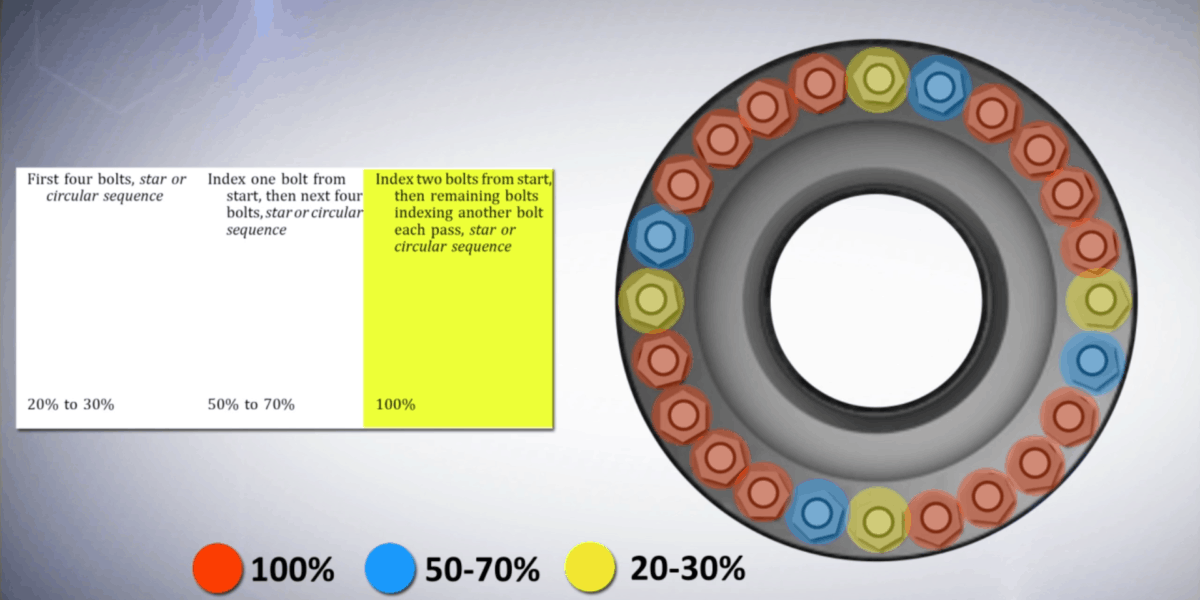

Tightening Flange Bolts Sequence . Use a calibrated torque wrench or tensioning device to achieve. Check flange gap around circumference for uniformity. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. Tighten to 20% to 30% of target torque usind cross pattern. The following procedure describes how to tighten flange bolts. In this article, you will learn about the torque sequence of pipe. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed.

from www.hextechnology.com

Use a calibrated torque wrench or tensioning device to achieve. Tighten to 20% to 30% of target torque usind cross pattern. Check flange gap around circumference for uniformity. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. The following procedure describes how to tighten flange bolts. In this article, you will learn about the torque sequence of pipe. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and.

Bolt Tightening Sequence and Restrictions Hex Technology

Tightening Flange Bolts Sequence Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. The following procedure describes how to tighten flange bolts. Use a calibrated torque wrench or tensioning device to achieve. In this article, you will learn about the torque sequence of pipe. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. Check flange gap around circumference for uniformity. Tighten to 20% to 30% of target torque usind cross pattern. A complete torque tightening sequence with charts for class 150 to 2500 flanges.

From www.scribd.com

Flange Bolt Torque Sequence and Torque Table A Complete Bolt Tightening Flange Bolts Sequence Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. In this article, you will learn about the torque sequence of pipe. Check flange gap around circumference for uniformity. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. A complete. Tightening Flange Bolts Sequence.

From www.ttpumps.com

Howto flanges, bolts & tightening Tightening Flange Bolts Sequence Tighten to 20% to 30% of target torque usind cross pattern. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. Use a calibrated torque wrench or tensioning device to achieve.. Tightening Flange Bolts Sequence.

From www.piping-designer.com

Bolt Tightening Procedure Tightening Flange Bolts Sequence By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. Check flange gap around circumference for uniformity.. Tightening Flange Bolts Sequence.

From blog.enerpac.com

Bolt Tightening Sequence Why it Matters Enerpac Blog Tightening Flange Bolts Sequence Tighten to 20% to 30% of target torque usind cross pattern. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. The following procedure describes how to tighten flange bolts. Use a calibrated torque. Tightening Flange Bolts Sequence.

From www.scribd.com

Flange Bolt Torque Sequence and Torque Table A Complete Bolt Tightening Flange Bolts Sequence By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Tighten to 20% to 30% of target torque usind cross pattern. The following procedure describes how to tighten flange bolts. Tighten the bolts in a star pattern, tightening each bolt. Tightening Flange Bolts Sequence.

