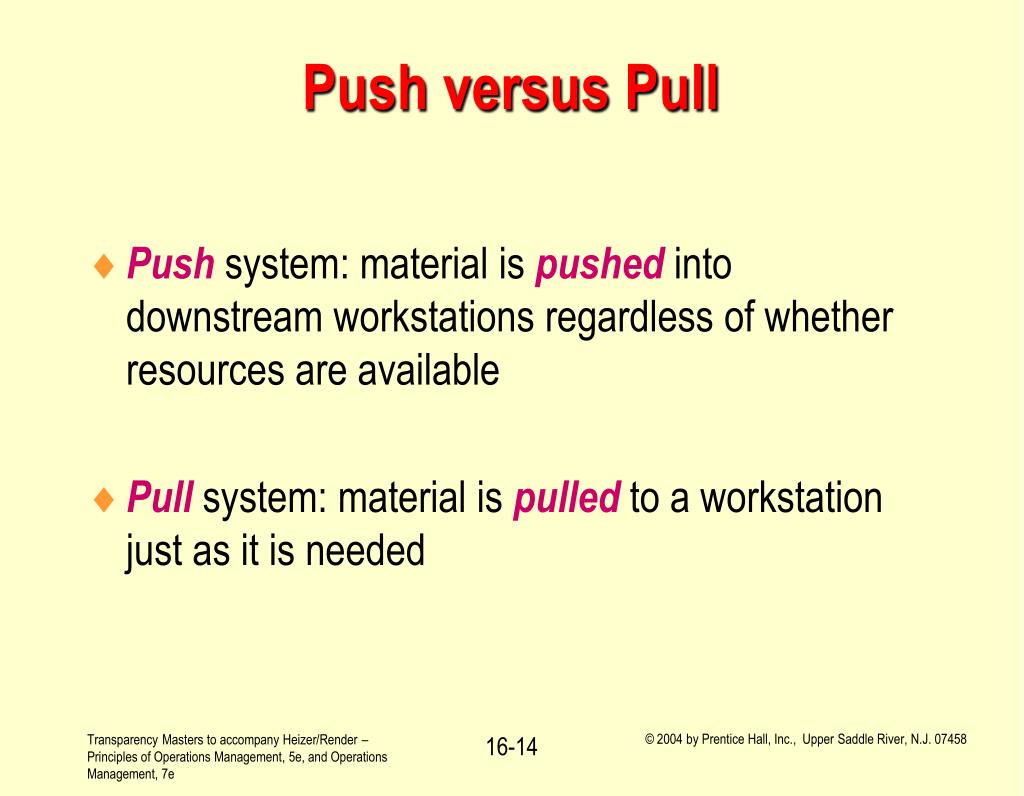

Push And Pull Operations Management . In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. Operations and supply chain management. In this post, we want to introduce another critical concept in lean operations: It also allows for more accurate forecasting and planning of production runs. This eventually helps to reduce waste and improve quality. The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. In general terms, push vs. Pull strategies refer to how you manage your. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. It dictates when and how much to produce. Balancing push and pull approaches to improvement.

from www.slideserve.com

In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. Balancing push and pull approaches to improvement. It dictates when and how much to produce. In this post, we want to introduce another critical concept in lean operations: The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. Pull strategies refer to how you manage your. It also allows for more accurate forecasting and planning of production runs. This eventually helps to reduce waste and improve quality. In general terms, push vs.

PPT Operations Management JustinTime and Lean Production Systems

Push And Pull Operations Management Pull strategies refer to how you manage your. It dictates when and how much to produce. In this post, we want to introduce another critical concept in lean operations: The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Pull strategies refer to how you manage your. In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. Operations and supply chain management. Balancing push and pull approaches to improvement. This eventually helps to reduce waste and improve quality. In general terms, push vs. The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. It also allows for more accurate forecasting and planning of production runs.

From www.slideserve.com

PPT Supply Chain Management PowerPoint Presentation, free download Push And Pull Operations Management It also allows for more accurate forecasting and planning of production runs. Operations and supply chain management. This eventually helps to reduce waste and improve quality. Pull strategies refer to how you manage your. The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. The main difference between push and pull manufacturing is. Push And Pull Operations Management.

From www.bwl-lexikon.de

PushPullStrategie » Definition, Erklärung & Beispiele + Übungsfragen Push And Pull Operations Management The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. This eventually helps to reduce waste and improve quality. Balancing push and pull approaches to improvement. In this post, we'll describe the. Push And Pull Operations Management.

From itgtechnology.vn

Pull System là gì? Chiến lược kéo trong quản lý hàng tồn kho Push And Pull Operations Management It dictates when and how much to produce. In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. In general terms, push vs. In this post, we want to introduce another critical concept in lean operations: The main difference between push and pull manufacturing is that in a push. Push And Pull Operations Management.

