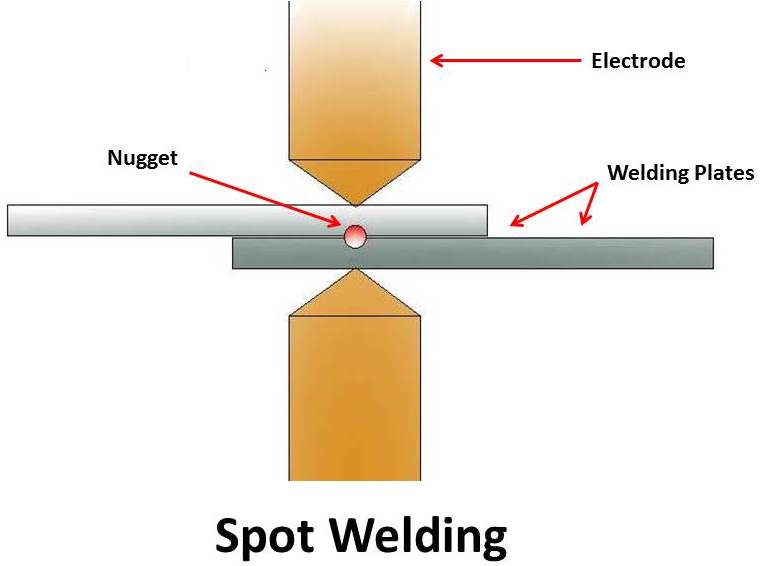

Resistance Spot Weld . Thicker sheets are more difficult to spot weld owing to the. Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. These general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding (rsw) process. Resistance spot welding, also known as resistance welding, is a process that involves the joining of metal sheets through the application of heat and pressure. Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. Spot welding, also known as resistance spot welding, is a widely used process for joining metal sheets or plates, particularly in the. Find out how to monitor weld quality, choose electrode materials, and avoid electrode wear. This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. Resistance spot welding is typically used when joining particular types of sheet metal, welded wire mesh, or bare wire mesh. The weld is made by conducting a strong current through the metal combination to heat up and finally melt the metals at localized point (s) predetermined by the design of the electrodes and/or the workpieces to be welded. A form of resistance welding, spot welding is one of the oldest welding processes whereby two or more sheets of metal are welded together without the use of any filler material.

from www.mech4study.com

A form of resistance welding, spot welding is one of the oldest welding processes whereby two or more sheets of metal are welded together without the use of any filler material. Resistance spot welding is typically used when joining particular types of sheet metal, welded wire mesh, or bare wire mesh. Resistance spot welding, also known as resistance welding, is a process that involves the joining of metal sheets through the application of heat and pressure. Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. Spot welding, also known as resistance spot welding, is a widely used process for joining metal sheets or plates, particularly in the. These general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding (rsw) process. Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. Find out how to monitor weld quality, choose electrode materials, and avoid electrode wear. The weld is made by conducting a strong current through the metal combination to heat up and finally melt the metals at localized point (s) predetermined by the design of the electrodes and/or the workpieces to be welded. Thicker sheets are more difficult to spot weld owing to the.

Resistance Welding Principle, Types, Application, Advantages and

Resistance Spot Weld Thicker sheets are more difficult to spot weld owing to the. Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. Resistance spot welding is typically used when joining particular types of sheet metal, welded wire mesh, or bare wire mesh. This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. The weld is made by conducting a strong current through the metal combination to heat up and finally melt the metals at localized point (s) predetermined by the design of the electrodes and/or the workpieces to be welded. Thicker sheets are more difficult to spot weld owing to the. Resistance spot welding, also known as resistance welding, is a process that involves the joining of metal sheets through the application of heat and pressure. Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. Find out how to monitor weld quality, choose electrode materials, and avoid electrode wear. A form of resistance welding, spot welding is one of the oldest welding processes whereby two or more sheets of metal are welded together without the use of any filler material. These general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding (rsw) process. Spot welding, also known as resistance spot welding, is a widely used process for joining metal sheets or plates, particularly in the.

From www.mdpi.com

An Exploratory Study on Resistance Spot Welding of Titanium Alloy Ti6Al4V Resistance Spot Weld The weld is made by conducting a strong current through the metal combination to heat up and finally melt the metals at localized point (s) predetermined by the design of the electrodes and/or the workpieces to be welded. Thicker sheets are more difficult to spot weld owing to the. Resistance spot welding, also known as resistance welding, is a process. Resistance Spot Weld.

From www.assemblymag.com

Resistance Spot Riveting 20170105 Assembly Magazine Resistance Spot Weld Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. Thicker sheets are more difficult to spot weld owing to the. This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. The weld. Resistance Spot Weld.

From weldguru.com

Spot Welding Explained What is It? And How Does it Work? Resistance Spot Weld The weld is made by conducting a strong current through the metal combination to heat up and finally melt the metals at localized point (s) predetermined by the design of the electrodes and/or the workpieces to be welded. Thicker sheets are more difficult to spot weld owing to the. Find out how to monitor weld quality, choose electrode materials, and. Resistance Spot Weld.

