Thread Forming Die . The dies, imprinted with the thread profile,. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. Thread forming creates threads without removing material, unlike thread cutting where material is cut. Allows forming of parts that are. Thread rolling makes use of hardened steel cylindrical dies to shape materials; When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. Forming or rolling threads is a chipless method of thread production. This means that in this process, the thread isn't. What is a thread forming tap? Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. When exposed to the pressure of a machine, the thread rolling die creates internal threading. In thread forming, you displace the material.

from theflyingxs.blogspot.com

Forming or rolling threads is a chipless method of thread production. In thread forming, you displace the material. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. Thread forming creates threads without removing material, unlike thread cutting where material is cut. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. This means that in this process, the thread isn't. With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. Thread rolling makes use of hardened steel cylindrical dies to shape materials; When exposed to the pressure of a machine, the thread rolling die creates internal threading. Allows forming of parts that are.

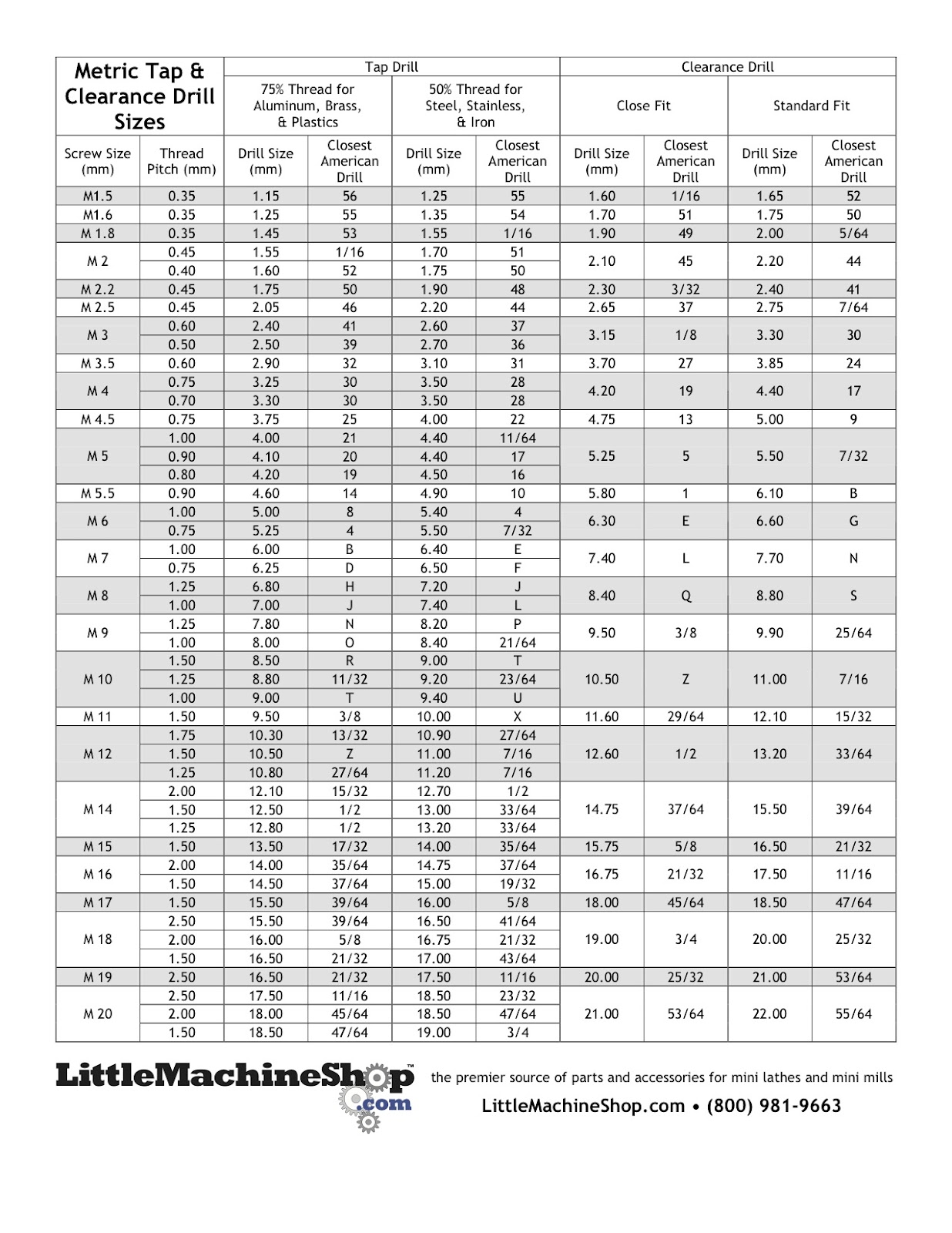

The Flying XS Metric Drill Tap Chart

Thread Forming Die When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. The dies, imprinted with the thread profile,. This means that in this process, the thread isn't. Thread forming creates threads without removing material, unlike thread cutting where material is cut. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. Forming or rolling threads is a chipless method of thread production. What is a thread forming tap? With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. In thread forming, you displace the material. Thread rolling makes use of hardened steel cylindrical dies to shape materials; When exposed to the pressure of a machine, the thread rolling die creates internal threading. Allows forming of parts that are.

From joilnmwqq.blob.core.windows.net

Tool That Can Cut Screws at Erica Carter blog Thread Forming Die Thread forming creates threads without removing material, unlike thread cutting where material is cut. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. Allows forming of parts that are. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. When a sufficient length of thread has been cut, the head of the threading dies opens to. Thread Forming Die.

From www.youtube.com

The Easiest & Safest Method Of Screw Cutting Threads On The Lathe Thread Forming Die What is a thread forming tap? Allows forming of parts that are. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. With thread forming, a shaped tool known. Thread Forming Die.

