Spindle Tool Clamp Up Sensor . this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. When sensor crashed / not working. I shut the air off and released the hose to the. The three positions of the tool clamp are usually acquired using three discrete sensors. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. during a tool change, i got a spindle tool clamp down sensor alarm. You should not do mechanical. May be dirt will cover. (tool clamp up / down sensor) this alarm may comes due to. effective tool change cleverly designed with inductive miniature sensors. Sensors are the components of choice for.

from www.haascnc.com

(tool clamp up / down sensor) this alarm may comes due to. effective tool change cleverly designed with inductive miniature sensors. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. May be dirt will cover. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. You should not do mechanical. during a tool change, i got a spindle tool clamp down sensor alarm. When sensor crashed / not working. I shut the air off and released the hose to the. Sensors are the components of choice for.

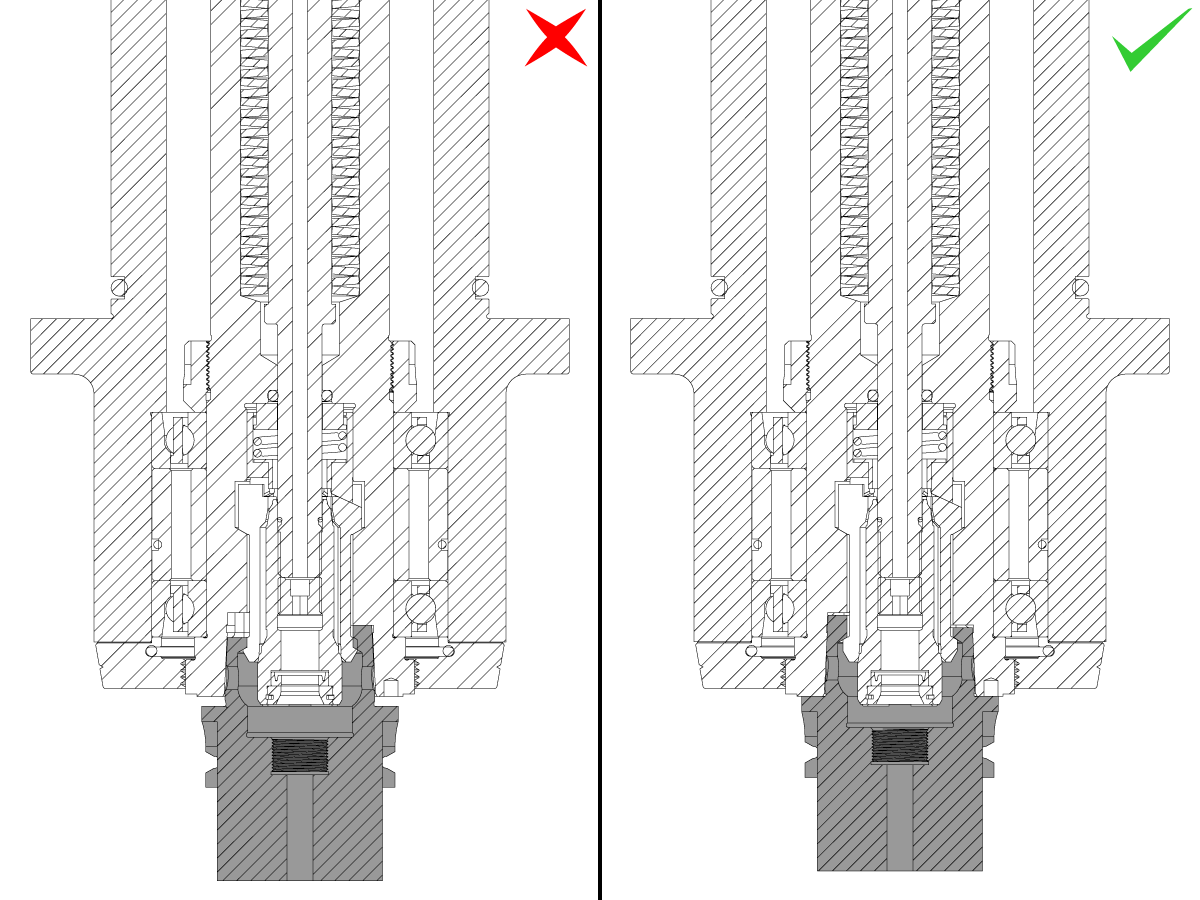

HSK Spindle Basics

Spindle Tool Clamp Up Sensor I shut the air off and released the hose to the. (tool clamp up / down sensor) this alarm may comes due to. during a tool change, i got a spindle tool clamp down sensor alarm. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. When sensor crashed / not working. The three positions of the tool clamp are usually acquired using three discrete sensors. May be dirt will cover. Sensors are the components of choice for. You should not do mechanical. I shut the air off and released the hose to the. effective tool change cleverly designed with inductive miniature sensors. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment.

