Wheel Bearing Axle Nut Torque . Wheel bearing hub axle nut torquing. Ensure that you have the correct torque for the. Refer to the following diagrams. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Front and rear axle nut torque specifications for fwd and rwd vehicles. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. Just or secure wheel bearings or wheel bearing units. It will also leave your spindle nut under or over torque resulting in hub assembly failure. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. Manual wheel bearing adjustment procedures.

from www.yumpu.com

It will also leave your spindle nut under or over torque resulting in hub assembly failure. Ensure that you have the correct torque for the. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Wheel bearing hub axle nut torquing. Refer to the following diagrams. Manual wheel bearing adjustment procedures. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Front and rear axle nut torque specifications for fwd and rwd vehicles.

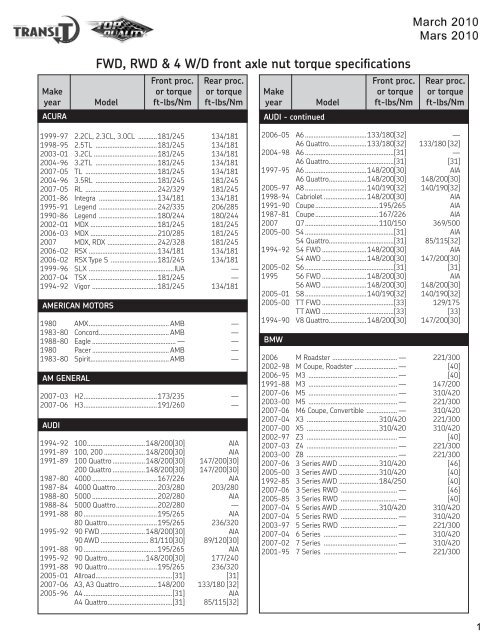

Front axle nut torque Torque Specification Guide

Wheel Bearing Axle Nut Torque Wheel bearing hub axle nut torquing. Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. Manual wheel bearing adjustment procedures. Ensure that you have the correct torque for the. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Refer to the following diagrams. It will also leave your spindle nut under or over torque resulting in hub assembly failure. Front and rear axle nut torque specifications for fwd and rwd vehicles. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. Wheel bearing hub axle nut torquing. Just or secure wheel bearings or wheel bearing units. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value.

From www.fordtransitusaforum.com

Transit 250 Torque to Yield hub bolt torque Ford Transit USA Forum Wheel Bearing Axle Nut Torque Ensure that you have the correct torque for the. It will also leave your spindle nut under or over torque resulting in hub assembly failure. Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. Front and rear axle nut torque specifications for fwd and rwd vehicles. Refer to the. Wheel Bearing Axle Nut Torque.

From www.justanswer.com

Jeep Grand Cherokee Front Axle Nut Torque Specs Q&A Wheel Bearing Axle Nut Torque Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Manual wheel bearing adjustment procedures. Front and rear axle nut torque specifications for fwd and rwd vehicles. Most drive axle wheel hubs have a. Wheel Bearing Axle Nut Torque.

From www.yumpu.com

Front axle nut torque Torque Specification Guide Wheel Bearing Axle Nut Torque The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Ensure that you have the correct torque for the. Manual wheel bearing adjustment procedures. Wheel bearing hub axle nut torquing. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can. Wheel Bearing Axle Nut Torque.

From repairchris88.z14.web.core.windows.net

2014 Ford Escape Axle Nut Torque Specs Wheel Bearing Axle Nut Torque Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. It will also leave your spindle nut under or over torque resulting in hub assembly failure. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value.. Wheel Bearing Axle Nut Torque.

From fixsonia99.z21.web.core.windows.net

Rear Axle Nut Torque Spec Wheel Bearing Axle Nut Torque It will also leave your spindle nut under or over torque resulting in hub assembly failure. Just or secure wheel bearings or wheel bearing units. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Many technicians use an impact gun when installing an axle nut. Wheel Bearing Axle Nut Torque.

From www.2carpros.com

Correct Method for Tightening Ratcheting Hub Nut Wheel Bearing Axle Nut Torque The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Front and rear axle nut torque specifications for fwd and rwd vehicles. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly.. Wheel Bearing Axle Nut Torque.

From www.youtube.com

How to properly install and torque an SKF spindle nut YouTube Wheel Bearing Axle Nut Torque Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. It will also leave your spindle nut under or over torque resulting. Wheel Bearing Axle Nut Torque.

