Flow Meter Upstream And Downstream . The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. Accurately measure flowrate up to a turndown of 25:1. Consequently, most mag meters can be placed as close as 3 pipe diameters upstream from a bend or other obstruction, versus a minimum 10 diameters for many other flowmeters. While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). Ultrasonic flow meters requires fully developed flow conditions to ensure the meter will perform as specified. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. As with other technologies, these. There are two basic types of measuring principles, doppler and transit time, with the latter being more commonly used for fiscal custody transfer applications of gas and petroleum liquids.

from www.omega.ca

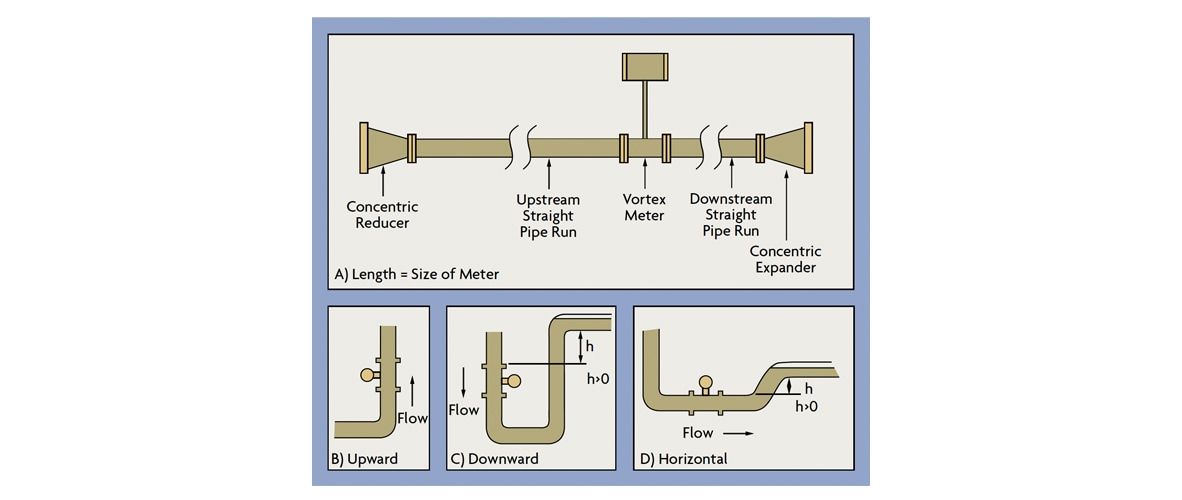

The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). Accurately measure flowrate up to a turndown of 25:1. Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. As with other technologies, these. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. Consequently, most mag meters can be placed as close as 3 pipe diameters upstream from a bend or other obstruction, versus a minimum 10 diameters for many other flowmeters. Ultrasonic flow meters requires fully developed flow conditions to ensure the meter will perform as specified. There are two basic types of measuring principles, doppler and transit time, with the latter being more commonly used for fiscal custody transfer applications of gas and petroleum liquids.

What is a Vortex Flow Meter?

Flow Meter Upstream And Downstream The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. Accurately measure flowrate up to a turndown of 25:1. Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). Ultrasonic flow meters requires fully developed flow conditions to ensure the meter will perform as specified. Consequently, most mag meters can be placed as close as 3 pipe diameters upstream from a bend or other obstruction, versus a minimum 10 diameters for many other flowmeters. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. As with other technologies, these. The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. There are two basic types of measuring principles, doppler and transit time, with the latter being more commonly used for fiscal custody transfer applications of gas and petroleum liquids. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping.

From www.sino-insts.com

Vortex Flow Meters for Small Pipes Threaded or Clamp Connection Flow Meter Upstream And Downstream Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. Accurately measure flowrate up to a turndown of 25:1. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. As with other technologies, these. Consequently, most mag meters can be placed as close. Flow Meter Upstream And Downstream.

From www.drurylandetheatre.com

Upstream and Downstream Flow Straight Pipe RequirementsFlowmeter Flow Meter Upstream And Downstream Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. Consequently, most mag meters can be placed as close as 3 pipe diameters upstream from a bend or other obstruction, versus a minimum 10 diameters for many other flowmeters. Moderate accuracy, typically ±2% of reading (steam) and. Flow Meter Upstream And Downstream.

From www.eng-tips.com

Positioning flow meter upstream or downstream a flow control valve Flow Meter Upstream And Downstream As with other technologies, these. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. Consequently, most mag meters can be placed as close as 3 pipe diameters upstream from a bend or other obstruction, versus a minimum 10 diameters for many other flowmeters. While each manufacturer may have different. Flow Meter Upstream And Downstream.

From controlandinstrumentation.com

Vortex Flow Meter Installation Guide Flow Meter Upstream And Downstream As with other technologies, these. Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. Accurately measure flowrate up to a turndown of 25:1. Flowmeter manufacturers will recommend various lengths of straight pipe. Flow Meter Upstream And Downstream.

