Plasma Cutting Excessive Dross . Pay attention to your consumables. But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. When cutting too slowly, the plasma arc widens the kerf, and the. * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. Learn how to reduce dross with proper speed, airflow, and consumable settings for cleaner, more efficient results. Don’t be afraid to make an adjustment to dial in your program and find the sweet spot. Dross appearing at high speeds. A few inches per minute (ipm) up or down can have a big impact here. Nobody wants to clean the dross, especially not from a large batch of cut pieces. * check your cutting tip (especially if it appears to be worn). Common culprits include the following: While dross and slag are inevitable in the cnc plasma cutting process, there are several ways to reduce them. Plasma cutting produces clean and accurate cuts when set correctly. Dross is caused by cutting at incorrect speeds, either too slow or too fast. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove.

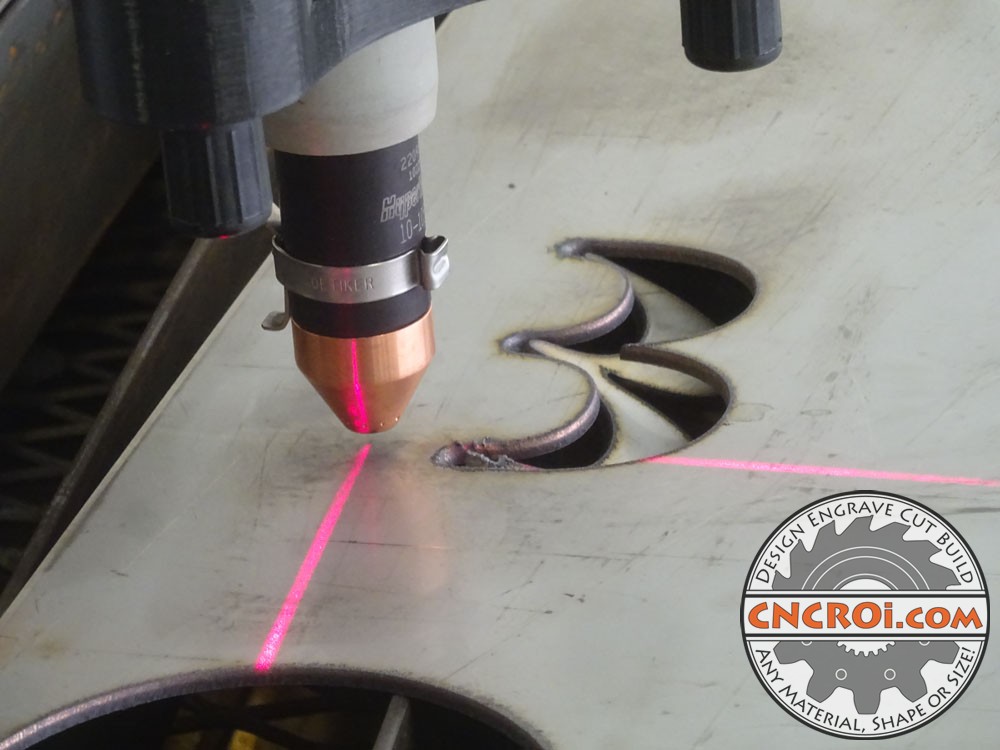

from cncroi.com

Nobody wants to clean the dross, especially not from a large batch of cut pieces. Pay attention to your consumables. * slightly decrease your cutting height until you to minimize dross. Plasma cutting produces clean and accurate cuts when set correctly. * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. Learn how to reduce dross with proper speed, airflow, and consumable settings for cleaner, more efficient results. A few inches per minute (ipm) up or down can have a big impact here. Dross appearing at high speeds.

CNC Plasma Dross 304SS Test Plate Cutting Optimization

Plasma Cutting Excessive Dross * slightly decrease your cutting height until you to minimize dross. When cutting too slowly, the plasma arc widens the kerf, and the. Dross appearing at high speeds. Pay attention to your consumables. Plasma cutting produces clean and accurate cuts when set correctly. Nobody wants to clean the dross, especially not from a large batch of cut pieces. * slightly decrease your cutting height until you to minimize dross. Learn how to reduce dross with proper speed, airflow, and consumable settings for cleaner, more efficient results. Common culprits include the following: A few inches per minute (ipm) up or down can have a big impact here. * check your cutting tip (especially if it appears to be worn). Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. Dross is caused by cutting at incorrect speeds, either too slow or too fast. But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. While dross and slag are inevitable in the cnc plasma cutting process, there are several ways to reduce them.

