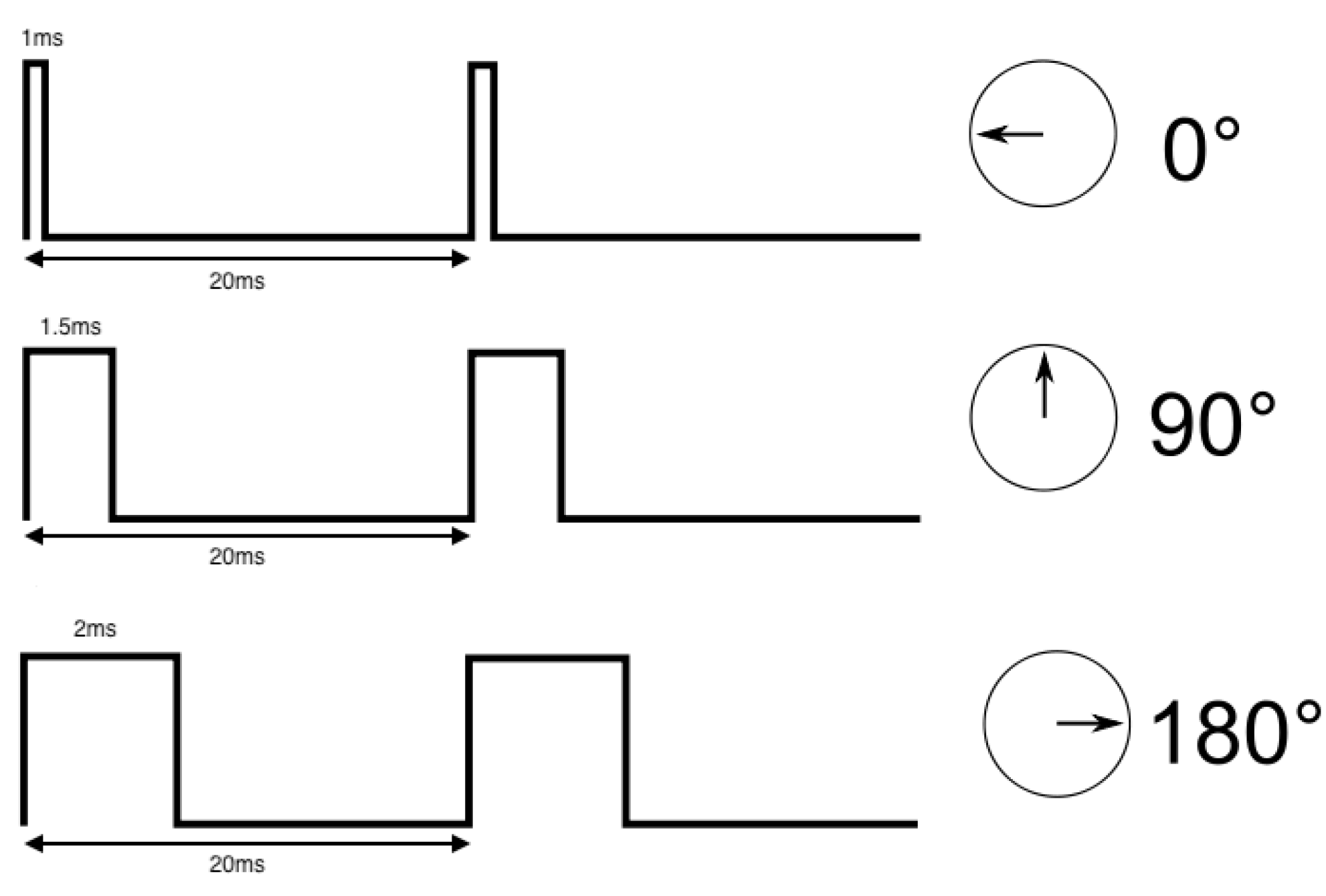

How To Calculate Duty Cycle Of Servo Motor . I am connecting this motor to 5v pin of a microcontroller. It represents the percentage of time the motor is doing useful work I am unsure of the relationship between duty cycle and angle. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. To prevent overheating failures, designers must accurately calculate the motor's safe duty cycle for each specific application. Last phase always has an end speed of 0 rpm. These two answers for rpi might help: (1) run the program in the. Commonly used for this purpose are duty. In this field you'll see help for the currently active field. Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. A pwm wave can be used to create such a voltage by applying extra hardware (capacitors) to smooth out, or average out, the wave form. For example, if you have a servo with 180° turn, then 90° is the. Duty cycle the duty cycle is the ratio between twork and tcycle. See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own servos!

from www.mdpi.com

It represents the percentage of time the motor is doing useful work I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. Manufacturers almost always provide data. (1) run the program in the. Commonly used for this purpose are duty. For example, if you have a servo with 180° turn, then 90° is the. I am connecting this motor to 5v pin of a microcontroller. Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. Duty cycle the duty cycle is the ratio between twork and tcycle. Last phase always has an end speed of 0 rpm.