From joidxxwtt.blob.core.windows.net

What Size Hole For A Monobloc Tap at Walter Millender blog Thread Forming Die When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. What is a thread forming tap? This means that in this process, the thread isn't. Forming or rolling threads is a chipless method of thread production. With thread forming, a. Thread Forming Die.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Forming Die What is a thread forming tap? With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. The dies, imprinted with the thread profile,. Allows forming of parts that are. When exposed to the pressure of a machine, the thread rolling die. Thread Forming Die.

From www.tungstencarbide-die.com

OEM ODM Screw Thread Forming Die , Flat Thread Rolling Dies DC53 M2 H9 Thread Forming Die In thread forming, you displace the material. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. When exposed to the pressure of a machine, the thread rolling die creates internal threading. Forming or rolling threads is a chipless method. Thread Forming Die.

From vesect.com

What Is It? How Does It Work? Process, Types (2022) Thread Forming Die Thread forming creates threads without removing material, unlike thread cutting where material is cut. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. With thread forming, a shaped tool known as a thread rolling die is pressed using a. Thread Forming Die.

From www.ofitexto.com.br

2Pcs M3M10 Metal Thread Tap for Shallow Cuts Pipe Cutting Tools Thread Forming Die What is a thread forming tap? Thread rolling makes use of hardened steel cylindrical dies to shape materials; When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. With thread forming, the screw itself isn’t necessarily modified or otherwise altered.. Thread Forming Die.

From www.universalnetworkcable.com

Thread Forming Tap Chart Universal Network Thread Forming Die The dies, imprinted with the thread profile,. Allows forming of parts that are. This means that in this process, the thread isn't. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. When exposed to the pressure of a machine, the thread rolling die creates internal threading. With thread forming, a shaped tool known as a thread rolling. Thread Forming Die.

From www.lzqtech.com

Pipe Threading Tap, Thread Mill LZQ TOOL CO., LTD. Thread Forming Die Allows forming of parts that are. With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. When a sufficient length of thread has been cut, the head of the threading. Thread Forming Die.

From www.eng-tips.com

Sheet metal forming Machines & Machining engineering EngTips Thread Forming Die In thread forming, you displace the material. With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. This means that in this process, the thread isn't. The dies, imprinted with the thread profile,. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. Forming or rolling threads is a chipless method. Thread Forming Die.