From www.youtube.com

Resistance welding process Spot welding and Seam welding process Resistance Spot Weld The weld is made by conducting a strong current through the metal combination to heat up and finally melt the metals at localized point (s) predetermined by the design of the electrodes and/or the workpieces to be welded. These general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding (rsw) process. Resistance. Resistance Spot Weld.

From www.researchgate.net

Conventional solid spot welding electrodes used in the study Resistance Spot Weld Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. Resistance welding is a welding technology widely used in manufacturing industry for joining. Resistance Spot Weld.

From weldguru.com

Spot Welding Explained What is It? And How Does it Work? Resistance Spot Weld Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. The weld is made by conducting a strong current through the metal combination to heat up and finally melt the metals at localized point (s) predetermined by the design of the electrodes and/or the workpieces to. Resistance Spot Weld.

From viewfloor.co

How To Spot Weld Floor Pans Viewfloor.co Resistance Spot Weld Spot welding, also known as resistance spot welding, is a widely used process for joining metal sheets or plates, particularly in the. Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. This technique relies on the concept of electrical resistance to generate heat at the. Resistance Spot Weld.

From www.mech4study.com

Resistance Welding Principle, Types, Application, Advantages and Resistance Spot Weld Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. Thicker sheets are more difficult to spot weld owing to the. The weld is made by conducting a strong current through the metal combination to heat up and finally melt the metals at localized point (s) predetermined by the design of the electrodes. Resistance Spot Weld.

From zerohourparts.com

What is Spot Welding? Zero Hour Parts Resistance Spot Weld Spot welding, also known as resistance spot welding, is a widely used process for joining metal sheets or plates, particularly in the. A form of resistance welding, spot welding is one of the oldest welding processes whereby two or more sheets of metal are welded together without the use of any filler material. Resistance spot welding, also known as resistance. Resistance Spot Weld.

From www.wileymetal.com

Resistance Welding Services from Wiley Metal Fabricating Resistance Spot Weld Resistance spot welding, also known as resistance welding, is a process that involves the joining of metal sheets through the application of heat and pressure. Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. Resistance welding is a welding technology widely used in manufacturing industry. Resistance Spot Weld.

From www.researchgate.net

(PDF) Improvement of the resistance spot welding of AlMgSi alloys by Resistance Spot Weld The weld is made by conducting a strong current through the metal combination to heat up and finally melt the metals at localized point (s) predetermined by the design of the electrodes and/or the workpieces to be welded. Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. Resistance spot welding, also known. Resistance Spot Weld.

From www.researchgate.net

Sketch for resistance spot welding and coordinate system Download Resistance Spot Weld Thicker sheets are more difficult to spot weld owing to the. These general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding (rsw) process. A form of resistance welding, spot welding is one of the oldest welding processes whereby two or more sheets of metal are welded together without the use of. Resistance Spot Weld.

From www.howtoresistanceweld.info

How does edge distance affect a resistance weld? HowTo Resistance Weld Resistance Spot Weld Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. These general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding (rsw) process. This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their. Resistance Spot Weld.

From www.slideserve.com

PPT WE 602 Resistance Welding Processes Review & Physics of Spot Resistance Spot Weld Spot welding, also known as resistance spot welding, is a widely used process for joining metal sheets or plates, particularly in the. These general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding (rsw) process. Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common. Resistance Spot Weld.

From punchlistzero.com

Explaining Spot Welding Process How It Works Resistance Spot Weld This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. The weld is made by conducting a strong current through the metal combination to heat up and finally melt the. Resistance Spot Weld.

From workshopinsider.com

What You Need To Know About The Types of Electric Resistance Welding Resistance Spot Weld Resistance spot welding is typically used when joining particular types of sheet metal, welded wire mesh, or bare wire mesh. This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. A form of resistance welding, spot welding is one of the oldest welding processes whereby two or. Resistance Spot Weld.

From www.dahching.com

What is Spot Welding Machine and how does it work? Daching Electric Resistance Spot Weld Spot welding, also known as resistance spot welding, is a widely used process for joining metal sheets or plates, particularly in the. This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets. Resistance Spot Weld.

From www.intechopen.com

Resistance Spot Welding Principles and Its Applications IntechOpen Resistance Spot Weld Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. A form of resistance welding, spot welding is one of the oldest welding processes whereby two or more sheets of metal are welded together without the use of any filler material. Find out how to monitor. Resistance Spot Weld.

From blog.thepipingmart.com

What Does Resistance Welding Mean? ThePipingMart Blog Resistance Spot Weld This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. Spot welding, also known as resistance spot welding, is a widely used process for joining metal sheets or plates, particularly in the. Thicker sheets are more difficult to spot weld owing to the. Learn about the basic. Resistance Spot Weld.

From www.mdpi.com

Materials Free FullText Effect of Welding Current on Weld Resistance Spot Weld A form of resistance welding, spot welding is one of the oldest welding processes whereby two or more sheets of metal are welded together without the use of any filler material. Resistance spot welding is typically used when joining particular types of sheet metal, welded wire mesh, or bare wire mesh. This technique relies on the concept of electrical resistance. Resistance Spot Weld.

