Drill Hole For Flat Head Screw . 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds. This size allows for the thread to engage the material while providing. Flat head screws are commonly used in woodworking and metalworking projects, but drilling holes for them requires a slightly. For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16″, a countersunk diameter of 1″, and a countersunk angle of 82°. A countersunk hole is created by drilling a tapered hole with a wide outer portion, allowing the flat head of the screw to sit neatly. Clearance hole chart for inch bolts and screws. Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. Learn how to effortlessly drill precise holes for flat head screws in diy projects! Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. Discover the optimal tools and techniques for.

from handycrowd.com

Flat head screws are commonly used in woodworking and metalworking projects, but drilling holes for them requires a slightly. This size allows for the thread to engage the material while providing. 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds. Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. A countersunk hole is created by drilling a tapered hole with a wide outer portion, allowing the flat head of the screw to sit neatly. Clearance hole chart for inch bolts and screws. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. Discover the optimal tools and techniques for. Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16″, a countersunk diameter of 1″, and a countersunk angle of 82°.

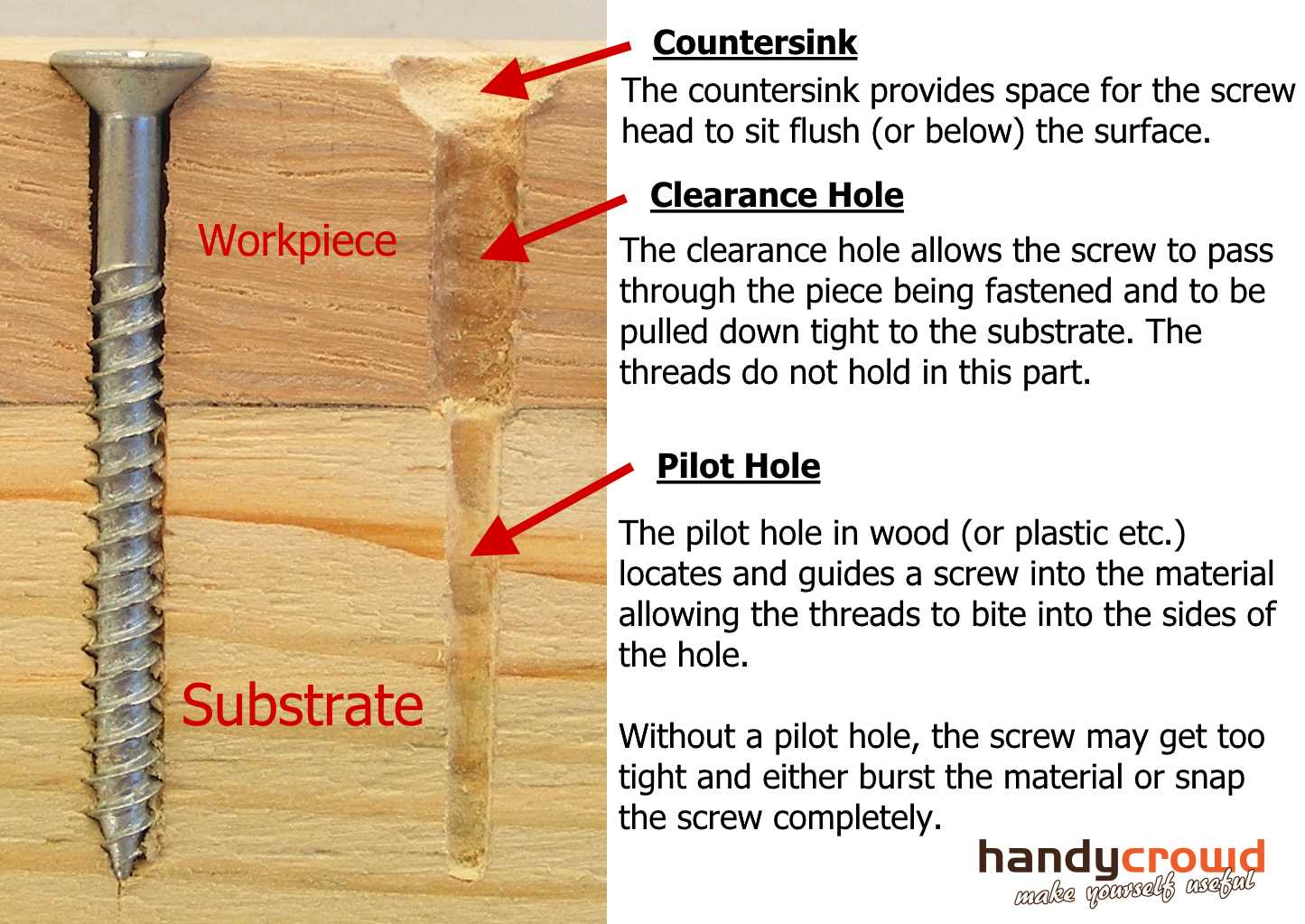

Screw sizes explained pilot, clearance, metric, wall plugs

Drill Hole For Flat Head Screw For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. Flat head screws are commonly used in woodworking and metalworking projects, but drilling holes for them requires a slightly. 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds. Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16″, a countersunk diameter of 1″, and a countersunk angle of 82°. A countersunk hole is created by drilling a tapered hole with a wide outer portion, allowing the flat head of the screw to sit neatly. Clearance hole chart for inch bolts and screws. Learn how to effortlessly drill precise holes for flat head screws in diy projects! Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. Discover the optimal tools and techniques for. This size allows for the thread to engage the material while providing. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°.

From helecu.com

Machine Screws and Nuts (2022) Drill Hole For Flat Head Screw 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm,. Drill Hole For Flat Head Screw.

From www.ejot.com