From www.youtube.com

Flowmeter Installation Guidelines for Horizontal & Vertical Flow Meter Upstream And Downstream As with other technologies, these. Accurately measure flowrate up to a turndown of 25:1. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. Moderate accuracy, typically. Flow Meter Upstream And Downstream.

From blog.thepipingmart.com

What A Differential Pressure Flow meter is used for? ThePipingMart Blog Flow Meter Upstream And Downstream As with other technologies, these. Ultrasonic flow meters requires fully developed flow conditions to ensure the meter will perform as specified. While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to. Flow Meter Upstream And Downstream.

From einvoice.fpt.com.vn

Upstream And Downstream Flow Straight Pipe, 49 OFF Flow Meter Upstream And Downstream While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). There are two basic types of measuring principles, doppler and transit time, with the latter being more commonly used for fiscal custody transfer applications of gas and. Flow Meter Upstream And Downstream.

From www.eng-tips.com

upstream and downstream pipe length of rotameter flow meter Chemical Flow Meter Upstream And Downstream Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. Ultrasonic flow meters requires fully developed flow conditions to ensure the meter will perform as specified. The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and. Flow Meter Upstream And Downstream.

From www.crossco.com

Flow Measurement The Truth About Upstream And Downstream Pipe Flow Meter Upstream And Downstream Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. As there are multiple flow technologies available, so too are the recommendations for proper. Flow Meter Upstream And Downstream.

From flavored.ph

SonoTrak ST30 Ultrasonic Flow Meter With Upstream and downstream Flow Meter Upstream And Downstream While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. There are two basic types of measuring principles, doppler and transit time, with the latter being more commonly used for fiscal custody transfer applications of gas and petroleum liquids. The two most important installation considerations for vortex. Flow Meter Upstream And Downstream.

From koboldusa.com

What are Straight Runs for Flow Meters? KOBOLD USA Flow Meter Upstream And Downstream Accurately measure flowrate up to a turndown of 25:1. There are two basic types of measuring principles, doppler and transit time, with the latter being more commonly used for fiscal custody transfer applications of gas and petroleum liquids. While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you. Flow Meter Upstream And Downstream.

From instrumentationtools.com

V Cone Flow Meter Principle, Advantages, Disadvantages Flow Meter Upstream And Downstream Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping.. Flow Meter Upstream And Downstream.

From zeroinstrument.com

vortex flow meter upstream and downstream requirements Just Measure it Flow Meter Upstream And Downstream Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. There are two basic types of measuring principles, doppler and transit time, with the latter being more commonly used for. Flow Meter Upstream And Downstream.

From zeroinstrument.com

turbine meter upstream and downstream requirements Just Measure it Flow Meter Upstream And Downstream The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter. Flow Meter Upstream And Downstream.

From www.spiraxsarco.com

Types of Steam Flowmeter Spirax Sarco Flow Meter Upstream And Downstream As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. Ultrasonic flow meters requires fully developed flow conditions to ensure the meter will perform as specified. Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). Accurately measure flowrate up to a turndown of 25:1. Table 3 shows recommended minimum. Flow Meter Upstream And Downstream.

From www.drurylandetheatre.com

Upstream and Downstream Flow Straight Pipe RequirementsFlowmeter Flow Meter Upstream And Downstream Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. Accurately measure flowrate up to a turndown of 25:1. Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). Consequently, most mag meters. Flow Meter Upstream And Downstream.

From koboldusa.com

Straight Piping Requirements for Flow Measurement KOBOLD USA Flow Meter Upstream And Downstream Ultrasonic flow meters requires fully developed flow conditions to ensure the meter will perform as specified. As with other technologies, these. The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the. Flow Meter Upstream And Downstream.

From www.eng-tips.com

upstream and downstream pipe length of rotameter flow meter Chemical Flow Meter Upstream And Downstream Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. As with other technologies, these. Consequently, most. Flow Meter Upstream And Downstream.

From engineerexcel.com

Upstream vs. Downstream Pipe Flow A Comparative Analysis EngineerExcel Flow Meter Upstream And Downstream Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. As with other technologies, these. Accurately measure flowrate up to a turndown of 25:1. As there are multiple flow technologies available, so too are the. Flow Meter Upstream And Downstream.

From pressurecalibrator.blogspot.com

Instrumentation & Automation Products Piping Requirements Flow Meter Upstream And Downstream There are two basic types of measuring principles, doppler and transit time, with the latter being more commonly used for fiscal custody transfer applications of gas and petroleum liquids. As with other technologies, these. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. Table 3 shows. Flow Meter Upstream And Downstream.

From www.omega.ca

What is a Vortex Flow Meter? Flow Meter Upstream And Downstream As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter. Flow Meter Upstream And Downstream.

