Compressed Air Validation Procedure . To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. Iso 8573 is the international standard for. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation.

from www.slideshare.net

To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Iso 8573 is the international standard for. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation.

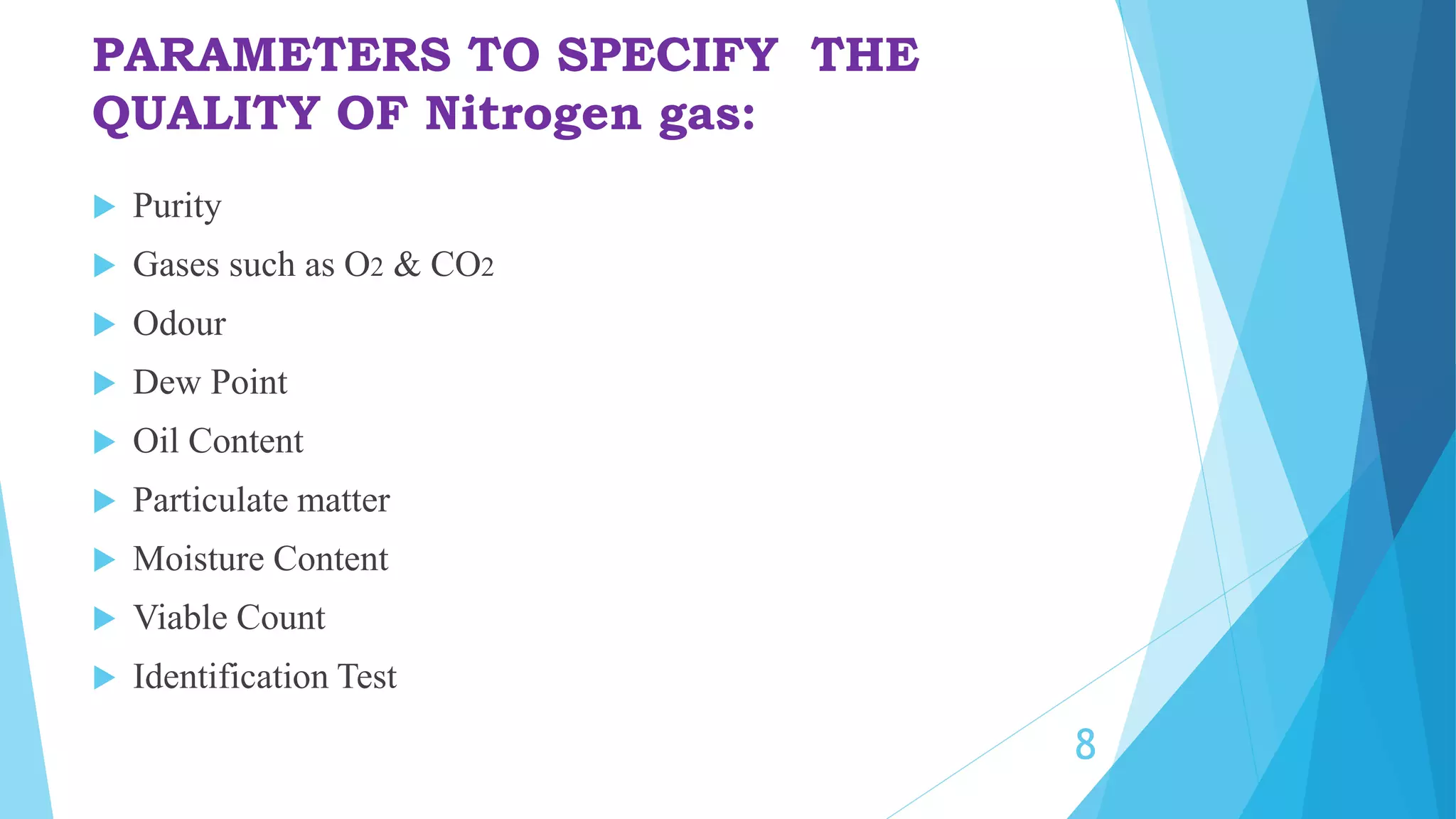

Validation of compressed air and nitrogen PPT

Compressed Air Validation Procedure Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. Iso 8573 is the international standard for. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,.

From www.coaireint.com

Compressed air Validation & Consulting Coaire Compressed Air Validation Procedure Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Iso 8573 is. Compressed Air Validation Procedure.

From www.airchecklab.com

Using ISO 85731 to Test Compressed Air Clearing the Confusion Trace Compressed Air Validation Procedure The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. Iso 8573 is the international standard for. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation PDF Compressed Air Validation Procedure Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. The purpose of this protocol. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation Compressed Air Validation Procedure Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Iso 8573 is the international standard for. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation PDF Compressed Air Validation Procedure To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. Testing for particles, water, oil,. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation Compressed Air Validation Procedure Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Learn about the importance of validating compressed. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation Compressed Air Validation Procedure To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Iso 8573 is the international standard for.. Compressed Air Validation Procedure.

From airtesting.com

Compressed Air Testing Services TRI Air Testing Inc. Compressed Air Validation Procedure Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Iso 8573 is the international standard for. Compressed air validation including tests like determination of moisture content, presence of oil content and. Compressed Air Validation Procedure.

