Robot Condition Monitoring . Robot condition monitoring can improve production capacity. The tool serves as a. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. However, due to the changes of robot in dynamic working state, this. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. Firstly, in the case of no fault, the.

from www.kuka.com

Firstly, in the case of no fault, the. The tool serves as a. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. However, due to the changes of robot in dynamic working state, this. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Robot condition monitoring can improve production capacity. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm.

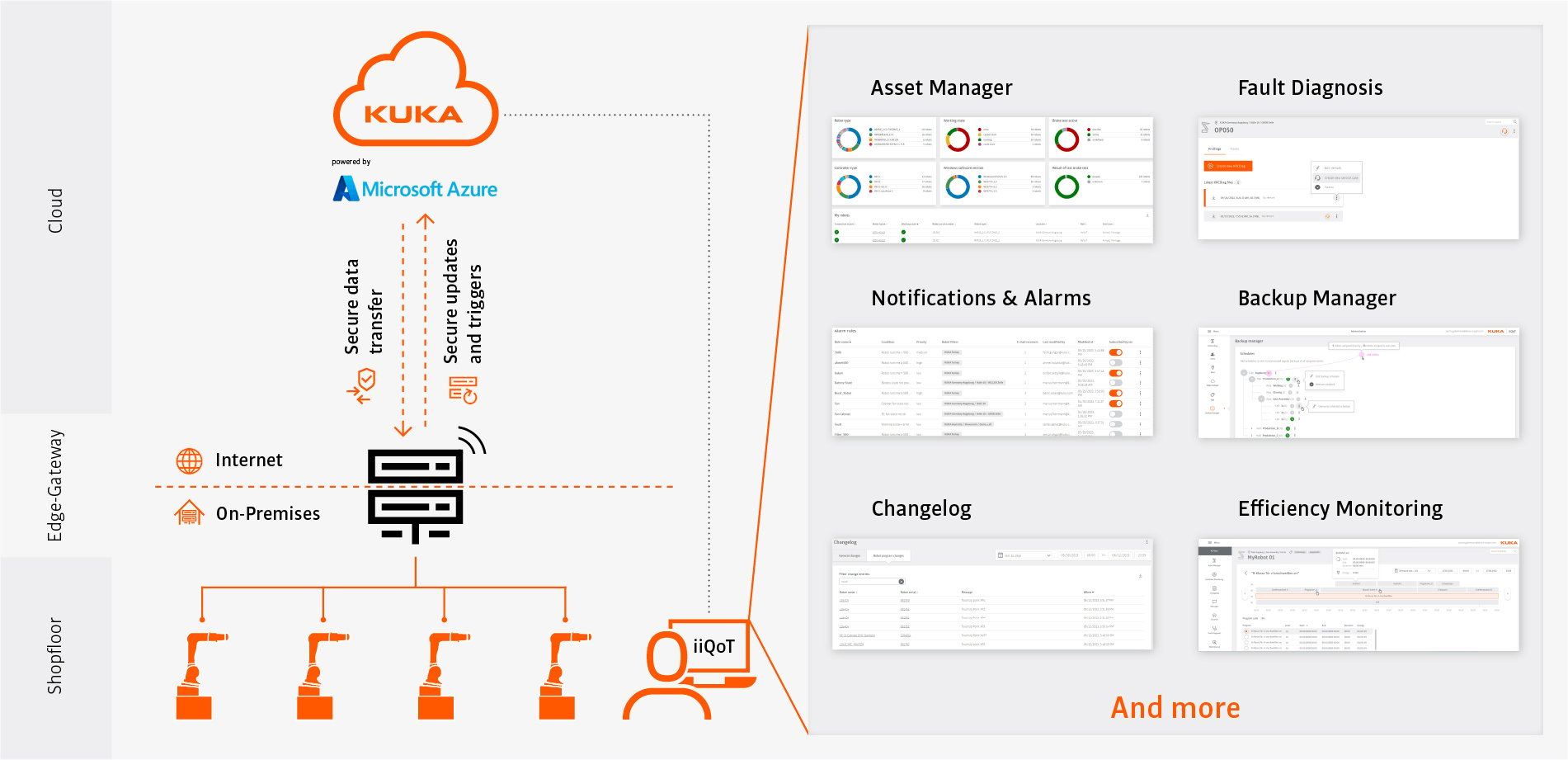

iiQoT Condition monitoring and scheduled maintenance of your robots

Robot Condition Monitoring Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Firstly, in the case of no fault, the. Robot condition monitoring can improve production capacity. However, due to the changes of robot in dynamic working state, this. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. The tool serves as a. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems.