From www.processindustryinformer.com

Oil And Gas Industry Flowmeter For Upstream & Downstream Applications Flow Meter Upstream And Downstream While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. As with other technologies, these. Accurately measure flowrate up to a turndown of 25:1. Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. Ultrasonic flow meters requires fully developed. Flow Meter Upstream And Downstream.

From www.eng-tips.com

Positioning flow meter upstream or downstream a flow control valve Flow Meter Upstream And Downstream Accurately measure flowrate up to a turndown of 25:1. Consequently, most mag meters can be placed as close as 3 pipe diameters upstream from a bend or other obstruction, versus a minimum 10 diameters for many other flowmeters. The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all. Flow Meter Upstream And Downstream.

From www.drurylandetheatre.com

Upstream and Downstream Flow Straight Pipe RequirementsFlowmeter Flow Meter Upstream And Downstream While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. There are two basic types of measuring principles, doppler and transit time, with the latter being more. Flow Meter Upstream And Downstream.

From www.emersonautomationexperts.com

Flow Technology Installation Specifications for Flow Meter Upstream And Downstream The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. As with other technologies, these. Consequently, most mag meters can be placed as close as 3 pipe diameters upstream from a bend or other obstruction, versus a minimum 10 diameters for many other flowmeters. Flowmeter. Flow Meter Upstream And Downstream.

From www.drurylandetheatre.com

Upstream and Downstream Flow Straight Pipe RequirementsFlowmeter Flow Meter Upstream And Downstream Ultrasonic flow meters requires fully developed flow conditions to ensure the meter will perform as specified. The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). As with other technologies, these. Consequently, most mag meters. Flow Meter Upstream And Downstream.

From www.youtube.com

Tips Installation of flow meter & BTU meter Upstream Downstream Flow Meter Upstream And Downstream Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. There are two basic types of measuring principles, doppler and transit time, with the latter being more commonly used for fiscal custody transfer applications of gas and petroleum liquids. The two most important installation considerations for vortex meters are upstream and downstream straight. Flow Meter Upstream And Downstream.

From www.eng-tips.com

Positioning flow meter upstream or downstream a flow control valve Flow Meter Upstream And Downstream Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. As with other technologies, these. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. As there are multiple flow technologies available, so too are the recommendations for proper meter. Flow Meter Upstream And Downstream.

From flavored.ph

SonoTrak ST30 Ultrasonic Flow Meter With Upstream and downstream Flow Meter Upstream And Downstream While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. Accurately measure flowrate up to a turndown of 25:1. The two most important installation considerations for vortex meters are upstream and downstream straight length requirements, and the need to keep all wetted parts flooded. There are two. Flow Meter Upstream And Downstream.

From zeroinstrument.com

turbine meter upstream and downstream requirements Just Measure it Flow Meter Upstream And Downstream Accurately measure flowrate up to a turndown of 25:1. As there are multiple flow technologies available, so too are the recommendations for proper meter placement in your process piping. While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. Table 3 shows recommended minimum required upstream and. Flow Meter Upstream And Downstream.

From www.solisplc.com

The Complete Guide to Flowmeters What They Are and How They Work? Flow Meter Upstream And Downstream Consequently, most mag meters can be placed as close as 3 pipe diameters upstream from a bend or other obstruction, versus a minimum 10 diameters for many other flowmeters. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. As with other technologies, these. Moderate accuracy, typically. Flow Meter Upstream And Downstream.

From www.youtube.com

Tips Installation of flow meter & BTU meter Upstream Downstream Flow Meter Upstream And Downstream Moderate accuracy, typically ±2% of reading (steam) and ±1.5% (condensate). Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. Accurately measure flowrate up. Flow Meter Upstream And Downstream.

From www.drurylandetheatre.com

Upstream and Downstream Flow Straight Pipe RequirementsFlowmeter Flow Meter Upstream And Downstream While each manufacturer may have different guidelines, below is a general overview of typical upstream and downstream piping requirements to get you started. Ultrasonic flow meters requires fully developed flow conditions to ensure the meter will perform as specified. Accurately measure flowrate up to a turndown of 25:1. As there are multiple flow technologies available, so too are the recommendations. Flow Meter Upstream And Downstream.

From coltraco.com

The Two Types of Ultrasonic Flow Meters Coltraco Ultrasonics Flow Meter Upstream And Downstream As with other technologies, these. There are two basic types of measuring principles, doppler and transit time, with the latter being more commonly used for fiscal custody transfer applications of gas and petroleum liquids. Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. As there are. Flow Meter Upstream And Downstream.

From instrumentationtools.com

Turbine Flow Meter Installation Procedure Instrumentation Tools Flow Meter Upstream And Downstream Consequently, most mag meters can be placed as close as 3 pipe diameters upstream from a bend or other obstruction, versus a minimum 10 diameters for many other flowmeters. Table 3 shows recommended minimum required upstream and downstream diameter distances for the most common flowmeter types. As with other technologies, these. The two most important installation considerations for vortex meters. Flow Meter Upstream And Downstream.