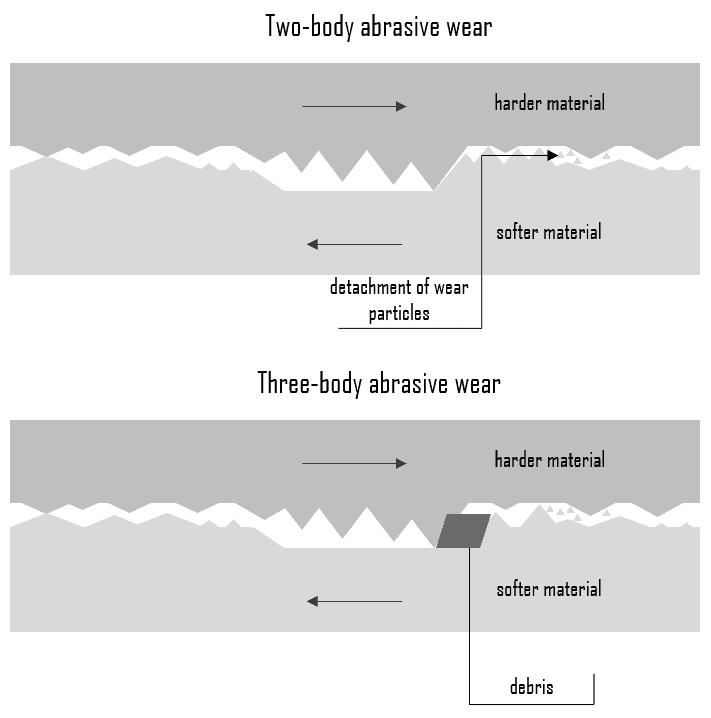

Abrasive Wear In Lubrication . The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. This article discusses the abrasive wear mechanism in. During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. There are two types of abrasive wear: The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the.

from www.nuclear-power.com

Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. There are two types of abrasive wear: This article discusses the abrasive wear mechanism in. The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the.

Adhesive Wear vs Abrasion Wear Mechanisms and Characteristics

Abrasive Wear In Lubrication The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. This article discusses the abrasive wear mechanism in. During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. There are two types of abrasive wear:

From www.researchgate.net

a, b Plowshare and c schematic diagram of abrasive wear Download Abrasive Wear In Lubrication There are two types of abrasive wear: The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. This article discusses the abrasive wear mechanism in. The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. The abrasive wear. Abrasive Wear In Lubrication.

From www.prnewswire.com

Breakthrough Innovation Lubrication Using Functional Proteins Abrasive Wear In Lubrication Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. There are two types of abrasive wear: During the course of the experiment a wear track is produced on. Abrasive Wear In Lubrication.

From www.nuclear-power.com

Abrasive Wear Mechanisms and Characteristics Abrasive Wear In Lubrication This article discusses the abrasive wear mechanism in. The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. There are two types of abrasive wear: Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. The abrasive wear happens. Abrasive Wear In Lubrication.

From onlinelibrary.wiley.com

Influence of rotation speed on abrasive wear behavior of the UHMWPE in Abrasive Wear In Lubrication During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. This article discusses the abrasive wear mechanism in. There are two types of abrasive wear: Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing. Abrasive Wear In Lubrication.

From www.researchgate.net

Examples of abrasive wear Download Scientific Diagram Abrasive Wear In Lubrication Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. There are two types of abrasive wear: The abrasive wear happens while asperities. Abrasive Wear In Lubrication.

From www.mdpi.com

Lubricants Free FullText ThreeBody Abrasive Wear Performance of Abrasive Wear In Lubrication The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. The more common way to check for abrasive wear is. Abrasive Wear In Lubrication.

From www.researchgate.net

Five Processes of Abrasive Wear [7] Download Scientific Diagram Abrasive Wear In Lubrication Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. There are two types of abrasive wear: The abrasive wear happens while asperities of a rough and hard particles. Abrasive Wear In Lubrication.

From www.mdpi.com

Lubricants Special Issue Assessment of Abrasive Wear Abrasive Wear In Lubrication This article discusses the abrasive wear mechanism in. The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. Abrasive wear is the material removal process that occurs when. Abrasive Wear In Lubrication.

From www.researchgate.net

(PDF) Fundamental aspects of abrasive wear Abrasive Wear In Lubrication Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. This article discusses the abrasive wear mechanism in. The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. The amount of detrimental abrasive. Abrasive Wear In Lubrication.

From www.alibaba.com

Lubricating Oil Friction Wear Analysis Device,Lubrication Wear Tester Abrasive Wear In Lubrication The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. This article discusses the abrasive wear mechanism in. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. During the course of the experiment a wear. Abrasive Wear In Lubrication.

From www.semanticscholar.org

Figure 3 from STUDY AND CHARACTERISTIC OF ABRASIVE WEAR MECHANISMS Abrasive Wear In Lubrication The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. The more common way to check for abrasive wear is by performing. Abrasive Wear In Lubrication.

From www.wjgnet.com

Biotribology of artificial hip joints Abrasive Wear In Lubrication Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample.. Abrasive Wear In Lubrication.

From www.mdpi.com

Lubricants Free FullText Analysis of Tool Wear and Counter Surface Abrasive Wear In Lubrication The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in. Abrasive Wear In Lubrication.

From www.mdpi.com

Lubricants Free FullText Analysis of Tool Wear and Counter Surface Abrasive Wear In Lubrication This article discusses the abrasive wear mechanism in. The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. Abrasive wear is a wear mode caused by hard, loose. Abrasive Wear In Lubrication.

