process of cutting sticker paper or vinyl. If you need to cut specific layers of material, kiss cutting. The reason it is referred to as “kiss” cutting is because when the material is. Kiss Cut Process.

From www.britishfelt.com

Kiss Cutting SelfAdhesive Felt, Foam and Sponge Kiss Cut Process A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any backing material intact. Most often, this is used to create a roll of parts, where. A kiss cut is a “light” cut that can be made with a die or laser. Kiss cutting is the process of cutting layers. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process What is a kiss cut? The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is “kissed” by the blade so it only cuts through the topmost layer. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. Kiss cutting is a process of. Kiss Cut Process.

From hi-tech-products.com

Kiss Cutting Rotary Die Cutting and Flatbed Die Cutting Kiss Cutting Kiss Cut Process If you need to cut specific layers of material, kiss cutting. Kiss cutting is a process of cutting sticker paper or vinyl. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. A kiss cut is a “light” cut that can be made with a die or laser. Kiss cut sticker. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process Kiss cutting is a process of cutting sticker paper or vinyl. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. If you need to cut specific layers of material, kiss cutting. The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is “kissed” by. Kiss Cut Process.

From accushapediecutting.com

Die Cut vs. Kiss Cut What is the Difference? • AccuShapeAccuShape Kiss Cut Process Kiss cut sticker sheet printing is when the adhesive top layer of a sticker sheet is “kissed” by a kiss vinyls. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. Kiss cutting is a process of cutting sticker paper or vinyl. Most often, this is used to create a roll. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is “kissed” by the blade so it only. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process A kiss cut is a “light” cut that can be made with a die or laser. Most often, this is used to create a roll of parts, where. Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. Kiss cutting is a process of cutting sticker paper. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process A kiss cut is a “light” cut that can be made with a die or laser. What is a kiss cut? If you need to cut specific layers of material, kiss cutting. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. Kiss cut sticker sheet printing is when the adhesive top layer of. Kiss Cut Process.

From southernrubber.com

Die Cutting, Kiss Cutting & Flash Cutting Southern Rubber Company, Inc. Kiss Cut Process The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is “kissed” by the blade so it only cuts through the topmost layer. Kiss cutting can consolidate the steps of an otherwise tedious process when used in tandem with through die cutting. Kiss cutting is the process of cutting layers of. Kiss Cut Process.

From hochintmachine.com

What Is The "Kisscut" Kiss Cut Process If you need to cut specific layers of material, kiss cutting. A kiss cut is a “light” cut that can be made with a die or laser. However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. The reason it is referred to as “kiss” cutting is because when the material is cut,. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process Kiss cutting is the process of cutting layers of material so that the top layer (s) are cut, but the back remains intact. It only penetrates the top layer and not the pressure sensitive adhesive liner or substrate layer. A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any. Kiss Cut Process.

From www.iqsdirectory.com

Die Cutting What Is It? How Does It Work? Parts, Design Kiss Cut Process However, it opens the door for numerous potential headaches with defects, and fallout increases when incorrectly performed. A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any backing material intact. Most often, this is used to create a roll of parts, where. The reason it is referred to as. Kiss Cut Process.

From www.iqsdirectory.com

Kiss Cutting What Is It? How Does It Work? Types, Products Kiss Cut Process The reason it is referred to as “kiss” cutting is because when the material is cut, the top layer is “kissed” by the blade so it only cuts through the topmost layer. A kiss cut is a type of cut that only cuts through the first layer of a material and leaves any backing material intact. If you need to. Kiss Cut Process.