Casting Mould Or Mold . A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Resulting mold has a stable shape and is both chemically and thermally resistant. The casting process can involve. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. You can use it to cast many materials including. Casting will typically involve metal, while molding focuses on plastics. The main difference between molding and casting is the use of the material in the process.

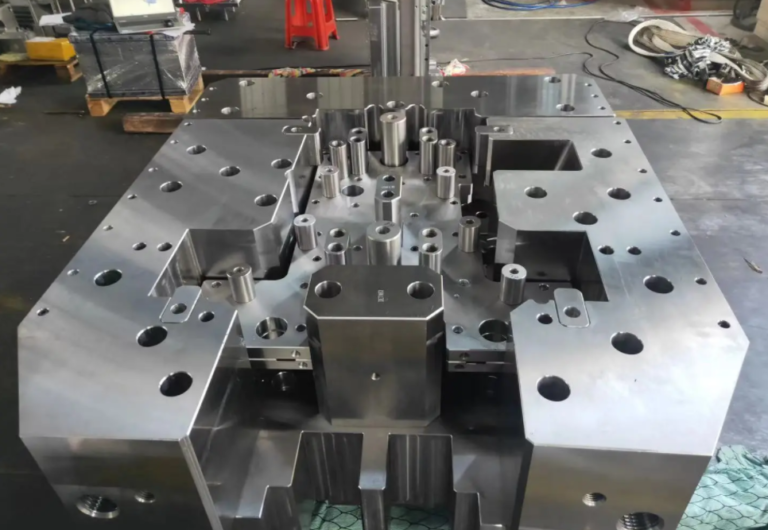

from hongyumolds.com

Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. You can use it to cast many materials including. Resulting mold has a stable shape and is both chemically and thermally resistant. The main difference between molding and casting is the use of the material in the process. Casting will typically involve metal, while molding focuses on plastics. The casting process can involve. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,.

Die Casting Mold Hongyu Molds

Casting Mould Or Mold You can use it to cast many materials including. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. You can use it to cast many materials including. Resulting mold has a stable shape and is both chemically and thermally resistant. The casting process can involve. Casting will typically involve metal, while molding focuses on plastics. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. The main difference between molding and casting is the use of the material in the process.

From www.ace-mold.com

About Gravity Die Casting Mould Material in China Casting Mould Or Mold Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The casting process can involve. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. Permanent mold casting is a metal casting process. Casting Mould Or Mold.

From www.weld2cast.com

Shell Moulding Casting Weld2Cast Casting Mould Or Mold You can use it to cast many materials including. Casting will typically involve metal, while molding focuses on plastics. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Resulting mold has a stable shape and is both chemically and thermally resistant. A cast refers to the object or part created by. Casting Mould Or Mold.

From www.youtube.com

Shell Molding Expandable Mold Casting Processes YouTube Casting Mould Or Mold You can use it to cast many materials including. The main difference between molding and casting is the use of the material in the process. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. Permanent mold casting is a metal casting process that employs. Casting Mould Or Mold.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Casting Mould Or Mold You can use it to cast many materials including. Resulting mold has a stable shape and is both chemically and thermally resistant. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The casting process can involve. Casting is a manufacturing process in which a liquid material is. Casting Mould Or Mold.

From monroeengineering.com

The 6Step Process of Sand Casting Molding OneMonroe Casting Mould Or Mold A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Casting will typically involve metal, while molding focuses on plastics. The main difference between molding and casting is the use of the material in the process. Molds are negative forms. Casting Mould Or Mold.

From www.ace-mold.com

Die Casting Mould Material for Industrial Applications Casting Mould Or Mold The casting process can involve. Casting will typically involve metal, while molding focuses on plastics. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The main difference between molding and casting is the use of the material in the process. You can use it to cast many. Casting Mould Or Mold.

From www.aliexpress.com

High quality professional manufacturers for plastic injection mould/die Casting Mould Or Mold A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The main difference between molding and casting is. Casting Mould Or Mold.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Casting Mould Or Mold A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. You can use it to cast many materials including. Molds are negative. Casting Mould Or Mold.

From www.researchgate.net

Schematic representation of a die casting mold Download Scientific Casting Mould Or Mold Resulting mold has a stable shape and is both chemically and thermally resistant. You can use it to cast many materials including. The casting process can involve. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Molds are negative. Casting Mould Or Mold.

From blog.thepipingmart.com

Die Casting vs Mold Casting What's the Difference Casting Mould Or Mold A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. The main difference between molding and casting is the use of the material in the process. Molds are negative forms that are used to shape casting materials, creating duplicates of. Casting Mould Or Mold.

From www.indiamart.com

Pressure Die Casting Mold at Rs 125000/set Casting Mould in Ludhiana Casting Mould Or Mold Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. The casting process can involve. The main difference between molding and casting is the use of the material in the process. Casting will typically involve metal, while molding focuses on plastics. A cast refers to the object or part created by pouring. Casting Mould Or Mold.

From www.leclairemfg.com

Ultimate Guide to the Permanent Mold Casting Process Casting Mould Or Mold The main difference between molding and casting is the use of the material in the process. You can use it to cast many materials including. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. Molds are negative forms that are used to shape casting. Casting Mould Or Mold.

From www.alamy.com

Riedlingen, Germany, production of a diecasting mold Stock Photo Alamy Casting Mould Or Mold Resulting mold has a stable shape and is both chemically and thermally resistant. The main difference between molding and casting is the use of the material in the process. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. Permanent mold casting is a metal. Casting Mould Or Mold.

