Air Compressor Pulley Ratio . The air compressor pulley calculator works on a simple principle. So if you have a big. The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. You can also get the right pulley size by dividing the speed in rpm of the pump by the speed in rpm of the motor. They are constant flow (volume) with variable pressure compressors. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. Which mean that at a given speed (rpm), they. It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements, and the size.

from www.offshoreonly.com

The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. You can also get the right pulley size by dividing the speed in rpm of the pump by the speed in rpm of the motor. So if you have a big. Which mean that at a given speed (rpm), they. It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. The air compressor pulley calculator works on a simple principle. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. They are constant flow (volume) with variable pressure compressors.

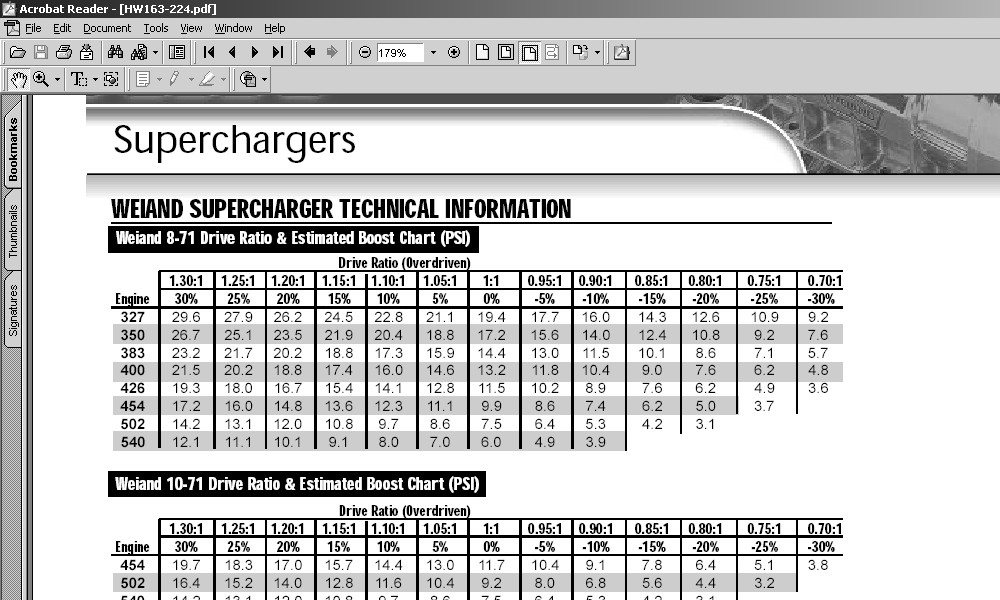

blower pulley size charts

Air Compressor Pulley Ratio The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements, and the size. The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements, and the size. The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. The air compressor pulley calculator works on a simple principle. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. So if you have a big. Which mean that at a given speed (rpm), they. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. They are constant flow (volume) with variable pressure compressors. It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. You can also get the right pulley size by dividing the speed in rpm of the pump by the speed in rpm of the motor.

From exohsvhug.blob.core.windows.net

Compressor Flywheel Pulley at Sebastian Malone blog Air Compressor Pulley Ratio So if you have a big. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. They are constant flow (volume) with variable pressure compressors.. Air Compressor Pulley Ratio.

From mojelicytacje.blogspot.com

Changing Pulley Size On Air Compressor Motor Air Compressor Pulley Ratio Which mean that at a given speed (rpm), they. The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. The air compressor pulley calculator works on a simple principle. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load. Air Compressor Pulley Ratio.

From topchooser.com

Air Compressor Motor Pulley Boost Performance With Ease! Air Compressor Pulley Ratio You can also get the right pulley size by dividing the speed in rpm of the pump by the speed in rpm of the motor. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. The calculator then employs this ratio to determine the appropriate pulley size for. Air Compressor Pulley Ratio.

From studylib.net

Pulley Ratio Chart PennTex Industries, Inc. Air Compressor Pulley Ratio The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements, and the size. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. The ratio formula is pretty easy, the ratio of the pulley diameters is the. Air Compressor Pulley Ratio.

From topchooser.com

Air Compressor Motor Pulley Boost Performance With Ease! Air Compressor Pulley Ratio So if you have a big. The air compressor pulley calculator works on a simple principle. It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. Which mean that at a given speed (rpm), they. The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements,. Air Compressor Pulley Ratio.