From productdesignonline.com

3D Printed Threads Model Them in Fusion 360 Practical Prints 2 Thread Forming Die Thread forming creates threads without removing material, unlike thread cutting where material is cut. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. This means that in this process,. Thread Forming Die.

From syndication.cloud

Thread Pitch Chart Syndication Cloud Thread Forming Die What is a thread forming tap? With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. When exposed to the pressure of a machine, the thread rolling die creates internal threading. This means that in this process, the thread isn't. Thread rolling makes use of hardened steel cylindrical dies to shape materials; Thread. Thread Forming Die.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Forming Die Thread forming creates threads without removing material, unlike thread cutting where material is cut. When exposed to the pressure of a machine, the thread rolling die creates internal threading. Forming or rolling threads is a chipless method of thread production. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. This means that in this process, the thread. Thread Forming Die.

From theflyingxs.blogspot.com

The Flying XS Metric Drill Tap Chart Thread Forming Die When exposed to the pressure of a machine, the thread rolling die creates internal threading. The dies, imprinted with the thread profile,. Allows forming of parts that are. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. Equalized thread. Thread Forming Die.

From www.youtube.com

Threading With a Die on the Lathe YouTube Thread Forming Die Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. What is a thread forming tap? When exposed to the pressure of a machine, the thread rolling die creates internal threading. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. Thread forming creates threads without removing material, unlike thread cutting where material is cut. With thread. Thread Forming Die.

From precimactool.com

High Accuracy Threading Dies Precimac Tool Ltd Thread Forming Die In thread forming, you displace the material. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. Thread rolling makes use of hardened steel cylindrical dies to shape materials; When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed.. Thread Forming Die.

From www.globalspec.com

Threading Dies Selection Guide Types, Features, Applications GlobalSpec Thread Forming Die In thread forming, you displace the material. Thread forming creates threads without removing material, unlike thread cutting where material is cut. Thread rolling makes use of hardened steel cylindrical dies to shape materials; When exposed to the pressure of a machine, the thread rolling die creates internal threading. This means that in this process, the thread isn't. Allows forming of. Thread Forming Die.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Forming Die This means that in this process, the thread isn't. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. Thread rolling makes use of hardened steel cylindrical dies to shape materials; The dies, imprinted with the thread profile,. When exposed. Thread Forming Die.

From www.manufacturingguide.com

Thread Rolling Find suppliers, processes & material Thread Forming Die Thread rolling makes use of hardened steel cylindrical dies to shape materials; Allows forming of parts that are. What is a thread forming tap? When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. This means that in this process,. Thread Forming Die.

From www.theengineerspost.com

10 Types of Dies Used in Manufacturing, Its Components (PDF) Thread Forming Die Thread rolling makes use of hardened steel cylindrical dies to shape materials; When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. This means that in this process, the thread isn't. With thread forming, a shaped tool known as a. Thread Forming Die.

From www.tungstencarbide-die.com

OEM ODM Screw Thread Forming Die , Flat Thread Rolling Dies DC53 M2 H9 Thread Forming Die The dies, imprinted with the thread profile,. With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. Thread forming creates threads without removing material, unlike thread cutting where material is cut. This means that in this process, the thread isn't. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. When exposed. Thread Forming Die.

From www.grainger.com

GREENFIELD THREADING Round Threading Die, Round, Thread Size 1/4"28 Thread Forming Die With thread forming, the screw itself isn’t necessarily modified or otherwise altered. With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. Allows forming of parts that are. Thread rolling makes use of hardened steel cylindrical dies to shape materials; This means that in this process, the thread isn't. The dies, imprinted with. Thread Forming Die.

From loeoneklk.blob.core.windows.net

Thread Die Size Chart at Victoria Moore blog Thread Forming Die The dies, imprinted with the thread profile,. In thread forming, you displace the material. What is a thread forming tap? With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. Allows forming of parts that are. Forming or rolling threads is a. Thread Forming Die.

From www.pinterest.com

Pin on General Refrence Thread Forming Die The dies, imprinted with the thread profile,. Thread forming creates threads without removing material, unlike thread cutting where material is cut. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. When exposed to the pressure of a machine, the. Thread Forming Die.

