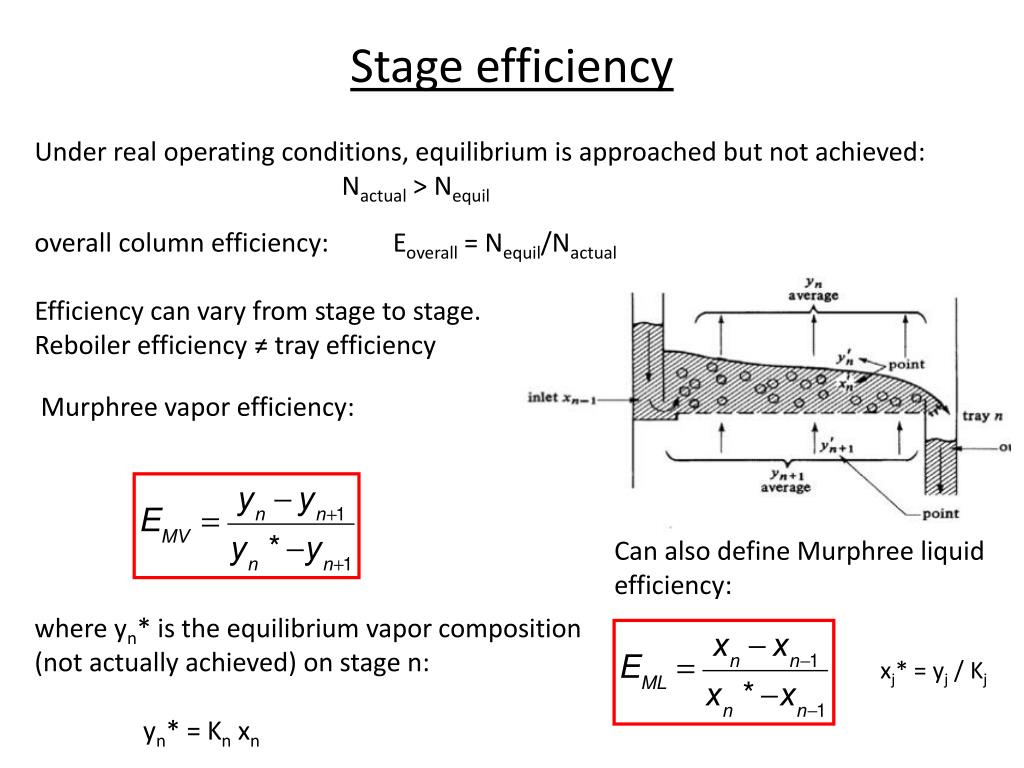

What Are The Different Types Of Tray Efficiency . You can consider em as the. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. the traditional murphree efficiency approach to tray design. • the number of trays is dependent on the number of equilibrium stages. The section efficiency is calculated based on fundamental. types of plate efficiency there are four different types of tray efficiencies that are used. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo.

from haipernews.com

due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. You can consider em as the. The section efficiency is calculated based on fundamental. types of plate efficiency there are four different types of tray efficiencies that are used. • the number of trays is dependent on the number of equilibrium stages. the traditional murphree efficiency approach to tray design.

How To Calculate Distillation Efficiency Haiper

What Are The Different Types Of Tray Efficiency types of plate efficiency there are four different types of tray efficiencies that are used. the traditional murphree efficiency approach to tray design. types of plate efficiency there are four different types of tray efficiencies that are used. • the number of trays is dependent on the number of equilibrium stages. The section efficiency is calculated based on fundamental. You can consider em as the. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of.

From design.udlvirtual.edu.pe

Types Of Trays In Distillation Column Ppt Design Talk What Are The Different Types Of Tray Efficiency You can consider em as the. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application. What Are The Different Types Of Tray Efficiency.

From www.hzdr.de

Fluid dynamics and separation efficiency of column trays Helmholtz What Are The Different Types Of Tray Efficiency You can consider em as the. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. the traditional murphree efficiency approach to tray design. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. due to the absence of downcomers, dual flow. What Are The Different Types Of Tray Efficiency.

From www.wermac.org

Distillation Column Column Internals, Bubble cap trays, Valve trays What Are The Different Types Of Tray Efficiency The section efficiency is calculated based on fundamental. You can consider em as the. • the number of trays is dependent on the number of equilibrium stages. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. types of plate efficiency there are four different types of tray efficiencies that are used.. What Are The Different Types Of Tray Efficiency.

From www.slideserve.com

PPT FLOW PATTERN PowerPoint Presentation, free download ID3277491 What Are The Different Types Of Tray Efficiency You can consider em as the. • the number of trays is dependent on the number of equilibrium stages. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. . What Are The Different Types Of Tray Efficiency.