From www.mdpi.com

Lubricants Free FullText Effect of Temperature and Sliding Abrasive Wear In Lubrication Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. There are two types of abrasive wear: During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. The more common way to check for abrasive wear. Abrasive Wear In Lubrication.

From www.youtube.com

Abrasive Wear(Two Body And Three Body) YouTube Abrasive Wear In Lubrication The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. This article discusses the abrasive wear mechanism in. Abrasive wear. Abrasive Wear In Lubrication.

From www.alibaba.com

Lubricating Oil Friction Wear Analysis Device,Lubrication Wear Tester Abrasive Wear In Lubrication The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. Abrasive wear is a wear mode caused by hard, loose abrasive particles. Abrasive Wear In Lubrication.

From www.youtube.com

M7033T WEAR 1 Part3 Abrasive wear YouTube Abrasive Wear In Lubrication This article discusses the abrasive wear mechanism in. During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. There are two types of abrasive wear: Abrasive. Abrasive Wear In Lubrication.

From www.slideserve.com

PPT Introduction to Tribology PowerPoint Presentation, free download Abrasive Wear In Lubrication The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. There are two types of abrasive wear: This article discusses the abrasive. Abrasive Wear In Lubrication.

From www.steeldata.info

Abrasive wear Bearing defects Abrasive Wear In Lubrication The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. This article discusses the abrasive wear mechanism in. Abrasive wear is a wear. Abrasive Wear In Lubrication.

From www.ebay.co.uk

Lubricating Oil Wear Abrasion Tester Lubricant Abrasive Testing Abrasive Wear In Lubrication The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. There are two types of abrasive wear: This article discusses the abrasive wear. Abrasive Wear In Lubrication.

From www.bearingtips.com

What do your bearings say about the condition of your equipment Abrasive Wear In Lubrication This article discusses the abrasive wear mechanism in. There are two types of abrasive wear: The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. Abrasive wear is the material removal process. Abrasive Wear In Lubrication.

From www.tribonet.org

Abrasive Wear About Tribology Abrasive Wear In Lubrication The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. This article discusses the abrasive wear mechanism in. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. During the course of the experiment a wear track is produced on the test. Abrasive Wear In Lubrication.

From www.mdpi.com

Lubricants Free FullText ThreeBody Abrasive Wear Performance of Abrasive Wear In Lubrication The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external. Abrasive Wear In Lubrication.

From www.researchgate.net

a Abrasive wear; b adhesion wear; c element diffusion loss of carbide Abrasive Wear In Lubrication There are two types of abrasive wear: Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. The more common way to check. Abrasive Wear In Lubrication.

From www.ebay.co.uk

Lubricating Oil Wear Abrasion Tester Lubricant Abrasive Testing Abrasive Wear In Lubrication Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. The more common way to check for abrasive wear is by performing wear. Abrasive Wear In Lubrication.

From www.slideserve.com

PPT Chapter 8 Lubrication, Friction and Wear PowerPoint Presentation Abrasive Wear In Lubrication Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. This article discusses the abrasive wear mechanism in. During the course of the experiment a. Abrasive Wear In Lubrication.

From www.mdpi.com

Lubricants Free FullText Abrasive Wear Resistance of HighStrength Abrasive Wear In Lubrication Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample.. Abrasive Wear In Lubrication.

From evolution.skf.com

Wear and surface fatigue in rolling bearings Evolution Online Abrasive Wear In Lubrication There are two types of abrasive wear: The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. The amount of detrimental abrasive wear depends upon the. Abrasive Wear In Lubrication.

From www.equipmac.com

Seal Lubrication Process Why It’s Important Equipment, Maintenance Abrasive Wear In Lubrication The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. Abrasive wear is a wear mode caused by hard, loose abrasive particles. Abrasive Wear In Lubrication.

From www.nuclear-power.com

Adhesive Wear vs Abrasion Wear Mechanisms and Characteristics Abrasive Wear In Lubrication During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. The abrasive wear happens while asperities of a rough and hard particles slides. Abrasive Wear In Lubrication.

From www.mdpi.com

Lubricants Free FullText Influence of Tempering Temperature on Abrasive Wear In Lubrication There are two types of abrasive wear: During the course of the experiment a wear track is produced on the test cylinder and the amount of wear can be measured either by. This article discusses the abrasive wear mechanism in. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. The. Abrasive Wear In Lubrication.

From www.researchgate.net

(PDF) Abrasive Wear of Rolling Bearings by Lubricant Borne Particles Abrasive Wear In Lubrication The amount of detrimental abrasive wear depends upon the lubricant film thickness and the presence and the quantity of abrasive particles in the. Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. The more common way to check for abrasive wear is by performing wear metal analysis on an oil. Abrasive Wear In Lubrication.

From www.researchgate.net

Mechanisms of wear in general adhesive wear; abrasive wear; fatigue Abrasive Wear In Lubrication The more common way to check for abrasive wear is by performing wear metal analysis on an oil sample. There are two types of abrasive wear: The abrasive wear happens while asperities of a rough and hard particles slides on the softer surface and remove the softer material and finally damages. Abrasive wear is a wear mode caused by hard,. Abrasive Wear In Lubrication.

From www.mdpi.com

Lubricants Free FullText Abrasive Wear Resistance of HighStrength Abrasive Wear In Lubrication Abrasive wear is a wear mode caused by hard, loose abrasive particles that are carried in by external impurities,. Abrasive wear is the material removal process that occurs when hard particles or surfaces slide against a softer material, causing erosion and. There are two types of abrasive wear: This article discusses the abrasive wear mechanism in. The more common way. Abrasive Wear In Lubrication.