From www.thestructuralsteeldetailing.com

Demystifying resistance spot welding technology Resistance Spot Weld This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. Resistance spot welding, also known as resistance welding, is a process that involves the joining of metal sheets through the application of heat and pressure. Thicker sheets are more difficult to spot weld owing to the. Resistance. Resistance Spot Weld.

From www.electricaldesks.com

Comparison Between Resistance Welding and Arc Welding Resistance Spot Weld Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. Resistance spot welding is typically used when joining particular types of sheet metal, welded wire mesh, or bare wire mesh. Thicker sheets are more difficult to spot weld owing to the. Find out how to monitor. Resistance Spot Weld.

From electricalworkbook.com

What is Resistance Welding? Process, Diagram, Types & Applications Resistance Spot Weld Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. The weld is made by conducting a strong current through the metal combination to heat up and finally melt the metals at localized point (s) predetermined by the design of the electrodes and/or the workpieces to be welded. Learn about the basic principles,. Resistance Spot Weld.

From spotweldinc.com

PressRite Press Spot Welders Spot Weld, Inc. Resistance Spot Weld This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. Find out how to monitor weld quality, choose electrode materials, and avoid electrode wear. These general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding (rsw) process. Resistance welding. Resistance Spot Weld.

From www.mdpi.com

Metals Free FullText Resistance Spot Welding of Aluminum Alloy and Resistance Spot Weld Resistance spot welding, also known as resistance welding, is a process that involves the joining of metal sheets through the application of heat and pressure. Resistance spot welding is typically used when joining particular types of sheet metal, welded wire mesh, or bare wire mesh. Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets. Resistance Spot Weld.

From www.canadianmetalworking.com

Welding Tech Spot welding vs. clinching you decide Resistance Spot Weld Resistance spot welding, also known as resistance welding, is a process that involves the joining of metal sheets through the application of heat and pressure. These general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding (rsw) process. Thicker sheets are more difficult to spot weld owing to the. Resistance spot welding. Resistance Spot Weld.

From blog.thepipingmart.com

Spot Welding vs Resistance Welding What's the Difference Resistance Spot Weld Find out how to monitor weld quality, choose electrode materials, and avoid electrode wear. Resistance spot welding is typically used when joining particular types of sheet metal, welded wire mesh, or bare wire mesh. Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. This technique relies on the concept of electrical resistance. Resistance Spot Weld.

From www.caretxdigital.com

resistance welding diagram Wiring Diagram and Schematics Resistance Spot Weld A form of resistance welding, spot welding is one of the oldest welding processes whereby two or more sheets of metal are welded together without the use of any filler material. Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. Spot welding, also known as resistance spot welding, is a widely used. Resistance Spot Weld.

From mechanicaljungle.com

Resistance Projection Welding Working of Resistance Projection Welding Resistance Spot Weld This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. Resistance spot welding, also known as resistance welding, is a process that involves. Resistance Spot Weld.

From www.howtoresistanceweld.info

Is there a minimum spacing between spot welds? HowTo Resistance Weld Resistance Spot Weld Thicker sheets are more difficult to spot weld owing to the. These general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding (rsw) process. Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process for joining steel sheets. Resistance welding is a. Resistance Spot Weld.

From www.lowcostwelder.com

Spot welding parameters setting optimal values for spotwelding Resistance Spot Weld Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. A form of resistance welding, spot welding is one of the oldest welding processes whereby two or more sheets of metal are welded together without the use of any filler material. The weld is made by conducting a strong current through the metal. Resistance Spot Weld.

From www.twi-global.com

Avoiding spot weld surface splash or electrode sticking TWI Resistance Spot Weld This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. Resistance welding is a welding technology widely used in manufacturing industry for joining metal sheets and components. Learn about the basic principles, process parameters, and electrode geometry of resistance spot welding (rsw), a common resistance welding process. Resistance Spot Weld.

From www.thefabricator.com

Demystifying resistance spot welding technology Resistance Spot Weld A form of resistance welding, spot welding is one of the oldest welding processes whereby two or more sheets of metal are welded together without the use of any filler material. Resistance spot welding is typically used when joining particular types of sheet metal, welded wire mesh, or bare wire mesh. This technique relies on the concept of electrical resistance. Resistance Spot Weld.

From blog.thepipingmart.com

Spot Welding vs Projection Welding What's the Difference Resistance Spot Weld Find out how to monitor weld quality, choose electrode materials, and avoid electrode wear. Resistance spot welding is typically used when joining particular types of sheet metal, welded wire mesh, or bare wire mesh. Thicker sheets are more difficult to spot weld owing to the. These general guidelines can be used to approximate which parameters can be used to begin. Resistance Spot Weld.

From www.metalsupermarkets.com

Resistance Welding Processes What is Spot Welding? Metal Supermarkets Resistance Spot Weld This technique relies on the concept of electrical resistance to generate heat at the interface of the metal sheets, leading to their fusion. Spot welding, also known as resistance spot welding, is a widely used process for joining metal sheets or plates, particularly in the. Find out how to monitor weld quality, choose electrode materials, and avoid electrode wear. Resistance. Resistance Spot Weld.