Air Compressor Definition Simple . air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. By doing so, these devices help to store large volumes of air in small containers. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into. By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. They have significantly impacted industries for decades by providing reliable sources of compressed air. a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for filling a. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). This air is stored in a tank until it's. — air compressors are mechanical machines that increase air pressure by reducing the volume. essentially, all air compressors do is create pressurized air using an element or air end. — put simply, air compressors transform regular, atmospheric air into pressurised compressed air by squeezing it into a much smaller space than it is usually in. One of the reasons compressed air has become so indispensable is its versatility. Notably, air compressors work in two phases, namely, the compression and the release operation phases.

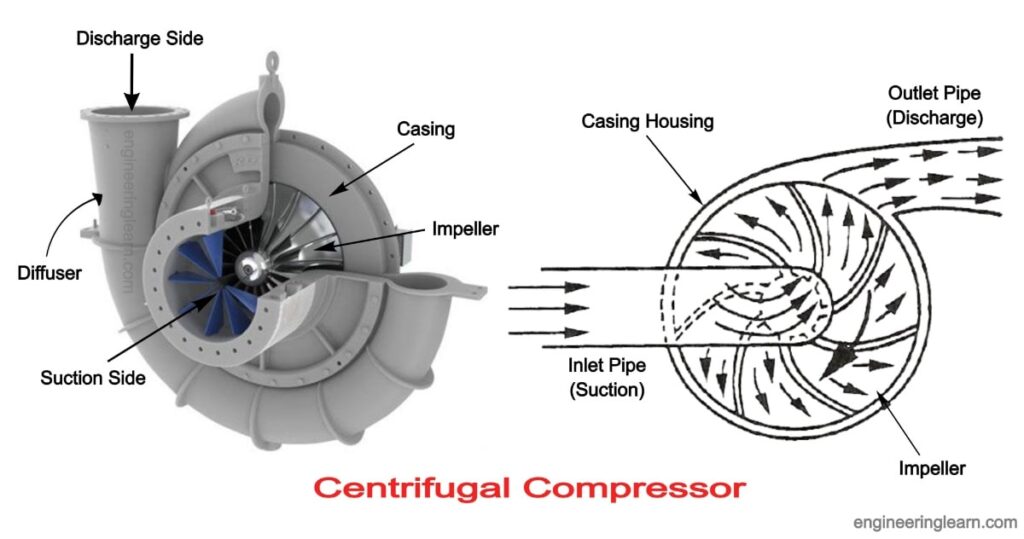

from engineeringlearn.com

— put simply, air compressors transform regular, atmospheric air into pressurised compressed air by squeezing it into a much smaller space than it is usually in. They have significantly impacted industries for decades by providing reliable sources of compressed air. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into. This air is stored in a tank until it's. By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. By doing so, these devices help to store large volumes of air in small containers. Notably, air compressors work in two phases, namely, the compression and the release operation phases. essentially, all air compressors do is create pressurized air using an element or air end.

7 Types of Air Compressor Definition, Uses & Working Principle

Air Compressor Definition Simple Notably, air compressors work in two phases, namely, the compression and the release operation phases. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into. One of the reasons compressed air has become so indispensable is its versatility. — put simply, air compressors transform regular, atmospheric air into pressurised compressed air by squeezing it into a much smaller space than it is usually in. They have significantly impacted industries for decades by providing reliable sources of compressed air. essentially, all air compressors do is create pressurized air using an element or air end. a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for filling a. Notably, air compressors work in two phases, namely, the compression and the release operation phases. — air compressors are mechanical machines that increase air pressure by reducing the volume. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. This air is stored in a tank until it's. air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. By doing so, these devices help to store large volumes of air in small containers.

From engineeringlearn.com

7 Types of Air Compressor Definition, Uses & Working Principle Air Compressor Definition Simple an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). essentially, all air compressors do is create pressurized air using an element or air end. — air compressors are mechanical machines that increase air pressure by reducing the. Air Compressor Definition Simple.

From compressorhut.com

How Do Air Compressors Fill Up Compressor Hut Air Compressor Definition Simple By doing so, these devices help to store large volumes of air in small containers. This air is stored in a tank until it's. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into. — air compressors are mechanical machines that increase air pressure by reducing the volume.. Air Compressor Definition Simple.

From www.youtube.com

Air Compressor Working Principle How does an Air compressor work Air Compressor Definition Simple air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. One of the reasons compressed air has become so indispensable is its versatility. — air compressors are mechanical machines that increase air pressure by reducing the volume. By doing. Air Compressor Definition Simple.

From educationleaves.com

What is Air Compressor? easily explained Air compressor types Air Compressor Definition Simple Notably, air compressors work in two phases, namely, the compression and the release operation phases. By doing so, these devices help to store large volumes of air in small containers. a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for filling a. an air compressor. Air Compressor Definition Simple.