Sensors Free FullText LowCost Servomotor Driver for PFM Control

How To Calculate Duty Cycle Of Servo Motor I am connecting this motor to 5v pin of a microcontroller. Duty cycle the duty cycle is the ratio between twork and tcycle. A pwm wave can be used to create such a voltage by applying extra hardware (capacitors) to smooth out, or average out, the wave form. I am connecting this motor to 5v pin of a microcontroller. For example, if you have a servo with 180° turn, then 90° is the. Commonly used for this purpose are duty. It represents the percentage of time the motor is doing useful work Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. These two answers for rpi might help: (1) run the program in the. I am unsure of the relationship between duty cycle and angle. Manufacturers almost always provide data. See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own servos! In this field you'll see help for the currently active field. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. Last phase always has an end speed of 0 rpm.

From exyirhrmx.blob.core.windows.net

How Is Duty Cycle Measured at Marilyn Reid blog How To Calculate Duty Cycle Of Servo Motor It represents the percentage of time the motor is doing useful work Last phase always has an end speed of 0 rpm. In this field you'll see help for the currently active field. See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own. How To Calculate Duty Cycle Of Servo Motor.

From webmotor.org

Servo Motor Pulse Width Calculator How To Calculate Duty Cycle Of Servo Motor Duty cycle the duty cycle is the ratio between twork and tcycle. Commonly used for this purpose are duty. I am connecting this motor to 5v pin of a microcontroller. For example, if you have a servo with 180° turn, then 90° is the. To prevent overheating failures, designers must accurately calculate the motor's safe duty cycle for each specific. How To Calculate Duty Cycle Of Servo Motor.

From www.researchgate.net

Duty cycle calculation algorithm Download Scientific Diagram How To Calculate Duty Cycle Of Servo Motor See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own servos! Manufacturers almost always provide data. Duty cycle the duty cycle is the ratio between twork and tcycle. I am unsure of the relationship between duty cycle and angle. It represents the percentage. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

Electronics How to calculate duty cycle of a servo motor? YouTube How To Calculate Duty Cycle Of Servo Motor Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. I am unsure of the relationship between duty cycle and angle. (1) run the program in the. These two answers for rpi might help: I am connecting this motor to 5v pin of a microcontroller. Commonly used for. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

servo motor plc programming servo motor rpm calculation servo motor How To Calculate Duty Cycle Of Servo Motor It represents the percentage of time the motor is doing useful work I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. For example, if you have a servo with 180° turn, then 90° is the. To prevent overheating failures, designers must accurately calculate the motor's safe duty cycle for each specific. How To Calculate Duty Cycle Of Servo Motor.

From webmotor.org

Servo Motor Pulse Width Calculator How To Calculate Duty Cycle Of Servo Motor See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own servos! Duty cycle the duty cycle is the ratio between twork and tcycle. In this field you'll see help for the currently active field. A pwm wave can be used to create such. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

Duty Cycle, Pulse Width & Frequency Rectangular and Square Waves How To Calculate Duty Cycle Of Servo Motor I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. I am unsure of the relationship between duty cycle and angle. For example, if you have a servo with 180° turn, then 90° is the. Manufacturers almost always provide data. It represents the percentage of time the motor is doing useful work. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

motor types/motor duty type/motor duty cycle calculation/motor duty How To Calculate Duty Cycle Of Servo Motor I am connecting this motor to 5v pin of a microcontroller. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. In this field you'll see help for the currently active field. Duty cycle the duty cycle is the ratio between twork and tcycle. Last phase always has an end speed of. How To Calculate Duty Cycle Of Servo Motor.

From www.firgelliauto.com

What is DUTY CYCLE in a linear actuator? FIRGELLI How To Calculate Duty Cycle Of Servo Motor Duty cycle the duty cycle is the ratio between twork and tcycle. Last phase always has an end speed of 0 rpm. I am connecting this motor to 5v pin of a microcontroller. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. I am unsure of the relationship between duty cycle. How To Calculate Duty Cycle Of Servo Motor.

From www.learnrobotics.org

How to Control a Servo with Raspberry Pi Learn Robotics How To Calculate Duty Cycle Of Servo Motor Duty cycle the duty cycle is the ratio between twork and tcycle. Last phase always has an end speed of 0 rpm. Manufacturers almost always provide data. Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. I see lots of tutorials online with many different equations to. How To Calculate Duty Cycle Of Servo Motor.