From www.wavetopsign.com

Automatic Tool Change Spindle Tool Clamp Jaws ISO20 ISO25 ISO30 BT30 Spindle Tool Clamp Up Sensor this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. May be dirt will cover. I shut the air off and released the hose to the. (tool clamp up / down sensor) this alarm may comes due to. Sensors are the components of choice for. You should not do mechanical.. Spindle Tool Clamp Up Sensor.

From www.wavetopsign.com

Automatic Tool Change Spindle Tool Clamp Jaws ISO20 ISO25 ISO30 BT30 Spindle Tool Clamp Up Sensor during a tool change, i got a spindle tool clamp down sensor alarm. The three positions of the tool clamp are usually acquired using three discrete sensors. May be dirt will cover. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. I shut the air off and released the. Spindle Tool Clamp Up Sensor.

From www.researchgate.net

Graphical representation of spindle integrated displacement sensors [16 Spindle Tool Clamp Up Sensor Sensors are the components of choice for. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. I shut the air off and released the hose to the. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. May be dirt will. Spindle Tool Clamp Up Sensor.

From www.interactivetrainingsystems.com

Repairs > Electrical Maintenance > Spindle Machining Unit Maintenance Spindle Tool Clamp Up Sensor I shut the air off and released the hose to the. The three positions of the tool clamp are usually acquired using three discrete sensors. during a tool change, i got a spindle tool clamp down sensor alarm. (tool clamp up / down sensor) this alarm may comes due to. You should not do mechanical. When sensor crashed. Spindle Tool Clamp Up Sensor.

From www.aliexpress.com

SpindleBT30ClawBT40BT50GripperExternalInternalThreadClawClamp Spindle Tool Clamp Up Sensor during a tool change, i got a spindle tool clamp down sensor alarm. When sensor crashed / not working. (tool clamp up / down sensor) this alarm may comes due to. May be dirt will cover. Sensors are the components of choice for. effective tool change cleverly designed with inductive miniature sensors. I shut the air off. Spindle Tool Clamp Up Sensor.

From www.thanksbuyer.com

ER11 Brushless Spindle 500W + Clamp Base + WS55220 BLDC Motor Driver Spindle Tool Clamp Up Sensor effective tool change cleverly designed with inductive miniature sensors. When sensor crashed / not working. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. The three positions of the tool clamp are usually acquired using three discrete sensors. You should not do mechanical. I shut the air off and. Spindle Tool Clamp Up Sensor.

From www.aliexpress.com

Spindle Motor Clamp Bracket Clamp Machine Tool Spindle Spindle Spindle Tool Clamp Up Sensor When sensor crashed / not working. You should not do mechanical. Sensors are the components of choice for. I shut the air off and released the hose to the. (tool clamp up / down sensor) this alarm may comes due to. May be dirt will cover. during a tool change, i got a spindle tool clamp down sensor. Spindle Tool Clamp Up Sensor.

From www.haascnc.com

HSK Spindle Basics Spindle Tool Clamp Up Sensor May be dirt will cover. When sensor crashed / not working. I shut the air off and released the hose to the. You should not do mechanical. effective tool change cleverly designed with inductive miniature sensors. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. (tool clamp up. Spindle Tool Clamp Up Sensor.

From www.adsens.net

Sensor Mounting Clamps ADSENS Technology Inc. Spindle Tool Clamp Up Sensor When sensor crashed / not working. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. I shut the air off and released the hose to the. May be dirt will cover. during a tool change, i got a spindle tool clamp down sensor alarm. (tool clamp up /. Spindle Tool Clamp Up Sensor.

From www.cnc-tool.com

CNC Drawbar Force Gauge HSK E32 Spindle Tool Clamp Up Sensor this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. during a tool change, i got a spindle tool clamp down sensor alarm. May be dirt will cover. Sensors are the components of choice for. (tool clamp up / down sensor) this alarm may comes due to. You should. Spindle Tool Clamp Up Sensor.

From www.youtube.com

Tutorial XPS HSK Spindle Clamp Set Maintenance Kit YouTube Spindle Tool Clamp Up Sensor (tool clamp up / down sensor) this alarm may comes due to. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. during a tool change, i got a spindle tool clamp down sensor alarm. this procedure explains how to verify and adjust the spindle clamping cone push. Spindle Tool Clamp Up Sensor.

From rshapland9.wixsite.com

SHARK CNC HD Series Spindle Clamp Kit Spindle Tool Clamp Up Sensor Sensors are the components of choice for. effective tool change cleverly designed with inductive miniature sensors. (tool clamp up / down sensor) this alarm may comes due to. You should not do mechanical. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. I shut the air off and. Spindle Tool Clamp Up Sensor.