From engineeringlearn.com

7 Types of Air Compressor Definition, Uses & Working Principle Air Compressor Definition Simple Notably, air compressors work in two phases, namely, the compression and the release operation phases. They have significantly impacted industries for decades by providing reliable sources of compressed air. air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. . Air Compressor Definition Simple.

From www.studypool.com

SOLUTION Lesson 4 1 air compressor and its components Studypool Air Compressor Definition Simple a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for filling a. Notably, air compressors work in two phases, namely, the compression and the release operation phases. — air compressors are mechanical machines that increase air pressure by reducing the volume. an air compressor. Air Compressor Definition Simple.

From azbigmedia.com

How to choose the right air compressor AZ Big Media Air Compressor Definition Simple an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). essentially, all air compressors do is create pressurized air using an element or air end. By doing so, these devices help to store large volumes of air in small. Air Compressor Definition Simple.

From www.bigrentz.com

How Air Compressors Work An Animated Guide BigRentz Air Compressor Definition Simple This air is stored in a tank until it's. air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. a piece of equipment that presses air into a smaller space so that it can be used under high pressure,. Air Compressor Definition Simple.

From www.engineeringchoice.com

What Is Air Compressor? Definition, Types And Working Engineering Choice Air Compressor Definition Simple They have significantly impacted industries for decades by providing reliable sources of compressed air. a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for filling a. essentially, all air compressors do is create pressurized air using an element or air end. air compressors work. Air Compressor Definition Simple.

From automotiveexclusive.blogspot.com

Use Of Air Compressors In Mechanical Engineering Industrial Air Compressor Definition Simple a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for filling a. Notably, air compressors work in two phases, namely, the compression and the release operation phases. — air compressors are mechanical machines that increase air pressure by reducing the volume. One of the reasons. Air Compressor Definition Simple.

From automationforum.co

Air compressor basics types & accessories Instrumentation and Air Compressor Definition Simple — put simply, air compressors transform regular, atmospheric air into pressurised compressed air by squeezing it into a much smaller space than it is usually in. They have significantly impacted industries for decades by providing reliable sources of compressed air. By doing so, these devices help to store large volumes of air in small containers. Notably, air compressors work. Air Compressor Definition Simple.

From www.linkedin.com

what is a Air compressor & function Air Compressor Definition Simple — air compressors are mechanical machines that increase air pressure by reducing the volume. By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. By doing so, these devices help to store large volumes of air in small containers. — put simply, air compressors transform regular, atmospheric air. Air Compressor Definition Simple.

From mechanicalpost.site

Air compressor its definition, types, working and uses with PDF Air Compressor Definition Simple One of the reasons compressed air has become so indispensable is its versatility. a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for filling a. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into.. Air Compressor Definition Simple.

From www.iqsdirectory.com

Industrial Air Compressors Types, Uses, Features and Benefits Air Compressor Definition Simple This air is stored in a tank until it's. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into. By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. an air compressor is a pneumatic device that converts. Air Compressor Definition Simple.

From automotivecore.blogspot.com

Air Compressor and function Automotive Air Compressor Definition Simple essentially, all air compressors do is create pressurized air using an element or air end. By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. This air is stored in a tank until it's. — air compressors are mechanical machines that increase air pressure by reducing the volume.. Air Compressor Definition Simple.

From www.rasmech.com

Rotary Screw Air Compressor Basics Rasmussen Mechanical Air Compressor Definition Simple a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for filling a. This air is stored in a tank until it's. Notably, air compressors work in two phases, namely, the compression and the release operation phases. They have significantly impacted industries for decades by providing reliable. Air Compressor Definition Simple.

From dxoawdroq.blob.core.windows.net

Compressor Definition English at Leonel Cyr blog Air Compressor Definition Simple They have significantly impacted industries for decades by providing reliable sources of compressed air. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). — put simply, air compressors transform regular, atmospheric air into pressurised compressed air by squeezing. Air Compressor Definition Simple.

From paolamccall.blogspot.com

air compressor working principle pdf Paola Mccall Air Compressor Definition Simple an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into. By doing so, these devices help to store large volumes of air in small containers. essentially, all air compressors do is create pressurized air using an element or air end. This air is stored in a tank until. Air Compressor Definition Simple.

From www.aircompressorsdirect.com

Contractor Air Compressor Buyer's Guide How To Pick The Perfect Air Compressor Definition Simple Notably, air compressors work in two phases, namely, the compression and the release operation phases. By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. essentially, all air compressors do is create pressurized air using an element or air end. One of the reasons compressed air has become so. Air Compressor Definition Simple.

From www.vrogue.co

5 Types Of Air Compressors Working Principle Applicat vrogue.co Air Compressor Definition Simple — air compressors are mechanical machines that increase air pressure by reducing the volume. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into. — put simply, air compressors transform regular, atmospheric air into pressurised compressed air by squeezing it into a much smaller space than it. Air Compressor Definition Simple.

