How To Fix Lathe Chuck Runout . the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. It’s very bad for tool life, so it’s good to know more about it. Be sure and check out his channel. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. i got the idea for this method at least in art from stan @ shadon hkw. 3 jaw chuck run out reduction and holding small parts that the chuck will. You only need a dial indicator, a test bar and a.

from thehabitofwoodworking.com

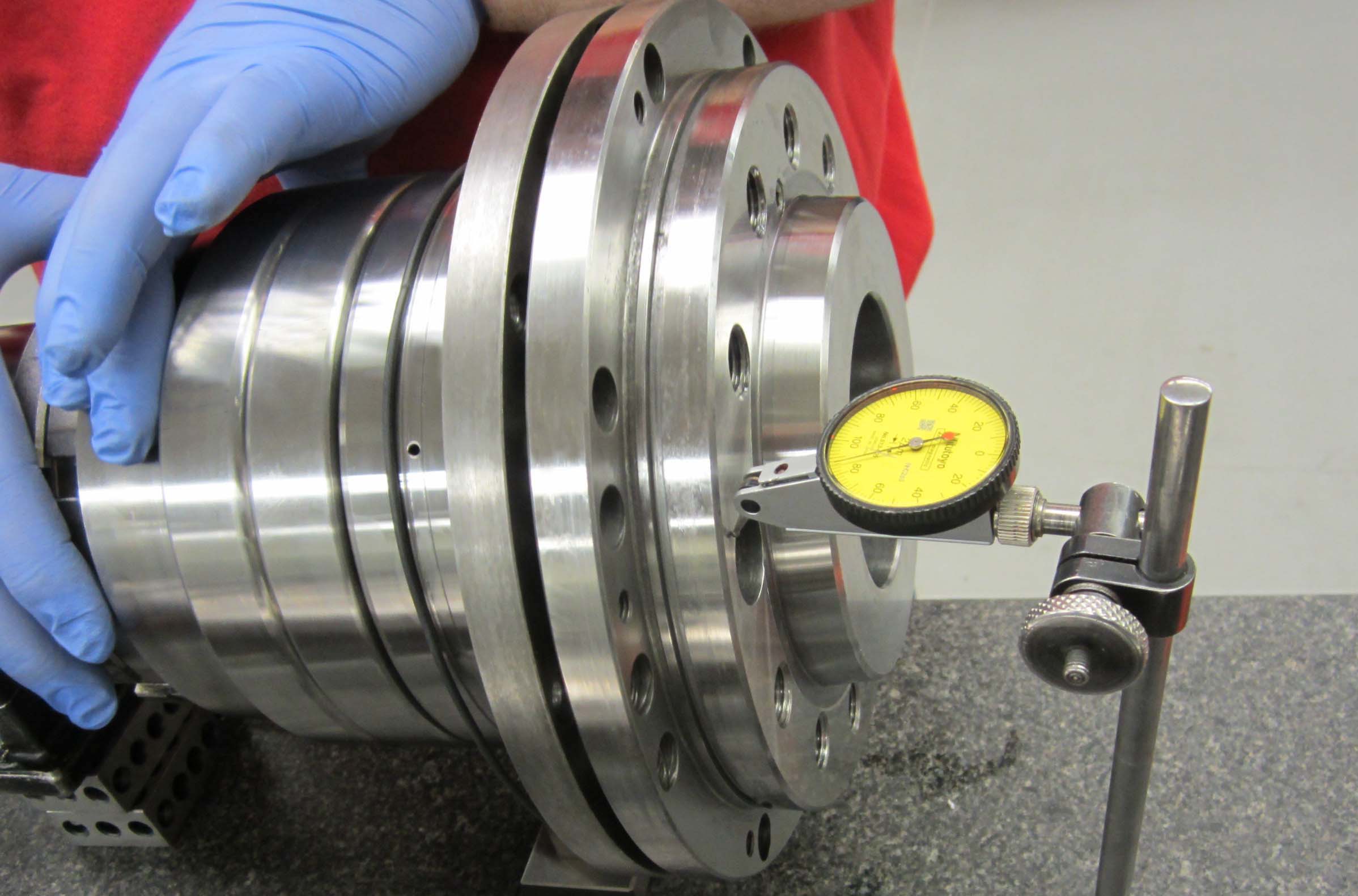

the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. It’s very bad for tool life, so it’s good to know more about it. 3 jaw chuck run out reduction and holding small parts that the chuck will. You only need a dial indicator, a test bar and a. the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. i got the idea for this method at least in art from stan @ shadon hkw. Be sure and check out his channel. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis.