From tacomaworld.com

The Torque Spec. Guide World Wheel Bearing Axle Nut Torque Front and rear axle nut torque specifications for fwd and rwd vehicles. Wheel bearing hub axle nut torquing. Ensure that you have the correct torque for the. Just or secure wheel bearings or wheel bearing units. Refer to the following diagrams. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only. Wheel Bearing Axle Nut Torque.

From www.rechargecolorado.org

Axle Nut Torque Specs Chart Best Picture Of Chart Wheel Bearing Axle Nut Torque Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Front and rear axle nut torque specifications for fwd and rwd vehicles. Refer to the following diagrams. It will also leave your spindle nut under or over torque resulting in hub assembly failure. Manual wheel bearing. Wheel Bearing Axle Nut Torque.

From mavink.com

Toyota Axle Nut Torque Spec Chart Wheel Bearing Axle Nut Torque It will also leave your spindle nut under or over torque resulting in hub assembly failure. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Wheel bearing hub axle nut torquing. Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. Many technicians. Wheel Bearing Axle Nut Torque.

From workshopsrgopalan5v1.z21.web.core.windows.net

Torque Spec Chart For Lug Nuts Wheel Bearing Axle Nut Torque Front and rear axle nut torque specifications for fwd and rwd vehicles. Refer to the following diagrams. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only. Wheel Bearing Axle Nut Torque.

From www.maverickforums.net

X3 Axle nut torque spec Wheel Bearing Axle Nut Torque Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. Front and rear axle nut torque specifications for fwd and rwd vehicles. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of.. Wheel Bearing Axle Nut Torque.

From gerald-nelsen.blogspot.com

subaru axle nut torque spec geraldnelsen Wheel Bearing Axle Nut Torque Manual wheel bearing adjustment procedures. Wheel bearing hub axle nut torquing. Front and rear axle nut torque specifications for fwd and rwd vehicles. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. Most drive axle wheel hubs. Wheel Bearing Axle Nut Torque.

From www.youtube.com

Properly torque a ConMet PreSet hub YouTube Wheel Bearing Axle Nut Torque The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Just or secure wheel bearings or wheel bearing units. Front and rear axle nut torque specifications for fwd and rwd vehicles. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but. Wheel Bearing Axle Nut Torque.

From forums.tdiclub.com

Achieving spec axle bolt torque. Forums Wheel Bearing Axle Nut Torque Refer to the following diagrams. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. It will also leave your spindle nut under or over torque resulting in hub assembly failure. Manual wheel bearing adjustment procedures. Many technicians use an impact gun when installing an axle. Wheel Bearing Axle Nut Torque.

From workshopharas2d.z21.web.core.windows.net

Wheel Bearing Torque Specs Chart Wheel Bearing Axle Nut Torque Manual wheel bearing adjustment procedures. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Ensure that you have the correct torque for the. It will also leave your spindle nut under or over torque resulting in hub assembly failure. Wheel bearing hub axle nut torquing. Refer to the following diagrams. Front and rear. Wheel Bearing Axle Nut Torque.

From www.etrailer.com

Dexter Service Bulletin 014 Wheel Bearing Axle Nut Torque The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Wheel bearing hub axle nut torquing. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Ensure that you have the correct torque for the. Just or secure wheel bearings. Wheel Bearing Axle Nut Torque.

From www.youtube.com

Proper Hub Axle Nut Torque YouTube Wheel Bearing Axle Nut Torque Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. Ensure that you have the correct torque for the. Manual wheel bearing adjustment procedures. Most drive axle wheel hubs have a center axle nut that must be torqued. Wheel Bearing Axle Nut Torque.

From repairmachinepilgrims.z21.web.core.windows.net

Bmw Wheel Nut Torque Chart Wheel Bearing Axle Nut Torque Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Front and rear axle nut torque specifications for fwd and rwd vehicles. Refer to the following diagrams. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. It will also. Wheel Bearing Axle Nut Torque.

From www.cumminsforum.com

Axle torque settings Cummins Diesel Forum Wheel Bearing Axle Nut Torque It will also leave your spindle nut under or over torque resulting in hub assembly failure. Just or secure wheel bearings or wheel bearing units. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only. Wheel Bearing Axle Nut Torque.

From www.import-car.com

Axle Torque Procedures Wheel Bearing Axle Nut Torque Just or secure wheel bearings or wheel bearing units. Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. Front and rear axle nut torque specifications for fwd and rwd vehicles. Refer to the following diagrams. Ensure that you have the correct torque for the. Many technicians use an impact. Wheel Bearing Axle Nut Torque.

