Main Bearing In Wind Turbine . this paper presents a review of existing theory and practice relating to main bearings for wind turbines. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. The use of plain bearings as main bearings can potentially reduce these costs. Operational expenditures amount to 32% of wind energy costs.

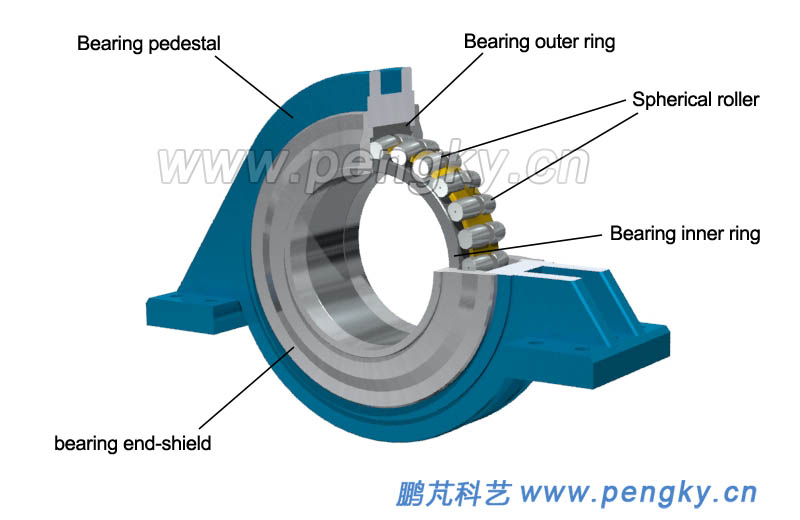

from www.pengky.cn

— the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. Operational expenditures amount to 32% of wind energy costs. The use of plain bearings as main bearings can potentially reduce these costs. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs.

Wind Turbine Bearings Horizontal Axis Wind Turbine PengKy

Main Bearing In Wind Turbine — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. Operational expenditures amount to 32% of wind energy costs. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. The use of plain bearings as main bearings can potentially reduce these costs. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. this paper presents a review of existing theory and practice relating to main bearings for wind turbines.

From www.mdpi.com

Machines Free FullText Reliability Sensitivity Analysis of Main Main Bearing In Wind Turbine wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high. Main Bearing In Wind Turbine.

From www.pengky.cn

Wind Turbine Bearings Horizontal Axis Wind Turbine PengKy Main Bearing In Wind Turbine wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. Operational expenditures amount. Main Bearing In Wind Turbine.

From www.liebherr.com

Main bearings for wind turbines Liebherr Main Bearing In Wind Turbine — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. Operational expenditures amount to 32% of wind energy costs. The use of plain bearings as main bearings can potentially reduce these costs. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more. Main Bearing In Wind Turbine.

From www.pengky.cn

Wind Turbine Bearings Horizontal Axis Wind Turbine PengKy Main Bearing In Wind Turbine — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair. Main Bearing In Wind Turbine.

From www.windsystemsmag.com

New highperformance main bearing solutions for wind turbines Wind Main Bearing In Wind Turbine Operational expenditures amount to 32% of wind energy costs. The use of plain bearings as main bearings can potentially reduce these costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and. Main Bearing In Wind Turbine.

From wes.copernicus.org

WES A review of wind turbine main bearings design, operation Main Bearing In Wind Turbine Operational expenditures amount to 32% of wind energy costs. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. — the operational conditions and loading for. Main Bearing In Wind Turbine.

From motion-drives.com

Global Wind Turbine Bearing Market 2016 Timken Company, Scheerer Main Bearing In Wind Turbine — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines.. Main Bearing In Wind Turbine.

From www.elege-energy.com

Configuration of wind turbine bearings Main Bearing In Wind Turbine — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. wind turbine main bearing life is an important driver of system reliability, availability, and operations and. Main Bearing In Wind Turbine.

From wes.copernicus.org

WES A review of wind turbine main bearings design, operation Main Bearing In Wind Turbine The use of plain bearings as main bearings can potentially reduce these costs. Operational expenditures amount to 32% of wind energy costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. . Main Bearing In Wind Turbine.

From www.windsystemsmag.com

New highperformance main bearing solutions for wind turbines Wind Main Bearing In Wind Turbine — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. The use of plain bearings as main bearings can potentially reduce these costs. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. Operational expenditures amount to. Main Bearing In Wind Turbine.

From www.windpowerengineering.com

How large offshore wind turbines are challenging bearing designs Main Bearing In Wind Turbine — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. Operational expenditures amount to 32% of wind energy costs. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. The use of plain bearings as main bearings. Main Bearing In Wind Turbine.

From www.bearingtips.com

Radial shaft seal ring for main bearings in wind turbines Bearing Tips Main Bearing In Wind Turbine Operational expenditures amount to 32% of wind energy costs. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. — rotor main bearings are critical components of wind turbines since a faulty. Main Bearing In Wind Turbine.

From www.skf.com

Bearing arrangements for wind turbine main shafts SKF Main Bearing In Wind Turbine Operational expenditures amount to 32% of wind energy costs. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. — in this paper, a finite element. Main Bearing In Wind Turbine.

From www.zys-bearing.com

Main shaft bearing for wind turbine Main Bearing In Wind Turbine — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. Operational expenditures amount to 32% of wind energy costs. — in this paper, a finite element model is. Main Bearing In Wind Turbine.

From www.windsystemsmag.com

New highperformance main bearing solutions for wind turbines Wind Main Bearing In Wind Turbine — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high. Main Bearing In Wind Turbine.