What Is Runout On A Lathe? The Habit of Woodworking

How To Fix Lathe Chuck Runout Be sure and check out his channel. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. 3 jaw chuck run out reduction and holding small parts that the chuck will. It’s very bad for tool life, so it’s good to know more about it. You only need a dial indicator, a test bar and a. i got the idea for this method at least in art from stan @ shadon hkw. the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. Be sure and check out his channel. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis.

From www.youtube.com

Torna aynası hassasiyeti Lathe chuck runout YouTube How To Fix Lathe Chuck Runout spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. i got the idea for this method at least in art from stan @ shadon hkw. the first step to controlling runout at the lathe. How To Fix Lathe Chuck Runout.

From shuntool.com

Troubleshooting Tips For Fixing Lathe Chuck Runout ShunTool How To Fix Lathe Chuck Runout the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. Be sure and check out his channel. i got the idea for this method at least in art from stan @ shadon hkw. You only need a dial indicator, a test bar and a. spindle runout,. How To Fix Lathe Chuck Runout.

From www.youtube.com

Lathe Chuck Removal Quick & Easy YouTube How To Fix Lathe Chuck Runout the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. You only need a dial indicator, a test bar and a. 3 jaw chuck run out reduction and holding small parts that the chuck will. i got the idea for this method at least in art. How To Fix Lathe Chuck Runout.

From www.youtube.com

Correcting chuck register runout on a Sherline micro lathe YouTube How To Fix Lathe Chuck Runout the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. i got the idea for this method at least in art from stan @ shadon hkw. Be sure and check out his channel. You only need a dial indicator, a test bar and a. spindle runout,. How To Fix Lathe Chuck Runout.

From www.youtube.com

Lathe Chuck Accuracy Fix your 3 Jaw Chuck YouTube How To Fix Lathe Chuck Runout You only need a dial indicator, a test bar and a. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. Be sure and check out his channel. 3 jaw chuck run out reduction and holding small parts that the chuck will. the best procedure is. How To Fix Lathe Chuck Runout.

From www.youtube.com

Measuring ER32 Lathe Collet Chuck Runout YouTube How To Fix Lathe Chuck Runout You only need a dial indicator, a test bar and a. It’s very bad for tool life, so it’s good to know more about it. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. Be sure. How To Fix Lathe Chuck Runout.

From www.youtube.com

Horizontal runout of a lathe chuck at 700 mm YouTube How To Fix Lathe Chuck Runout i got the idea for this method at least in art from stan @ shadon hkw. 3 jaw chuck run out reduction and holding small parts that the chuck will. You only need a dial indicator, a test bar and a. It’s very bad for tool life, so it’s good to know more about it. the first. How To Fix Lathe Chuck Runout.

From www.youtube.com

Bison 8" 3 jaw lathe chuck runout issues. YouTube How To Fix Lathe Chuck Runout You only need a dial indicator, a test bar and a. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe). How To Fix Lathe Chuck Runout.

From www.youtube.com

How to measure the runout of a self centering lathe chuck with fine How To Fix Lathe Chuck Runout You only need a dial indicator, a test bar and a. 3 jaw chuck run out reduction and holding small parts that the chuck will. i got the idea for this method at least in art from stan @ shadon hkw. Be sure and check out his channel. spindle runout, or tool runout, as it can also. How To Fix Lathe Chuck Runout.