From www.mdpi.com

Sensors Free FullText LowCost Servomotor Driver for PFM Control How To Calculate Duty Cycle Of Servo Motor I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. Commonly used for this purpose are duty. A pwm wave can be used to create such a voltage by applying extra hardware (capacitors) to smooth out, or average out, the wave form. Manufacturers almost always provide data. Duty cycle the duty cycle. How To Calculate Duty Cycle Of Servo Motor.

From www.globalspec.com

Servo MotorWorking Principle GlobalSpec How To Calculate Duty Cycle Of Servo Motor A pwm wave can be used to create such a voltage by applying extra hardware (capacitors) to smooth out, or average out, the wave form. It represents the percentage of time the motor is doing useful work (1) run the program in the. Last phase always has an end speed of 0 rpm. Commonly used for this purpose are duty.. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

servo motor pulse calculation servo motor frequency calculation How To Calculate Duty Cycle Of Servo Motor I am unsure of the relationship between duty cycle and angle. To prevent overheating failures, designers must accurately calculate the motor's safe duty cycle for each specific application. A pwm wave can be used to create such a voltage by applying extra hardware (capacitors) to smooth out, or average out, the wave form. Last phase always has an end speed. How To Calculate Duty Cycle Of Servo Motor.

From www.researchgate.net

Duty Cycle and Angle Equation (Servo Motor) Download Scientific Diagram How To Calculate Duty Cycle Of Servo Motor Last phase always has an end speed of 0 rpm. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. I am connecting this motor to 5v pin of a microcontroller. Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

Servo Motor Working Principle YouTube How To Calculate Duty Cycle Of Servo Motor See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own servos! (1) run the program in the. It represents the percentage of time the motor is doing useful work A pwm wave can be used to create such a voltage by applying extra. How To Calculate Duty Cycle Of Servo Motor.

From weldguru.com

Welding Duty Cycle Importance & How to Calculate It How To Calculate Duty Cycle Of Servo Motor Commonly used for this purpose are duty. (1) run the program in the. In this field you'll see help for the currently active field. Last phase always has an end speed of 0 rpm. Manufacturers almost always provide data. Duty cycle the duty cycle is the ratio between twork and tcycle. A pwm wave can be used to create such. How To Calculate Duty Cycle Of Servo Motor.

From wiringfixmount.z13.web.core.windows.net

Duty Cycle Circuit Diagram How To Calculate Duty Cycle Of Servo Motor These two answers for rpi might help: I am unsure of the relationship between duty cycle and angle. See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own servos! To prevent overheating failures, designers must accurately calculate the motor's safe duty cycle for. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

What is Duty Cycle? YouTube How To Calculate Duty Cycle Of Servo Motor Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. Last phase always has an end speed of 0 rpm. A pwm wave can be used to create such a voltage by applying extra hardware (capacitors) to smooth out, or average out, the wave form. To prevent overheating. How To Calculate Duty Cycle Of Servo Motor.

From www.pinterest.com

Sg90 servo motor pwm signal requirements duty cycle and frequency How To Calculate Duty Cycle Of Servo Motor Duty cycle the duty cycle is the ratio between twork and tcycle. These two answers for rpi might help: In this field you'll see help for the currently active field. A pwm wave can be used to create such a voltage by applying extra hardware (capacitors) to smooth out, or average out, the wave form. I see lots of tutorials. How To Calculate Duty Cycle Of Servo Motor.

From www.a-m-c.com

Overview ADVANCED Motion Controls How To Calculate Duty Cycle Of Servo Motor I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. For example, if you have a servo with 180° turn, then 90° is the. These two answers for rpi might help: To prevent overheating failures, designers must accurately calculate the motor's safe duty cycle for each specific application. It represents the percentage. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

servo motor pulse/degree calculation servo plc programming servo How To Calculate Duty Cycle Of Servo Motor To prevent overheating failures, designers must accurately calculate the motor's safe duty cycle for each specific application. These two answers for rpi might help: Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. It represents the percentage of time the motor is doing useful work I am. How To Calculate Duty Cycle Of Servo Motor.

From webmotor.org

How To Calculate Power Of Servo Motor How To Calculate Duty Cycle Of Servo Motor (1) run the program in the. Duty cycle the duty cycle is the ratio between twork and tcycle. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. It represents the percentage of time the motor is doing useful work Commonly used for this purpose are duty. Manufacturers almost always provide data.. How To Calculate Duty Cycle Of Servo Motor.