From www.micronhvac.com

Compressed Air Validation Micron HVAC Pvt. Ltd. Pune, Maharashtra, India Compressed Air Validation Procedure The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Iso 8573 is the international standard for.. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation PDF Compressed Air Validation Procedure The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Iso 8573 is the international standard for. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. To set up a successful compressed air system validation, it is important to designate specification. Compressed Air Validation Procedure.

From www.scribd.com

Compressed Air Validation PDF Valve Flow Measurement Compressed Air Validation Procedure Iso 8573 is the international standard for. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. The purpose of this protocol is to provide the procedure for the validation of compressed air. Compressed Air Validation Procedure.

From dokumen.tips

(PPT) Validation of Compressed Air DOKUMEN.TIPS Compressed Air Validation Procedure Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. Iso 8573 is the international standard for. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation PDF Compressed Air Validation Procedure The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. To set up a successful. Compressed Air Validation Procedure.

From www.scribd.com

Pharmaceutical Compressed Air Validation 1657011960 PDF Flow Compressed Air Validation Procedure Iso 8573 is the international standard for. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. Testing for particles, water, oil, and microorganisms is an important part of any compressed air. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation PDF Compressed Air Validation Procedure Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. The purpose of this protocol. Compressed Air Validation Procedure.

From www.scribd.com

Compressed Air Validation Gases Energy Technology Compressed Air Validation Procedure The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. Iso 8573 is the international standard for. Testing for particles, water, oil, and microorganisms is an important part of any compressed air. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation PDF Compressed Air Validation Procedure Iso 8573 is the international standard for. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Testing for particles, water, oil, and microorganisms is an important part of any compressed air. Compressed Air Validation Procedure.

From www.youtube.com

Compressed air Qualification Compressed air Validation Compressed Air Validation Procedure The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. Iso 8573 is the international standard for. Testing for particles, water, oil, and microorganisms is an important part of any compressed air. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation Compressed Air Validation Procedure Iso 8573 is the international standard for. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Testing for particles, water, oil, and microorganisms is an important part of any compressed air. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation PDF Compressed Air Validation Procedure Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. Iso 8573 is the international standard for. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Compressed air validation including tests like determination of moisture content, presence of oil content and. Compressed Air Validation Procedure.

From www.scribd.com

Validation of Compressed Air Gas Compressor Verification And Validation Compressed Air Validation Procedure Iso 8573 is the international standard for. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or. Compressed Air Validation Procedure.

From www.coaireint.com

Compressed air Validation & Consulting Coaire Compressed Air Validation Procedure Iso 8573 is the international standard for. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. The purpose of this protocol is to provide the procedure for the validation of compressed air. Compressed Air Validation Procedure.

From www.youtube.com

Sampling and Testing of Compressed Air For Viable Count YouTube Compressed Air Validation Procedure Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Iso 8573 is the international standard. Compressed Air Validation Procedure.

From usvalidation.com

Validation of Compressed Air Systems Compressed Air Validation Procedure The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. Iso 8573 is the international standard for. Testing for particles, water, oil, and microorganisms is an important part of any compressed air. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation Compressed Air Validation Procedure Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Iso 8573 is the international standard for. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system. Compressed Air Validation Procedure.

From www.safewellsolutions.co.uk

Compressed Air Quality Testing & Validation in accordance with ISO 8573 Compressed Air Validation Procedure Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Testing for particles, water, oil,. Compressed Air Validation Procedure.

From www.slideshare.net

Validation of compressed air and nitrogen PPT Compressed Air Validation Procedure The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Iso 8573 is the international standard for. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp,. Compressed Air Validation Procedure.

From www.scribd.com

Validation Protocol for Compressed Air System PDF Business Compressed Air Validation Procedure Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. Iso 8573 is the international. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation PDF Compressed Air Validation Procedure To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Iso 8573 is the international standard for. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation.. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation Compressed Air Validation Procedure Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. Iso 8573 is the international standard for. Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline,. Compressed Air Validation Procedure.

From dxoyuzkvz.blob.core.windows.net

What Is Compressed Air Validation at Wendell Janus blog Compressed Air Validation Procedure Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. Iso 8573 is the international standard. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation PDF Compressed Air Validation Procedure Compressed air validation including tests like determination of moisture content, presence of oil content and microbial evaluation. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. Learn about the importance of validating. Compressed Air Validation Procedure.

From www.scribd.com

Presentation On Validation of Compressed Air PDF Verification And Compressed Air Validation Procedure The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Iso 8573 is the international standard for. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas. Compressed Air Validation Procedure.

From www.scribd.com

Glimpses On Compressed Air System Validation Test PDF Flow Compressed Air Validation Procedure To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Testing for particles, water, oil, and microorganisms is an important part of any compressed air or gas system validation. The purpose of this protocol is to provide the procedure for the validation of compressed air distribution system. Iso 8573 is the international. Compressed Air Validation Procedure.

From www.slideshare.net

Protocol for compressed air validation Compressed Air Validation Procedure To set up a successful compressed air system validation, it is important to designate specification requirements, timeline, protocols,. Learn about the importance of validating compressed air systems in the pharmaceutical industry, following ispe, usp, and other regulatory guidelines. Iso 8573 is the international standard for. Compressed air validation including tests like determination of moisture content, presence of oil content and. Compressed Air Validation Procedure.