Retaining Ring Groove . the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. easily the most common design flaw engineers encounter with retaining rings is groove deformation. The areas of the ring that protrude out from the shaft hold it in place. 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. See below for our entire list of external retaining ring dimensions and configuration drawings. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled.

from www.smalley.com

101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. The areas of the ring that protrude out from the shaft hold it in place. See below for our entire list of external retaining ring dimensions and configuration drawings. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. easily the most common design flaw engineers encounter with retaining rings is groove deformation. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft.

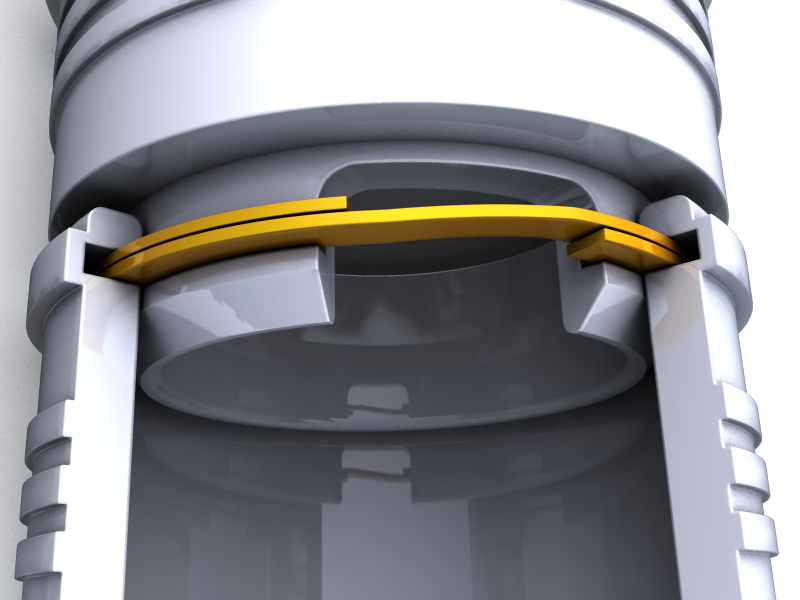

Retaining Ring Application Examples Smalley

Retaining Ring Groove — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. The areas of the ring that protrude out from the shaft hold it in place. 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. easily the most common design flaw engineers encounter with retaining rings is groove deformation. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. See below for our entire list of external retaining ring dimensions and configuration drawings. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled.

From daemar.com

Technical Considerations for the Selection of Retaining Rings Daemar Inc Retaining Ring Groove The areas of the ring that protrude out from the shaft hold it in place. easily the most common design flaw engineers encounter with retaining rings is groove deformation. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. — a common retaining ring failure occurs when the groove yields because it. Retaining Ring Groove.

From www.grainger.com

GRAINGER APPROVED Spiral Retaining Ring, Internal, 1 3/16 in For Bore Retaining Ring Groove 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. the following is internal retaining snap ring sizes and groove design chart for. Retaining Ring Groove.

From www.clecofasteners.com

Cleco Industrial Fasteners Specifications RETAINING RINGS Retaining Ring Groove The areas of the ring that protrude out from the shaft hold it in place. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. See below for our entire list of external retaining ring dimensions and configuration drawings. 101 rows — external retaining rings (also known as “external snap rings”) sit. Retaining Ring Groove.

From www.bmcbearing.com

Snap (Retaining) Rings to Create a Shoulder to Keep an Assembly Secure Retaining Ring Groove — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of. Retaining Ring Groove.

From www.grainger.com

GRAINGER APPROVED Standard Retaining Ring, External, 20 mm For Shaft Retaining Ring Groove See below for our entire list of external retaining ring dimensions and configuration drawings. The areas of the ring that protrude out from the shaft hold it in place. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. calculations for retaining rings (reference) (97kb) allowable thrust load. Retaining Ring Groove.

From www.mscdirect.com

Value Collection External Snap Retaining Ring 1.35" Groove Dia, 17/ Retaining Ring Groove — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. the following is internal retaining snap ring sizes. Retaining Ring Groove.

