Pipe Sizing For Vacuum Systems . Sizes should be calculated using the formulas in appendix 1. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. Capacities of vacuum pump exhaust pipes. Easily find pressure drops for any pipe size. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. • vacuum pumping ports leading to the vacuum pumps must be designed to. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. Online calculator to quickly determine pipe sizing by velocity for air. Allowable piping pressure loss this is calculated using the allowable pressure. Input gas or vacuum type, pressure, and length for fast and. Pressure loss data for sizing vacuum pipe, low pressure vacuum system.

from printableschoolepiscope.z21.web.core.windows.net

Allowable piping pressure loss this is calculated using the allowable pressure. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. Capacities of vacuum pump exhaust pipes. • vacuum pumping ports leading to the vacuum pumps must be designed to. Easily find pressure drops for any pipe size. Input gas or vacuum type, pressure, and length for fast and. Sizes should be calculated using the formulas in appendix 1.

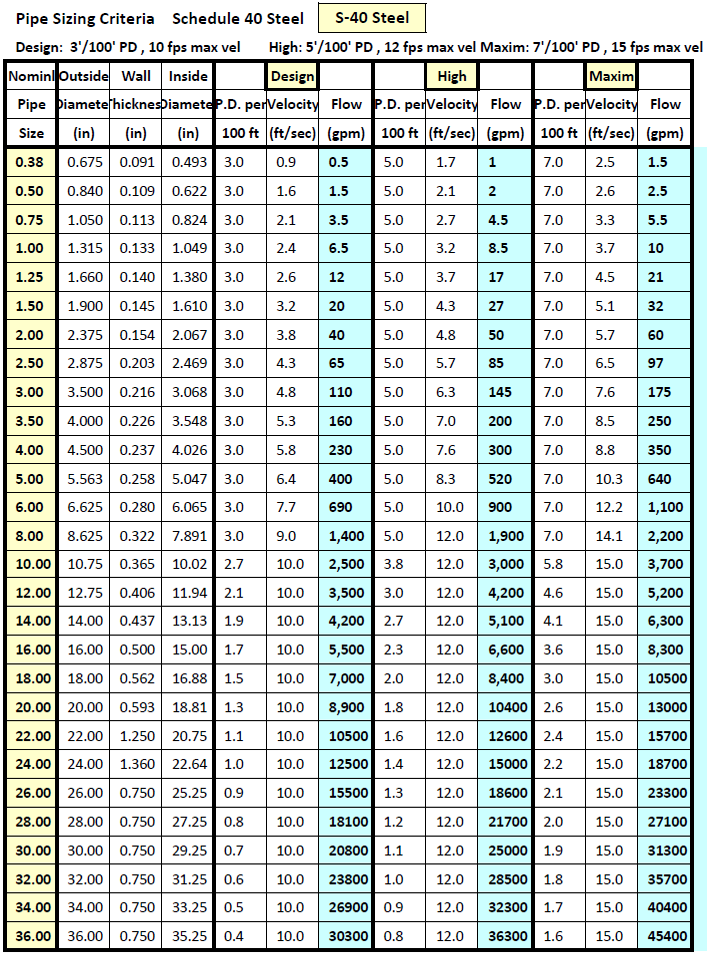

Pipe Unit Weight Chart

Pipe Sizing For Vacuum Systems This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. Online calculator to quickly determine pipe sizing by velocity for air. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. • vacuum pumping ports leading to the vacuum pumps must be designed to. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. Capacities of vacuum pump exhaust pipes. Input gas or vacuum type, pressure, and length for fast and. Sizes should be calculated using the formulas in appendix 1. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. Easily find pressure drops for any pipe size. Allowable piping pressure loss this is calculated using the allowable pressure.

From ponasa.clinica180grados.es

Medical Vacuum Pipe Sizing Chart Ponasa Pipe Sizing For Vacuum Systems • vacuum pumping ports leading to the vacuum pumps must be designed to. Capacities of vacuum pump exhaust pipes. Online calculator to quickly determine pipe sizing by velocity for air. Sizes should be calculated using the formulas in appendix 1. Easily find pressure drops for any pipe size. Input gas or vacuum type, pressure, and length for fast and. Allowable. Pipe Sizing For Vacuum Systems.

