Heating Plate Soldering . Then you let it cool off and its done! There are five ways to solder smd parts that i can think of: A diy temperature controlled hot plate for soldering smd components. Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Find this and other hardware projects on hackster.io. Solder smds with a pan o’ sand | hackaday. A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering.

from mightyohm.com

Find this and other hardware projects on hackster.io. In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. Solder smds with a pan o’ sand | hackaday. The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). A diy temperature controlled hot plate for soldering smd components. There are five ways to solder smd parts that i can think of: Then you let it cool off and its done!

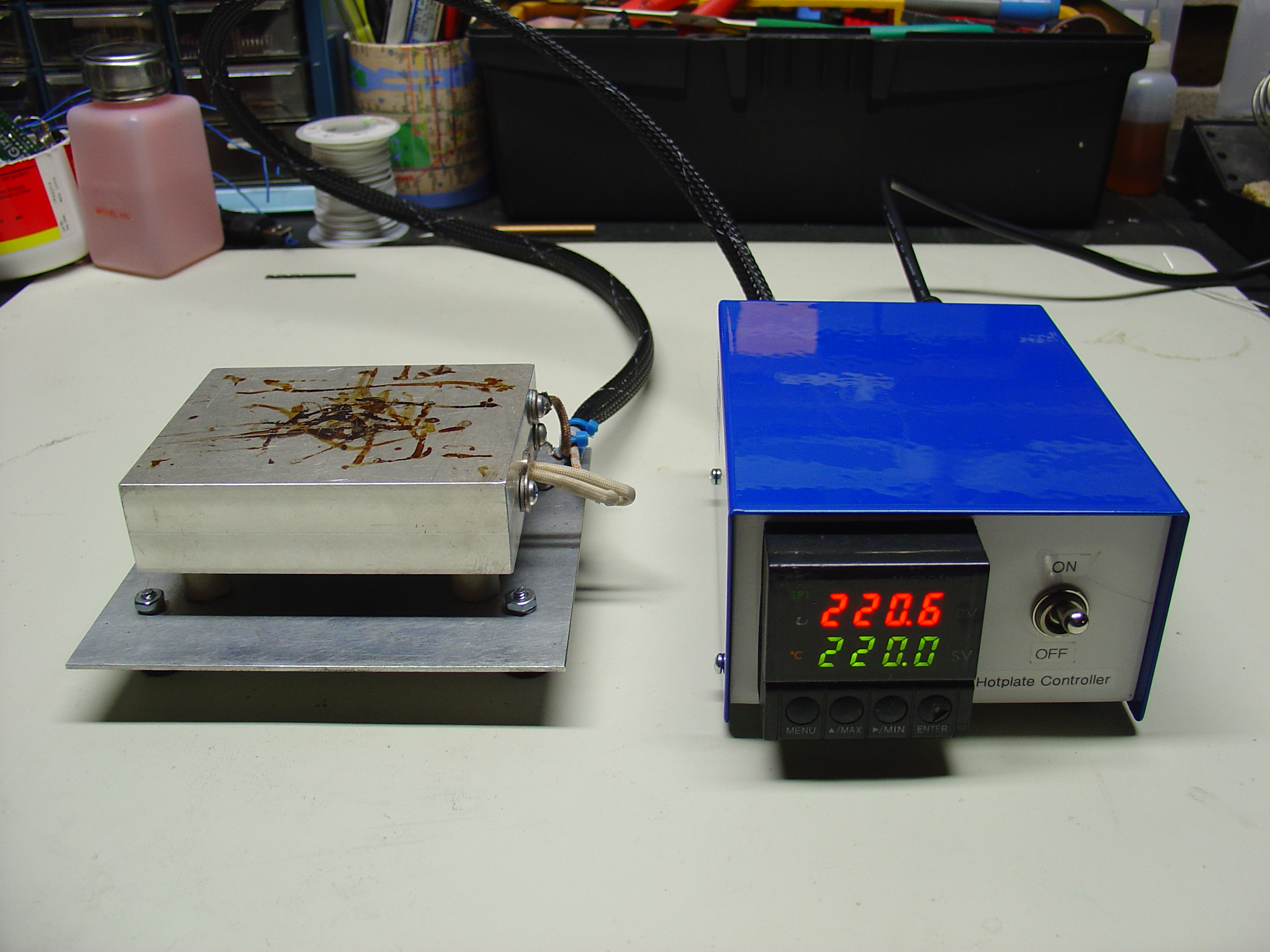

DIY PID Controlled Soldering Hotplate MightyOhm

Heating Plate Soldering The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Find this and other hardware projects on hackster.io. Solder smds with a pan o’ sand | hackaday. A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. A diy temperature controlled hot plate for soldering smd components. In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Then you let it cool off and its done! There are five ways to solder smd parts that i can think of: Hand soldering (default) toasting (ok) industrial reflow (pretty crummy).

From ultraflexpower.com

Induction Soldering of Aluminum Plate with Glass Block UltraFlex Power Heating Plate Soldering Then you let it cool off and its done! There are five ways to solder smd parts that i can think of: Solder smds with a pan o’ sand | hackaday. The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. A. Heating Plate Soldering.

From soldering102.blogspot.com

Soldering, AntiStatic, ThermoMeters Philippines Heating Plate (Hot Plate) digital Preheater Heating Plate Soldering A diy temperature controlled hot plate for soldering smd components. In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder. Heating Plate Soldering.

From www.tempco.it

Soldering connections on brazed plate heat exchanger how to do Tempco Blog Heating Plate Soldering Then you let it cool off and its done! A diy temperature controlled hot plate for soldering smd components. In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. There are five ways to solder smd parts that i can think of: A hot plate comprises an. Heating Plate Soldering.

From www.aliexpress.com