From issuu.com

What is an Air Compressor? by Joel Green Issuu Air Compressor Definition Simple By doing so, these devices help to store large volumes of air in small containers. They have significantly impacted industries for decades by providing reliable sources of compressed air. — air compressors are mechanical machines that increase air pressure by reducing the volume. — put simply, air compressors transform regular, atmospheric air into pressurised compressed air by squeezing. Air Compressor Definition Simple.

From lewissystemsinc.com

Air Compressor Installation Guide Tips & Setup Diagram Air Compressor Definition Simple By doing so, these devices help to store large volumes of air in small containers. Notably, air compressors work in two phases, namely, the compression and the release operation phases. essentially, all air compressors do is create pressurized air using an element or air end. One of the reasons compressed air has become so indispensable is its versatility. By. Air Compressor Definition Simple.

From aircompressorinsider.com

What is a Single Stage Air Compressor Detailed Guide 2023 Air Air Compressor Definition Simple Notably, air compressors work in two phases, namely, the compression and the release operation phases. — air compressors are mechanical machines that increase air pressure by reducing the volume. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air).. Air Compressor Definition Simple.

From www.bigrentz.com

How Air Compressors Work An Animated Guide BigRentz Air Compressor Definition Simple an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). This air is stored in a tank until it's. By doing so, these devices help to store large volumes of air in small containers. By one of several methods, an. Air Compressor Definition Simple.

From www.aircompressormanufacturers.org

Air Compressor Manufacturers Air Compressor Suppliers Air Compressor Definition Simple a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for filling a. — put simply, air compressors transform regular, atmospheric air into pressurised compressed air by squeezing it into a much smaller space than it is usually in. — air compressors are mechanical machines. Air Compressor Definition Simple.

From www.cattanicompressors.com.au

Air Compressor Parts Experts' Guide To Machine Maintenance Air Compressor Definition Simple air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. Notably, air compressors work in two phases, namely, the compression and the release operation phases. By doing so, these devices help to store large volumes of air in small containers.. Air Compressor Definition Simple.

From www.sunrise-metal.com

Types of Air Compressors Choose Right Air Compressor For Your Usage Air Compressor Definition Simple air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. essentially, all air compressors do is create pressurized air using an element or air end. — put simply, air compressors transform regular, atmospheric air into pressurised compressed air. Air Compressor Definition Simple.

From magilsitinawang.blogspot.com

28+ Simple Air Compressor Diagram Magilsitinawang Air Compressor Definition Simple Notably, air compressors work in two phases, namely, the compression and the release operation phases. air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. an air compressor is a pneumatic device that converts power (using an electric motor,. Air Compressor Definition Simple.

From www.studypool.com

SOLUTION Lesson 4 1 air compressor and its components Studypool Air Compressor Definition Simple Notably, air compressors work in two phases, namely, the compression and the release operation phases. a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for filling a. — put simply, air compressors transform regular, atmospheric air into pressurised compressed air by squeezing it into a. Air Compressor Definition Simple.

From engineeringlearn.com

7 Types of Air Compressor Definition, Uses & Working Principle Air Compressor Definition Simple Notably, air compressors work in two phases, namely, the compression and the release operation phases. By doing so, these devices help to store large volumes of air in small containers. essentially, all air compressors do is create pressurized air using an element or air end. They have significantly impacted industries for decades by providing reliable sources of compressed air.. Air Compressor Definition Simple.

From airtoolguy.com

How Air Compressors Work? AIR TOOL GUY Air Compressor Definition Simple Notably, air compressors work in two phases, namely, the compression and the release operation phases. — air compressors are mechanical machines that increase air pressure by reducing the volume. an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into. This air is stored in a tank until it's.. Air Compressor Definition Simple.

From reviewmotors.co

Air Compressor Parts And Functions Reviewmotors.co Air Compressor Definition Simple an air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into. Notably, air compressors work in two phases, namely, the compression and the release operation phases. a piece of equipment that presses air into a smaller space so that it can be used under high pressure, for example for. Air Compressor Definition Simple.

From www.powdercoatguide.com

Choosing an Air Compressor Powder Coating The Complete Guide Air Compressor Definition Simple One of the reasons compressed air has become so indispensable is its versatility. air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. This air is stored in a tank until it's. essentially, all air compressors do is create. Air Compressor Definition Simple.

From engineeringlearn.com

7 Types of Air Compressor Definition, Uses & Working Principle Air Compressor Definition Simple They have significantly impacted industries for decades by providing reliable sources of compressed air. By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. One of the reasons compressed air has become so indispensable is its versatility. — air compressors are mechanical machines that increase air pressure by reducing. Air Compressor Definition Simple.

From lah.elearningontario.ca

SPH4C Air Compressor Definition Simple They have significantly impacted industries for decades by providing reliable sources of compressed air. Notably, air compressors work in two phases, namely, the compression and the release operation phases. One of the reasons compressed air has become so indispensable is its versatility. essentially, all air compressors do is create pressurized air using an element or air end. This air. Air Compressor Definition Simple.