Dry Etching Techniques . learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. Using either a reactive gas or plasma (atoms or radical species). • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. dry etching techniques for control of size and shape of colloidal particles are examined in detail. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. lecture 7 dry etching techniques. • the influence of dry etching. !pattern transfer by dry etching:

from www.metaletching.org

dry etching techniques for control of size and shape of colloidal particles are examined in detail. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. !pattern transfer by dry etching: dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. lecture 7 dry etching techniques. Using either a reactive gas or plasma (atoms or radical species). • the influence of dry etching.

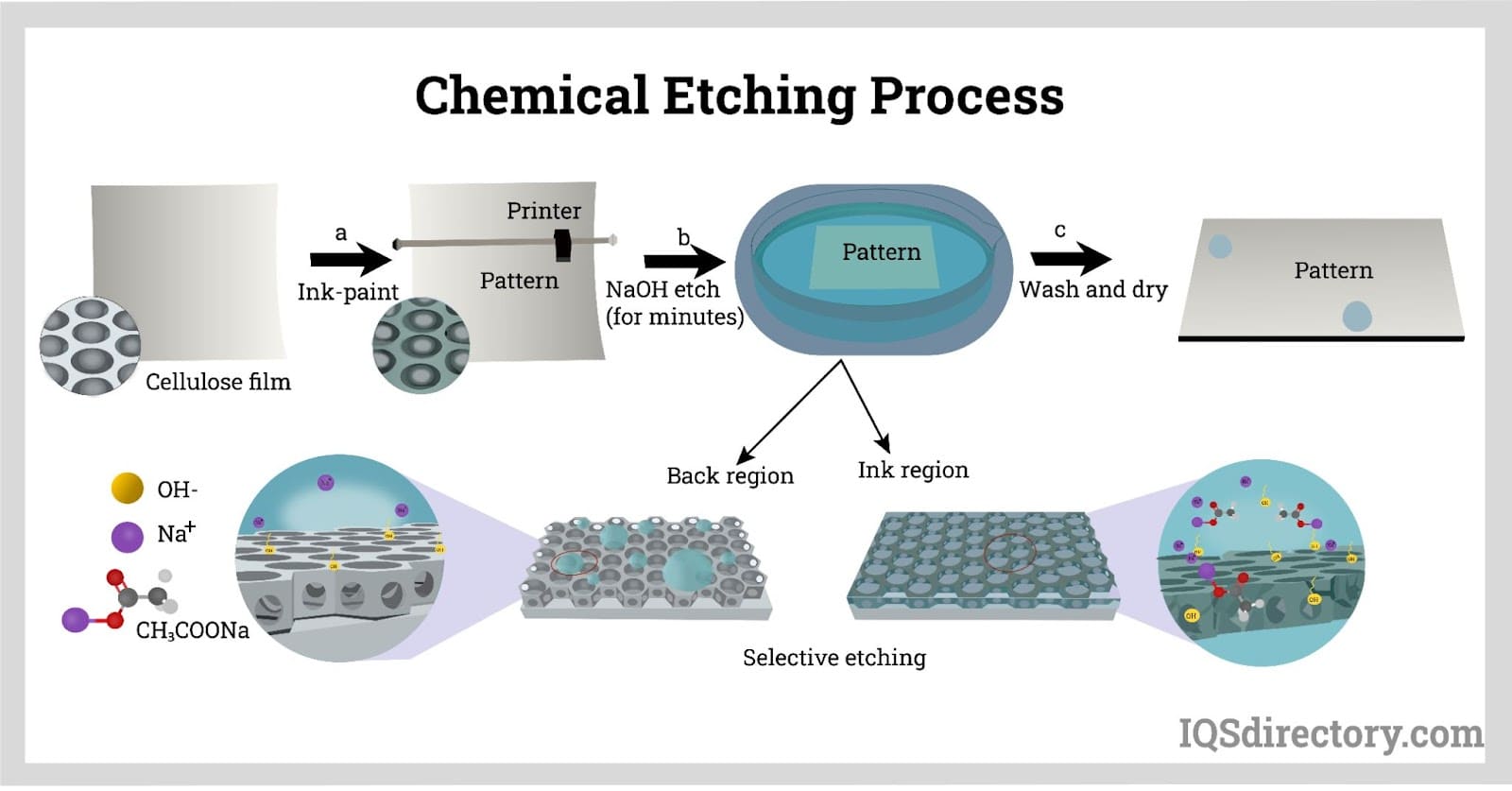

Chemical Etching Companies Chemical Etching Services

Dry Etching Techniques dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. Using either a reactive gas or plasma (atoms or radical species). learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. • the influence of dry etching. lecture 7 dry etching techniques. dry etching techniques for control of size and shape of colloidal particles are examined in detail. !pattern transfer by dry etching:

