Engine Belt Bearing . Flat belts have high efficiency and flexibility as well as low wear and low noise levels; However, they require relatively high pretensioning forces! Its only purpose is to carry the belt—it has no. Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. The bearings in locating positions of belt drive.

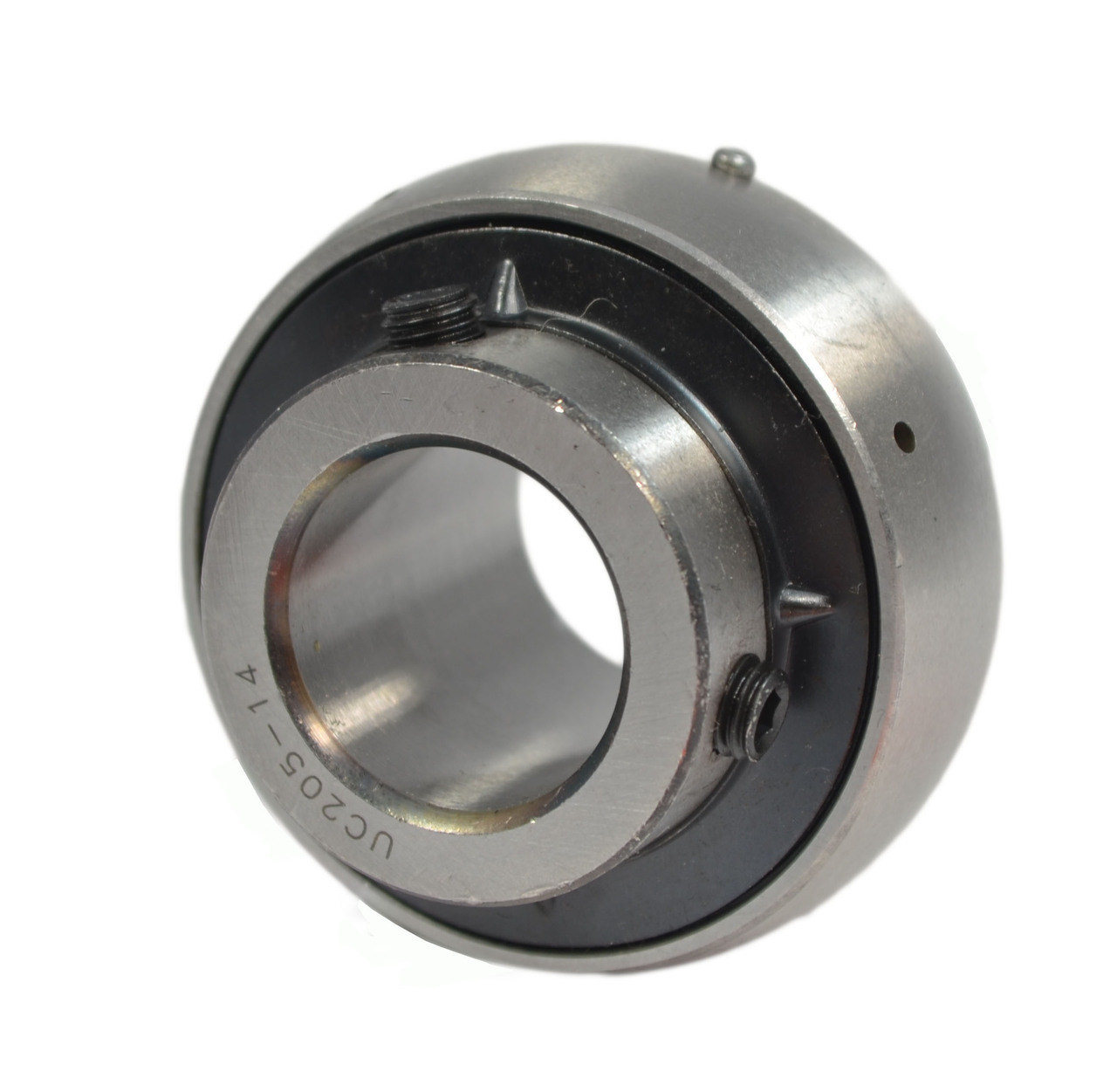

from www.qualitybearingsbeltsandchain.com

Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Its only purpose is to carry the belt—it has no. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. Flat belts have high efficiency and flexibility as well as low wear and low noise levels; The bearings in locating positions of belt drive. However, they require relatively high pretensioning forces! Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications.

UC208 40 mm Bore Quality Bearings Belts and Chain

Engine Belt Bearing The bearings in locating positions of belt drive. Its only purpose is to carry the belt—it has no. The bearings in locating positions of belt drive. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. However, they require relatively high pretensioning forces! An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. Flat belts have high efficiency and flexibility as well as low wear and low noise levels; Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications.

