Shear Failure Theory . The basis of this theory is that failure will occur when the maximum shear stress. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. Theories of failures for ductile materials. Theories of failure for ductile and brittle materials. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive.

from www.engineeringcorecourses.com

Theories of failures for ductile materials. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. The basis of this theory is that failure will occur when the maximum shear stress. Theories of failure for ductile and brittle materials. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive.

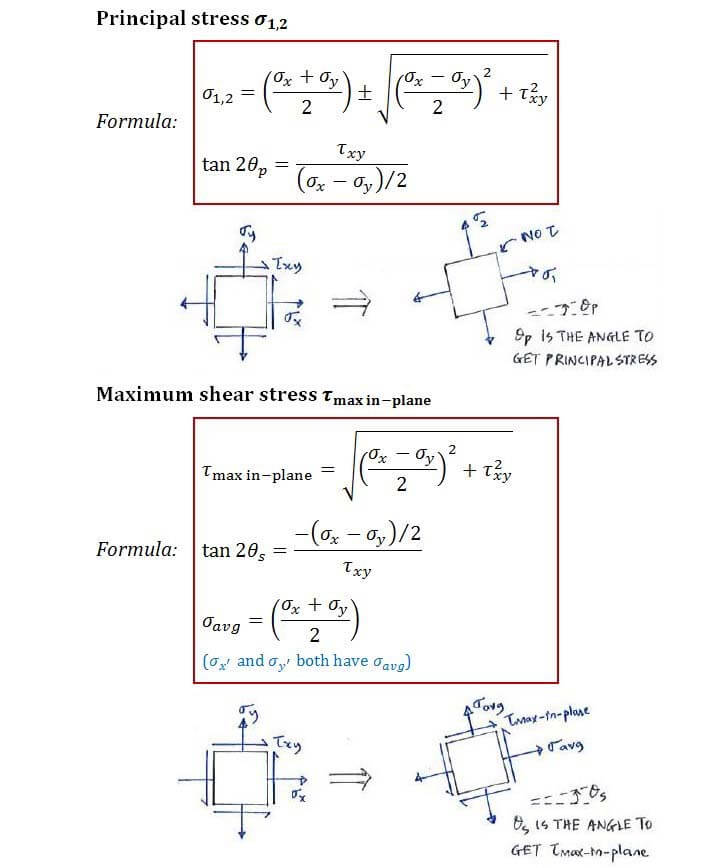

Theory C7.2 Principal Stress and Maxinplane Shear Stress Solid Mechanics I

Shear Failure Theory One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. Theories of failure for ductile and brittle materials. The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. Theories of failures for ductile materials. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion.

From featips.com

A Comparison of Failure Theories Distortion Energy (vonMises) vs Maximum Shear Stress FEA Tips Shear Failure Theory Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. Theories of failure for ductile and brittle materials. The basis of this theory is that failure will occur when the maximum shear stress. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the. Shear Failure Theory.

From www.youtube.com

Maximum Shear Stress Theory Shear Stress Theory Guest Theory Machine Element Design YouTube Shear Failure Theory In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that. Shear Failure Theory.

From www.youtube.com

Mohr Coulomb Failure Theory II SHEAR STRENGTH SOIL MECHANICS YouTube Shear Failure Theory The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. Theories of failures for ductile materials. Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of. Shear Failure Theory.

From www.researchgate.net

Shear ductile failure in the cable bolt under impact loading, shown in... Download Scientific Shear Failure Theory Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. Under compression the microscopic. Shear Failure Theory.

From www.researchgate.net

Illustration of shear failure mechanics along pillar interface showing... Download Scientific Shear Failure Theory One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). Theories of failures for ductile materials. Theories of failure for ductile and brittle materials. The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance. Shear Failure Theory.

From www.slideshare.net

Lecture 3 mohr’s circle and theory of failure Shear Failure Theory Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. Theories of failure for ductile and brittle materials. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss).. Shear Failure Theory.