From www.youtube.com

Improve 3 jaw chuck runout YouTube How To Fix Lathe Chuck Runout i got the idea for this method at least in art from stan @ shadon hkw. Be sure and check out his channel. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. It’s very bad. How To Fix Lathe Chuck Runout.

From www.youtube.com

Vertical runout of a lathe chuck at 100 mm YouTube How To Fix Lathe Chuck Runout It’s very bad for tool life, so it’s good to know more about it. Be sure and check out his channel. i got the idea for this method at least in art from stan @ shadon hkw. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to.. How To Fix Lathe Chuck Runout.

From www.youtube.com

FIX THE RUNOUT ON A BUCK 3 JAW ADJUST TRU CHUCK YouTube How To Fix Lathe Chuck Runout You only need a dial indicator, a test bar and a. It’s very bad for tool life, so it’s good to know more about it. i got the idea for this method at least in art from stan @ shadon hkw. the best procedure is to use three (or more) different diameters so that the jaw alignment is. How To Fix Lathe Chuck Runout.

From www.hobby-machinist.com

MT3 Collet Chuck In lathe runout The HobbyMachinist How To Fix Lathe Chuck Runout It’s very bad for tool life, so it’s good to know more about it. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. i got the idea for this method at least in art from stan @ shadon hkw. spindle runout, or tool runout, as. How To Fix Lathe Chuck Runout.

From www.hobby-machinist.com

MT3 Collet Chuck In lathe runout The HobbyMachinist How To Fix Lathe Chuck Runout Be sure and check out his channel. the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the. How To Fix Lathe Chuck Runout.

From makingwithmetal.com

Atlas 5C Quickie Collet Chuck An Ideal Lathe Workholding Solution How To Fix Lathe Chuck Runout spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. You only need a dial. How To Fix Lathe Chuck Runout.

From www.youtube.com

Lathe Chuck Runout YouTube How To Fix Lathe Chuck Runout the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. the best procedure is. How To Fix Lathe Chuck Runout.

From thehabitofwoodworking.com

What Is Runout On A Lathe? The Habit of Woodworking How To Fix Lathe Chuck Runout Be sure and check out his channel. It’s very bad for tool life, so it’s good to know more about it. 3 jaw chuck run out reduction and holding small parts that the chuck will. i got the idea for this method at least in art from stan @ shadon hkw. You only need a dial indicator, a. How To Fix Lathe Chuck Runout.

From www.youtube.com

How to Check Cnc Chuck Run Out Cnc Programming for Mechanical How To Fix Lathe Chuck Runout It’s very bad for tool life, so it’s good to know more about it. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece. How To Fix Lathe Chuck Runout.

From www.hobby-machinist.com

MT3 Collet Chuck In lathe runout The HobbyMachinist How To Fix Lathe Chuck Runout the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. 3 jaw chuck run. How To Fix Lathe Chuck Runout.

From www.youtube.com

Mini Lathe Mods IMPROVE Chuck run Out YouTube How To Fix Lathe Chuck Runout You only need a dial indicator, a test bar and a. Be sure and check out his channel. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. i got the idea for this method at least in art from stan @ shadon hkw. It’s very bad. How To Fix Lathe Chuck Runout.

From www.youtube.com

lathe machine Chuck runout correction is possible! YouTube How To Fix Lathe Chuck Runout the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. You only need a dial indicator, a test bar and a. the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. 3 jaw chuck run. How To Fix Lathe Chuck Runout.

From www.youtube.com

A fixture to install or remove lathe chucks YouTube How To Fix Lathe Chuck Runout You only need a dial indicator, a test bar and a. Be sure and check out his channel. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. 3 jaw chuck run out reduction and holding small parts that the chuck will. spindle runout, or tool. How To Fix Lathe Chuck Runout.

From www.youtube.com

Horizontal runout of a lathe chuck at 100 mm YouTube How To Fix Lathe Chuck Runout 3 jaw chuck run out reduction and holding small parts that the chuck will. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. It’s very bad for tool life, so it’s good to know more about it. the best procedure is to use three (or. How To Fix Lathe Chuck Runout.