From www.horiba.com

Semiconductor Processing Etch Dry Etching Techniques dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. • the influence of dry etching. lecture 7 dry etching techniques. dry etching techniques for control of size and. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques • the influence of dry etching. Using either a reactive gas or plasma (atoms or radical species). !pattern transfer by dry etching: provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. dry etching techniques. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. Using either a reactive gas or plasma (atoms or radical species). lecture 7 dry etching techniques. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. learn what are the key differences and applications. Dry Etching Techniques.

From www.pinterest.ca

drypoint etching techniques Google Search Intaglio Printmaking Dry Etching Techniques learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. • the influence of dry etching. Using either a reactive gas or plasma (atoms or radical species). dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. lecture 7 dry etching techniques.. Dry Etching Techniques.

From www.researchgate.net

Six typical glass microstructure fabrication techniques. (a) Wet Dry Etching Techniques • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. • the influence of dry etching. learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. Using either a reactive gas or plasma (atoms or radical species). !pattern transfer by dry etching:. Dry Etching Techniques.

From www.belindadelpesco.com

Drypoint on Plexiglass Printmaking and inking with a la poupée Dry Etching Techniques Using either a reactive gas or plasma (atoms or radical species). lecture 7 dry etching techniques. learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. dry etching refers to. Dry Etching Techniques.

From www.researchgate.net

Different masking techniques for dry etching methods. a) Masking with Dry Etching Techniques dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. • the influence of dry etching. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. !pattern transfer by dry etching: learn what are the key differences and applications between. Dry Etching Techniques.

From www.researchgate.net

Fabrication method based on combination use of dry and wet etching Dry Etching Techniques provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. • the influence of dry etching. lecture 7 dry etching techniques. !pattern transfer by dry etching: learn what are the key differences and. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques dry etching techniques for control of size and shape of colloidal particles are examined in detail. lecture 7 dry etching techniques. • the influence of dry etching. dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. learn what are the key differences and applications between dry etching. Dry Etching Techniques.

From www.semanticscholar.org

Plasmabased dry etching techniques in the silicon integrated circuit Dry Etching Techniques • the influence of dry etching. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. lecture 7 dry etching techniques. learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. dry etching techniques for control of size and shape. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. • the influence of dry etching. . Dry Etching Techniques.

From pediaa.com

Difference Between Dry and Wet Etching Definition, Technique Dry Etching Techniques Using either a reactive gas or plasma (atoms or radical species). dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. !pattern transfer by dry etching: • the influence of dry etching. • selectivity is the. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. • the influence of dry etching. !pattern transfer by dry etching: dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. Using either a reactive gas or plasma (atoms or radical species). •. Dry Etching Techniques.

From nanohub.org

Resources ECE 695Q Lecture 45 Dry Etching I Watch Dry Etching Techniques !pattern transfer by dry etching: • the influence of dry etching. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. lecture 7 dry etching techniques. Using either a reactive gas. Dry Etching Techniques.

From www.semanticscholar.org

Dry etching Semantic Scholar Dry Etching Techniques provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. lecture 7 dry etching techniques. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material.. Dry Etching Techniques.

From www.youtube.com

Dry etching, DRIE, Etching process(Part 3) YouTube Dry Etching Techniques lecture 7 dry etching techniques. dry etching techniques for control of size and shape of colloidal particles are examined in detail. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. • the influence of dry etching. provides a comprehensive, systematic guide to dry etching technologies, from. Dry Etching Techniques.

From pv-manufacturing.org

Dry Etching Techniques provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. lecture 7 dry etching techniques. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. dry etching techniques for control of size and shape of colloidal particles are examined in detail. • the. Dry Etching Techniques.

From plasma.oxinst.com

Deep Silicon Etch (DSiE) Oxford Instruments Dry Etching Techniques !pattern transfer by dry etching: learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. • the influence of dry etching. lecture 7 dry etching techniques. dry etching techniques for control of size and shape of colloidal particles are examined in detail. • selectivity is the ratio of the etch. Dry Etching Techniques.