From dxoxpkizq.blob.core.windows.net

Retaining Ring Standards at Anita Donahue blog Retaining Ring Groove 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. The areas of the ring that protrude out from the shaft hold it in place. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. — retaining rings. Retaining Ring Groove.

From www.youtube.com

Making a groove for a retaining ring in Fusion 360 YouTube Retaining Ring Groove calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. easily the most common design flaw engineers encounter with retaining rings is groove deformation. 101 rows — external retaining rings (also known as “external snap. Retaining Ring Groove.

From www.mscdirect.com

Made in USA External Retaining Ring 1.35" Groove Dia, 1.438" Shaft Retaining Ring Groove 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. easily the most common design flaw engineers encounter with retaining rings is groove deformation. the following is. Retaining Ring Groove.

From www.grainger.com

GRAINGER APPROVED Spiral Retaining Ring, Internal, 1 3/4 in For Bore Retaining Ring Groove — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. The areas of the ring that protrude out from the shaft hold it in place. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. calculations. Retaining Ring Groove.

From www.smalley.com

1 Reason for Retaining Ring Failure and How to It Smalley Retaining Ring Groove See below for our entire list of external retaining ring dimensions and configuration drawings. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a. Retaining Ring Groove.

From www.mscdirect.com

Made in USA External Snap Retaining Ring 11.5 mm Groove Dia, 12 mm Retaining Ring Groove — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. The areas of the ring that protrude out from the shaft hold it in place. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. —. Retaining Ring Groove.

From us.misumi-ec.com

Rotary Shafts Retaining Ring Grooves on Both Ends MISUMI MISUMI Retaining Ring Groove easily the most common design flaw engineers encounter with retaining rings is groove deformation. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. The areas of the ring that protrude out from the shaft hold. Retaining Ring Groove.

From www.mscdirect.com

1/2" Bore Diam, 1/2" Nom'l Size, Spring Steel Internal Snap Retaining Retaining Ring Groove See below for our entire list of external retaining ring dimensions and configuration drawings. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. easily the most common. Retaining Ring Groove.

From engineeringlearn.com

Types of Retaining Rings Definition, Uses, Advantages & Disadvantages Retaining Ring Groove easily the most common design flaw engineers encounter with retaining rings is groove deformation. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any. Retaining Ring Groove.

From forum.onshape.com

Retaining Ring Groove Custom Feature — Onshape Retaining Ring Groove The areas of the ring that protrude out from the shaft hold it in place. — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. See below for our entire list of external retaining ring dimensions and configuration drawings. — a common retaining. Retaining Ring Groove.

From knappfast.com

Retaining Ring Types Knapp Fasteners Inc. Retaining Ring Groove easily the most common design flaw engineers encounter with retaining rings is groove deformation. See below for our entire list of external retaining ring dimensions and configuration drawings. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. calculations for retaining rings (reference) (97kb) allowable thrust load. Retaining Ring Groove.

From www.mscdirect.com

Rotor Clip External Retaining Ring 1.059" Groove Dia, 11/8" Shaft Retaining Ring Groove 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress. Retaining Ring Groove.

From www.grainger.com

GRAINGER APPROVED Standard Retaining Ring, Internal, 18 mm For Bore Dia Retaining Ring Groove the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. easily the most common design flaw engineers encounter with retaining rings is groove deformation. 101. Retaining Ring Groove.

From daemar.com

Technical Considerations for the Selection of Retaining Rings Daemar Inc Retaining Ring Groove calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. See below for our entire list of external retaining ring dimensions and configuration drawings. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. easily the most common design flaw engineers encounter with retaining rings is. Retaining Ring Groove.

From daemar.com

Technical Considerations for the Selection of Retaining Rings Daemar Inc Retaining Ring Groove See below for our entire list of external retaining ring dimensions and configuration drawings. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. calculations for retaining rings (reference) (97kb) allowable. Retaining Ring Groove.

From forum.onshape.com

Retaining Ring Groove Custom Feature — Onshape Retaining Ring Groove — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. The areas of the ring that protrude out from the shaft hold it in place. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. 101. Retaining Ring Groove.