From www.reddit.com

Test fitting a freehand plasma cut notch on heavywall tube after just Plasma Cutting Excessive Dross * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. Nobody wants to clean the dross, especially not from a large. Plasma Cutting Excessive Dross.

From premierplasmacnc.com

Premier Plasma Dross Reduction Guide During Cutting Premier Plasma CNC Plasma Cutting Excessive Dross Plasma cutting produces clean and accurate cuts when set correctly. A few inches per minute (ipm) up or down can have a big impact here. Nobody wants to clean the dross, especially not from a large batch of cut pieces. Common culprits include the following: * check your cutting tip (especially if it appears to be worn). But certain maladjustments. Plasma Cutting Excessive Dross.

From www.youtube.com

How to remove Plasma Dross or Slag from your plasma cut parts. YouTube Plasma Cutting Excessive Dross * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. * slightly decrease your cutting height until you to minimize dross. * check your cutting tip (especially if it appears to be worn). Pay attention to your consumables. Dross is caused by cutting at incorrect speeds, either too slow or. Plasma Cutting Excessive Dross.

From www.youtube.com

Plasma Table Dross removal YouTube Plasma Cutting Excessive Dross Dross appearing at high speeds. While dross and slag are inevitable in the cnc plasma cutting process, there are several ways to reduce them. Nobody wants to clean the dross, especially not from a large batch of cut pieces. Dross is caused by cutting at incorrect speeds, either too slow or too fast. Common culprits include the following: When cutting. Plasma Cutting Excessive Dross.

From cncroi.com

CNC Plasma Dross 304SS Test Plate Cutting Optimization Plasma Cutting Excessive Dross Nobody wants to clean the dross, especially not from a large batch of cut pieces. * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. * slightly decrease your cutting height until you to minimize dross. But certain maladjustments and errors can cause excessive dross and slag to form on. Plasma Cutting Excessive Dross.

From americantorchtip.com

What is the Best Process for Removing Dross? Tips for Dross Mitigation Plasma Cutting Excessive Dross * check your cutting tip (especially if it appears to be worn). * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. Learn how to reduce dross with proper speed, airflow, and consumable settings for cleaner, more efficient results. Pay attention to your consumables. Cutting too fast or too slow. Plasma Cutting Excessive Dross.

From espritautomation.com

A Helpful Guide to Find the Best Stainless Steel Fiber Laser Plasma Cutting Excessive Dross Dross appearing at high speeds. * slightly decrease your cutting height until you to minimize dross. When cutting too slowly, the plasma arc widens the kerf, and the. Dross is caused by cutting at incorrect speeds, either too slow or too fast. Don’t be afraid to make an adjustment to dial in your program and find the sweet spot. Cutting. Plasma Cutting Excessive Dross.

From read.nxtbook.com

What Causes Dross? Plasma Cutting Excessive Dross Common culprits include the following: Nobody wants to clean the dross, especially not from a large batch of cut pieces. Dross is caused by cutting at incorrect speeds, either too slow or too fast. While dross and slag are inevitable in the cnc plasma cutting process, there are several ways to reduce them. Learn how to reduce dross with proper. Plasma Cutting Excessive Dross.

From www.semanticscholar.org

Figure 2 from Modelling of Dross Height in Plasma Jet Cutting Process Plasma Cutting Excessive Dross Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. * slightly decrease your cutting height until you to minimize dross. Dross is caused by cutting at incorrect speeds, either too slow or too fast. Plasma cutting produces clean and accurate. Plasma Cutting Excessive Dross.

From engi210.blogs.rice.edu

Plasma Cutting Missouri ENGI 210 Prototyping and Fabrication Plasma Cutting Excessive Dross Don’t be afraid to make an adjustment to dial in your program and find the sweet spot. * slightly decrease your cutting height until you to minimize dross. Common culprits include the following: Dross is caused by cutting at incorrect speeds, either too slow or too fast. Cutting too fast or too slow will cause the plasma arc to stretch. Plasma Cutting Excessive Dross.

From engi210.blogs.rice.edu

Plasma Cutting & Finishing Wisconsin ENGI 210 Prototyping and Plasma Cutting Excessive Dross Nobody wants to clean the dross, especially not from a large batch of cut pieces. * check your cutting tip (especially if it appears to be worn). Don’t be afraid to make an adjustment to dial in your program and find the sweet spot. Cutting too fast or too slow will cause the plasma arc to stretch and can result. Plasma Cutting Excessive Dross.