From www.lightningrodder.com

PULLEY RATIOS Lightning Rodder Air Compressor Pulley Ratio To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of. Air Compressor Pulley Ratio.

From www.youtube.com

Compound Gears, Pulley & Belt Systems, and Sprockets Examples YouTube Air Compressor Pulley Ratio It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. You can also get the right pulley size by dividing the speed in rpm of the pump by the speed in rpm of the motor. They are constant flow (volume) with variable pressure compressors. The air compressor pulley calculator works on a simple. Air Compressor Pulley Ratio.

From dir.indiamart.com

Compressor Pulley Compressor Fan Pulley Latest Price, Manufacturers Air Compressor Pulley Ratio You can also get the right pulley size by dividing the speed in rpm of the pump by the speed in rpm of the motor. It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the. Air Compressor Pulley Ratio.

From www.about-air-compressors.com

Air Compressor Motor Pulley Sizing Guide With Worked Example Air Compressor Pulley Ratio The air compressor pulley calculator works on a simple principle. So if you have a big. They are constant flow (volume) with variable pressure compressors. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. Which mean that at a given speed (rpm), they. The. Air Compressor Pulley Ratio.

From yournorthfieldimages.blogspot.com

Pulley Rpm Formula / How to determine pulley size? Air Compressor Pulley Ratio The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. So if you have a big. Which mean that at a given speed (rpm), they. The ratio formula. Air Compressor Pulley Ratio.

From fyowgvwqw.blob.core.windows.net

How To Calculate Ratio Of Pulleys at Martha Freeman blog Air Compressor Pulley Ratio It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. You can also get the right pulley size by dividing the speed in rpm of the pump by the speed in rpm of the motor. They are constant flow (volume) with variable pressure compressors. To determine the pipe size of your air compressor,. Air Compressor Pulley Ratio.

From mavink.com

Blower Sizing Chart Air Compressor Pulley Ratio It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. You can also get the right pulley size by dividing the speed in rpm of the pump by. Air Compressor Pulley Ratio.

From www.pinterest.com.mx

Belt Length Calculator Distance Between Pulleys Calculator Pulley Air Compressor Pulley Ratio Which mean that at a given speed (rpm), they. The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements, and the size. You can also get the right pulley size by dividing the speed in rpm of the pump by the speed in rpm of the motor. They are constant flow (volume). Air Compressor Pulley Ratio.

From calculatorshub.net

Air Compressor Pulley Calculator Online Air Compressor Pulley Ratio The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. The air compressor pulley calculator works on a simple principle. So if you have a big. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. The ratio. Air Compressor Pulley Ratio.

From www.chegg.com

An electric motor (60 hp 900 rpm) pulley drives an Air Compressor Pulley Ratio The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements, and the size. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum. Air Compressor Pulley Ratio.

From www.offshoreonly.com

blower pulley size charts Air Compressor Pulley Ratio The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. You can also get the right pulley size by dividing the speed in rpm of the pump by the speed in rpm of the motor. To determine the pipe size of your air compressor, first identify the. Air Compressor Pulley Ratio.

From mojelicytacje.blogspot.com

Changing Pulley Size On Air Compressor Motor Air Compressor Pulley Ratio The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements, and the size. Which mean that at a given speed (rpm), they. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. They are constant flow (volume) with variable pressure. Air Compressor Pulley Ratio.

From techengineeringeb.blogspot.com

2. How to calculate the size of Pulleys for a machine Technical Air Compressor Pulley Ratio Which mean that at a given speed (rpm), they. They are constant flow (volume) with variable pressure compressors. The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. To determine. Air Compressor Pulley Ratio.

From www.chevelles.com

Compression ratio for blown BBC on pump gas? Chevelle Tech Air Compressor Pulley Ratio To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. Which mean. Air Compressor Pulley Ratio.

From bceweb.org

Blower Pulley Ratio Chart A Visual Reference of Charts Chart Master Air Compressor Pulley Ratio It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. Which mean that at a given speed (rpm), they. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. They are constant flow (volume) with variable pressure compressors.. Air Compressor Pulley Ratio.