From www.lazada.com.ph

Automatic Tool Change Spindle Tool Clamp Jaws ISO20 ISO25 ISO30 BT30 Spindle Tool Clamp Up Sensor You should not do mechanical. during a tool change, i got a spindle tool clamp down sensor alarm. When sensor crashed / not working. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. effective tool change cleverly designed with inductive miniature sensors. May be dirt will cover. Sensors. Spindle Tool Clamp Up Sensor.

From s3.cnccookbook.com

CNC Cookbook Blog Apr to Jul 2008 Spindle Tool Clamp Up Sensor I shut the air off and released the hose to the. (tool clamp up / down sensor) this alarm may comes due to. When sensor crashed / not working. effective tool change cleverly designed with inductive miniature sensors. The three positions of the tool clamp are usually acquired using three discrete sensors. May be dirt will cover. Sensors. Spindle Tool Clamp Up Sensor.

From www.cncsparetools.com

Adjustable Spindle Mount Bracket Spindle Tool Clamp for CNC Router Spindle Tool Clamp Up Sensor during a tool change, i got a spindle tool clamp down sensor alarm. May be dirt will cover. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. (tool clamp up / down sensor) this alarm may comes due to. The three positions of the tool clamp are usually. Spindle Tool Clamp Up Sensor.

From www.cncsparetools.com

Adjustable Spindle Mount Bracket Spindle Tool Clamp for CNC Router Spindle Tool Clamp Up Sensor The three positions of the tool clamp are usually acquired using three discrete sensors. May be dirt will cover. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. during a tool change, i got a spindle tool clamp down sensor alarm. this procedure explains how to verify and. Spindle Tool Clamp Up Sensor.

From www.youtube.com

No.2015 Spindle Tool Clamp/Unclamp Alarm On CNC Machine... YouTube Spindle Tool Clamp Up Sensor this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. (tool clamp up / down sensor) this alarm may comes due to. May be dirt will cover. effective tool change cleverly designed with inductive miniature sensors. Sensors are the components of choice for. this procedure tells you how. Spindle Tool Clamp Up Sensor.

From www.aliexpress.com

Spindle Machine Tool Clamping Rod Er11 Shaft 5 Motor Lengthened Spindle Tool Clamp Up Sensor You should not do mechanical. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. May be dirt will cover. (tool clamp up / down sensor) this alarm may comes due to. The three positions of the tool clamp are usually acquired using three discrete sensors. effective tool change. Spindle Tool Clamp Up Sensor.

From tosatool.com

High Speed Spindle Clamp Tosa Tool Spindle Tool Clamp Up Sensor this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. (tool clamp up / down sensor) this alarm may comes due to. during a tool change, i got a spindle tool clamp down sensor alarm. Sensors are the components of choice for. I shut the air off and released. Spindle Tool Clamp Up Sensor.

From www.indiamart.com

CNC Spindle Tool Clamp Force Meter for All Types of Spindle Tapers BT Spindle Tool Clamp Up Sensor this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. Sensors are the components of choice for. during a tool change, i got a spindle tool clamp down sensor alarm. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. When. Spindle Tool Clamp Up Sensor.

From www.kuvamtechnologies.com

Precision CNC Spindle Tool Clamp Force Meter Kuvam Technologies Spindle Tool Clamp Up Sensor this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. May be dirt will cover. When sensor crashed / not working. effective tool change cleverly designed with inductive miniature sensors. (tool clamp up / down sensor) this alarm may comes due to. You should not do mechanical. I shut. Spindle Tool Clamp Up Sensor.

From www.cutwel.co.uk

SK40 Machine Spindle Clamping Force Gauge (Diebold) Cutwel Machine Spindle Tool Clamp Up Sensor I shut the air off and released the hose to the. May be dirt will cover. during a tool change, i got a spindle tool clamp down sensor alarm. effective tool change cleverly designed with inductive miniature sensors. The three positions of the tool clamp are usually acquired using three discrete sensors. (tool clamp up / down. Spindle Tool Clamp Up Sensor.

From www.indiamart.com

CNC Spindle Tool Clamp Force Meter for All Types of Spindle Tapers BT Spindle Tool Clamp Up Sensor May be dirt will cover. When sensor crashed / not working. (tool clamp up / down sensor) this alarm may comes due to. Sensors are the components of choice for. The three positions of the tool clamp are usually acquired using three discrete sensors. this procedure explains how to verify and adjust the spindle clamping cone push out. Spindle Tool Clamp Up Sensor.