From www.piping-designer.com

Bolt Tightening Procedure Tightening Flange Bolts Sequence In this article, you will learn about the torque sequence of pipe. The following procedure describes how to tighten flange bolts. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. A complete torque tightening sequence with charts for class. Tightening Flange Bolts Sequence.

From www.hextechnology.com

Bolt Tightening Sequence and Restrictions Hex Technology Tightening Flange Bolts Sequence Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. Tighten to 20% to 30% of target torque usind cross pattern. A complete torque tightening sequence with charts for class 150. Tightening Flange Bolts Sequence.

From paktechpoint.com

BOLT TORQUING AND TENSIONING METHOD STATEMENT PAKTECHPOINT Tightening Flange Bolts Sequence Check flange gap around circumference for uniformity. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. The following procedure describes how to tighten flange bolts. Use a calibrated torque wrench or tensioning device to achieve. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that. Tightening Flange Bolts Sequence.

From whatispiping.com

Flange Bolt Tightening Procedure Bolt Tightening Steps What Is Piping Tightening Flange Bolts Sequence A complete torque tightening sequence with charts for class 150 to 2500 flanges. The following procedure describes how to tighten flange bolts. Use a calibrated torque wrench or tensioning device to achieve. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there. Tightening Flange Bolts Sequence.

From www.piping-designer.com

Bolt Tightening Procedure Tightening Flange Bolts Sequence Use a calibrated torque wrench or tensioning device to achieve. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load. Tightening Flange Bolts Sequence.

From hardhatengineer.com

Flange Bolt Torque Sequence and Torque Table A Complete Bolt Tightening Flange Bolts Sequence A complete torque tightening sequence with charts for class 150 to 2500 flanges. The following procedure describes how to tighten flange bolts. Tighten to 20% to 30% of target torque usind cross pattern. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. By bringing the flanges together slowly and parallel when installing a. Tightening Flange Bolts Sequence.

From www.piping-designer.com

Bolt Tightening Procedure Tightening Flange Bolts Sequence In this article, you will learn about the torque sequence of pipe. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Tighten to 20% to 30% of target torque usind cross pattern. Use a calibrated torque wrench or tensioning device to achieve. The following procedure describes how to tighten flange bolts. Check flange gap around circumference. Tightening Flange Bolts Sequence.

From studylib.net

Flange Tightening Procedure Tightening Flange Bolts Sequence Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. The following procedure describes how to tighten flange bolts. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. Use a calibrated torque wrench or tensioning device to achieve. By bringing. Tightening Flange Bolts Sequence.

From quizzzonehirsch.z13.web.core.windows.net

Bolt Tightening Flange Torque Sequence Chart Tightening Flange Bolts Sequence Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. Check flange gap around circumference for uniformity. A complete torque tightening sequence with charts for class 150 to 2500 flanges. The following procedure describes how to tighten flange bolts. By bringing the flanges together slowly and parallel when installing a gasket and taking a. Tightening Flange Bolts Sequence.

From breinerco.com

Investigating the Proper Bolt Tightening Sequence Breiner Tightening Flange Bolts Sequence A complete torque tightening sequence with charts for class 150 to 2500 flanges. In this article, you will learn about the torque sequence of pipe. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Check flange gap around circumference. Tightening Flange Bolts Sequence.

From blog.enerpac.com

Bolt Tightening Sequence Why it Matters Enerpac Blog Tightening Flange Bolts Sequence Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. Use a calibrated torque wrench or tensioning device to achieve. Tighten to 20% to 30% of target torque usind cross pattern. A complete torque tightening sequence with charts for class 150 to 2500 flanges. In this article,. Tightening Flange Bolts Sequence.

From www.youtube.com

Flange Bolt tightening sequence. YouTube Tightening Flange Bolts Sequence The following procedure describes how to tighten flange bolts. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. Use a calibrated torque wrench or tensioning device to achieve. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. In this. Tightening Flange Bolts Sequence.

From www.hextechnology.com

Bolt Tightening Sequence and Restrictions Hex Technology Tightening Flange Bolts Sequence The following procedure describes how to tighten flange bolts. In this article, you will learn about the torque sequence of pipe. A complete torque tightening sequence with charts for class 150 to 2500 flanges. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening. Tightening Flange Bolts Sequence.

From www.hextechnology.com

Bolt Tightening Sequence and Restrictions Hex Technology Tightening Flange Bolts Sequence Use a calibrated torque wrench or tensioning device to achieve. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Tighten to 20% to 30% of target torque usind cross pattern. The following procedure describes how to tighten flange bolts.. Tightening Flange Bolts Sequence.

From thegraduateengineer.com

Why Bolt Tightening Sequences Are Important Tightening Flange Bolts Sequence Tighten to 20% to 30% of target torque usind cross pattern. In this article, you will learn about the torque sequence of pipe. The following procedure describes how to tighten flange bolts. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. Use a calibrated torque wrench. Tightening Flange Bolts Sequence.