From www.youtube.com

Types of Shear failures in Beam? Civil Engineering YouTube Shear Failure Theory Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. Theories of failures for ductile materials. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear. Shear Failure Theory.

From www.youtube.com

Types Of Failures in Beams//Shear Failure//Flexural Failure !! Full Explanation in Hindi. YouTube Shear Failure Theory Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. Theories of failures for ductile materials. The basis of this theory is that failure will occur when the maximum shear stress. Theories of failure for ductile and brittle materials.. Shear Failure Theory.

From www.fidelisfea.com

Brittle And Ductile Failure Theories In FEA Which Ones Should We Choose? Shear Failure Theory Theories of failures for ductile materials. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. The basis of this theory is that failure. Shear Failure Theory.

From www.youtube.com

Finding Factor of Safety with Maximum Shear Stress Static Failure Theory 1 & 2 Plane Shaft Shear Failure Theory The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. Theories of failure for ductile and brittle materials. One theory that is used for the prediction of failure in a ductile material is the maximum shear. Shear Failure Theory.

From www.numerade.com

In the diagram below, the curves for Maximum Shear Stress (MSS) or Tresca Failure Theory and the Shear Failure Theory Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. The basis of this theory is that failure will occur when the maximum shear stress. Theories of failures for ductile materials. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of. Shear Failure Theory.

From www.chegg.com

Solved 1. In the diagram below, the curves for Maximum Shear Shear Failure Theory Theories of failure for ductile and brittle materials. The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. One theory that is used for the prediction of failure in a ductile material is the maximum shear. Shear Failure Theory.

From whatispiping.com

Maximum Shear Stress Theory Tresca Theory of Failure What Is Piping Shear Failure Theory Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). The basis of this theory is that failure will occur when the maximum shear stress. In this question, we try. Shear Failure Theory.

From dailycivil.com

Types Of Failures In Beam Shear Strength Failure & Flrexure Failure Shear Failure Theory In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. The basis of this theory is that failure will occur when the maximum shear stress. One. Shear Failure Theory.

From www.slideserve.com

PPT Lecture8 Shear Strength of Soils PowerPoint Presentation ID758585 Shear Failure Theory Theories of failures for ductile materials. The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. Theories of failure for ductile and brittle materials. Maximum shear stress theory states that when the maximum shear stress in. Shear Failure Theory.

From www.engineeringcorecourses.com

Theory C7.2 Principal Stress and Maxinplane Shear Stress Solid Mechanics I Shear Failure Theory Theories of failure for ductile and brittle materials. The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the. Shear Failure Theory.

From www.slideserve.com

PPT Failures Due to Static Loading PowerPoint Presentation, free download ID6014340 Shear Failure Theory In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. Theories. Shear Failure Theory.

From www.slideserve.com

PPT Failure Theories (5.35.8, 5.14) PowerPoint Presentation ID6649264 Shear Failure Theory One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). The basis of this theory is that failure will occur when the maximum shear stress. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress. Shear Failure Theory.

From www.researchgate.net

Conditions for shear and tensile failure (adapted from Julian and... Download Scientific Diagram Shear Failure Theory Theories of failures for ductile materials. The basis of this theory is that failure will occur when the maximum shear stress. Theories of failure for ductile and brittle materials. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). In this question, we try to understand the e ect. Shear Failure Theory.

From www.youtube.com

Theory Of Failure Principal Stress Theory Shear Stress Theory Maximum Shear Stress Theory Shear Failure Theory Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. The basis of this. Shear Failure Theory.

From loewtxuol.blob.core.windows.net

What Is Maximum Shear Stress Theory at Jennifer Tran blog Shear Failure Theory One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). Theories of failure for ductile and brittle materials. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. The basis of this theory is that failure will occur when the. Shear Failure Theory.

From www.academia.edu

(DOC) MAXIMUM SHEAR STRESS THEORY OF FAILURE A THEORY OF FAILURE APPLICABLE TO DUCTILE MATERIALS Shear Failure Theory In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. One. Shear Failure Theory.