From blog.robotiq.com

DLR & KUKA Grasp Planning & Control with the 3Finger Robot Gripper Robot Condition Monitoring The tool serves as a. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. A statistical test appears to be the most. Robot Condition Monitoring.

From www.kewaunee.in

Sensors and Automation in Laboratory Monitoring Systems Kewaunee Robot Condition Monitoring The tool serves as a. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. A statistical test. Robot Condition Monitoring.

From automationforum.co

What are sensors on a robot and why are sensors important to robots Robot Condition Monitoring Firstly, in the case of no fault, the. Robot condition monitoring can improve production capacity. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Condition monitoring of industrial robots has the potential to decrease. Robot Condition Monitoring.

From lantern.splunk.com

Monitoring Robotic Process Automation (RPA) systems Splunk Lantern Robot Condition Monitoring However, due to the changes of robot in dynamic working state, this. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Condition monitoring of industrial robots has the potential to decrease downtimes in. Robot Condition Monitoring.

From www.clickmaint.com

Condition Monitoring Techniques You Must Know Robot Condition Monitoring The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Robot condition monitoring can improve production capacity. The tool serves as a. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. Firstly, in the case of no fault, the. In this paper, a. Robot Condition Monitoring.

From www.daacoworks.com

Universal Robots Condition Monitoring Robot Condition Monitoring Robot condition monitoring can improve production capacity. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. The tool serves as a. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Firstly, in the case of no fault, the. Health management of industrial. Robot Condition Monitoring.

From www.thefabricator.com

Robot monitoring system designed to enhance safety Robot Condition Monitoring Firstly, in the case of no fault, the. Robot condition monitoring can improve production capacity. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. The tool serves as a. A statistical test appears. Robot Condition Monitoring.

From www.winwinrobot.com

ABB robot part CONDITION MONITORING MODULE Robot Condition Monitoring Firstly, in the case of no fault, the. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. However, due to the changes of robot in dynamic working state, this. Robot condition monitoring can improve production capacity. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent. Robot Condition Monitoring.

From www.edgeir.com

IBM uses AIenabled robots for improved facility monitoring at the edge Robot Condition Monitoring Firstly, in the case of no fault, the. However, due to the changes of robot in dynamic working state, this. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. The tool serves as a. Robot. Robot Condition Monitoring.

From wardautomation.ie

Collaborative Robots at Ward Automation Ward Automation Robot Condition Monitoring In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. However, due to the changes of robot in dynamic working state, this. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. Robot condition monitoring can improve production capacity. Condition monitoring of industrial robots has the potential to decrease. Robot Condition Monitoring.

From www.alamy.com

A smart robot conducts realtime monitoring of the conditions in an Robot Condition Monitoring Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. However, due to the changes of robot in dynamic working state, this. A statistical test appears to be the most suitable approach for trend detection and the local outlier. Robot Condition Monitoring.

From www.robotlab.com

Cruzr Health Monitoring Robot Robot Condition Monitoring In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. The tool serves as a. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. However, due to. Robot Condition Monitoring.

From www.ifm.com

Condition monitoring in Warehouse Automation ifm Robot Condition Monitoring The tool serves as a. Robot condition monitoring can improve production capacity. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Firstly, in the case of no fault, the. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. However, due to the changes. Robot Condition Monitoring.

From openwetware.org

Remote Patient Monitoring OpenWetWare Robot Condition Monitoring The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. In this paper, a condition monitoring method for industrial. Robot Condition Monitoring.

From todaysmachiningworld.com

Productive Robotics Launches Analytics A CloudBased System for Remote Robot Condition Monitoring Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. However, due to the changes of robot in dynamic working state, this. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. In this paper, a condition monitoring method for industrial robots based on vibration. Robot Condition Monitoring.

From www.youtube.com

Safe Robotics Safe sequence monitoring YouTube Robot Condition Monitoring The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. The tool serves as a. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. However, due to the changes of robot in dynamic working state, this. Condition monitoring of industrial robots has the potential. Robot Condition Monitoring.

From www.youtube.com

Robot Spotlight Autonomous Construction Site Monitoring Robot Condition Monitoring Firstly, in the case of no fault, the. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. In this paper, a condition monitoring method for industrial robots based on vibration. Robot Condition Monitoring.

From www.winwinrobot.com

ABB robot part CONDITION MONITORING MODULE Robot Condition Monitoring The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. In this paper, a condition. Robot Condition Monitoring.

From www.environmentalengineering.org.uk

Condition Based Maintenance For Robots Robot Condition Monitoring In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. The tool serves as a. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. A statistical test appears. Robot Condition Monitoring.