From www.kebamerica.com

4 Duty Cycles for Motors Engineers Need to Know How To Calculate Duty Cycle Of Servo Motor I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. I am unsure of the relationship between duty cycle and angle. Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. (1) run the program in the. These two answers. How To Calculate Duty Cycle Of Servo Motor.

From electronics.stackexchange.com

motor Duty cycle calculation Electrical Engineering Stack Exchange How To Calculate Duty Cycle Of Servo Motor In this field you'll see help for the currently active field. Commonly used for this purpose are duty. I am unsure of the relationship between duty cycle and angle. To prevent overheating failures, designers must accurately calculate the motor's safe duty cycle for each specific application. These two answers for rpi might help: It represents the percentage of time the. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

What is motor Duty Cycle What is duty cycleWhat is S1,S2,S3,S4 in How To Calculate Duty Cycle Of Servo Motor In this field you'll see help for the currently active field. Manufacturers almost always provide data. (1) run the program in the. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. For example, if you have a servo with 180° turn, then 90° is the. A pwm wave can be used. How To Calculate Duty Cycle Of Servo Motor.

From electronics.stackexchange.com

motor controller 555 Timer duty cycle changing formula Electrical How To Calculate Duty Cycle Of Servo Motor In this field you'll see help for the currently active field. I am unsure of the relationship between duty cycle and angle. For example, if you have a servo with 180° turn, then 90° is the. To prevent overheating failures, designers must accurately calculate the motor's safe duty cycle for each specific application. I am connecting this motor to 5v. How To Calculate Duty Cycle Of Servo Motor.

From www.quora.com

How to calculate the torque of the servo motor (SG90)? The torque of How To Calculate Duty Cycle Of Servo Motor Manufacturers almost always provide data. Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own servos! A pwm wave can be. How To Calculate Duty Cycle Of Servo Motor.

From ceeizfao.blob.core.windows.net

Rc Servo Duty Cycle at Derek Gregory blog How To Calculate Duty Cycle Of Servo Motor Last phase always has an end speed of 0 rpm. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own servos! Commonly used for this. How To Calculate Duty Cycle Of Servo Motor.

From www.celeramotion.com

Efficiency and Power in Servo Drives Ingenia Servo Drives How To Calculate Duty Cycle Of Servo Motor I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. I am unsure of the relationship between duty cycle and angle. To prevent overheating failures, designers must accurately calculate the motor's safe duty cycle for each specific application. These two answers for rpi might help: Manufacturers almost always provide data. See if. How To Calculate Duty Cycle Of Servo Motor.

From www.electronicwings.com

Servo Motor Basics, Working principle & interfacing with Arduino How To Calculate Duty Cycle Of Servo Motor Manufacturers almost always provide data. See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own servos! These two answers for rpi might help: (1) run the program in the. A pwm wave can be used to create such a voltage by applying extra. How To Calculate Duty Cycle Of Servo Motor.

From ceeizfao.blob.core.windows.net

Rc Servo Duty Cycle at Derek Gregory blog How To Calculate Duty Cycle Of Servo Motor It represents the percentage of time the motor is doing useful work I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. Manufacturers almost always provide data. See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

servo motor pulse calculation servo motor rpm calculate servo motor How To Calculate Duty Cycle Of Servo Motor These two answers for rpi might help: Last phase always has an end speed of 0 rpm. Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. I am connecting this motor to 5v pin of a microcontroller. Commonly used for this purpose are duty. (1) run the. How To Calculate Duty Cycle Of Servo Motor.

From exyirhrmx.blob.core.windows.net

How Is Duty Cycle Measured at Marilyn Reid blog How To Calculate Duty Cycle Of Servo Motor See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own servos! Commonly used for this purpose are duty. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. I am connecting this motor to 5v. How To Calculate Duty Cycle Of Servo Motor.

From www.youtube.com

servo motor pulse calculation servo motor rpm calculate servo motor How To Calculate Duty Cycle Of Servo Motor Commonly used for this purpose are duty. For example, if you have a servo with 180° turn, then 90° is the. These two answers for rpi might help: Manufacturers almost always provide data. See if you can use the command line tools or the libraries to figure out what duty cycles correspond to what kind of movement in your own. How To Calculate Duty Cycle Of Servo Motor.

From www.wexterhome.com

Control de Servomotor con Arduino Programar y Conectar un Servo How To Calculate Duty Cycle Of Servo Motor I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. Duty cycle “duty cycle” is the width of positive pulse ( square wave ) and a deciding factor for servo’s angular position. It represents the percentage of time the motor is doing useful work I am connecting this motor to 5v pin. How To Calculate Duty Cycle Of Servo Motor.