From ponasa.clinica180grados.es

Medical Vacuum Pipe Sizing Chart Ponasa Pipe Sizing For Vacuum Systems Allowable piping pressure loss this is calculated using the allowable pressure. • vacuum pumping ports leading to the vacuum pumps must be designed to. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. Input gas or. Pipe Sizing For Vacuum Systems.

From fluidpowerjournal.com

All About Vacuum Sizing Vacuum Components Fluid Power Journal Pipe Sizing For Vacuum Systems Sizes should be calculated using the formulas in appendix 1. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. • vacuum pumping ports leading to the vacuum pumps must be designed to. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm. Pipe Sizing For Vacuum Systems.

From mavink.com

Schematic Of Compressed Air Flow Pipe Sizing Pipe Sizing For Vacuum Systems The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. Sizes should be calculated using the formulas. Pipe Sizing For Vacuum Systems.

From captionscuteviralnyc.blogspot.com

Vacuum System Design Calculation Captions Cute Viral Pipe Sizing For Vacuum Systems Input gas or vacuum type, pressure, and length for fast and. Easily find pressure drops for any pipe size. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. Sizes should be calculated using the formulas in appendix 1. Online calculator to quickly determine pipe sizing by velocity for air.. Pipe Sizing For Vacuum Systems.

From dentechindustrial.com

Industrial Vacuum Systems DenTech Industrial Pipe Sizing For Vacuum Systems • vacuum pumping ports leading to the vacuum pumps must be designed to. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. Capacities of vacuum pump exhaust pipes. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water. Pipe Sizing For Vacuum Systems.

From www.scribd.com

11__PipeSizingData.75102626 Natural Gas Pressure Pipe Sizing For Vacuum Systems Easily find pressure drops for any pipe size. Input gas or vacuum type, pressure, and length for fast and. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. • vacuum pumping ports leading to the vacuum. Pipe Sizing For Vacuum Systems.

From infinitypipesystems.com.au

Compressed Air Pipe Sizing Chart Infinity Pipe Systems Pipe Sizing For Vacuum Systems • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. • vacuum pumping ports leading to the vacuum pumps must be designed to. Easily find pressure drops for any pipe size. Input gas or vacuum type, pressure,. Pipe Sizing For Vacuum Systems.

From mungfali.com

Vacuum Pipe Sizing Chart Pipe Sizing For Vacuum Systems This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. Online calculator to quickly determine pipe sizing by velocity for air. Allowable piping pressure loss this is calculated using the. Pipe Sizing For Vacuum Systems.

From www.csm-cryogenic.com

Vacuum Jacketed Pipe VJ Pipe Supplier Super Insulated Vacuum Line Pipe Sizing For Vacuum Systems Easily find pressure drops for any pipe size. Allowable piping pressure loss this is calculated using the allowable pressure. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. Capacities of vacuum pump exhaust pipes. Sizes should be calculated using the formulas in appendix 1. Input gas or vacuum type, pressure, and length for fast and. Online calculator to. Pipe Sizing For Vacuum Systems.

From plastomatic.com

thermoplastic vacuum breakers pvc cpvc pvdf pp Pipe Sizing For Vacuum Systems Allowable piping pressure loss this is calculated using the allowable pressure. Online calculator to quickly determine pipe sizing by velocity for air. • vacuum pumping ports leading to the vacuum pumps must be designed to. Input gas or vacuum type, pressure, and length for fast and. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. Sizes should be. Pipe Sizing For Vacuum Systems.

From vacaero.com

Looking after Mechanical Vacuum Pumps Pipe Sizing For Vacuum Systems Capacities of vacuum pump exhaust pipes. Input gas or vacuum type, pressure, and length for fast and. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. • vacuum pumping. Pipe Sizing For Vacuum Systems.

From ponasa.clinica180grados.es

Medical Vacuum Pipe Sizing Chart Ponasa Pipe Sizing For Vacuum Systems Pressure loss data for sizing vacuum pipe, low pressure vacuum system. • vacuum pumping ports leading to the vacuum pumps must be designed to. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. Capacities of vacuum. Pipe Sizing For Vacuum Systems.

From mungfali.com

Vacuum Pipe Sizing Chart Pipe Sizing For Vacuum Systems Allowable piping pressure loss this is calculated using the allowable pressure. • vacuum pumping ports leading to the vacuum pumps must be designed to. Sizes should be calculated using the formulas in appendix 1. Input gas or vacuum type, pressure, and length for fast and. The design of a vacuum system includes the selection of vacuum components, fittings, and seals,. Pipe Sizing For Vacuum Systems.