From kimray.com

Gas Absorber Tower How the 3 Types Work to Dehydrate Your Natural Gas What Are The Different Types Of Tray Efficiency the traditional murphree efficiency approach to tray design. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. • the number of trays is dependent on the number of equilibrium stages. types of plate efficiency there are four different types of tray efficiencies that are used. the most. What Are The Different Types Of Tray Efficiency.

From chemknowhow.blogspot.com

Chemical Engineering Knowledge Plate Columns and Comparison of Tray Types What Are The Different Types Of Tray Efficiency You can consider em as the. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. types of plate efficiency there are four different types of tray efficiencies that are used. • the number of trays is dependent on the number of equilibrium stages. different tray efficiency models as well recommendations for. What Are The Different Types Of Tray Efficiency.

From achs-prod.acs.org

Efficiency Estimation of Tray Columns Based on Flow Profiles and Vapor What Are The Different Types Of Tray Efficiency the traditional murphree efficiency approach to tray design. • the number of trays is dependent on the number of equilibrium stages. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. You can consider em as the. different tray efficiency models as well recommendations for selecting tray. What Are The Different Types Of Tray Efficiency.

From www.slideserve.com

PPT Separations PowerPoint Presentation, free download ID639956 What Are The Different Types Of Tray Efficiency due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. types of plate efficiency there are four different types of tray efficiencies that are used. the traditional murphree. What Are The Different Types Of Tray Efficiency.

From www.pinterest.com.mx

Tray or Packed Columns for Distillation Chemical engineering, Nursing What Are The Different Types Of Tray Efficiency due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. the traditional murphree efficiency approach to tray design. The section efficiency is calculated based on fundamental. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. You can consider em as the.. What Are The Different Types Of Tray Efficiency.

From www.homestratosphere.com

8 Different Types of Serving Trays What Are The Different Types Of Tray Efficiency You can consider em as the. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. types. What Are The Different Types Of Tray Efficiency.

From frippo.com

5 Different Types of Serving Trays Frippo News What Are The Different Types Of Tray Efficiency the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. The section efficiency is calculated based on fundamental. due to the absence of downcomers, dual flow tray gives more tray area hence a greater. What Are The Different Types Of Tray Efficiency.

From www.scribd.com

Valve Tray Efficiency Data PDF Physical Sciences Chemistry What Are The Different Types Of Tray Efficiency the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. types of plate efficiency there are four different types of tray efficiencies that are used. due to the absence of downcomers, dual flow tray gives. What Are The Different Types Of Tray Efficiency.

From www.wermac.org

Distillation Column Column Internals, Bubble cap trays, Valve trays What Are The Different Types Of Tray Efficiency due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. You can consider em as the. the traditional murphree efficiency approach to tray design. • the number of trays is dependent on. What Are The Different Types Of Tray Efficiency.

From www.dreamstime.com

Slanted View Different Types of Black Trays Isolated on White What Are The Different Types Of Tray Efficiency • the number of trays is dependent on the number of equilibrium stages. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. The section efficiency is calculated based on. What Are The Different Types Of Tray Efficiency.

From www.homestratosphere.com

8 Different Types of Serving Trays What Are The Different Types Of Tray Efficiency different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. The section efficiency is calculated based on fundamental. You can consider em as the. types of plate efficiency there are four different types of tray efficiencies that are used. • the number of trays is dependent on the number of. What Are The Different Types Of Tray Efficiency.

From dxokncqye.blob.core.windows.net

Valve Tray Types at Hugh Aube blog What Are The Different Types Of Tray Efficiency The section efficiency is calculated based on fundamental. types of plate efficiency there are four different types of tray efficiencies that are used. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo.. What Are The Different Types Of Tray Efficiency.

From www.separationprocesses.com

Plant Operation Tray Components What Are The Different Types Of Tray Efficiency the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. the traditional murphree efficiency approach to tray design. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity. What Are The Different Types Of Tray Efficiency.

From www.slideshare.net

Types and design of the towers trays What Are The Different Types Of Tray Efficiency types of plate efficiency there are four different types of tray efficiencies that are used. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. The section efficiency is calculated based on fundamental.. What Are The Different Types Of Tray Efficiency.

From www.homestratosphere.com

8 Different Types of Serving Trays What Are The Different Types Of Tray Efficiency types of plate efficiency there are four different types of tray efficiencies that are used. the traditional murphree efficiency approach to tray design. • the number of trays is dependent on the number of equilibrium stages. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. due to the absence. What Are The Different Types Of Tray Efficiency.

From www.homestratosphere.com

8 Different Types of Serving Trays What Are The Different Types Of Tray Efficiency due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. different tray efficiency models as. What Are The Different Types Of Tray Efficiency.