From westernmachine.com

Wind Turbine Main Shaft & Components Repair Western Machine Works Main Bearing In Wind Turbine wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. — in. Main Bearing In Wind Turbine.

From www.engineerlive.com

Optimised designs of rotor bearings for wind turbines Engineer Live Main Bearing In Wind Turbine The use of plain bearings as main bearings can potentially reduce these costs. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. wind turbine main bearing life. Main Bearing In Wind Turbine.

From www.atlantic-bearing.com

Rail and truck transportation of Wind Turbine Main Shaft Assembly Main Bearing In Wind Turbine wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. The use of plain bearings as main bearings can potentially reduce these costs. Operational expenditures amount to 32% of wind energy costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. . Main Bearing In Wind Turbine.

From www.mechanical-knowledge.com

TURBINE BEARING MAINTENANCE Main Bearing In Wind Turbine this paper presents a review of existing theory and practice relating to main bearings for wind turbines. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. The use of plain bearings as main bearings can potentially reduce these costs. — in this paper, a finite element model. Main Bearing In Wind Turbine.

From www.pengky.cn

Wind Turbine Bearings Horizontal Axis Wind Turbine PengKy Main Bearing In Wind Turbine — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. Operational expenditures amount to 32% of wind energy costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. The use of plain bearings as main bearings can potentially. Main Bearing In Wind Turbine.

From encyclopedia.pub

Wind Turbines Encyclopedia MDPI Main Bearing In Wind Turbine The use of plain bearings as main bearings can potentially reduce these costs. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. Operational expenditures amount to 32% of wind energy. Main Bearing In Wind Turbine.

From www.liebherr.com

Main bearings for wind turbines Liebherr Main Bearing In Wind Turbine Operational expenditures amount to 32% of wind energy costs. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. The use of plain bearings as main bearings can potentially reduce these costs. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more. Main Bearing In Wind Turbine.

From www.slideserve.com

PPT System dynamic modelling applied to wind turbine bearings Main Bearing In Wind Turbine Operational expenditures amount to 32% of wind energy costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. The use of plain bearings as main bearings can potentially reduce these costs. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. . Main Bearing In Wind Turbine.

From wes.copernicus.org

WES A review of wind turbine main bearings design, operation Main Bearing In Wind Turbine — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. The use of plain bearings as main bearings can potentially reduce these costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. — the operational conditions and loading for wind. Main Bearing In Wind Turbine.

From knowledge.ulprospector.com

Greases for slow and steady wind turbine bearings Main Bearing In Wind Turbine — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. Operational expenditures amount to 32% of wind energy costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. wind turbine main bearing life is an important driver of system reliability,. Main Bearing In Wind Turbine.

From www.slewing-bearing.com

slewing bearings for wind turbines Main Bearing In Wind Turbine this paper presents a review of existing theory and practice relating to main bearings for wind turbines. Operational expenditures amount to 32% of wind energy costs. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. The use of plain bearings as main bearings can potentially reduce these costs. . Main Bearing In Wind Turbine.

From www.windsystemsmag.com

Main shaft bearing lubrication Wind Systems Magazine Main Bearing In Wind Turbine — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. this paper presents a review of existing theory and practice relating to main bearings for wind. Main Bearing In Wind Turbine.

From www.windsystemsmag.com

Fundamentals of Wind Turbines Wind Systems Magazine Main Bearing In Wind Turbine — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. Operational expenditures amount to 32% of wind energy costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. The use of plain bearings as main bearings can potentially reduce these costs.. Main Bearing In Wind Turbine.

From www.windsystemsmag.com

New highperformance main bearing solutions for wind turbines Wind Main Bearing In Wind Turbine The use of plain bearings as main bearings can potentially reduce these costs. Operational expenditures amount to 32% of wind energy costs. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. this paper presents a review of existing theory and practice relating to main bearings. Main Bearing In Wind Turbine.

From exowwdzjh.blob.core.windows.net

Main Shaft Of Wind Turbine at Ethel Taylor blog Main Bearing In Wind Turbine The use of plain bearings as main bearings can potentially reduce these costs. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. wind turbine main bearing life is an important. Main Bearing In Wind Turbine.

From www.pinterest.com

Components of a typical wind turbine as illustrated on NORDEX N80 Main Bearing In Wind Turbine wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. The use of plain bearings as main bearings can potentially reduce these costs. Operational expenditures amount to 32% of wind energy costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. . Main Bearing In Wind Turbine.

From www.researchgate.net

(PDF) A review of wind turbine main bearings Design, operation Main Bearing In Wind Turbine Operational expenditures amount to 32% of wind energy costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. The use of plain bearings as main bearings can potentially reduce these costs. — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and. Main Bearing In Wind Turbine.

From www.daidometal.com

Newly Developed Products Bearings for Wind Power Generation Daido Main Bearing In Wind Turbine — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs. — rotor. Main Bearing In Wind Turbine.

From www.windsystemsmag.com

Protecting WindTurbine Bearings Wind Systems Magazine Main Bearing In Wind Turbine — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. — the operational conditions and loading for wind turbine main bearings deviate significantly from those of more conventional power. wind. Main Bearing In Wind Turbine.

From www.liebherr.com

Main bearings for wind turbines Liebherr Main Bearing In Wind Turbine — rotor main bearings are critical components of wind turbines since a faulty main bearing leads to downtime and high repair costs. this paper presents a review of existing theory and practice relating to main bearings for wind turbines. wind turbine main bearing life is an important driver of system reliability, availability, and operations and maintenance costs.. Main Bearing In Wind Turbine.