From www.slideshare.net

Push pull strategy business model Push And Pull Operations Management It dictates when and how much to produce. The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. Balancing push and pull approaches to improvement. Pull strategies refer to how you manage your. In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why. Push And Pull Operations Management.

From www.allaboutlean.com

Logistic Plan Push Pull? Push And Pull Operations Management Operations and supply chain management. In general terms, push vs. Pull strategies refer to how you manage your. In this post, we want to introduce another critical concept in lean operations: This eventually helps to reduce waste and improve quality. It dictates when and how much to produce. Balancing push and pull approaches to improvement. The main difference between push. Push And Pull Operations Management.

From www.retaildogma.com

Push & Pull Strategy Explained With RealLife Example Push And Pull Operations Management The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. The. Push And Pull Operations Management.

From cashflowinventory.com

Pull and Push Strategy in Supply Chain Management Push And Pull Operations Management The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Operations and supply chain management. In this post, we want to introduce another critical concept in lean operations: Balancing push and pull. Push And Pull Operations Management.

From www.slideserve.com

PPT International Operations Management PowerPoint Presentation, free Push And Pull Operations Management Pull strategies refer to how you manage your. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. It dictates when and how much to produce. Operations and supply chain management. The. Push And Pull Operations Management.

From www.slideserve.com

PPT International Operations Management PowerPoint Presentation, free Push And Pull Operations Management It also allows for more accurate forecasting and planning of production runs. Operations and supply chain management. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. In this post, we want. Push And Pull Operations Management.

From www.novelvista.com

Strategic Dynamics Exploring Push vs. Pull Systems in Operations Push And Pull Operations Management Balancing push and pull approaches to improvement. In general terms, push vs. This eventually helps to reduce waste and improve quality. Pull strategies refer to how you manage your. It also allows for more accurate forecasting and planning of production runs. It dictates when and how much to produce. The main difference between push and pull manufacturing is that in. Push And Pull Operations Management.

From www.impactfirst.co

Pull System Definition, Its 3 Types & Differences with Push Push And Pull Operations Management The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. It dictates when and how much to produce. In this post, we want to introduce another critical concept in lean operations: It. Push And Pull Operations Management.

From 101blockchains.com

Push and Pull Strategy in Supply Chain Management A Comprehensive Guide Push And Pull Operations Management It dictates when and how much to produce. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. It also allows for more accurate forecasting and planning of production runs. Balancing push. Push And Pull Operations Management.

From www.slideteam.net

Push And Pull Strategy Powerpoint Ppt Template Bundles PPT Template Push And Pull Operations Management It also allows for more accurate forecasting and planning of production runs. In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. It dictates when and how much to produce. Pull strategies refer to how you manage your. Balancing push and pull approaches to improvement. In this post, we. Push And Pull Operations Management.

From slidemodel.com

Manufacturing Pull vs Push PowerPoint Template SlideModel Push And Pull Operations Management This eventually helps to reduce waste and improve quality. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. In this post, we'll describe the differences between push and pull systems and. Push And Pull Operations Management.

From operationsinsider.com

Push vs Pull — Operations Insider Push And Pull Operations Management Operations and supply chain management. The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. It dictates when and how much to produce. Pull strategies refer to how you manage your. In this post, we want to introduce another critical concept in lean operations: In this post, we'll describe the differences between push. Push And Pull Operations Management.

From www.sketchbubble.com

Push and Pull Strategy PowerPoint Template SketchBubble Push And Pull Operations Management It also allows for more accurate forecasting and planning of production runs. In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. Balancing push and pull approaches to improvement. This eventually helps to reduce waste and improve quality. In general terms, push vs. Pull strategies refer to how you. Push And Pull Operations Management.

From mavink.com

Push And Pull System Push And Pull Operations Management In general terms, push vs. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Operations and supply chain management. In this post, we'll describe the differences between push and pull systems. Push And Pull Operations Management.

From hs.bleexo.com

Comment passer d'un push à un pull management Push And Pull Operations Management This eventually helps to reduce waste and improve quality. In this post, we want to introduce another critical concept in lean operations: The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. It also allows for more accurate forecasting and planning of production runs. Operations and supply chain management. The main difference between. Push And Pull Operations Management.

From www.slideshare.net

Basics of Supply Chain Managment Push And Pull Operations Management This eventually helps to reduce waste and improve quality. It also allows for more accurate forecasting and planning of production runs. In this post, we want to introduce another critical concept in lean operations: Pull strategies refer to how you manage your. The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. In. Push And Pull Operations Management.

From www.slideserve.com

PPT International Operations Management PowerPoint Presentation, free Push And Pull Operations Management Balancing push and pull approaches to improvement. In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. In this post, we want to introduce another critical concept in lean operations: The main difference between push and pull manufacturing is that in a push system, production dictates how much of. Push And Pull Operations Management.