From www.eurotherm.com

Semiconductor Fabrication Dry Etch Processing Solution Eurotherm Limited Dry Etching Techniques learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. dry etching techniques for control of size and shape of colloidal particles are examined in detail. lecture 7 dry etching techniques. Using either a reactive gas or plasma (atoms or radical species). • selectivity is the ratio of the etch. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. dry etching techniques for control of size and shape of colloidal particles are examined in detail. !pattern transfer by dry etching: lecture 7 dry etching techniques. Using either a reactive gas or plasma (atoms or radical species). • selectivity. Dry Etching Techniques.

From spie.org

Highly selective dryplasmafree chemical etch technique for advanced Dry Etching Techniques dry etching techniques for control of size and shape of colloidal particles are examined in detail. lecture 7 dry etching techniques. Using either a reactive gas or plasma (atoms or radical species). • the influence of dry etching. learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. dry. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. !pattern transfer by dry etching: lecture 7 dry etching techniques. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. • the influence of dry etching. Using either a reactive gas or plasma (atoms. Dry Etching Techniques.

From nanohub.org

Resources ECE 695Q Lecture 47 Dry Etching III Watch Dry Etching Techniques lecture 7 dry etching techniques. dry etching techniques for control of size and shape of colloidal particles are examined in detail. dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. • selectivity is the ratio of the etch rate of the target material being etched to the etch. Dry Etching Techniques.

From dingspring.blogspot.com

你可不要遺憾。 Fabrication Dry Etching Dry Etching Techniques dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. lecture 7 dry etching techniques. • the influence of dry etching. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. Using either a reactive gas or plasma (atoms or radical species). learn what. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques • the influence of dry etching. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. lecture 7 dry etching techniques. dry etching techniques for control of size and shape of colloidal particles are. Dry Etching Techniques.

From spie.org

Highly selective dryplasmafree chemical etch technique for advanced Dry Etching Techniques lecture 7 dry etching techniques. learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. Using either a reactive gas or plasma (atoms or radical species). !pattern transfer by dry etching: • the influence of dry etching. dry etching refers to the processes that use energetic gaseous species produced by. Dry Etching Techniques.

From www.uweinc.com

Photo Etching Process A StepbyStep Guide UWE Dry Etching Techniques learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. • the influence of dry etching. dry etching techniques for control of size and shape of colloidal particles are examined in detail. lecture 7 dry etching techniques. Using either a reactive gas or plasma (atoms or radical species). provides. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques lecture 7 dry etching techniques. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. Using either a reactive gas or plasma (atoms or radical species). !pattern transfer by dry etching: • the influence of dry etching. provides a comprehensive, systematic guide to dry etching technologies, from basics. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. lecture 7 dry etching techniques. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. Using either a reactive gas or plasma (atoms or radical species). dry etching refers to the processes that. Dry Etching Techniques.

From nanohub.org

Resources ME 517 Lecture 06 Microfabrication Dry Etching Techniques learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. • the influence of dry etching. Using either. Dry Etching Techniques.

From www.slideserve.com

PPT V. Dry Etching, General Principles Advanced Dry Etching Dry Etching Techniques dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. • selectivity is the ratio of the etch rate of the target material being etched to the etch rate of. Using either a reactive gas or. Dry Etching Techniques.

From exommwdsl.blob.core.windows.net

Photo Etching Process at Tammy Rawlings blog Dry Etching Techniques dry etching techniques for control of size and shape of colloidal particles are examined in detail. learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. • the influence of dry etching. dry etching refers. Dry Etching Techniques.

From www.metaletching.org

Chemical Etching Companies Chemical Etching Services Dry Etching Techniques dry etching refers to the processes that use energetic gaseous species produced by a plasma to remove material. !pattern transfer by dry etching: learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. • the influence of dry etching. provides a comprehensive, systematic guide to dry etching technologies, from basics. Dry Etching Techniques.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Dry Etching Techniques lecture 7 dry etching techniques. dry etching techniques for control of size and shape of colloidal particles are examined in detail. learn what are the key differences and applications between dry etching and wet etching processes in microelectronic. provides a comprehensive, systematic guide to dry etching technologies, from basics to latest technologies. • the influence of. Dry Etching Techniques.