From making-a-mold.blogspot.com

Mold making and Casting products through EnvironMolds, LLC Backdating Casting Mould Or Mold Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. Casting will typically involve metal, while molding focuses on plastics. The casting process can involve. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Molds are. Casting Mould Or Mold.

From www.sunrise-metal.com

Die Cast Aluminum Mold Sunrise Metal Aluminium Die Casting Expert Casting Mould Or Mold A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Casting will typically involve metal, while molding focuses on plastics. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. The casting. Casting Mould Or Mold.

From hongyumolds.com

Die Casting Mold Hongyu Molds Casting Mould Or Mold The main difference between molding and casting is the use of the material in the process. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. The casting process can involve. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it. Casting Mould Or Mold.

From www.reliance-foundry.com

Sand Casting Metal Casting Resources Casting Mould Or Mold Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. The casting process can involve. Resulting mold has a stable shape and is both chemically and thermally resistant. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and. Casting Mould Or Mold.

From www.gabrian.com

What is Aluminum Die Casting? 5 Things You Need to Know Casting Mould Or Mold You can use it to cast many materials including. The casting process can involve. Casting will typically involve metal, while molding focuses on plastics. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Resulting mold has a stable shape. Casting Mould Or Mold.

From www.indiamart.com

8x10 Inch Aluminum Pressure Die Casting Mould at Rs 140000 Goregaon Casting Mould Or Mold A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Resulting mold has a stable shape and is both chemically and thermally resistant. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which. Casting Mould Or Mold.

From pacdiecast.com

Die Casting Mold Design & Fabrication Mold Making Casting Mould Or Mold Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The main difference between molding and casting is the use of the material in the process. Casting will typically involve metal, while molding focuses on plastics. The casting process can involve. You can use it to cast many. Casting Mould Or Mold.

From www.sunrise-metal.com

Die Casting Mold Expert Sunrise Metal Your Reliable Partner Casting Mould Or Mold The main difference between molding and casting is the use of the material in the process. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. Casting will typically involve metal, while molding focuses on plastics. The casting process can involve. Resulting mold has a stable shape and. Casting Mould Or Mold.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Casting Mould Or Mold Resulting mold has a stable shape and is both chemically and thermally resistant. Casting will typically involve metal, while molding focuses on plastics. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually. Casting Mould Or Mold.

From chinametalcastings.com

Die casting mold Aluminum & Zinc Die casting China Casting Mould Or Mold The casting process can involve. Casting will typically involve metal, while molding focuses on plastics. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually. Casting Mould Or Mold.

From oeform.com

Die casting mold design Alu; Zinc;Mg Die casting OEFORM Casting Mould Or Mold Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. Resulting mold has a stable shape and is both chemically and thermally resistant. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,.. Casting Mould Or Mold.

From www.open.edu

Ceramic mould casting OpenLearn Open University Casting Mould Or Mold The main difference between molding and casting is the use of the material in the process. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. You can use it to cast many materials including. Permanent mold casting is a. Casting Mould Or Mold.

From www.mlsmold.com

Die casting mold Casting mold parts Die casting die MLS Mold Casting Mould Or Mold The casting process can involve. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. The main difference between molding and casting is the use of the. Casting Mould Or Mold.

From www.alibaba.com

Aluminum Die Casting Making As 3d Drawing & Sample Cast Lead Mold Lead Casting Mould Or Mold The main difference between molding and casting is the use of the material in the process. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The casting process can involve. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from. Casting Mould Or Mold.

From piq2.com

Die Casting Mold/Mould Design CastleMIND Software PIQ2 Casting Mould Or Mold The main difference between molding and casting is the use of the material in the process. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Casting is a manufacturing. Casting Mould Or Mold.

From www.diecasting-mould.com

Die Casting Mold Manufacturer & Supplier Mold Making Service Junying Casting Mould Or Mold Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. The main difference between molding and casting is the use of the material in the process. A. Casting Mould Or Mold.

From www.gang-mould.com

High Precision Rubber Mold Mould Casting Mould Or Mold Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. Resulting mold has a stable shape and is both chemically and thermally resistant. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then. Casting Mould Or Mold.

From www.rubbermolding.org

Nott Company Rubber Molding Casting Mould Or Mold The casting process can involve. Resulting mold has a stable shape and is both chemically and thermally resistant. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Permanent mold casting is a metal casting process that employs reusable molds. Casting Mould Or Mold.

From www.themouldinfo.com

Aluminum Die Casting Mold /Die Casting Mold Mould Products, Mould Casting Mould Or Mold Casting will typically involve metal, while molding focuses on plastics. The casting process can involve. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing. Casting Mould Or Mold.

From www.aniwaa.com

Guide to 3D printing molds for metal casting Aniwaa Casting Mould Or Mold Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. The main difference between molding and casting is the use of the material in the process. Resulting mold has a stable shape and is both chemically and thermally resistant. Casting will typically involve metal, while molding focuses on plastics. A cast refers. Casting Mould Or Mold.

From prototechasia.com

What is Plastic Injection Molding? Our Comprehensive Overview Casting Mould Or Mold Resulting mold has a stable shape and is both chemically and thermally resistant. Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape,. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. The casting process can. Casting Mould Or Mold.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Casting Mould Or Mold Resulting mold has a stable shape and is both chemically and thermally resistant. You can use it to cast many materials including. A cast refers to the object or part created by pouring or injecting a liquid material into a mold, allowing it to solidify, and then removing it from the mold. Casting is a manufacturing process in which a. Casting Mould Or Mold.