Head styles and types of drives Selfdrilling screws Guidebook Part 2 Drill Hole For Flat Head Screw Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. For example, an iso m10 flat head screw with a normal fit countersunk hole will require. Drill Hole For Flat Head Screw.

From www.walmart.com

THE CIMPLE CO 100pc Stainless Steel Self Drilling Tapping Screws 8 x Drill Hole For Flat Head Screw 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds. Learn how to effortlessly drill precise holes for flat head screws in diy projects! Clearance hole chart for inch bolts and screws. A countersunk hole is created by drilling. Drill Hole For Flat Head Screw.

From www.stainless-steelscrews.com

Stainless Steel Phillips Drive Self Drilling Screws CSK Head, Flat Head Drill Hole For Flat Head Screw For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16″, a countersunk diameter of 1″, and a countersunk angle of 82°. A countersunk hole is created by drilling a tapered hole with a wide outer portion, allowing the flat head of the screw to sit neatly. Use. Drill Hole For Flat Head Screw.

From helecu.com

Machine Screws and Nuts (2022) Drill Hole For Flat Head Screw Clearance hole chart for inch bolts and screws. A countersunk hole is created by drilling a tapered hole with a wide outer portion, allowing the flat head of the screw to sit neatly. Learn how to effortlessly drill precise holes for flat head screws in diy projects! Use the image and chart below to determine what dimensions to use, all. Drill Hole For Flat Head Screw.

From www.carbideanddiamondtooling.com

Countersink 82 Degree Angle Clearance, Drill and Countersink for Flat Drill Hole For Flat Head Screw Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds. This size allows for the thread to. Drill Hole For Flat Head Screw.

From www.indiamart.com

CSK Head Self Drilling Screw at Rs 1/pieces Self Screw in Mumbai ID Drill Hole For Flat Head Screw For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. For example, an. Drill Hole For Flat Head Screw.

From www.linquip.com

A Practical Guide to Types Of Screw Heads Drill Hole For Flat Head Screw Clearance hole chart for inch bolts and screws. Discover the optimal tools and techniques for. Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. Flat head screws are commonly used in woodworking and metalworking projects, but drilling holes for them requires a slightly. A countersunk hole is. Drill Hole For Flat Head Screw.

From www.albanycountyfasteners.com

818 Zinc Plated Steel Phillips Flat Head Self Drilling Screws Drill Hole For Flat Head Screw A countersunk hole is created by drilling a tapered hole with a wide outer portion, allowing the flat head of the screw to sit neatly. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°.. Drill Hole For Flat Head Screw.