From www.tjlituo.com

Screw Thread Rolling Die Lituo Fasteners Manufacturer Thread Forming Die Thread forming creates threads without removing material, unlike thread cutting where material is cut. This means that in this process, the thread isn't. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. The dies, imprinted with the thread profile,. When exposed to the pressure of a machine, the thread rolling die creates internal threading. Equalized thread rolling. Thread Forming Die.

From www.tungstencarbide-die.com

OEM ODM Screw Thread Forming Die , Flat Thread Rolling Dies DC53 M2 H9 Thread Forming Die In thread forming, you displace the material. Allows forming of parts that are. Forming or rolling threads is a chipless method of thread production. Thread rolling makes use of hardened steel cylindrical dies to shape materials; The dies, imprinted with the thread profile,. What is a thread forming tap? Equalized thread rolling pressure virtually eliminates spindle wear and part deflection.. Thread Forming Die.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Forming Die The dies, imprinted with the thread profile,. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. In thread forming, you displace the material. With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. Forming or rolling threads is a chipless method of thread production. Thread rolling makes use of hardened. Thread Forming Die.

From www.rolledthreads.com

Determining Pre Roll Blank Diameters Not As Simple As It Sounds Thread Forming Die With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. Thread rolling makes use of hardened steel cylindrical dies to shape materials; Forming or rolling threads is a chipless method of thread production. The dies, imprinted with the thread profile,. When exposed to the pressure of a machine, the thread rolling die creates. Thread Forming Die.

From www.mdpi.com

Metals Free FullText Forming a Flanged Hole When Quenching Press Thread Forming Die Allows forming of parts that are. Thread forming creates threads without removing material, unlike thread cutting where material is cut. Forming or rolling threads is a chipless method of thread production. This means that in this process, the thread isn't. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. With thread forming, a shaped tool known as a. Thread Forming Die.

From vesect.com

What Is It? How Does It Work? Process, Types (2022) Thread Forming Die Thread forming creates threads without removing material, unlike thread cutting where material is cut. This means that in this process, the thread isn't. Thread rolling makes use of hardened steel cylindrical dies to shape materials; The dies, imprinted with the thread profile,. Forming or rolling threads is a chipless method of thread production. With thread forming, a shaped tool known. Thread Forming Die.

From www.aliexpress.com

10Pcs Alloy Steel Metric Threading Die Set M6 M12 Threading Tools Hand Thread Forming Die Forming or rolling threads is a chipless method of thread production. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. With thread forming, a shaped tool known as a thread rolling die is pressed using a machine. In thread forming, you displace the material. Equalized thread rolling pressure virtually eliminates spindle wear and part deflection. The dies,. Thread Forming Die.

From davida.davivienda.com

Printable Metric Thread Chart Printable Word Searches Thread Forming Die Thread forming creates threads without removing material, unlike thread cutting where material is cut. This means that in this process, the thread isn't. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. Forming or rolling threads is a chipless. Thread Forming Die.

From mu-mould.com

Plastic Threading mold Muyoung mould Thread Forming Die This means that in this process, the thread isn't. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. In thread forming, you displace the material. With thread forming, the screw itself isn’t necessarily modified or otherwise altered. With thread. Thread Forming Die.

From www.rollerthread.com

China Worm Type Thread Rolling Dies Suppliers, Manufacturers Factory Thread Forming Die This means that in this process, the thread isn't. Forming or rolling threads is a chipless method of thread production. Allows forming of parts that are. Thread forming creates threads without removing material, unlike thread cutting where material is cut. In thread forming, you displace the material. When a sufficient length of thread has been cut, the head of the. Thread Forming Die.

From www.lzqtech.com

Thread Roller, Tube End Forming Die LZQ TOOL CO., LTD. Thread Forming Die The dies, imprinted with the thread profile,. When a sufficient length of thread has been cut, the head of the threading dies opens to allow the head to retract rapidly without interfering with the new thread formed. This means that in this process, the thread isn't. Thread forming creates threads without removing material, unlike thread cutting where material is cut.. Thread Forming Die.