From civiljungle.com

Types of Bearing Capacity Failures of Foundation Bearing Capacity Definitions Theory of Shear Failure Theory The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. Theories of failure for ductile and brittle materials. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the. Shear Failure Theory.

From www.slideserve.com

PPT THEORIES OF FAILURE PowerPoint Presentation, free download ID6912153 Shear Failure Theory Theories of failures for ductile materials. The basis of this theory is that failure will occur when the maximum shear stress. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. Theories of failure for ductile and brittle materials. Under compression the microscopic flaws are. Shear Failure Theory.

From edurev.in

MohrCoulomb Failure theory Shear Strength of Soil, Soil Mechanics Soil Mechanics Notes Shear Failure Theory Theories of failures for ductile materials. Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. The basis of this theory is that failure will occur when the maximum shear stress. Theories of failure for ductile and brittle materials.. Shear Failure Theory.

From www.scribd.com

Failure Theories for Static Loads A Comparison of the Maximum Shear Stress Theory and Shear Failure Theory One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of. Shear Failure Theory.

From www.slideserve.com

PPT Lecture8 Shear Strength of Soils PowerPoint Presentation ID758585 Shear Failure Theory The basis of this theory is that failure will occur when the maximum shear stress. Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that. Shear Failure Theory.

From www.youtube.com

MDI MAXIMUM SHEAR STRESS THEORY OF FAILURE/ GUEST & TRESCA's THEORY OF FAILURE YouTube Shear Failure Theory The basis of this theory is that failure will occur when the maximum shear stress. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. In this question, we try to understand the e ect of a hydrostatic stress on yielding in the case of tresca's maximum shear stress criterion. One. Shear Failure Theory.

From www.slideserve.com

PPT Failure Theories (5.35.8, 5.14) PowerPoint Presentation ID6649264 Shear Failure Theory One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). The basis of this theory is that failure will occur when the maximum shear stress. Theories of failures for ductile materials. Theories of failure for ductile and brittle materials. Under compression the microscopic flaws are pressed together, increasing resistance. Shear Failure Theory.

From www.slideserve.com

PPT THEORIES OF FAILURE PowerPoint Presentation, free download ID6912153 Shear Failure Theory Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). Theories of failures for ductile materials. In this question, we try to understand the e ect of a hydrostatic stress. Shear Failure Theory.

From www.scribd.com

Lecture1819 Theories of Failure Maximum Shear Stress Theory (Guest Tresca Theory) Maximum Shear Failure Theory Theories of failure for ductile and brittle materials. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). The basis of this theory is that failure will occur when the maximum shear stress. In this question, we try to understand the e ect of a hydrostatic stress on yielding. Shear Failure Theory.

From www.slideserve.com

PPT Theories of Failure PowerPoint Presentation, free download ID9122152 Shear Failure Theory The basis of this theory is that failure will occur when the maximum shear stress. One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). Theories of failures for ductile materials. Theories of failure for ductile and brittle materials. In this question, we try to understand the e ect. Shear Failure Theory.

From www.scientific.net

The Shear Failure Modes and Anisotropy Based on the Shear Strength Theory in Classical Solid Shear Failure Theory Theories of failures for ductile materials. The basis of this theory is that failure will occur when the maximum shear stress. Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. One theory that is used for the prediction. Shear Failure Theory.

From www.linkedin.com

Types of Shear Failure Shear Failure Theory Theories of failure for ductile and brittle materials. Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive. Theories of. Shear Failure Theory.

From www.youtube.com

Maximum Shear Stress Theory Theories of Failure GATE Strength of Materials YouTube Shear Failure Theory One theory that is used for the prediction of failure in a ductile material is the maximum shear stress theory (mss). Maximum shear stress theory states that when the maximum shear stress in an object reaches or exceeds the magnitude of yield shear stress in uniaxial loading, the object material undergoes failure. Theories of failures for ductile materials. Under compression. Shear Failure Theory.