From bdnfasteners.com

10 Different SelfTapping screw head types BDN Fasteners Drill Hole For Flat Head Screw Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. Discover the optimal tools and techniques for. Learn how to effortlessly drill precise holes for flat head screws in diy projects! For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require. Drill Hole For Flat Head Screw.

From engineersbible.com

Countersunk Hole Size for Flat Head Screws (ISO) The Engineer's Bible Drill Hole For Flat Head Screw This size allows for the thread to engage the material while providing. Flat head screws are commonly used in woodworking and metalworking projects, but drilling holes for them requires a slightly. Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. Learn how to effortlessly drill precise holes. Drill Hole For Flat Head Screw.

From handycrowd.com

Screw sizes explained pilot, clearance, metric, wall plugs Drill Hole For Flat Head Screw Clearance hole chart for inch bolts and screws. A countersunk hole is created by drilling a tapered hole with a wide outer portion, allowing the flat head of the screw to sit neatly. This size allows for the thread to engage the material while providing. Use the image and chart below to determine what dimensions to use, all dimensions are. Drill Hole For Flat Head Screw.

From www.yousta.com.au

Self drilling screws for metal phillips undercut countersunk head Drill Hole For Flat Head Screw 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds. A countersunk hole is created by drilling a tapered hole with a wide outer portion, allowing the flat head of the screw to sit neatly. For example, an iso. Drill Hole For Flat Head Screw.

From anthropology.iresearchnet.com

Woodworking Pocket Hole Screw Jig Drill Bits Set Cross Oblique Flat Drill Hole For Flat Head Screw Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds. A countersunk hole is created by drilling. Drill Hole For Flat Head Screw.

From fyoxdsmer.blob.core.windows.net

Drill Bit For Flat Head Screws at Debra Kilgore blog Drill Hole For Flat Head Screw Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. Clearance hole chart for inch bolts and screws. Learn how to effortlessly drill precise holes for flat head screws in diy projects! Flat head screws are commonly used in woodworking and metalworking projects, but drilling holes for them. Drill Hole For Flat Head Screw.

From forums.autodesk.com

Countersink Diameter for Flat Head Screws too Small Autodesk Community Drill Hole For Flat Head Screw Clearance hole chart for inch bolts and screws. Discover the optimal tools and techniques for. Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts. Drill Hole For Flat Head Screw.

From www.aliexpress.com

M4.8 Tapping Screw Self Drilling Sheet Metal Screws Undercut Flat Head Drill Hole For Flat Head Screw For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16″, a countersunk diameter of 1″, and a countersunk angle of 82°. Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. 25 rows it is. Drill Hole For Flat Head Screw.

From www.selfdrillingscrews.cn

Flat head, CSK head, counter sunk head Self Drilling Screws and Self Drill Hole For Flat Head Screw Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. A countersunk hole. Drill Hole For Flat Head Screw.

From monsterbolts.com

440 Phillips Flat Head Screws Flat Head Machine Screw Flat Head Drill Hole For Flat Head Screw Clearance hole chart for inch bolts and screws. Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or. Drill Hole For Flat Head Screw.

From www.moujaesco.com

PHILLIPS COUNTERSUNK HEAD SELFDRILLING SCREWS Ets. Wadih S. Moujaes Drill Hole For Flat Head Screw For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16″, a countersunk diameter of 1″, and a countersunk angle of 82°. Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. This size allows for. Drill Hole For Flat Head Screw.

From www.animalia-life.club

Hex Head Self Tapping Screws Drill Hole For Flat Head Screw 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds. This size allows for the thread to engage the material while providing. Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres. Drill Hole For Flat Head Screw.

From www.aftfasteners.com

1/414 x 3 Phil Flat Self Drill Screw 3 Bulk AFT Drill Hole For Flat Head Screw Flat head screws are commonly used in woodworking and metalworking projects, but drilling holes for them requires a slightly. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. This size allows for the thread. Drill Hole For Flat Head Screw.