From powerslides.com

Push vs Pull Strategy 7,000+ Templates PowerSlides™ Push And Pull Operations Management Balancing push and pull approaches to improvement. In this post, we want to introduce another critical concept in lean operations: In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. It also. Push And Pull Operations Management.

From dev.powerslides.com

Push vs Pull Strategy 7,000+ Templates PowerSlides™ Push And Pull Operations Management The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. It dictates when and how much to produce. In general terms, push vs. This eventually helps to reduce waste and improve quality.. Push And Pull Operations Management.

From alexsibaja.blogspot.com

Lean Manufacturing & Six Sigma Pull Production Systems 生産システムを引いて Push And Pull Operations Management It also allows for more accurate forecasting and planning of production runs. This eventually helps to reduce waste and improve quality. Pull strategies refer to how you manage your. In this post, we want to introduce another critical concept in lean operations: Balancing push and pull approaches to improvement. Operations and supply chain management. It dictates when and how much. Push And Pull Operations Management.

From www.scribd.com

Push and Pull Operations Management Mathematical Optimization Push And Pull Operations Management It also allows for more accurate forecasting and planning of production runs. In general terms, push vs. Balancing push and pull approaches to improvement. In this post, we want to introduce another critical concept in lean operations: Operations and supply chain management. Pull strategies refer to how you manage your. This eventually helps to reduce waste and improve quality. In. Push And Pull Operations Management.

From mungfali.com

Push And Pull System Push And Pull Operations Management The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. It also allows for more accurate forecasting and planning of production runs. In this post, we want to introduce another critical concept. Push And Pull Operations Management.

From www.markarina.com

Estrategias de Push y Pull, definición y 5 ejemplos Push And Pull Operations Management The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. It dictates when and how much to produce. Pull strategies refer to how you manage your. Operations and supply chain management. In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. It. Push And Pull Operations Management.

From www.dozuki.com

Push vs. Pull System in Manufacturing A Complete Overview for Push And Pull Operations Management It dictates when and how much to produce. The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. This eventually helps to reduce waste and improve quality. Operations and supply chain management. Pull strategies refer to how you manage your. It also allows for more accurate forecasting and planning of production runs. The. Push And Pull Operations Management.

From www.slideserve.com

PPT Operations Management JustinTime and Lean Production Systems Push And Pull Operations Management In this post, we want to introduce another critical concept in lean operations: Balancing push and pull approaches to improvement. It dictates when and how much to produce. Operations and supply chain management. In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. The push strategy relies on forecasts. Push And Pull Operations Management.

From der-prozessmanager.de

5 Lean Prinzipien, die Sie kennen müssen! Push And Pull Operations Management It dictates when and how much to produce. The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. Operations and supply chain management. This eventually helps to reduce waste and improve quality. In this post, we want to introduce another critical concept in lean operations: Balancing push and pull approaches to improvement. In. Push And Pull Operations Management.

From elsmar.com

Push vs. Pull Push And Pull Operations Management The push strategy relies on forecasts and planning, while the pull strategy responds to actual demand signals. In general terms, push vs. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e.. Push And Pull Operations Management.

From www.slideshare.net

Push versus pull strategy Push And Pull Operations Management This eventually helps to reduce waste and improve quality. Operations and supply chain management. In this post, we'll describe the differences between push and pull systems and provide some examples to help illustrate why pull. In general terms, push vs. Balancing push and pull approaches to improvement. In this post, we want to introduce another critical concept in lean operations:. Push And Pull Operations Management.

From bitrebels.com

Push vs. Pull System Understanding The Basics And How It Affects Your Push And Pull Operations Management The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Balancing push and pull approaches to improvement. It dictates when and how much to produce. In this post, we want to introduce. Push And Pull Operations Management.

From www.thehrealestate.com

Push VS. Pull Leadership HALBERDIER Real Estate, The H Real Estate Push And Pull Operations Management In general terms, push vs. Operations and supply chain management. In this post, we want to introduce another critical concept in lean operations: This eventually helps to reduce waste and improve quality. Pull strategies refer to how you manage your. Balancing push and pull approaches to improvement. The main difference between push and pull manufacturing is that in a push. Push And Pull Operations Management.

From sixsigmadsi.com

What Are Push and Pull Systems? Push And Pull Operations Management In general terms, push vs. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Operations and supply chain management. In this post, we want to introduce another critical concept in lean. Push And Pull Operations Management.

From www.deskera.com

Push System vs. Pull System in Manufacturing Management Push And Pull Operations Management It dictates when and how much to produce. Operations and supply chain management. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. It also allows for more accurate forecasting and planning. Push And Pull Operations Management.