400W PTC Heating Plate Chip BGA Soldering Ball Split Aluminum LED Remover Welding Station Heating Plate Soldering In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. A diy temperature controlled hot plate for soldering smd components. Find this and other hardware projects on hackster.io. Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). Then you let it cool off and its done! Solder. Heating Plate Soldering.

From www.walmart.com

65W Hot Plate SMD Preheater Preheating Rework Station PCB Board Soldering Desoldering Heating Heating Plate Soldering There are five ways to solder smd parts that i can think of: Find this and other hardware projects on hackster.io. Then you let it cool off and its done! Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb). Heating Plate Soldering.

From www.youtube.com

Homemade Hot Plate for Wireless SMD Soldering! Using ESP32, Flat Iron, and IR temperature sensor Heating Plate Soldering In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. Solder smds with a pan o’ sand | hackaday. A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. Find this. Heating Plate Soldering.

From www.desertcart.co.za

Buy POHOVE PTC HeatingSoldering Plate,PTC Heating Plate Soldering Chip Welding B GA Station Heating Plate Soldering A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. Find this and other hardware projects on hackster.io. A diy temperature controlled hot plate for soldering smd components. In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent. Heating Plate Soldering.

From ifuturetech.org

300W SMT BGA SOLDERING REFLOW PLATE iFuture Technology Heating Plate Soldering Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). Then you let it cool off and its done! Solder smds with a pan o’ sand | hackaday. Find this and other hardware projects on hackster.io. A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd). Heating Plate Soldering.

From www.youtube.com

The Best way to Solder? Hot Plate to the rescue! (DIY or Buy) YouTube Heating Plate Soldering A diy temperature controlled hot plate for soldering smd components. Then you let it cool off and its done! The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Solder smds with a pan o’ sand | hackaday. In broad terms the. Heating Plate Soldering.

From ifuturetech.org

300W SMT BGA SOLDERING REFLOW PLATE iFuture Technology Heating Plate Soldering In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. A diy temperature controlled hot plate for soldering smd components. Find this and other hardware projects on hackster.io. A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit. Heating Plate Soldering.

