Pipe Flaring Process . Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. When you know how to use swaging and flaring tools for. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Flaring copper tubing is simple if you know what you are doing and you have the right tools. Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds.

from texasmethaneflaringcoalition.org

Flaring copper tubing is simple if you know what you are doing and you have the right tools. Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). When you know how to use swaging and flaring tools for. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly.

Frequently Asked Questions The Texas Methane & Flaring Coalition

Pipe Flaring Process The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). When you know how to use swaging and flaring tools for. Flaring copper tubing is simple if you know what you are doing and you have the right tools.

From whatispiping.com

Flare System Definition, Types, Components, and Design What Is Piping Pipe Flaring Process Flaring copper tubing is simple if you know what you are doing and you have the right tools. When you know how to use swaging and flaring tools for. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Using. Pipe Flaring Process.

From www.youtube.com

How to do really simple to believe Flaring 150mm pipe on a lathe YouTube Pipe Flaring Process Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Learn how to use a simple tool to. Pipe Flaring Process.

From whatispiping.com

Flare System Definition, Types, Components, and Design What Is Piping Pipe Flaring Process Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. Flaring copper tubing is simple if you know what you are doing and you have the right tools. Learn how to use a simple tool to flare pipe and make sure your. Pipe Flaring Process.

From www.youtube.com

How To Flare Copper Tubing Larsen Supply YouTube Pipe Flaring Process Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. When you know how to use swaging and flaring tools for. Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. Water. Pipe Flaring Process.

From www.supercheapauto.com.au

How to Create a Tube Flare Pipe Flaring Process The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. Learn how to use a simple tool to. Pipe Flaring Process.

From www.researchgate.net

Schematic drawing of a flaring punch Download Scientific Diagram Pipe Flaring Process Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand. Pipe Flaring Process.

From wisconsinmetaltech.com

Tube Flaring Streamlined Processes, Single Point Project Management Pipe Flaring Process Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. Flaring copper tubing is simple if you know what you are doing and you have the right tools. Learn how to use a simple tool to flare pipe and make sure your. Pipe Flaring Process.

From hvacseer.com

How To Flare Copper Tubing [A Detailed Guide For Beginners] Pipe Flaring Process The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Water service applications generally use a flare to iron pipe. Pipe Flaring Process.

From www.researchgate.net

Analytical model of multiflaring process (a. global view of flaring Pipe Flaring Process Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. Flaring copper tubing is simple if you know what you are doing and you have the right tools. When you know how to use swaging and flaring tools for. Learn how to. Pipe Flaring Process.

From www.plumbingsupply.com

How to Use a Pipe Flaring Tool Pipe Flaring Process Flaring copper tubing is simple if you know what you are doing and you have the right tools. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Learn how to use a simple tool to flare pipe and make. Pipe Flaring Process.

From www.supercheapauto.com.au

How to Create a Tube Flare Pipe Flaring Process Flaring copper tubing is simple if you know what you are doing and you have the right tools. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Using innovative technology, swaging and flaring spins are a new concept in. Pipe Flaring Process.

From designandengg.com

Basics of flare System in any Operating Plant Design and Engineering Pipe Flaring Process When you know how to use swaging and flaring tools for. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. Flaring copper tubing is simple if you. Pipe Flaring Process.

From www.pipsisland.com

7 Simple Steps To Flare Copper Pipe Pipe Flaring Process The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. When you know how to use swaging and. Pipe Flaring Process.

From www.supercheapauto.com.au

How to Create a Tube Flare Pipe Flaring Process Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. When you know how to use swaging and flaring tools for. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Water. Pipe Flaring Process.

From texasmethaneflaringcoalition.org

Frequently Asked Questions The Texas Methane & Flaring Coalition Pipe Flaring Process The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Flaring copper tubing is simple if you know what you are doing and you have the right tools. Using innovative technology, swaging and flaring spins are a new concept in. Pipe Flaring Process.