From www.canadianmetalworking.com

Spindle maintenance update Spindle Tool Clamp Up Sensor I shut the air off and released the hose to the. Sensors are the components of choice for. You should not do mechanical. When sensor crashed / not working. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. (tool clamp up / down sensor) this alarm may comes due. Spindle Tool Clamp Up Sensor.

From www.aliexpress.com

spindle motor clamp tool rod C25 ER16 32L 6mm 8mm 10mm shaft motor Spindle Tool Clamp Up Sensor (tool clamp up / down sensor) this alarm may comes due to. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. When sensor crashed / not working. Sensors are the components of choice for. You should not do mechanical. effective tool change cleverly designed with inductive miniature sensors.. Spindle Tool Clamp Up Sensor.

From stronghandtools.com

Spindle for FClamps Strong Hand Tools Spindle Tool Clamp Up Sensor May be dirt will cover. I shut the air off and released the hose to the. effective tool change cleverly designed with inductive miniature sensors. during a tool change, i got a spindle tool clamp down sensor alarm. When sensor crashed / not working. this procedure tells you how to adjust the tool release piston clamp/unclamp switches. Spindle Tool Clamp Up Sensor.

From quinko.en.made-in-china.com

Spindle Clamping System China Spindle and Chuck Spindle Tool Clamp Up Sensor When sensor crashed / not working. effective tool change cleverly designed with inductive miniature sensors. The three positions of the tool clamp are usually acquired using three discrete sensors. May be dirt will cover. Sensors are the components of choice for. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or. Spindle Tool Clamp Up Sensor.

From www.cncsparetools.com

Adjustable Spindle Mount Bracket Spindle Tool Clamp for CNC Router Spindle Tool Clamp Up Sensor during a tool change, i got a spindle tool clamp down sensor alarm. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. Sensors are the components of choice for. I. Spindle Tool Clamp Up Sensor.

From tempsens.com

NonInvasive Clamp Sensor Spindle Tool Clamp Up Sensor this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. effective tool change cleverly designed with inductive miniature sensors. I shut the air off and released the hose to the. When sensor crashed / not working. (tool clamp up / down sensor) this alarm may comes due to. . Spindle Tool Clamp Up Sensor.

From www.aliexpress.com

2.2kw spindle kit 220v 80mm CNC milling spindle motor+2.2kw inverter+ Spindle Tool Clamp Up Sensor The three positions of the tool clamp are usually acquired using three discrete sensors. I shut the air off and released the hose to the. May be dirt will cover. effective tool change cleverly designed with inductive miniature sensors. When sensor crashed / not working. during a tool change, i got a spindle tool clamp down sensor alarm.. Spindle Tool Clamp Up Sensor.

From www.wavetopsign.com

Automatic Tool Change Spindle Tool Clamp Jaws ISO20 ISO25 ISO30 BT30 Spindle Tool Clamp Up Sensor this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. I shut the air off and released the hose to the. Sensors are the components of choice for. You should not do mechanical. May be dirt will cover. during a tool change, i got a spindle tool clamp down sensor. Spindle Tool Clamp Up Sensor.

From spindlerepair.com

Spindle Monitoring System Monitor Spindle Vibrations, Temperature & More Spindle Tool Clamp Up Sensor You should not do mechanical. during a tool change, i got a spindle tool clamp down sensor alarm. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. The three positions of the tool clamp are usually acquired using three discrete sensors. I shut the air off and released the. Spindle Tool Clamp Up Sensor.

From www.kuvamtechnologies.com

Precision CNC Spindle Tool Clamp Force Meter Kuvam Technologies Spindle Tool Clamp Up Sensor The three positions of the tool clamp are usually acquired using three discrete sensors. this procedure tells you how to adjust the tool release piston clamp/unclamp switches of a 30 or 40. (tool clamp up / down sensor) this alarm may comes due to. May be dirt will cover. effective tool change cleverly designed with inductive miniature. Spindle Tool Clamp Up Sensor.

From www.nivus.com

ClampOn Sensor Accessories Spindle Tool Clamp Up Sensor Sensors are the components of choice for. May be dirt will cover. (tool clamp up / down sensor) this alarm may comes due to. I shut the air off and released the hose to the. this procedure explains how to verify and adjust the spindle clamping cone push out and trp sensor adjustment. this procedure tells you. Spindle Tool Clamp Up Sensor.

From www.haascnc.com

Mill Spindle Troubleshooting Guide Spindle Tool Clamp Up Sensor When sensor crashed / not working. The three positions of the tool clamp are usually acquired using three discrete sensors. May be dirt will cover. Sensors are the components of choice for. during a tool change, i got a spindle tool clamp down sensor alarm. this procedure tells you how to adjust the tool release piston clamp/unclamp switches. Spindle Tool Clamp Up Sensor.