From cehdbwca.blob.core.windows.net

Different Types Of Engine Belts at Gabriela Williams blog Engine Belt Bearing Flat belts have high efficiency and flexibility as well as low wear and low noise levels; Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. Motors in belt drive applications can experience. Engine Belt Bearing.

From www.howacarworks.com

Checking, adjusting and refitting drive belts How a Car Works Engine Belt Bearing Its only purpose is to carry the belt—it has no. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Flat belts have high efficiency and flexibility as well as low wear and low. Engine Belt Bearing.

From enginehum.com

The Comprehensive Guide to Car Drive Belt Bearings EngineHum Engine Belt Bearing Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. However, they require relatively high. Engine Belt Bearing.

From www.qualitybearingsbeltsandchain.com

CSB20210 Quality Bearings Belts and Chain Engine Belt Bearing However, they require relatively high pretensioning forces! Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. Its only purpose is to carry the belt—it has no. The bearings in locating positions of belt drive. The forces acting in the belt press the belt onto the pulley and thus also act. Engine Belt Bearing.

From klapzlkbv.blob.core.windows.net

LinkBelt Bearings at Catherine Dowling blog Engine Belt Bearing Flat belts have high efficiency and flexibility as well as low wear and low noise levels; Its only purpose is to carry the belt—it has no. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated. Engine Belt Bearing.

From www.youtube.com

HOW TO Replace Idler Pulley Bearing YouTube Engine Belt Bearing Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. The bearings in locating positions of belt drive. Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine. Engine Belt Bearing.

From fyowalmnb.blob.core.windows.net

Belt Drive Or Pulley at John Doucette blog Engine Belt Bearing Flat belts have high efficiency and flexibility as well as low wear and low noise levels; However, they require relatively high pretensioning forces! Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. Its. Engine Belt Bearing.

From workshopfixwambengers.z13.web.core.windows.net

Bearings In The Engine Engine Belt Bearing Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. The bearings in locating positions of belt drive. Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. However, they require relatively high pretensioning forces! Flat belts have high efficiency and flexibility as. Engine Belt Bearing.

From www.aetnabearing.com

VBelt Idler Single Row Bearing Aetna Bearing Company Engine Belt Bearing Its only purpose is to carry the belt—it has no. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. An idler pulley is a wheel or roller that’s part of your. Engine Belt Bearing.

From www.partsgiant.com

BDL Primary Belt Drive with Idler Bearing Parts Giant Engine Belt Bearing However, they require relatively high pretensioning forces! Flat belts have high efficiency and flexibility as well as low wear and low noise levels; The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Its. Engine Belt Bearing.

From exybabtrl.blob.core.windows.net

Drive Belt Change Car at Maxwell Parker blog Engine Belt Bearing Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. The bearings in locating positions of belt drive. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Flat belts have high efficiency and flexibility as well as low wear and low noise levels; However, they. Engine Belt Bearing.

From www.cbac.com

Car Basics All the Drive Belts Explained Christian Brothers Engine Belt Bearing Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. The bearings in locating positions of belt drive. Its only purpose is to carry the belt—it has no. Flat belts have high efficiency and flexibility as. Engine Belt Bearing.

From www.foleyengines.com

Deutz 2011 Timing Belt Kits Foley Industrial Engines Engine Belt Bearing Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. Flat belts have high efficiency and flexibility as well as low wear and low noise levels; An idler pulley is a wheel or roller that’s. Engine Belt Bearing.

From www.2carpros.com

2004 Pontiac Vibe Serpentine Belt Routing and Timing Belt Diagrams Engine Belt Bearing Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Motors in belt drive applications can experience. Engine Belt Bearing.

From www.dreamstime.com

Timing Belt and Bearing on White Background, Isolated, Car Maintenance Engine Belt Bearing Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. Flat belts have high efficiency and flexibility as well as low wear and low noise levels; However, they require relatively high pretensioning forces! Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity.. Engine Belt Bearing.

From www.youtube.com

How to replace Camshaft bearings Toyota Corolla 4AFE and 7AFE engines Engine Belt Bearing The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Motors in belt drive applications. Engine Belt Bearing.

From www.bimabelt.com

BIMA BELT BME BALL BEARING Engine Belt Bearing Flat belts have high efficiency and flexibility as well as low wear and low noise levels; Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. The bearings in locating positions of belt drive. The forces. Engine Belt Bearing.

From www.bearingwholesalers.com.au

Timing Belt Kits Products Bearing Wholesalers Engine Belt Bearing An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. Flat belts have high efficiency and flexibility as well as low wear and low noise levels; However, they require relatively high pretensioning forces! The forces acting. Engine Belt Bearing.

From www.qualitybearingsbeltsandchain.com

UC208 40 mm Bore Quality Bearings Belts and Chain Engine Belt Bearing Flat belts have high efficiency and flexibility as well as low wear and low noise levels; However, they require relatively high pretensioning forces! An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. Nsk’s range of. Engine Belt Bearing.