From www.piping-designer.com

Bolt Tightening Procedure Tightening Flange Bolts Sequence By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Check flange gap around circumference for uniformity. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. A complete torque tightening sequence with charts. Tightening Flange Bolts Sequence.

From www.youtube.com

PROPER SEQUENCE IN MANUAL AND HYDRAULIC BOLT TORQUING / BOLT TIGHTENING Tightening Flange Bolts Sequence Use a calibrated torque wrench or tensioning device to achieve. In this article, you will learn about the torque sequence of pipe. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. The following procedure describes how to tighten flange bolts. Tighten to 20% to 30% of target torque usind cross pattern. By bringing. Tightening Flange Bolts Sequence.

From www.appliedbolting.com

Flange Applied Bolting Technology Products Tightening Flange Bolts Sequence By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. Flange bolt torque technology involves controlling the. Tightening Flange Bolts Sequence.

From bceweb.org

Flange Bolt Torque Sequence Chart A Visual Reference of Charts Chart Tightening Flange Bolts Sequence Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. The following procedure describes how to tighten flange bolts. Tighten to 20% to 30% of target torque usind cross pattern. Check flange gap around circumference for uniformity. A complete torque tightening sequence with charts for class 150. Tightening Flange Bolts Sequence.

From blog.enerpac.com

Bolt Tightening Sequence Why it Matters Enerpac Blog Tightening Flange Bolts Sequence In this article, you will learn about the torque sequence of pipe. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Tighten to 20% to 30% of target torque usind cross pattern. Check. Tightening Flange Bolts Sequence.

From www.hextechnology.com

Bolt Tightening Sequence and Restrictions Hex Technology Tightening Flange Bolts Sequence In this article, you will learn about the torque sequence of pipe. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Tighten to 20% to 30% of target torque usind cross pattern. The. Tightening Flange Bolts Sequence.

From www.youtube.com

Flange Bolt Tightening Sequence YouTube Tightening Flange Bolts Sequence Tighten to 20% to 30% of target torque usind cross pattern. The following procedure describes how to tighten flange bolts. Check flange gap around circumference for uniformity. In this article, you will learn about the torque sequence of pipe. Use a calibrated torque wrench or tensioning device to achieve. By bringing the flanges together slowly and parallel when installing a. Tightening Flange Bolts Sequence.

From katecrawford.z13.web.core.windows.net

Bolt Tightening Flange Torque Sequence Chart Tightening Flange Bolts Sequence Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. In this article, you will learn about the torque sequence of pipe. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Tighten the. Tightening Flange Bolts Sequence.

From fyolkgyjb.blob.core.windows.net

How To Tighten A Bolt Without A Socket Wrench at Terry Leyva blog Tightening Flange Bolts Sequence In this article, you will learn about the torque sequence of pipe. Check flange gap around circumference for uniformity. The following procedure describes how to tighten flange bolts. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Tighten to 20% to 30% of target torque usind cross pattern. By bringing the flanges together slowly and parallel. Tightening Flange Bolts Sequence.

From hardhatengineer.com

Flange Bolt Torque Sequence and Torque Table A Complete Bolt Tightening Flange Bolts Sequence In this article, you will learn about the torque sequence of pipe. The following procedure describes how to tighten flange bolts. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and.. Tightening Flange Bolts Sequence.

From savree.com

Flange Nuts and Bolts Explained (Fasteners) saVRee Tightening Flange Bolts Sequence By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. Flange bolt torque technology involves controlling the. Tightening Flange Bolts Sequence.

From hswhite.com

Flange Bolt Torque Sequence H.S. White Corporation Flange Bolt Tightening Flange Bolts Sequence Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. The following procedure describes how to tighten flange bolts. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there. Tightening Flange Bolts Sequence.

From www.youtube.com

Flange Alignment & Bolt Tightening Correct Method YouTube Tightening Flange Bolts Sequence The following procedure describes how to tighten flange bolts. In this article, you will learn about the torque sequence of pipe. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Tighten to 20% to 30% of target torque usind cross. Tightening Flange Bolts Sequence.

From torcstark.com

How to Properly Tighten Flange Bolts? TorcStark® Tightening Flange Bolts Sequence Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed. A complete torque tightening sequence with charts for class 150 to 2500 flanges. Flange bolt torque technology involves controlling the tightening force through preset torque values ensuring uniformity and. In this article, you will learn about the. Tightening Flange Bolts Sequence.

From www.hextechnology.com

Bolt Tightening Sequence and Restrictions Hex Technology Tightening Flange Bolts Sequence In this article, you will learn about the torque sequence of pipe. By bringing the flanges together slowly and parallel when installing a gasket and taking a minimum of four bolt tightening passes, following the correct bolt tightening sequence, there is a. Use a calibrated torque wrench or tensioning device to achieve. Tighten to 20% to 30% of target torque. Tightening Flange Bolts Sequence.