From printableschoolepiscope.z21.web.core.windows.net

Pipe Unit Weight Chart Pipe Sizing For Vacuum Systems Input gas or vacuum type, pressure, and length for fast and. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. Sizes should be calculated using the formulas in appendix 1. Allowable piping pressure loss this is. Pipe Sizing For Vacuum Systems.

From partdiagramacapteu6.z13.web.core.windows.net

Schedule 40 Pipe Internal Diameter Pipe Sizing For Vacuum Systems Capacities of vacuum pump exhaust pipes. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. Online calculator to quickly determine pipe sizing by velocity for air. Sizes should be calculated using the formulas in appendix 1. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. • vacuum. Pipe Sizing For Vacuum Systems.

From corecryolab.com

MVE Vacuum Jacketed Pipe Core Cryolab Pipe Sizing For Vacuum Systems Capacities of vacuum pump exhaust pipes. Sizes should be calculated using the formulas in appendix 1. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. Allowable piping pressure loss this is calculated using the allowable pressure.. Pipe Sizing For Vacuum Systems.

From amulettejewelry.com

Vacuum Chart amulette Pipe Sizing For Vacuum Systems The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. Sizes should be calculated using the formulas in appendix 1. Capacities of vacuum pump exhaust pipes. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. Input gas or vacuum type, pressure, and length for fast and. • the. Pipe Sizing For Vacuum Systems.

From ponasa.clinica180grados.es

Medical Vacuum Pipe Sizing Chart Ponasa Pipe Sizing For Vacuum Systems Pressure loss data for sizing vacuum pipe, low pressure vacuum system. Input gas or vacuum type, pressure, and length for fast and. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. Capacities of vacuum pump exhaust pipes. • vacuum pumping ports leading to the vacuum pumps must be designed. Pipe Sizing For Vacuum Systems.

From dentechindustrial.com

Industrial Vacuum Systems DenTech Industrial Pipe Sizing For Vacuum Systems • vacuum pumping ports leading to the vacuum pumps must be designed to. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. Sizes should be calculated using the formulas in appendix 1. Allowable piping pressure loss this is calculated using the allowable pressure. Easily find pressure drops for any. Pipe Sizing For Vacuum Systems.

From www.eng-tips.com

Pipe Line Sizing Water vs. Gas vs. Vacuum HVAC/R engineering EngTips Pipe Sizing For Vacuum Systems Online calculator to quickly determine pipe sizing by velocity for air. • vacuum pumping ports leading to the vacuum pumps must be designed to. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. Sizes should be calculated using. Pipe Sizing For Vacuum Systems.

From info.atcvacuumtruck.com

A Buyer's Guide to SlideIn Vacuum Tank Units Pipe Sizing For Vacuum Systems Allowable piping pressure loss this is calculated using the allowable pressure. Capacities of vacuum pump exhaust pipes. Online calculator to quickly determine pipe sizing by velocity for air. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm. Pipe Sizing For Vacuum Systems.

From www.youtube.com

Hdpe Round Drip Irrigation Pipe Sizing Vacuum Machine YouTube Pipe Sizing For Vacuum Systems Sizes should be calculated using the formulas in appendix 1. Capacities of vacuum pump exhaust pipes. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. Pressure loss data for sizing vacuum pipe, low pressure vacuum system.. Pipe Sizing For Vacuum Systems.

From www.iqsdirectory.com

Central Vacuum System What is it & How Does It Work? Pipe Sizing For Vacuum Systems The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. Allowable piping pressure loss this is calculated using the allowable pressure. Capacities of vacuum pump exhaust pipes. Sizes should be calculated using the formulas in appendix 1. Input gas or vacuum type, pressure, and length for fast and. Online calculator. Pipe Sizing For Vacuum Systems.

From www.indiamart.com

Water 9 Meter HDPE Pipe Vacuum Sizing Tank Machine, 630 mm at best Pipe Sizing For Vacuum Systems The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. Online calculator to quickly determine pipe sizing by velocity for air. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. Capacities of vacuum pump exhaust pipes. Allowable piping pressure. Pipe Sizing For Vacuum Systems.