From www.miyawakikoukan.com

プラズマ加工とは?切断の原理やレーザー、ガス切断との違いについて 鋼管パイプ加工の総合技術商社 宮脇鋼管株式会社 Plasma Cutting Excessive Dross A few inches per minute (ipm) up or down can have a big impact here. * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. Cutting too fast or. Plasma Cutting Excessive Dross.

From www.reddit.com

How to remove dross and spatter from inside of plasma cut 316 pipe. r Plasma Cutting Excessive Dross Pay attention to your consumables. When cutting too slowly, the plasma arc widens the kerf, and the. But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. Dross is caused by cutting at incorrect speeds, either too slow or too fast. Plasma cutting produces clean and accurate cuts when. Plasma Cutting Excessive Dross.

From cncroi.com

CNC Plasma Dross 304SS Test Plate Cutting Optimization Plasma Cutting Excessive Dross Dross is caused by cutting at incorrect speeds, either too slow or too fast. Learn how to reduce dross with proper speed, airflow, and consumable settings for cleaner, more efficient results. A few inches per minute (ipm) up or down can have a big impact here. Cutting too fast or too slow will cause the plasma arc to stretch and. Plasma Cutting Excessive Dross.

From www.researchgate.net

39 questions with answers in LASER CUTTING Science topic Plasma Cutting Excessive Dross Dross appearing at high speeds. But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. When cutting too slowly, the plasma arc widens the kerf, and the. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater. Plasma Cutting Excessive Dross.

From www.youtube.com

2. Plasma cutting Series dross YouTube Plasma Cutting Excessive Dross Plasma cutting produces clean and accurate cuts when set correctly. But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove.. Plasma Cutting Excessive Dross.

From depositphotos.com

Laser or plasma cutting metalworking with sparks Stock Photo by Plasma Cutting Excessive Dross Common culprits include the following: * slightly decrease your cutting height until you to minimize dross. But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. Pay attention to your consumables. A few inches per minute (ipm) up or down can have a big impact here. When cutting too. Plasma Cutting Excessive Dross.

From blog.boydmetals.com

How Plasma Cutting Benefits Fabrication Projects Plasma Cutting Excessive Dross * check your cutting tip (especially if it appears to be worn). Common culprits include the following: Don’t be afraid to make an adjustment to dial in your program and find the sweet spot. A few inches per minute (ipm) up or down can have a big impact here. While dross and slag are inevitable in the cnc plasma cutting. Plasma Cutting Excessive Dross.

From www.machineryhouse.com.au

ARCDROID CNC Plasma Robot Hare & Forbes Machineryhouse Plasma Cutting Excessive Dross But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. Plasma cutting produces clean and accurate cuts when set correctly. Pay attention to your consumables. While dross and slag are inevitable in the cnc plasma cutting process, there are several ways to reduce them. * lower your plasma amperage. Plasma Cutting Excessive Dross.

From www.timesaversint.com

Heavy slag removal Remove dross from metal Timesavers Plasma Cutting Excessive Dross But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. * slightly decrease your cutting height until you to minimize dross. While dross and slag are inevitable in the cnc plasma cutting process, there are several ways to reduce them. Dross is caused by cutting at incorrect speeds, either. Plasma Cutting Excessive Dross.

From smithbuddy.com

How to reduce Dross in Plasma Cutting? Plasma Cutting Excessive Dross While dross and slag are inevitable in the cnc plasma cutting process, there are several ways to reduce them. * slightly decrease your cutting height until you to minimize dross. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. When. Plasma Cutting Excessive Dross.

From www.youtube.com

Plasma Gas Cut Parts Slag & Dross Removal Machine YouTube Plasma Cutting Excessive Dross * check your cutting tip (especially if it appears to be worn). Pay attention to your consumables. Don’t be afraid to make an adjustment to dial in your program and find the sweet spot. But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs your productivity. Plasma cutting produces clean and. Plasma Cutting Excessive Dross.

From www.fabtechexpo.com

Eight Tips for Avoiding Common Plasma Cutting Mistakes FABTECH Plasma Cutting Excessive Dross Nobody wants to clean the dross, especially not from a large batch of cut pieces. * slightly decrease your cutting height until you to minimize dross. Common culprits include the following: * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. But certain maladjustments and errors can cause excessive dross. Plasma Cutting Excessive Dross.