From www.walmart.com

Electric Hot Plate, Soldering Pro Heating Tool, Portable Preheating Heating Station Soldering Heating Plate Soldering Find this and other hardware projects on hackster.io. A diy temperature controlled hot plate for soldering smd components. Then you let it cool off and its done! Solder smds with a pan o’ sand | hackaday. In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. Hand. Heating Plate Soldering.

From www.aliexpress.com

550W Aluminum LED Remover PTC Heating Plate Soldering Chip Remove Weld BGA Solder Ball Station Heating Plate Soldering Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). A diy temperature controlled hot plate for soldering smd components. In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. Solder smds with a pan o’ sand | hackaday. There are five ways to solder smd parts that. Heating Plate Soldering.

From www.walmart.com

Electric Hot Plate Soldering Heater Station Soldering Pro Heating Tool Preheating Station Heating Plate Soldering Solder smds with a pan o’ sand | hackaday. There are five ways to solder smd parts that i can think of: In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. Find this and other hardware projects on hackster.io. The basic idea is that you put. Heating Plate Soldering.

From inductionheat.wordpress.com

Induction Soldering Brass to Steel Plate HLQ Induction Heating Machine Manufacturer Heating Plate Soldering The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). Then you let it cool off and its done! Solder smds with a pan o’ sand | hackaday. In broad terms the heating. Heating Plate Soldering.

From alpinemobilehomes.com

The Best Soldering Heating Station Home Previews Heating Plate Soldering Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). Find this and other hardware projects on hackster.io. A diy temperature controlled hot plate for soldering smd components. Solder smds with a pan o’ sand | hackaday. There are five ways to solder smd parts that i can think of: A hot plate comprises an electronically heated platform allowing precision temperature. Heating Plate Soldering.

From www.instructables.com

Heating Plate for SMD Soldering Simple, Small and Low Cost 3 Steps (with Pictures Heating Plate Soldering A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. Find this and other hardware projects on hackster.io. In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. There are five. Heating Plate Soldering.

From mightyohm.com

DIY PID Controlled Soldering Hotplate MightyOhm Heating Plate Soldering There are five ways to solder smd parts that i can think of: In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. Solder smds with a pan o’ sand | hackaday. Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). A diy temperature controlled hot plate. Heating Plate Soldering.

From www.amazon.com

TKDMR 300W PTC HeatingSoldering Plate Hot Plate LED Remover Chip Welding Station for LED Heating Plate Soldering The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Find this and other hardware projects on hackster.io. There are five ways to solder smd parts that i can think of: Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). In broad. Heating Plate Soldering.

From www.walmart.com

Soiiw 110V 850W Soldering Hot Plate LED Electric Preheat Soldering Station Welder Heating Plate Soldering A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. A diy temperature controlled hot plate for soldering smd components. Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). Then you let it cool off and its done! There are five ways to solder. Heating Plate Soldering.

From www.youtube.com

Hot Plate soldering YouTube Heating Plate Soldering Solder smds with a pan o’ sand | hackaday. There are five ways to solder smd parts that i can think of: In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). A diy temperature controlled hot plate. Heating Plate Soldering.

From www.aliexpress.com

D26 Digital constant temperature heating platform/Preheating Station/Hot Plate/Heat Platform Heating Plate Soldering Then you let it cool off and its done! The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Solder smds with a pan o’ sand | hackaday. Find this and other hardware projects on hackster.io. There are five ways to solder. Heating Plate Soldering.

From alexnld.com

300W Aluminum LED Remover PTC Heating Plate Pads Soldering Chip Remove Weld BGA Solder Ball Heating Plate Soldering A diy temperature controlled hot plate for soldering smd components. There are five ways to solder smd parts that i can think of: The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Solder smds with a pan o’ sand | hackaday.. Heating Plate Soldering.

From www.amazon.com

soldering plate Heating Plate Soldering Then you let it cool off and its done! Solder smds with a pan o’ sand | hackaday. There are five ways to solder smd parts that i can think of: A diy temperature controlled hot plate for soldering smd components. Find this and other hardware projects on hackster.io. A hot plate comprises an electronically heated platform allowing precision temperature. Heating Plate Soldering.