From fyoxdsmer.blob.core.windows.net

Drill Bit For Flat Head Screws at Debra Kilgore blog Drill Hole For Flat Head Screw Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. Flat head screws are commonly used in woodworking and metalworking projects, but drilling holes for them requires a slightly. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole. Drill Hole For Flat Head Screw.

From www.amazon.com

8 Phillips Flat Head Self Drilling Screws 410 Stainless Drill Hole For Flat Head Screw Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. Flat head screws are commonly used in woodworking and metalworking projects, but drilling holes for them requires a slightly. This size allows for the thread to engage the material while providing. 25 rows it is considered good practice. Drill Hole For Flat Head Screw.

From www.yousta.com.au

Flat head screws phillips flat head drill point Drill Hole For Flat Head Screw This size allows for the thread to engage the material while providing. Learn how to effortlessly drill precise holes for flat head screws in diy projects! Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. Clearance hole chart for inch bolts and screws. 25 rows it is. Drill Hole For Flat Head Screw.

From www.asmc.net

1/4"14 x 1" (FT) Self Drilling Screws Square Drive Flat Head 3 Point Drill Hole For Flat Head Screw For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16″, a countersunk diameter of 1″, and a countersunk angle of 82°. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter. Drill Hole For Flat Head Screw.

From www.pinterest.com

A guide to wood screw sizes Wood screws, Screws, Nails and screws Drill Hole For Flat Head Screw For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16″, a countersunk. Drill Hole For Flat Head Screw.

From persberg.com

Stainless Steel Flat Head Phillips Wood Screw 14 x 3/4″ 50Pcs Persberg Drill Hole For Flat Head Screw Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. Use the image and chart below to determine what dimensions to use, all dimensions are in millimetres apart from the countersink angle. A countersunk hole is created by drilling a tapered hole with a wide outer portion, allowing. Drill Hole For Flat Head Screw.

From www.youtube.com

How to Drill a CounterSunk Hole for Flat Head Screw YouTube Drill Hole For Flat Head Screw Clearance hole chart for inch bolts and screws. Discover the optimal tools and techniques for. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. A countersunk hole is created by drilling a tapered hole. Drill Hole For Flat Head Screw.

From www.walmart.com

8 x 5/8" Hex Washer Head SelfDrilling Sheet Metal Tek Screws 410 SST Drill Hole For Flat Head Screw A countersunk hole is created by drilling a tapered hole with a wide outer portion, allowing the flat head of the screw to sit neatly. Clearance hole chart for inch bolts and screws. Discover the optimal tools and techniques for. 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f. Drill Hole For Flat Head Screw.

From www.wonkeedonkeetools.co.uk

Screw Glossary Wonkee Donkee Tools Drill Hole For Flat Head Screw Discover the optimal tools and techniques for. 25 rows it is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11. Drill Hole For Flat Head Screw.

From www.aliexpress.com

200pcs New M3 Self Tapping Screws Stainless Steel Pan Flat Head Self Drill Hole For Flat Head Screw For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16″, a countersunk diameter of 1″, and a countersunk angle of 82°. Flat head screws are commonly used in woodworking and metalworking projects, but drilling holes for them requires a slightly. Learn how to effortlessly drill precise holes. Drill Hole For Flat Head Screw.

From www.aliexpress.com

5PCS 410 Stainless Steel Flat Head Self Drilling Screw / Countersunk Drill Hole For Flat Head Screw Use the image and chart below to determine what dimensions to use, all dimensions are in inches apart from the countersink angle. Discover the optimal tools and techniques for. For example, an ansi inch 1/2″ flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 9/16″, a countersunk diameter of 1″, and a countersunk. Drill Hole For Flat Head Screw.

From shuntool.com

The Proper Technique For Drilling Holes To Flat Head Screws Drill Hole For Flat Head Screw For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. This size allows for the thread to engage the material while providing. 25 rows it is considered good practice to countersink or break the edges. Drill Hole For Flat Head Screw.

From www.stainless-steelscrews.com

Phillips Countersunk Head Tek Screw, Flat Head Drill Point, Self Drill Hole For Flat Head Screw For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. This size allows for the thread to engage the material while providing. 25 rows it is considered good practice to countersink or break the edges. Drill Hole For Flat Head Screw.