From www.researchgate.net

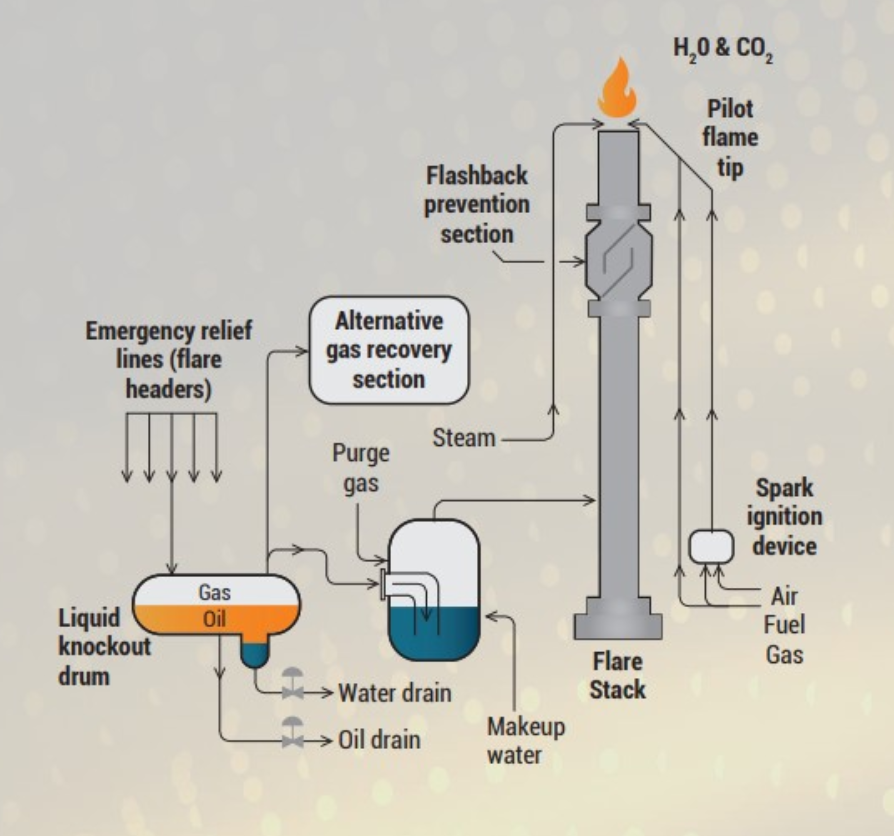

Typical structure of the flare relief system. Download Scientific Diagram Pipe Flaring Process Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. When you know how to use swaging and flaring tools for. Flaring copper tubing is simple if you know what you are doing and you have the right tools. Using innovative technology, swaging and flaring spins are a new concept. Pipe Flaring Process.

From www.pipsisland.com

7 Simple Steps To Flare Copper Pipe Pipe Flaring Process Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Water service. Pipe Flaring Process.

From www.supercheapauto.com.au

How to Create a Tube Flare Pipe Flaring Process The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Water service applications generally use a flare to iron pipe. Pipe Flaring Process.

From whatispiping.com

Flare System Definition, Types, Components, and Design What Is Piping Pipe Flaring Process Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Flaring copper tubing is simple if you know what you are doing and you have the right tools.. Pipe Flaring Process.

From www.plumbingsupply.com

How to Use a Pipe Flaring Tool Pipe Flaring Process When you know how to use swaging and flaring tools for. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main. Pipe Flaring Process.

From www.linkedin.com

Understanding Tube Flaring and Flanging Applications, ORFS and JIC 37 Pipe Flaring Process Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand. Pipe Flaring Process.

From www.air-way.com

Flares for Tubing AirWay Manufacturing Pipe Flaring Process Water service applications generally use a flare to iron pipe connection when connecting the copper tube to the main and/or the meter. Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. The first step to flare copper properly is to cut. Pipe Flaring Process.

From www.youtube.com

Metal Flaring Machine for Tube Flaring & End Forming YouTube Pipe Flaring Process The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Flaring copper tubing is simple if you know what you. Pipe Flaring Process.

From www.pipsisland.com

7 Simple Steps To Flare Copper Pipe Pipe Flaring Process Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. When you know how to use swaging and flaring tools for. Water. Pipe Flaring Process.

From hvacseer.com

How To Flare Copper Tubing [A Detailed Guide For Beginners] Pipe Flaring Process Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. Flaring copper tubing is simple if you know what you are doing. Pipe Flaring Process.

From www.plumbingsupply.com

How to Use a Pipe Flaring Tool Pipe Flaring Process Flaring copper tubing is simple if you know what you are doing and you have the right tools. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Using innovative technology, swaging and flaring spins are a new concept in. Pipe Flaring Process.

From phihydraulics.com

DF (DoubleFlare) End Finishing Machine PHI Pipe Flaring Process When you know how to use swaging and flaring tools for. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any. Pipe Flaring Process.

From thepipingtalk.com

Flare systempartⅠ flare process, flare Drums & flare seals The Pipe Flaring Process Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). When you. Pipe Flaring Process.

From hvacseer.com

How To Flare Copper Tubing [A Detailed Guide For Beginners] Pipe Flaring Process Flaring copper tubing is simple if you know what you are doing and you have the right tools. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. When you know how to use swaging and flaring tools for. Water service applications generally use a flare to iron pipe connection. Pipe Flaring Process.

From www.balkanplumbing.com

How To Flare Copper 5 Step Guide With Tools and Techniques Pipe Flaring Process Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Water service applications generally use a flare to iron pipe connection when. Pipe Flaring Process.

From www.youtube.com

How to Flare Copper Pipes or Tubes YouTube Pipe Flaring Process The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Flaring copper tubing is simple if you know what you are doing and you have the right tools. Using innovative technology, swaging and flaring spins are a new concept in. Pipe Flaring Process.

From www.youtube.com

How To Flare Copper Water Tubing Learn From A Plumbing Professional Pipe Flaring Process When you know how to use swaging and flaring tools for. Flaring copper tubing is simple if you know what you are doing and you have the right tools. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. Water service applications generally use a flare to iron pipe connection. Pipe Flaring Process.

From www.plumbingsupply.com

How to Use a Pipe Flaring Tool Pipe Flaring Process When you know how to use swaging and flaring tools for. Learn how to use a simple tool to flare pipe and make sure your flare fitting connections are installed properly. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing. Pipe Flaring Process.

From whatispiping.com

Flare System Definition, Types, Components, and Design What Is Piping Pipe Flaring Process Using innovative technology, swaging and flaring spins are a new concept in hvac tools, ready to quickly flare/expand any copper or aluminium tube, in just a few seconds. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Learn how. Pipe Flaring Process.

From www.plumbingsupply.com

How to Use a Pipe Flaring Tool Pipe Flaring Process Flaring copper tubing is simple if you know what you are doing and you have the right tools. The first step to flare copper properly is to cut the tubing to the right length (remember that pipe and water tubing are two distinctly different types of plumbing materials). Using innovative technology, swaging and flaring spins are a new concept in. Pipe Flaring Process.