From www.desertcart.co.za

Buy POHOVE PTC HeatingSoldering Plate,PTC Heating Plate Soldering Chip Welding B GA Station Heating Plate Soldering The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. There are five ways to solder smd parts that i can think of: A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit. Heating Plate Soldering.

From www.youtube.com

Homemade Reflow Hot Plate for SMD Soldering 3000W YouTube Heating Plate Soldering Find this and other hardware projects on hackster.io. A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the. Heating Plate Soldering.

From www.bigmessowires.com

Hot Plate Reflow Soldering Round 1 Big Mess o' Wires Heating Plate Soldering A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. Solder smds with a pan o’ sand | hackaday. Find this and other hardware projects on hackster.io. A diy temperature controlled hot plate for soldering smd components. Then you let it cool off and. Heating Plate Soldering.

From alexnld.com

MHP30 Mini OLED Hot Plate Preheater 60W 350 Soldering Station Preset Temperature with PD Power Heating Plate Soldering Solder smds with a pan o’ sand | hackaday. In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take a. A diy temperature controlled hot plate for soldering smd components. Find this and other hardware projects on hackster.io. The basic idea is that you put the circuit board. Heating Plate Soldering.

From www.amazon.com

Soldering Heating Plate, 65w Mini Hot Plate Welder, Solder Plate With Fast Heating, Electric Heating Plate Soldering Solder smds with a pan o’ sand | hackaday. Then you let it cool off and its done! There are five ways to solder smd parts that i can think of: A diy temperature controlled hot plate for soldering smd components. Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). In broad terms the heating plate is a piece of. Heating Plate Soldering.

From gbr.grandado.com

550W Aluminum LED Remover PTC Heating Plate Soldering Chip Remove Weld BGA Solder Ball Station Heating Plate Soldering A diy temperature controlled hot plate for soldering smd components. Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). There are five ways to solder smd parts that i can think of: A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. Find this. Heating Plate Soldering.

From www.youtube.com

MHP30 heat plate soldering YouTube Heating Plate Soldering A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. A diy temperature controlled hot plate for soldering smd components. Find this and other hardware projects on hackster.io. Then you let it cool off and its done! The basic idea is that you put. Heating Plate Soldering.

From www.aliexpress.com

Digital constant temperature heating platform/Preheating Station/Hot Plate/Heat Platform/Heating Heating Plate Soldering The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. A diy temperature controlled hot plate for soldering smd components. In broad terms the heating plate is a piece of aluminium around 40mm diameter (or equivalent rectangular area), thick enough to take. Heating Plate Soldering.

From www.mscdirect.com

Weller Soldering Heating Plate MSC Industrial Supply Co. Heating Plate Soldering Then you let it cool off and its done! Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. Solder smds with a pan o’ sand | hackaday. A diy temperature controlled hot plate for. Heating Plate Soldering.

From www.aliexpress.com

Store Home Products Outdoor Fun Feedback Heating Plate Soldering The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Hand soldering (default) toasting (ok) industrial reflow (pretty crummy). A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount. Heating Plate Soldering.

From www.youtube.com

Soldering with a hot plate YouTube Heating Plate Soldering Solder smds with a pan o’ sand | hackaday. The basic idea is that you put the circuit board on something (like a hot plate or a skillet) and then heat it up until the solder melts. Find this and other hardware projects on hackster.io. A diy temperature controlled hot plate for soldering smd components. Hand soldering (default) toasting (ok). Heating Plate Soldering.

From uk.rs-online.com

T0053364899 Weller Soldering Accessory Soldering Iron Pre Heating Plate, for use with Weller Heating Plate Soldering A hot plate comprises an electronically heated platform allowing precision temperature control up to 300°c necessary for print circuit board (pcb) surface mount device (smd) soldering. Then you let it cool off and its done! Solder smds with a pan o’ sand | hackaday. A diy temperature controlled hot plate for soldering smd components. The basic idea is that you. Heating Plate Soldering.