From www.linkedin.com

Advantages and Disadvantages of Various Types of Rotating Equipment Engine Belt Bearing However, they require relatively high pretensioning forces! Flat belts have high efficiency and flexibility as well as low wear and low noise levels; Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. The bearings in locating positions of belt drive. Its only purpose is to carry the belt—it has no. The. Engine Belt Bearing.

From www.pelicanparts.com

BMW E60 5Series M54 6Cylinder Engine Drive Belt Replacement Pelican Engine Belt Bearing Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. Flat belts have high efficiency and flexibility as well as low wear and low noise levels; Nsk’s range of engine bearings, assemblies, pulleys, and. Engine Belt Bearing.

From www.toyotaofnorthcharlotte.com

A Brief Guide on Engine Belts Toyota of North Charlotte Engine Belt Bearing Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. The bearings in locating positions of belt drive. Its only. Engine Belt Bearing.

From www.readersdigest.ca

Checking a Serpentine Belt for Wear StepbyStep Instructions Engine Belt Bearing However, they require relatively high pretensioning forces! Flat belts have high efficiency and flexibility as well as low wear and low noise levels; The bearings in locating positions of belt drive. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size. Engine Belt Bearing.

From www.yourmechanic.com

How to Replace Your Serpentine Belt YourMechanic Advice Engine Belt Bearing Its only purpose is to carry the belt—it has no. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. Flat belts have high efficiency and flexibility as well as low wear and low noise. Engine Belt Bearing.

From sbindustrialsupply.com

NEW LINK BELT FC3U232N BALL BEARING SB Industrial Supply, Inc. Engine Belt Bearing The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Flat belts have high efficiency and. Engine Belt Bearing.

From www.offroadsolutions.com

Tensioner Bearing, for Timing Belt, 3.4L 5VZFE Products Off Road Engine Belt Bearing Its only purpose is to carry the belt—it has no. Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. The forces acting in the belt press the belt onto the pulley and thus also. Engine Belt Bearing.

From www.autozone.com

Repair Guides Engine Mechanical Crankshaft And Main Bearings Engine Belt Bearing Its only purpose is to carry the belt—it has no. Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. Flat belts have high efficiency and flexibility as well as low wear and low noise levels; The bearings in locating positions of belt drive. The forces acting in the belt press the belt onto. Engine Belt Bearing.

From www.carid.com

Koyo® PU306630ARR9D Driver Side Lower Timing Belt Idler Bearing Engine Belt Bearing However, they require relatively high pretensioning forces! Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Flat. Engine Belt Bearing.

From www.qualitybearingsbeltsandchain.com

W210PPB6 Quality Bearings Belts and Chain Engine Belt Bearing Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. However, they require relatively high pretensioning forces! The bearings in. Engine Belt Bearing.

From www.alibaba.com

[oneka] 2445037100 2445037120 Engine G6ba Timing Belt Pulley Assy Engine Belt Bearing Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. The forces acting in the belt press the belt onto. Engine Belt Bearing.

From gmb.net

Why It Is Critical To Replace Your Timing Belt Kit Before It Fails Engine Belt Bearing Engineered to oe specifications, continental timing belts are built with enhanced rubber compounds formulated to resist tooth deformity. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. However, they require relatively high pretensioning forces! Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled. Engine Belt Bearing.

From fyoyjtmve.blob.core.windows.net

Serpentine Belt Squeals When First Started at Marilyn Rae blog Engine Belt Bearing However, they require relatively high pretensioning forces! Its only purpose is to carry the belt—it has no. The bearings in locating positions of belt drive. Flat belts have high efficiency and flexibility as well as low wear and low noise levels; Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components.. Engine Belt Bearing.

From www.indiamart.com

Motor Bearings, Ss Bearings Naroda, Ahmedabad Belt And Bearing Engine Belt Bearing Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. The bearings in locating positions of belt drive. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Flat belts have high efficiency and flexibility as well as low wear and low noise levels; However, they require relatively. Engine Belt Bearing.

From www.totalperformance.net.au

LS1 LS2 LS3 Main Engine Bearings HSeries Set. Chevy 5.7L 6.0L 6.2L LS Engine Belt Bearing Flat belts have high efficiency and flexibility as well as low wear and low noise levels; Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled applications. Its only purpose is to carry the belt—it has no. An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. However, they. Engine Belt Bearing.

From gobdp.com

Replacing an Engine Belt BlueDevil Products Engine Belt Bearing An idler pulley is a wheel or roller that’s part of your engine’s drive belt system. Its only purpose is to carry the belt—it has no. Nsk’s range of engine bearings, assemblies, pulleys, and tensioners provide the right size and reliability for compact engine components. Motors in belt drive applications can experience significantly different load scenarios compared to direct coupled. Engine Belt Bearing.