From www.shopownermag.com

Top Ten Wheel Bearing Torque Tips Wheel Bearing Axle Nut Torque Refer to the following diagrams. It will also leave your spindle nut under or over torque resulting in hub assembly failure. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Manual wheel bearing adjustment procedures. Many technicians use an impact gun when installing an axle. Wheel Bearing Axle Nut Torque.

From www.youtube.com

FORD TRANSIT “Rear Axle Nut” TORQUE SPECS!!!!!! YouTube Wheel Bearing Axle Nut Torque Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Front and rear axle nut torque specifications for fwd and rwd vehicles.. Wheel Bearing Axle Nut Torque.

From garagerepairnosheries.z14.web.core.windows.net

Ford Ranger Axle Nut Torque Spec Wheel Bearing Axle Nut Torque Ensure that you have the correct torque for the. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Refer to the following diagrams. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing. Wheel Bearing Axle Nut Torque.

From sophiegould.z21.web.core.windows.net

Wheel Bearing Torque Chart Wheel Bearing Axle Nut Torque Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Just or secure wheel. Wheel Bearing Axle Nut Torque.

From www.2carpros.com

Torque Specs for the Front Wheel Axle Nut/wheel Bearing Hub Needed... Wheel Bearing Axle Nut Torque Manual wheel bearing adjustment procedures. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. Refer to the following diagrams. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle. Wheel Bearing Axle Nut Torque.

From www.youtube.com

Axle Nut Torque Tips YouTube Wheel Bearing Axle Nut Torque It will also leave your spindle nut under or over torque resulting in hub assembly failure. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Ensure that you have the correct torque for the. Manual wheel bearing adjustment procedures. Refer to the following diagrams. Just or secure wheel bearings or wheel bearing units.. Wheel Bearing Axle Nut Torque.

From www.undergraceovercoffee.com

Truck Wheel Nut Torque Settings Chart Reviews Of Chart Wheel Bearing Axle Nut Torque Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. Wheel bearing hub axle. Wheel Bearing Axle Nut Torque.

From workshopfixbeane101.z19.web.core.windows.net

Ram 5500 Rear Axle Nut Torque Wheel Bearing Axle Nut Torque Ensure that you have the correct torque for the. Manual wheel bearing adjustment procedures. Wheel bearing hub axle nut torquing. Front and rear axle nut torque specifications for fwd and rwd vehicles. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Just or secure wheel bearings or wheel bearing units. It will also. Wheel Bearing Axle Nut Torque.

From graceholloway.z13.web.core.windows.net

Truck Wheel Nut Torque Settings Chart Wheel Bearing Axle Nut Torque Wheel bearing hub axle nut torquing. Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. Front and rear axle nut torque specifications for fwd and rwd vehicles. Just or secure wheel bearings or wheel bearing units. Many technicians use an impact gun when installing an axle nut on a. Wheel Bearing Axle Nut Torque.

From www.autozone.com

Repair Guides Specifications Torque Specifications Wheel Bearing Axle Nut Torque Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. Front and rear axle nut torque specifications for fwd and rwd vehicles. Manual wheel bearing adjustment procedures. Refer to the following diagrams. Just or secure wheel bearings or wheel bearing units. Wheel bearing hub axle nut torquing. It will also. Wheel Bearing Axle Nut Torque.

From hxedebwsz.blob.core.windows.net

Drive Axle Wheel Bearing Torque at Heidi Maguire blog Wheel Bearing Axle Nut Torque The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Just or secure wheel bearings or wheel bearing units. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Refer to the following diagrams. Front and rear axle nut torque. Wheel Bearing Axle Nut Torque.

From www.justanswer.com

What is the procedure to torque axle on GM 1998 3500HD 1ton full floater?.. And torque specs. Wheel Bearing Axle Nut Torque Wheel bearing hub axle nut torquing. Just or secure wheel bearings or wheel bearing units. Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating. Front and rear axle nut torque specifications for fwd and rwd vehicles. Ensure that you have the correct torque for the. It will also leave. Wheel Bearing Axle Nut Torque.

From garagebrezdomec3bu.z21.web.core.windows.net

Trailer Wheel Lug Nut Torque Spec Chart Wheel Bearing Axle Nut Torque Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. Ensure that you have the correct torque for the. Just or secure wheel bearings or wheel bearing units. Most drive axle wheel hubs have a center axle nut. Wheel Bearing Axle Nut Torque.

From hxedebwsz.blob.core.windows.net

Drive Axle Wheel Bearing Torque at Heidi Maguire blog Wheel Bearing Axle Nut Torque The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of. Ensure that you have the correct torque for the. Refer to the following diagrams. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the. Wheel Bearing Axle Nut Torque.