From ponasa.clinica180grados.es

Medical Vacuum Pipe Sizing Chart Ponasa Pipe Sizing For Vacuum Systems Capacities of vacuum pump exhaust pipes. Sizes should be calculated using the formulas in appendix 1. Input gas or vacuum type, pressure, and length for fast and. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. This article discusses the principles of proper piping design for common plant equipment,. Pipe Sizing For Vacuum Systems.

From nicholasgeorge.z13.web.core.windows.net

Trac Pipe Sizing Chart Pipe Sizing For Vacuum Systems Online calculator to quickly determine pipe sizing by velocity for air. Capacities of vacuum pump exhaust pipes. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained • the air flow should be slowed to 500 fpm to. • vacuum pumping ports leading to the vacuum pumps must. Pipe Sizing For Vacuum Systems.

From www.dhpdental.com

Vacuum Systems Dansereau Dental Equipment Pipe Sizing For Vacuum Systems Pressure loss data for sizing vacuum pipe, low pressure vacuum system. Capacities of vacuum pump exhaust pipes. Sizes should be calculated using the formulas in appendix 1. Online calculator to quickly determine pipe sizing by velocity for air. • the dry air flow in piping should be 6000 fpm for dry air and 3000 fpm for air with water entrained. Pipe Sizing For Vacuum Systems.

From ponasa.clinica180grados.es

Medical Vacuum Pipe Sizing Chart Ponasa Pipe Sizing For Vacuum Systems Easily find pressure drops for any pipe size. Input gas or vacuum type, pressure, and length for fast and. Allowable piping pressure loss this is calculated using the allowable pressure. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. Online calculator to quickly determine pipe sizing by velocity for air. Sizes should be calculated using the formulas in. Pipe Sizing For Vacuum Systems.

From ponasa.clinica180grados.es

Medical Vacuum Pipe Sizing Chart Ponasa Pipe Sizing For Vacuum Systems Easily find pressure drops for any pipe size. • vacuum pumping ports leading to the vacuum pumps must be designed to. Capacities of vacuum pump exhaust pipes. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. Allowable piping pressure loss this is calculated using the allowable pressure. • the. Pipe Sizing For Vacuum Systems.

From www.rechargecolorado.org

Natural Gas Sizing Chart 5 Psi Best Picture Of Chart Pipe Sizing For Vacuum Systems Capacities of vacuum pump exhaust pipes. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. Input gas or vacuum type, pressure, and length for fast and. Allowable piping pressure loss this is calculated using the allowable pressure. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. •. Pipe Sizing For Vacuum Systems.

From www.cryocomp.com

About Vacuum Jacketed Piping Systems and Accessories Pipe Sizing For Vacuum Systems Input gas or vacuum type, pressure, and length for fast and. Allowable piping pressure loss this is calculated using the allowable pressure. Capacities of vacuum pump exhaust pipes. Online calculator to quickly determine pipe sizing by velocity for air. • vacuum pumping ports leading to the vacuum pumps must be designed to. This article discusses the principles of proper piping. Pipe Sizing For Vacuum Systems.

From deedo-machinery.en.made-in-china.com

PE PVC PPR Pert Pipe Vacuum Sizing Tank Machine China Pipe Vacuum Pipe Sizing For Vacuum Systems Capacities of vacuum pump exhaust pipes. The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. • vacuum pumping ports leading to the vacuum pumps must be designed to. Sizes should be calculated using the formulas in appendix 1. Pressure loss data for sizing vacuum pipe, low pressure vacuum system.. Pipe Sizing For Vacuum Systems.

From itchol.com

Pump Piping Design Considerations Make Piping Easy (2022) Pipe Sizing For Vacuum Systems Allowable piping pressure loss this is calculated using the allowable pressure. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and float traps. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. Online calculator to quickly determine pipe sizing by velocity for air. The design of a vacuum system includes. Pipe Sizing For Vacuum Systems.

From vacumaid.com

Commercial Vacuum System Design Manufacturer of VacuMaid Central Pipe Sizing For Vacuum Systems The design of a vacuum system includes the selection of vacuum components, fittings, and seals, appropriate for the intended application. Online calculator to quickly determine pipe sizing by velocity for air. Pressure loss data for sizing vacuum pipe, low pressure vacuum system. This article discusses the principles of proper piping design for common plant equipment, such as tailpipes, hotwells and. Pipe Sizing For Vacuum Systems.