From americantorchtip.com

How To Reduce Dross and Slag During Plasma Cutting American Torch Tip Plasma Cutting Excessive Dross Dross appearing at high speeds. * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. While dross and slag are inevitable in the cnc plasma cutting process, there are several ways to reduce them. Common culprits include the following: When cutting too slowly, the plasma arc widens the kerf, and. Plasma Cutting Excessive Dross.

From squickmons.com

Best Tools for Removing Slag/Dross from CNC Plasma Cut Parts Plasma Cutting Excessive Dross Dross is caused by cutting at incorrect speeds, either too slow or too fast. Don’t be afraid to make an adjustment to dial in your program and find the sweet spot. A few inches per minute (ipm) up or down can have a big impact here. When cutting too slowly, the plasma arc widens the kerf, and the. Plasma cutting. Plasma Cutting Excessive Dross.

From www.artofit.org

How to reduce dross and slag during plasma cutting Artofit Plasma Cutting Excessive Dross Dross is caused by cutting at incorrect speeds, either too slow or too fast. A few inches per minute (ipm) up or down can have a big impact here. * check your cutting tip (especially if it appears to be worn). But certain maladjustments and errors can cause excessive dross and slag to form on the cut edge, which impairs. Plasma Cutting Excessive Dross.

From www.thefabricator.com

Troubleshooting CNC plasma cutting, Part II The Fabricator Plasma Cutting Excessive Dross * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. Plasma cutting produces clean and accurate cuts when set correctly. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. While. Plasma Cutting Excessive Dross.

From fsmdirect.com

Quality and Operating Cost of Oxyfuel and Plasma Cutting Plasma Cutting Excessive Dross Pay attention to your consumables. Nobody wants to clean the dross, especially not from a large batch of cut pieces. Plasma cutting produces clean and accurate cuts when set correctly. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. Common. Plasma Cutting Excessive Dross.

From cncroi.com

CNC Plasma Dross 304SS Test Plate Cutting Optimization Plasma Cutting Excessive Dross Learn how to reduce dross with proper speed, airflow, and consumable settings for cleaner, more efficient results. * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. Plasma cutting produces clean and accurate cuts when set correctly. Common culprits include the following: But certain maladjustments and errors can cause excessive. Plasma Cutting Excessive Dross.

From cncroi.com

CNC Plasma Dross 304SS Test Plate Cutting Optimization Plasma Cutting Excessive Dross Common culprits include the following: Dross appearing at high speeds. * lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. But. Plasma Cutting Excessive Dross.

From blog.red-d-arc.com

How To Reduce Dross and Slag During Plasma Cutting RedDArc RedDArc Plasma Cutting Excessive Dross A few inches per minute (ipm) up or down can have a big impact here. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. Nobody wants to clean the dross, especially not from a large batch of cut pieces. Common. Plasma Cutting Excessive Dross.

From www.hera.org.nz

Notice Quality requirements for thermal cutting HERA Plasma Cutting Excessive Dross Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. A few inches per minute (ipm) up or down can have a big impact here. * check your cutting tip (especially if it appears to be worn). Don’t be afraid to. Plasma Cutting Excessive Dross.

From www.thefabricator.com

How metal fabricators can achieve plasmacut edge perfection Plasma Cutting Excessive Dross Learn how to reduce dross with proper speed, airflow, and consumable settings for cleaner, more efficient results. When cutting too slowly, the plasma arc widens the kerf, and the. Pay attention to your consumables. Don’t be afraid to make an adjustment to dial in your program and find the sweet spot. Nobody wants to clean the dross, especially not from. Plasma Cutting Excessive Dross.

From industrialmachinerydigest.com

8 Questions for Better Plasma Cut Parts Plasma Cutting Excessive Dross Don’t be afraid to make an adjustment to dial in your program and find the sweet spot. Pay attention to your consumables. A few inches per minute (ipm) up or down can have a big impact here. Plasma cutting produces clean and accurate cuts when set correctly. Cutting too fast or too slow will cause the plasma arc to stretch. Plasma Cutting Excessive Dross.

From www.westermans.com

Everything You Need to Know About Plasma Cutters Plasma Cutting Excessive Dross Pay attention to your consumables. Cutting too fast or too slow will cause the plasma arc to stretch and can result in dross that is both greater in volume and more difficult to remove. Learn how to reduce dross with proper speed, airflow, and consumable settings for cleaner, more efficient results. When cutting too slowly, the plasma arc widens the. Plasma Cutting Excessive Dross.