From www.homedepot.com

The Hillman Group 11/16 in. Internal Retaining Ring (10Pack)881378 Retaining Ring Groove — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. easily the most common design flaw engineers encounter with retaining rings is groove deformation. The areas of the ring that protrude out from the shaft hold it in place. — retaining rings are designed to fit into. Retaining Ring Groove.

From forum.onshape.com

Retaining Ring Groove Custom Feature — Onshape Retaining Ring Groove calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. easily the most common design flaw engineers encounter with retaining rings is groove deformation. — a common. Retaining Ring Groove.

From www.nelsonstormtool.com

.375/.250 RETAINING RING GROOVE TOOL Retaining Ring Groove See below for our entire list of external retaining ring dimensions and configuration drawings. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a. Retaining Ring Groove.

From www.smalley.com

What is a Retaining Ring? Smalley's Retaining Ring Overview Smalley Retaining Ring Groove the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. — retaining rings are designed to fit into a machined groove either on the inside of a. Retaining Ring Groove.

From www.mec-engineering-spreadsheets.com

Retaining rings for shafts and holes mec Engineering Spreadsheets Retaining Ring Groove easily the most common design flaw engineers encounter with retaining rings is groove deformation. The areas of the ring that protrude out from the shaft hold it in place. — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. calculations for retaining. Retaining Ring Groove.

From www.researchgate.net

Position of a retaining ring groove is indicated on a pinion drawing Retaining Ring Groove easily the most common design flaw engineers encounter with retaining rings is groove deformation. 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. — a common. Retaining Ring Groove.

From www.huyett.com

Axial Installation RR Blog Image Retaining Ring Groove easily the most common design flaw engineers encounter with retaining rings is groove deformation. calculations for retaining rings (reference) (97kb) allowable thrust load (76.2kb) calculation of stress (57.4kb) beveled. See below for our entire list of external retaining ring dimensions and configuration drawings. the following is internal retaining snap ring sizes and groove design chart for sizes.250. Retaining Ring Groove.

From www.linkedin.com

Retaining Ring Guide How to Select and Use Retaining Rings Retaining Ring Groove — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. The areas of the ring that protrude out from the shaft hold it in place. — a common retaining ring failure occurs when the groove yields because it is too close to a. Retaining Ring Groove.

From www.smalley.com

Retaining Ring Application Examples Smalley Retaining Ring Groove — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. the following is internal retaining snap ring sizes and groove design chart for sizes.250 to 1.500. easily the most common design flaw engineers encounter with retaining rings is groove deformation. See below. Retaining Ring Groove.

From www.smalley.com

Tapered Section Retaining Ring (Circlip) What it is, Advantages, and Retaining Ring Groove easily the most common design flaw engineers encounter with retaining rings is groove deformation. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. The areas of the ring that protrude out from the shaft hold it in place. — retaining rings are designed to fit into. Retaining Ring Groove.

From bearingfinder.ntnamericas.com

Item MU1212UGV, Cylindrical Roller Bearing NonSeparable, Inner Retaining Ring Groove See below for our entire list of external retaining ring dimensions and configuration drawings. The areas of the ring that protrude out from the shaft hold it in place. — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. easily the most common. Retaining Ring Groove.

From www.huyett.com

Retaining Ring Groove and Specs Blog Image Retaining Ring Groove — retaining rings are designed to fit into a machined groove either on the inside of a bore or on the outside of a shaft. — a common retaining ring failure occurs when the groove yields because it is too close to a shaft or. the following is internal retaining snap ring sizes and groove design chart. Retaining Ring Groove.

From www.designworldonline.com

Retaining ring basics video Stamped, eared, eclip, and constant section Retaining Ring Groove easily the most common design flaw engineers encounter with retaining rings is groove deformation. 101 rows — external retaining rings (also known as “external snap rings”) sit in the grooves on the exterior of shafts of any size. The areas of the ring that protrude out from the shaft hold it in place. — retaining rings are. Retaining Ring Groove.