From www.chemicalslearning.com

Tray dryer Construction and Working Principle and Advantages What Are The Different Types Of Tray Efficiency different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. You can consider em as the. The section efficiency is calculated based on fundamental. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. the traditional murphree efficiency approach. What Are The Different Types Of Tray Efficiency.

From enggyd.blogspot.com

Engineers Guide Selection and Sizing of A Distillation Column What Are The Different Types Of Tray Efficiency types of plate efficiency there are four different types of tray efficiencies that are used. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. You can consider em as the. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than. What Are The Different Types Of Tray Efficiency.

From www.scribd.com

Tray Efficiency Determination PDF Heat Transfer Distillation What Are The Different Types Of Tray Efficiency the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. the traditional murphree efficiency approach to tray design. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on. What Are The Different Types Of Tray Efficiency.

From exowfihfa.blob.core.windows.net

Types Of Cable Tray And Trunking at Wilmer Coon blog What Are The Different Types Of Tray Efficiency The section efficiency is calculated based on fundamental. the traditional murphree efficiency approach to tray design. types of plate efficiency there are four different types of tray efficiencies that are used. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. due to the absence of downcomers, dual flow tray. What Are The Different Types Of Tray Efficiency.

From studylib.net

Factors influencing plate efficiency What Are The Different Types Of Tray Efficiency The section efficiency is calculated based on fundamental. the traditional murphree efficiency approach to tray design. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. types of plate efficiency there are four different types. What Are The Different Types Of Tray Efficiency.

From amacs.com

What Are Trays and How Are They Used in Process Plants? AMACS What Are The Different Types Of Tray Efficiency the traditional murphree efficiency approach to tray design. • the number of trays is dependent on the number of equilibrium stages. You can consider em as the. the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. types of plate efficiency there are four different types of tray efficiencies that are used.. What Are The Different Types Of Tray Efficiency.

From www.slideshare.net

Assignment 1 What Are The Different Types Of Tray Efficiency types of plate efficiency there are four different types of tray efficiencies that are used. • the number of trays is dependent on the number of equilibrium stages. The section efficiency is calculated based on fundamental. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. the traditional murphree. What Are The Different Types Of Tray Efficiency.

From www.slideshare.net

Types and design of the towers trays What Are The Different Types Of Tray Efficiency You can consider em as the. • the number of trays is dependent on the number of equilibrium stages. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. due to the absence. What Are The Different Types Of Tray Efficiency.

From magazine.zhermack.com

Different types of impression tray What Are The Different Types Of Tray Efficiency The section efficiency is calculated based on fundamental. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. • the number of trays is dependent on the number of equilibrium stages. . What Are The Different Types Of Tray Efficiency.

From www.slideshare.net

Types and design of the towers trays What Are The Different Types Of Tray Efficiency You can consider em as the. the traditional murphree efficiency approach to tray design. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. types of plate efficiency there are four different. What Are The Different Types Of Tray Efficiency.

From chemknowhow.blogspot.com

Chemical Engineering Knowledge Plate Columns and Comparison of Tray Types What Are The Different Types Of Tray Efficiency due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. the traditional murphree efficiency approach to tray design. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. You can consider em as the. different tray efficiency models as well. What Are The Different Types Of Tray Efficiency.

From www.countingaccounting.com

3 Types of Efficiency in Economics. Overview and Explanation What Are The Different Types Of Tray Efficiency the traditional murphree efficiency approach to tray design the section efficiency is calculated based on. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. The section efficiency is calculated based on fundamental. due to the absence of downcomers, dual flow tray gives more tray area hence a greater. What Are The Different Types Of Tray Efficiency.

From www.semanticscholar.org

Figure 2 from Design and Construction of a Novel Oldershawtype What Are The Different Types Of Tray Efficiency The section efficiency is calculated based on fundamental. types of plate efficiency there are four different types of tray efficiencies that are used. the most commonly used ones are the murphree tray efficiency, em, and overall tray efficiency, eo. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the.. What Are The Different Types Of Tray Efficiency.

From haipernews.com

How To Calculate Distillation Efficiency Haiper What Are The Different Types Of Tray Efficiency types of plate efficiency there are four different types of tray efficiencies that are used. • the number of trays is dependent on the number of equilibrium stages. due to the absence of downcomers, dual flow tray gives more tray area hence a greater capacity than any of. The section efficiency is calculated based on fundamental. the. What Are The Different Types Of Tray Efficiency.

From fr.dreamstime.com

Slanted View Different Types of Baking Trays Isolated on White What Are The Different Types Of Tray Efficiency You can consider em as the. types of plate efficiency there are four different types of tray efficiencies that are used. The section efficiency is calculated based on fundamental. different tray efficiency models as well recommendations for selecting tray efficiency models for industrial application based on the. the traditional murphree efficiency approach to tray design the section. What Are The Different Types Of Tray Efficiency.