From tricitytoolparts.com

Air Compressor Pulleys tagged Tri City Tool Parts Air Compressor Pulley Ratio The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. So if you have a big. You could just try a 2.5 pulley = 718. Air Compressor Pulley Ratio.

From www.yourmechanic.com

How to Replace a Car Air Conditioning (AC) Compressor YourMechanic Advice Air Compressor Pulley Ratio Which mean that at a given speed (rpm), they. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. It uses the speed ratio, which is. Air Compressor Pulley Ratio.

From www.dreamstime.com

The Motor and Pulley on Air Compressor Stock Photo Image of close Air Compressor Pulley Ratio Which mean that at a given speed (rpm), they. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements, and the size. The ratio formula is pretty easy, the ratio of the pulley. Air Compressor Pulley Ratio.

From edspi31415.blogspot.com

Eddie's Math and Calculator Blog HP 42S/Free42/DM42 Pulley Sheave and Air Compressor Pulley Ratio To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. They are constant flow (volume) with variable pressure compressors. The air compressor pulley calculator works on a simple principle. The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor. Air Compressor Pulley Ratio.

From screencast-o-matic.com

CMTR 13d_05 Eg 7 Pulley Ratio; Eg 8 Material Stress Air Compressor Pulley Ratio To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. They are constant flow (volume) with variable pressure compressors. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. The size of the pulley depends on various factors such. Air Compressor Pulley Ratio.

From www.pinterest.pt

This document shows you how to make an effective and useful pulley Air Compressor Pulley Ratio It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air. Air Compressor Pulley Ratio.

From www.pinterest.ca

1948 best Mechanic's Corner images on Pinterest Crystals, Crystals Air Compressor Pulley Ratio The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. The air compressor pulley calculator works on a simple principle. So if you have a. Air Compressor Pulley Ratio.

From topchooser.com

Air Compressor Motor Pulley Boost Performance With Ease! Air Compressor Pulley Ratio It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. The air compressor pulley calculator works on a simple principle. You can also get the right pulley size by dividing the speed in rpm. Air Compressor Pulley Ratio.

From small-pulley.com

Small Pulley Specialist smallpulley Air Compressor Pulley Ratio You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. Which mean that at a given speed (rpm), they. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. The calculator then employs. Air Compressor Pulley Ratio.

From mungfali.com

Blower Pulley Ratio Chart Air Compressor Pulley Ratio The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. You can also get the right pulley size by dividing the speed in. Air Compressor Pulley Ratio.

From mojelicytacje.blogspot.com

Changing Pulley Size On Air Compressor Motor Air Compressor Pulley Ratio The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load. Air Compressor Pulley Ratio.

From www.pinterest.de

This document shows you how to make an effective and useful pulley Air Compressor Pulley Ratio So if you have a big. It uses the speed ratio, which is the quotient of the motor speed and the compressor speed. You can also get the right pulley size by dividing the speed in rpm of the pump by the speed in rpm of the motor. Which mean that at a given speed (rpm), they. The calculator then. Air Compressor Pulley Ratio.

From www.indiamart.com

Nile 15inch Stainless Steel Air Compressor Pulley, 3 m, MultiGroove at Air Compressor Pulley Ratio So if you have a big. The ratio formula is pretty easy, the ratio of the pulley diameters is the opposite of the ratio of the shaft rpm. The calculator then employs this ratio to determine the appropriate pulley size for the motor, ensuring a balance in the air compressor system. You can also get the right pulley size by. Air Compressor Pulley Ratio.

From topchooser.com

Air Compressor Motor Pulley Boost Performance With Ease! Air Compressor Pulley Ratio The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements, and the size. You could just try a 2.5 pulley = 718 pump rpm and check amps at the maximum load (highest air pressure just before regulator shuts. The air compressor pulley calculator works on a simple principle. So if you have. Air Compressor Pulley Ratio.

From www.youtube.com

HOW TO FIND BELT DRIVE PULLEY RPM AND DIAMETER BY CALCULATION Air Compressor Pulley Ratio The air compressor pulley calculator works on a simple principle. The size of the pulley depends on various factors such as the desired speed ratio, power transmission requirements, and the size. To determine the pipe size of your air compressor, first identify the inlet and outlet connections on the compressor. They are constant flow (volume) with variable pressure compressors. It. Air Compressor Pulley Ratio.