From www.kuka.com

iiQoT Condition monitoring and scheduled maintenance of your robots Robot Condition Monitoring Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. Firstly, in the case of no fault, the. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. A statistical test appears to. Robot Condition Monitoring.

From press.igus.com

Sensors for condition monitoring on robot dresspacks igus Press Robot Condition Monitoring Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. The condition monitoring (cm) of industrial collaborative robots (cobots) has. Robot Condition Monitoring.

From www.acdnv.be

Getting Started Condition Monitoring ACD Robot Condition Monitoring The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. However, due to the changes of robot in dynamic working state, this. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. In this paper, a condition monitoring method for industrial. Robot Condition Monitoring.

From www.youtube.com

Wafer Transfer Robot Condition Monitoring systemdantleplus YouTube Robot Condition Monitoring A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. Robot condition monitoring can improve production capacity. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. In this paper, a condition monitoring method for industrial robots based on vibration analysis. Robot Condition Monitoring.

From www.kuka.com

Towards a more efficient robot fleet with KUKA iiQoT software KUKA AG Robot Condition Monitoring Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. Firstly, in the case of no fault, the. However, due to the changes of robot in dynamic working state, this. The tool serves as a. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. The condition monitoring. Robot Condition Monitoring.

From www.alamy.com

iot smart industry robot 4.0 agriculture concept,industrial agronomist Robot Condition Monitoring Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. Robot condition monitoring can improve production capacity. However, due to the changes of robot in dynamic working state, this. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. The condition monitoring (cm) of industrial collaborative robots (cobots) has. Robot Condition Monitoring.

From blog.robotiq.com

5 Issues to Solve Before Monitoring Robot Performance Robot Condition Monitoring The tool serves as a. However, due to the changes of robot in dynamic working state, this. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. Firstly, in the case of no fault, the. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Health management of. Robot Condition Monitoring.

From roboticsandautomationnews.com

inar Speed and separation monitoring system from SICK and Universal Robot Condition Monitoring The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. The tool serves as a. However, due to the changes of robot in dynamic working state, this. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. In this paper, a. Robot Condition Monitoring.

From www.gudel.com

Condition Monitoring Robot Condition Monitoring Firstly, in the case of no fault, the. Robot condition monitoring can improve production capacity. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Health management of industrial robots is paramount for maintaining. Robot Condition Monitoring.

From www.mdpi.com

Sensors Free FullText LiDARBased Maintenance of a Safe Distance Robot Condition Monitoring Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. Firstly, in the case of no fault, the. A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. Robot condition. Robot Condition Monitoring.

From www.vecteezy.com

illustration of a real time monitoring system's software, manager Robot Condition Monitoring A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Robot condition monitoring can improve production capacity. However, due to the changes of robot in dynamic working state, this. Condition monitoring of industrial robots has. Robot Condition Monitoring.

From www.alamy.com

iot smart industry robot 4.0 agriculture concept,industrial agronomist Robot Condition Monitoring A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. Robot condition monitoring can improve production capacity. Condition monitoring of industrial robots has the potential to decrease downtimes in highly automated production systems. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Health management. Robot Condition Monitoring.

From hotrobotics.co.uk

KUKA LBR Iiwa 14 R820 Hot Robotics Robot Condition Monitoring A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. However, due to the changes of robot in dynamic working state, this. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. In this paper, a condition monitoring method for industrial robots based on vibration analysis. Robot Condition Monitoring.

From www.anybotics.com

ANYmal X ExProof Inspection Robot ANYbotics Robot Condition Monitoring In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. Robot condition monitoring can improve production capacity. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. Firstly, in the case of no fault, the. The tool serves as a. However, due to the changes of robot in dynamic. Robot Condition Monitoring.

From www.mmsonline.com

Kuka Introduces Guide to Assist With Robot Selection Process Modern Robot Condition Monitoring A statistical test appears to be the most suitable approach for trend detection and the local outlier factor algorithm. Firstly, in the case of no fault, the. In this paper, a condition monitoring method for industrial robots based on vibration analysis is proposed. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly. Robot Condition Monitoring.

From robotplace.io

Mobile Robot and Robotic Monitoring of Power System site RobotPlace Robot Condition Monitoring However, due to the changes of robot in dynamic working state, this. Health management of industrial robots is paramount for maintaining effective operations, ensuring consistent performance, minimizing. The condition monitoring (cm) of industrial collaborative robots (cobots) has the potential to decrease downtimes in highly automated production systems. Condition monitoring of industrial robots has the potential to decrease downtimes in highly. Robot Condition Monitoring.