From www.youtube.com

LATHE CHUCK RUNOUT YouTube How To Fix Lathe Chuck Runout Be sure and check out his channel. the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. i got the idea for this method at. How To Fix Lathe Chuck Runout.

From www.youtube.com

How to measure the runout of a self centering lathe chuck with fine How To Fix Lathe Chuck Runout 3 jaw chuck run out reduction and holding small parts that the chuck will. Be sure and check out his channel. the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. spindle runout, or tool runout, as it can also be called, is the inaccuracies that. How To Fix Lathe Chuck Runout.

From www.youtube.com

Chuck Install Guide How to YouTube How To Fix Lathe Chuck Runout You only need a dial indicator, a test bar and a. It’s very bad for tool life, so it’s good to know more about it. the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. the first step to controlling runout at the lathe is building a. How To Fix Lathe Chuck Runout.

From www.practicalmachinist.com

Fixing runout on my 3 jaw lathe chuck ? Page 2 How To Fix Lathe Chuck Runout Be sure and check out his channel. 3 jaw chuck run out reduction and holding small parts that the chuck will. the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. the best procedure is to use three (or more) different diameters so that the jaw. How To Fix Lathe Chuck Runout.

From www.youtube.com

3 Jaw Chuck runout YouTube How To Fix Lathe Chuck Runout the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. You only need a dial indicator, a test bar and a. 3 jaw chuck run out reduction and holding small parts that the chuck will. i got the idea for this method at least in art. How To Fix Lathe Chuck Runout.

From www.youtube.com

Checking Runout on a Lathe Chuck YouTube How To Fix Lathe Chuck Runout the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. i got the idea for this method at least in art from stan @ shadon hkw. Be sure and check out his channel. 3 jaw chuck run out reduction and holding small parts that the chuck. How To Fix Lathe Chuck Runout.

From www.youtube.com

Wood Lathe Chuck Basics How to install lathe chuck correctly? YouTube How To Fix Lathe Chuck Runout the first step to controlling runout at the lathe is building a process that negates the errors that are inherent to. i got the idea for this method at least in art from stan @ shadon hkw. Be sure and check out his channel. You only need a dial indicator, a test bar and a. the best. How To Fix Lathe Chuck Runout.

From www.hobby-machinist.com

MT3 Collet Chuck In lathe runout Page 2 The HobbyMachinist How To Fix Lathe Chuck Runout Be sure and check out his channel. It’s very bad for tool life, so it’s good to know more about it. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. the first step to controlling. How To Fix Lathe Chuck Runout.

From www.youtube.com

Lathe chuck runout YouTube How To Fix Lathe Chuck Runout the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. Be sure and check out his channel. 3 jaw chuck run out reduction and holding small parts that the chuck will. You only need a dial indicator, a test bar and a. the first step to. How To Fix Lathe Chuck Runout.

From www.youtube.com

Lathe Chuck Runout YouTube How To Fix Lathe Chuck Runout It’s very bad for tool life, so it’s good to know more about it. Be sure and check out his channel. You only need a dial indicator, a test bar and a. 3 jaw chuck run out reduction and holding small parts that the chuck will. i got the idea for this method at least in art from. How To Fix Lathe Chuck Runout.

From www.youtube.com

Checking the runout of the chuck jaws after grinding. YouTube How To Fix Lathe Chuck Runout the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. spindle runout, or tool runout, as it can also be called, is the inaccuracies that cause a tool (in a mill) or workpiece (in a lathe) to spin off the ideal axis. You only need a dial. How To Fix Lathe Chuck Runout.

From www.youtube.com

How to easily change the bolt up chuck on a small metal lathe YouTube How To Fix Lathe Chuck Runout the best procedure is to use three (or more) different diameters so that the jaw alignment is averaged over a fairly. Be sure and check out his channel. i got the idea for this method at least in art from stan @ shadon hkw. 3 jaw chuck run out reduction and holding small parts that the chuck. How To Fix Lathe Chuck Runout.